A construction waste disposal device

A technology for processing equipment and construction waste, applied in grain processing, solid separation, chemical instruments and methods, etc., can solve problems such as unfavorable transportation and recycling, inability to guarantee crushing effect, uneven crushing effect, etc., and achieve fast and efficient processing. , to facilitate subsequent transportation, to ensure the effect of crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

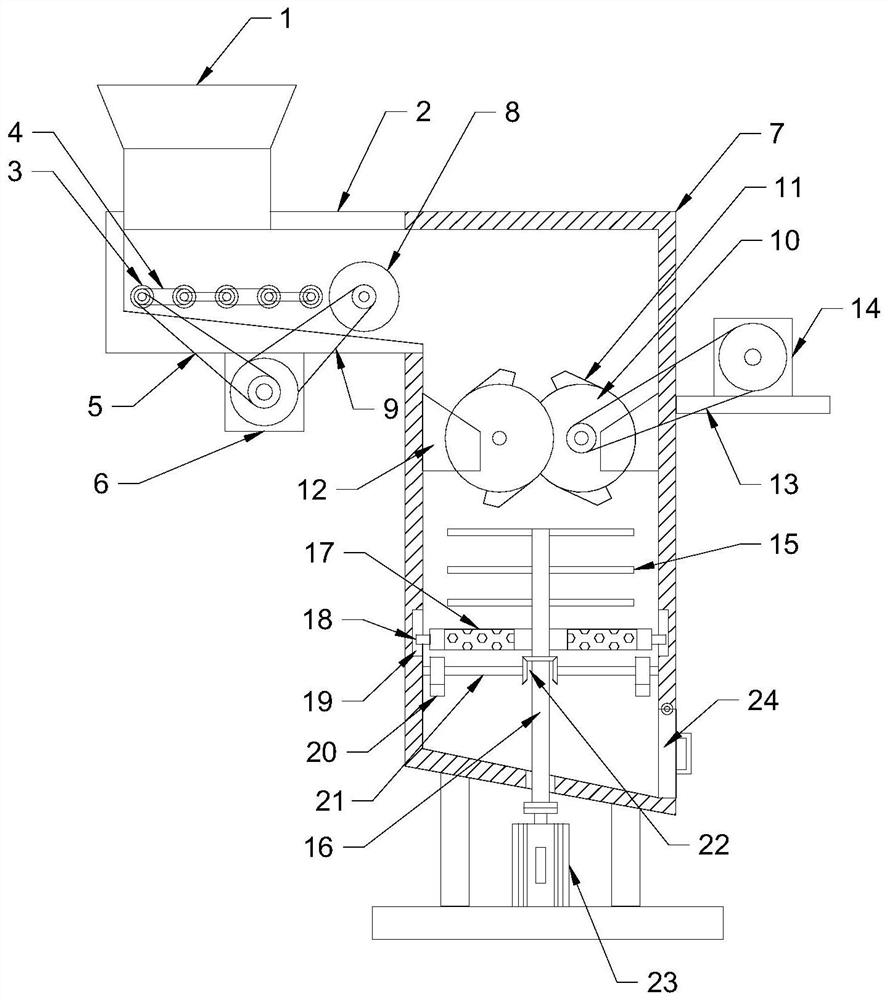

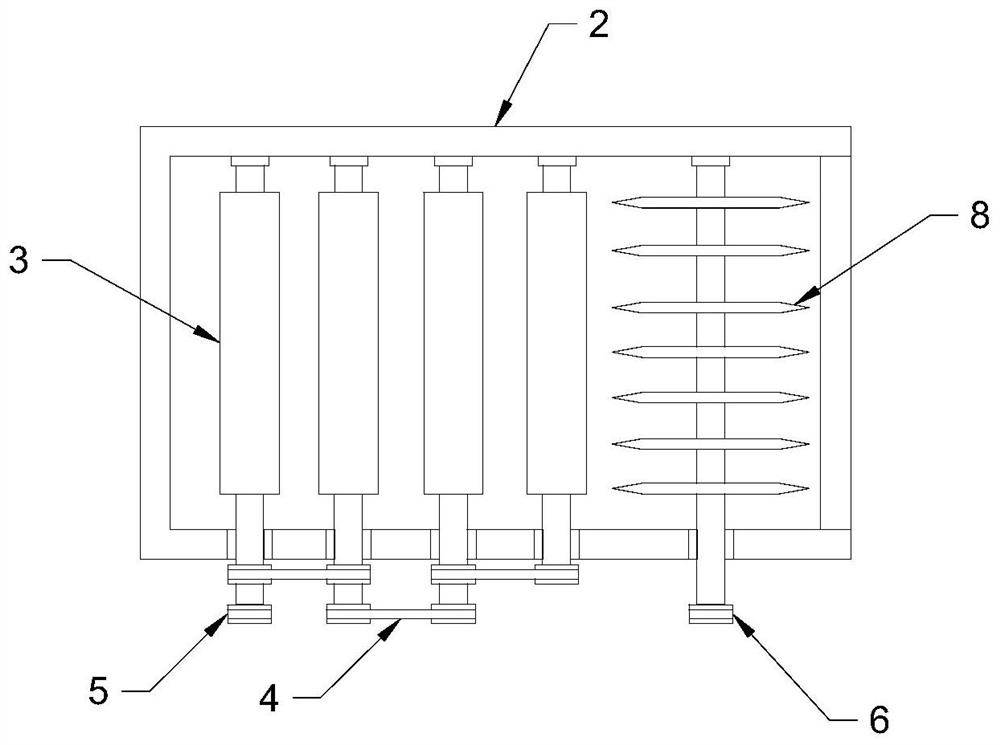

[0023] see Figure 1~3 , in an embodiment of the present invention, a construction waste treatment device includes a feeding hopper 1, a feeding box 2 and a crushing box 7; a feeding box 2 is communicated with the bottom of the feeding hopper 1, and an equidistant Distributed delivery rollers 3, the delivery rollers 3 are rotationally connected with the inner wall of the delivery box 2, the delivery rollers 3 are connected through the first transmission belt 4, and the delivery rollers 3 at the end are connected with the second transmission belt 5 An output shaft of the drive motor 6, the first drive motor 6 is fixedly connected with the lower end surface of the material delivery box 2 by means of bolts, and the first drive motor 6 drives the delivery roller 3 to rotate to transport the construction waste block.

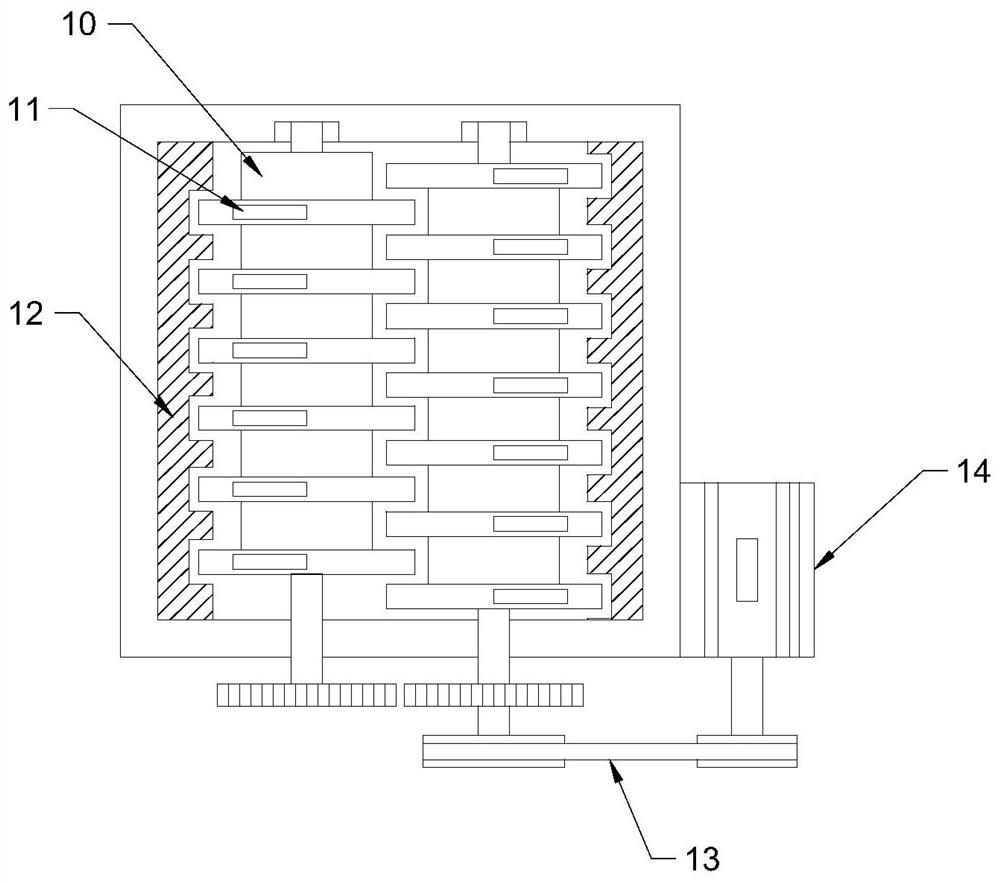

[0024] The right side of the conveying box 2 is connected with a pulverizing box 7, and a cutting blade roller 8 is arranged at the communication place between the f...

Embodiment 2

[0028] see Figure 4 The difference between this embodiment and Embodiment 1 is that: the inner wall of the upper end of the crushing box 7 is fixedly connected with a dust collection cover 25, the dust collection cover 25 is connected with an induced draft fan 26 through a pipeline, and the induced draft fan 26 is connected with a cyclone settling cylinder 27 through a pipeline , Actively absorb the dust in the crushing process to avoid dust overflow and pollute the working environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com