Gas sealing structure and extraction drying device

A technology of gas sealing and structure, applied in the direction of progressive dryer, engine sealing, drying, etc., can solve the problems of large-scale equipment and increased cost, and achieve the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

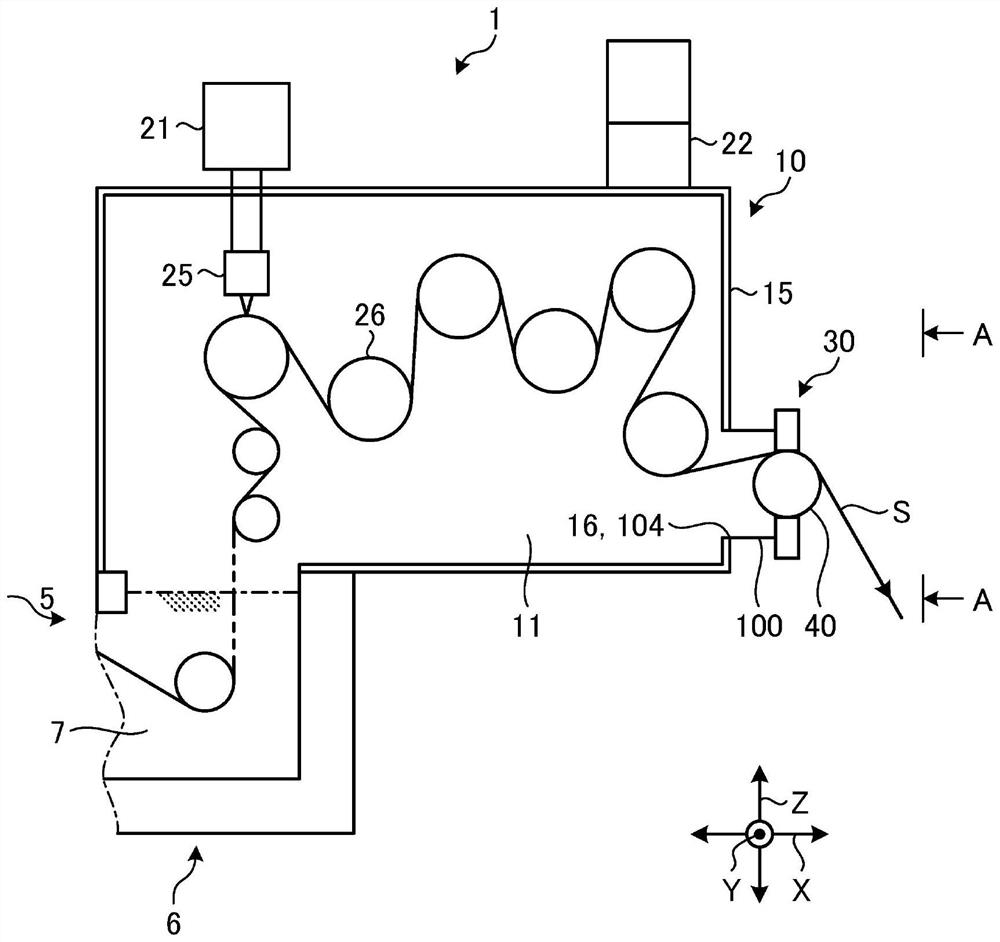

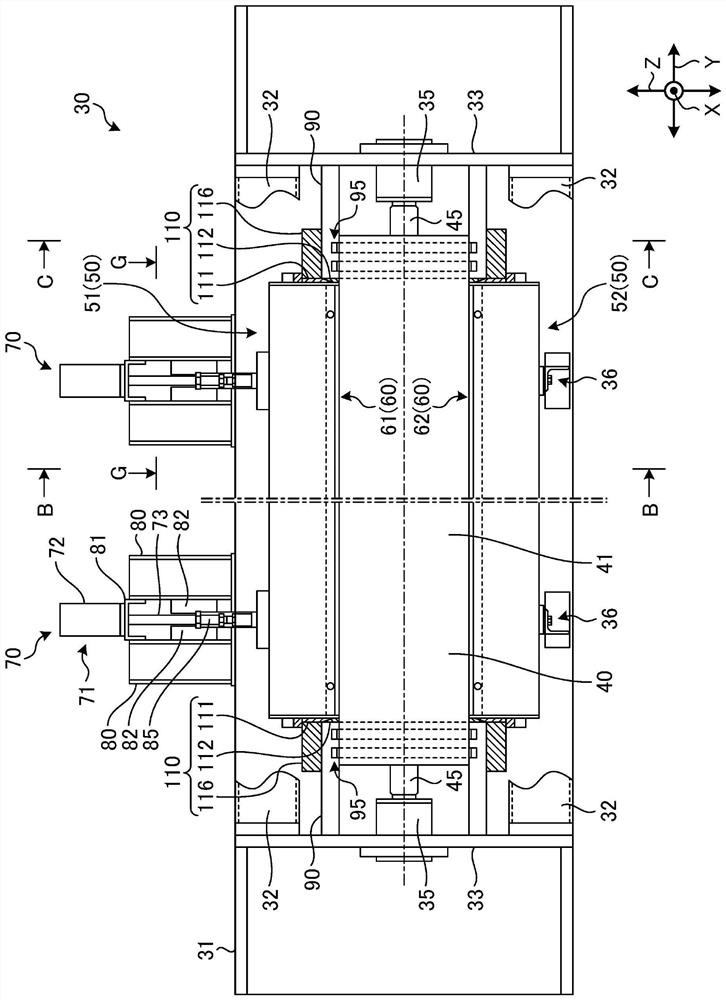

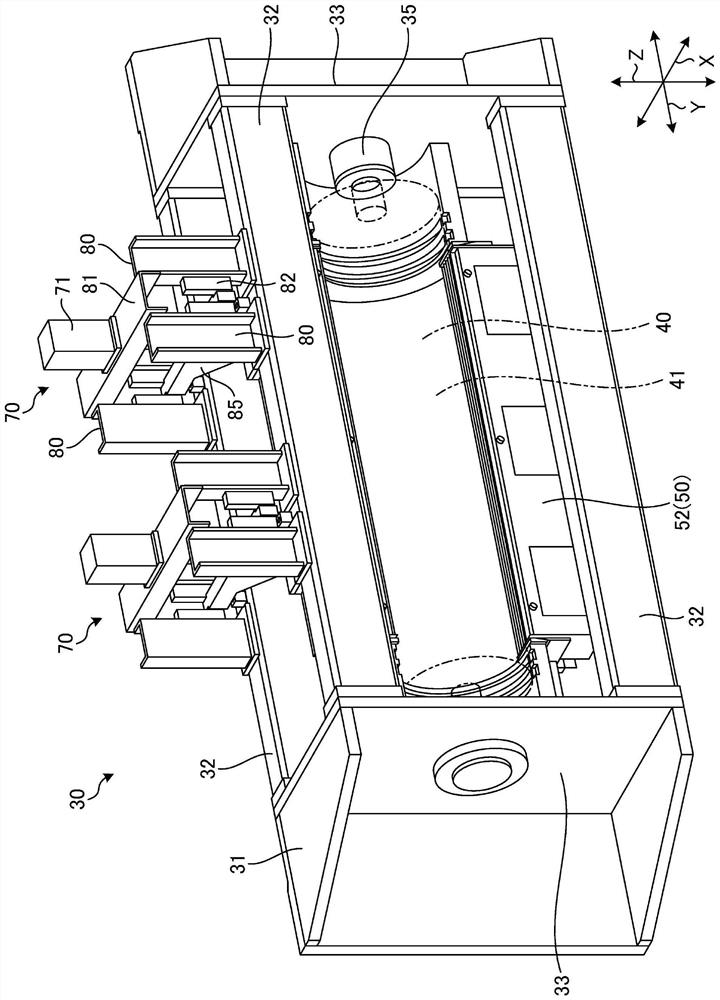

[0041] figure 1 It is a schematic diagram which shows the apparatus structure of the extraction-drying apparatus 1 concerning Embodiment 1. In addition, in the following description, the up-down direction in the normal use state of the extraction-drying apparatus 1 is demonstrated as the up-down direction Z of the extraction-drying apparatus 1, and the upper side in the normal use state of the extraction-drying apparatus 1 is demonstrated. The upper side of the extraction and drying apparatus 1 and the lower side in a normal use state of the extraction and drying apparatus 1 will be described as the lower side of the extraction and drying apparatus 1 . In addition, the horizontal direction in the normal use state of the extraction-drying apparatus 1 is demonstrated as a horizontal direction also in the extraction-drying apparatus 1. FIG. Furthermore, in the horizontal direction, the extending direction of the sealing roller 40 of the gas sealing structure 30 described later i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com