Flexible micropore uniformly-distributed oxygenation pipe

A technology of oxygen-increasing tubes and micropores, which is applied in the field of flexible micro-porous uniformly distributed oxygen-increasing tubes, which can solve the problems of poor toughness, no water available, and water leakage in seepage tubes, and achieve the effect of high strength and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

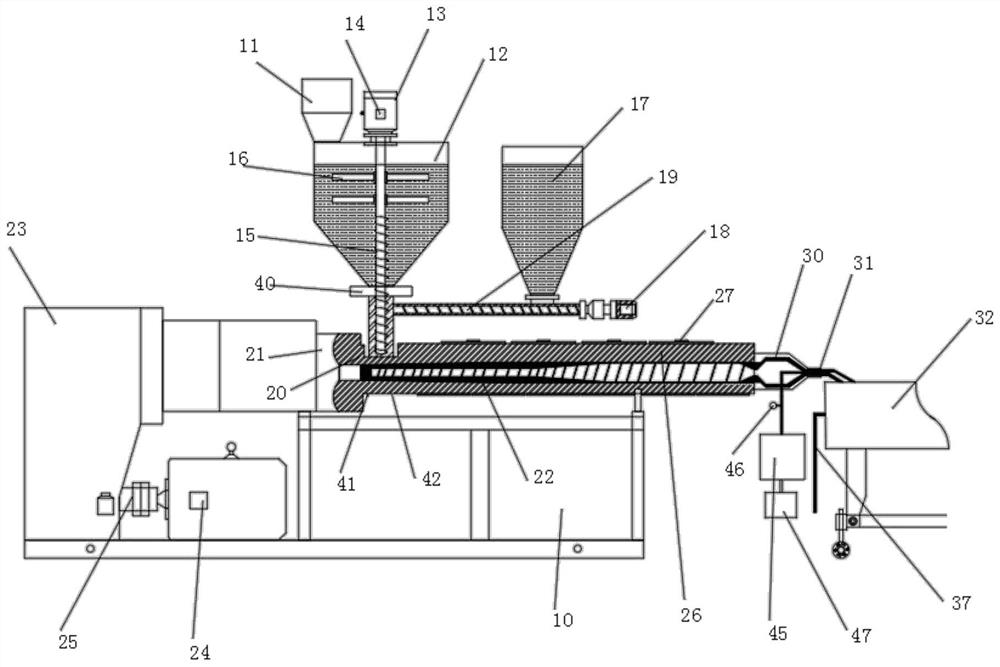

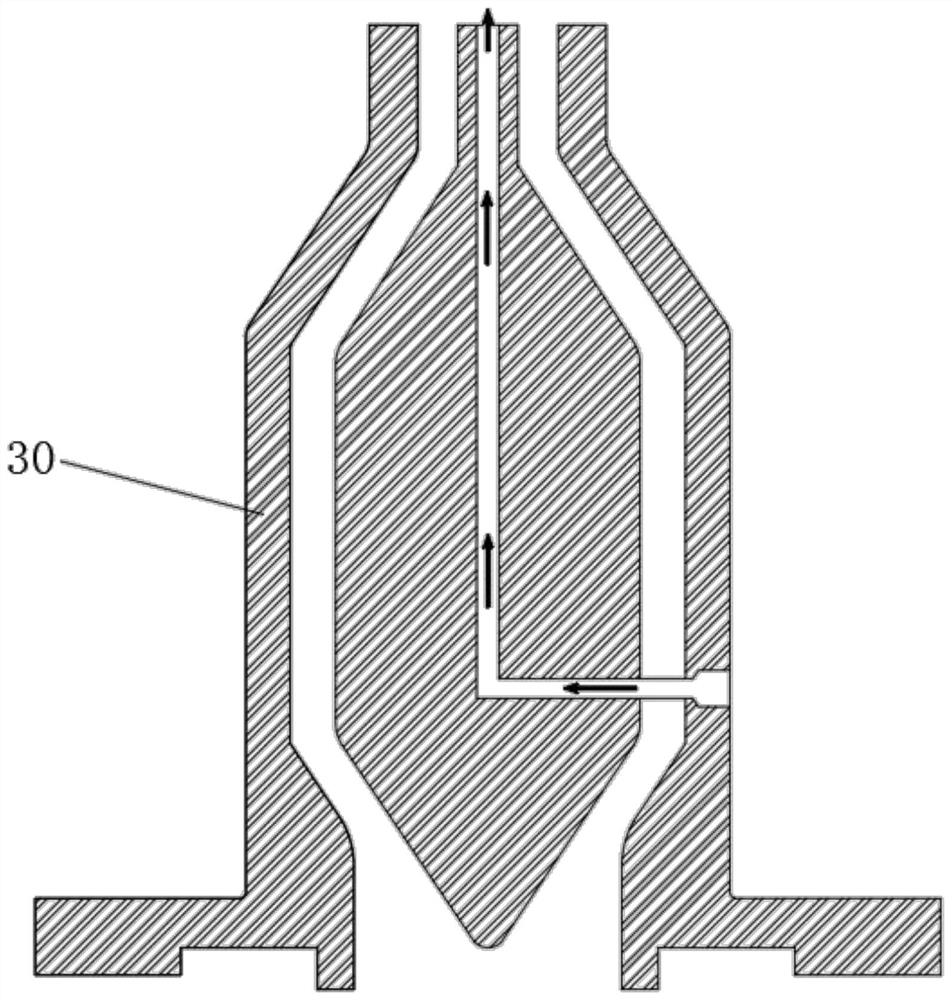

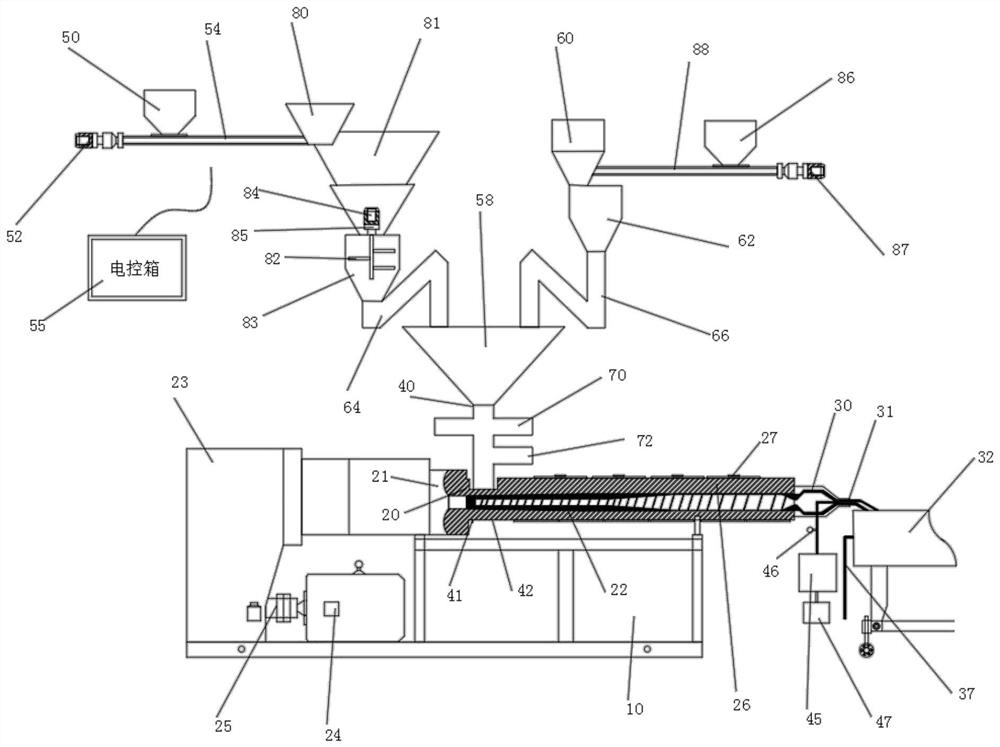

[0026] Example: see Figure 1-3, the present invention provides a technical solution: a flexible microporous uniform oxygenation pipe, including an extrusion device 10, the extrusion device 10 is a conventional single-screw extruder, and the left side of the extrusion device 10 is provided with Gear box 23, the inner cavity of gear box 23 is provided with driving belt 25 and motor 24, and gear box 23 is driven by relatively larger motor 24 by connecting driving belt 25, and the top of extruding device 10 is provided with stirring hopper 12, stirring The left side of the top of the hopper 12 is provided with a drying chamber 11, the top of the stirring hopper 12 is provided with a first motor 13, the first motor 13 is provided with a driving arm 14, and the bottom of the first motor 13 is provided with a screw 15, the screw 15 The outer ring is fixedly connected with an anti-bridging arm 16, the bottom of the mixing hopper 12 is provided with a cold water jacket 40, the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com