Hydraulic actuators for operating friction clutches

A friction clutch and actuator technology, applied in the field of power transmission, can solve the problems of failure of pressure balance function and inability to reliably prevent water from entering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

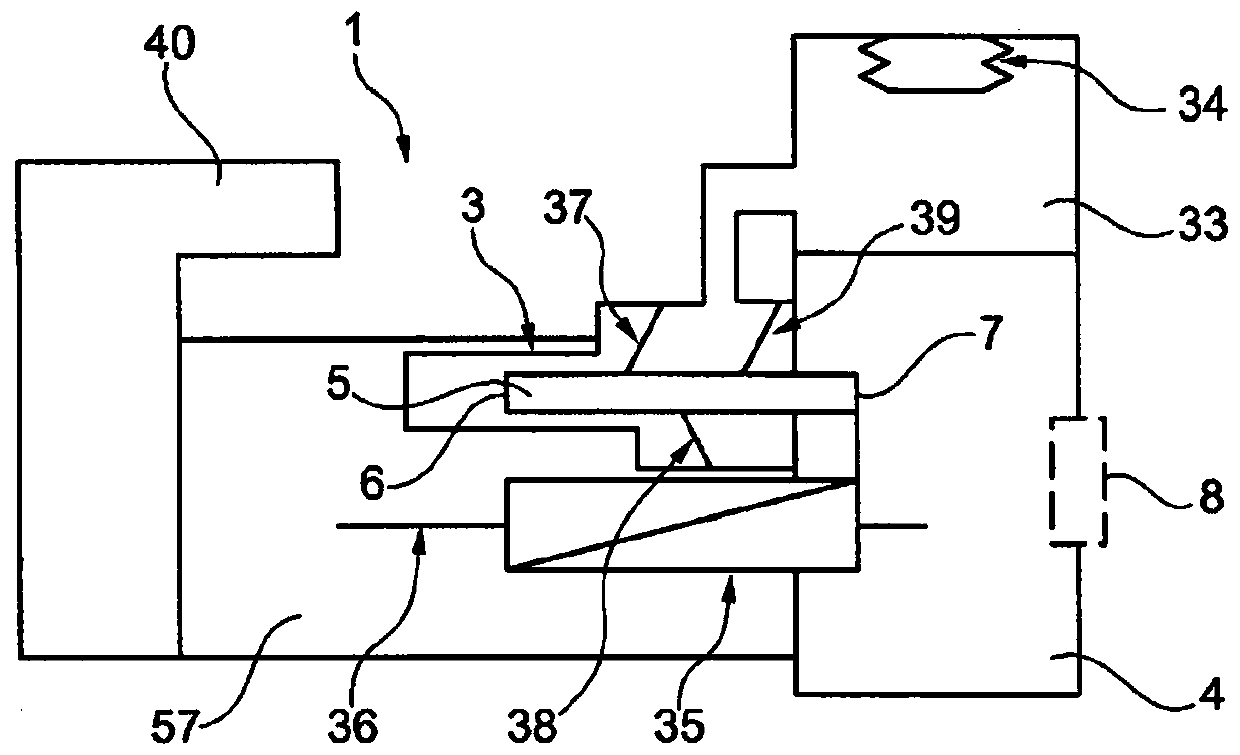

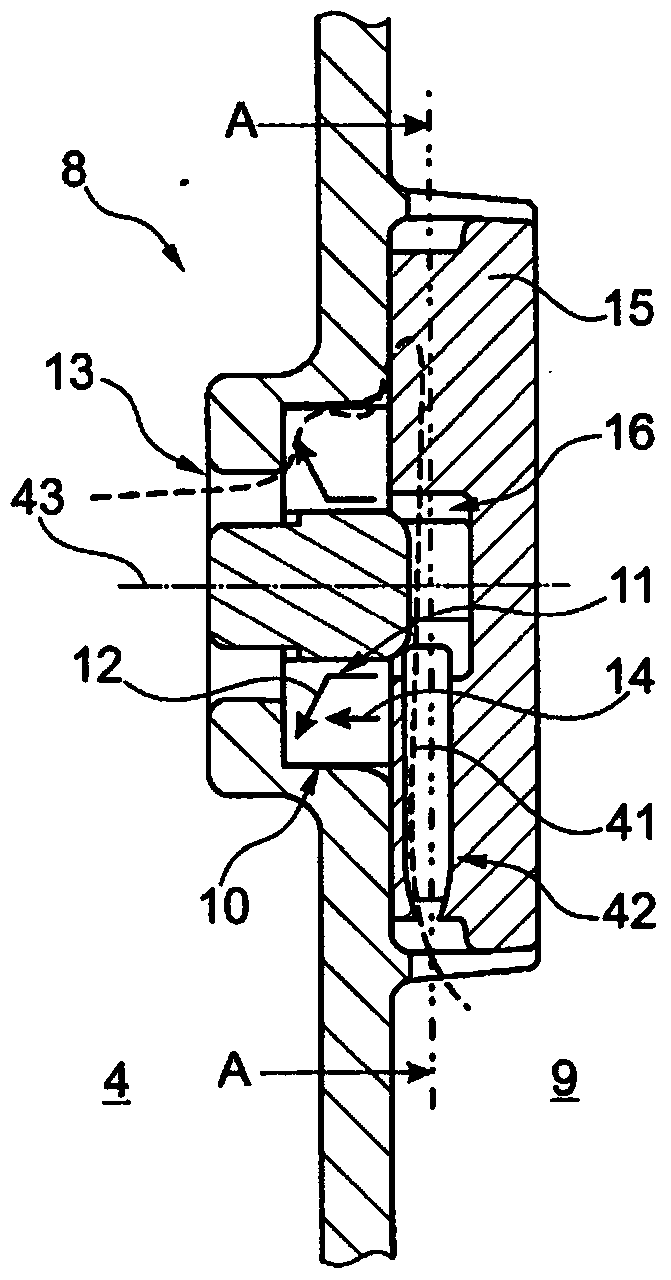

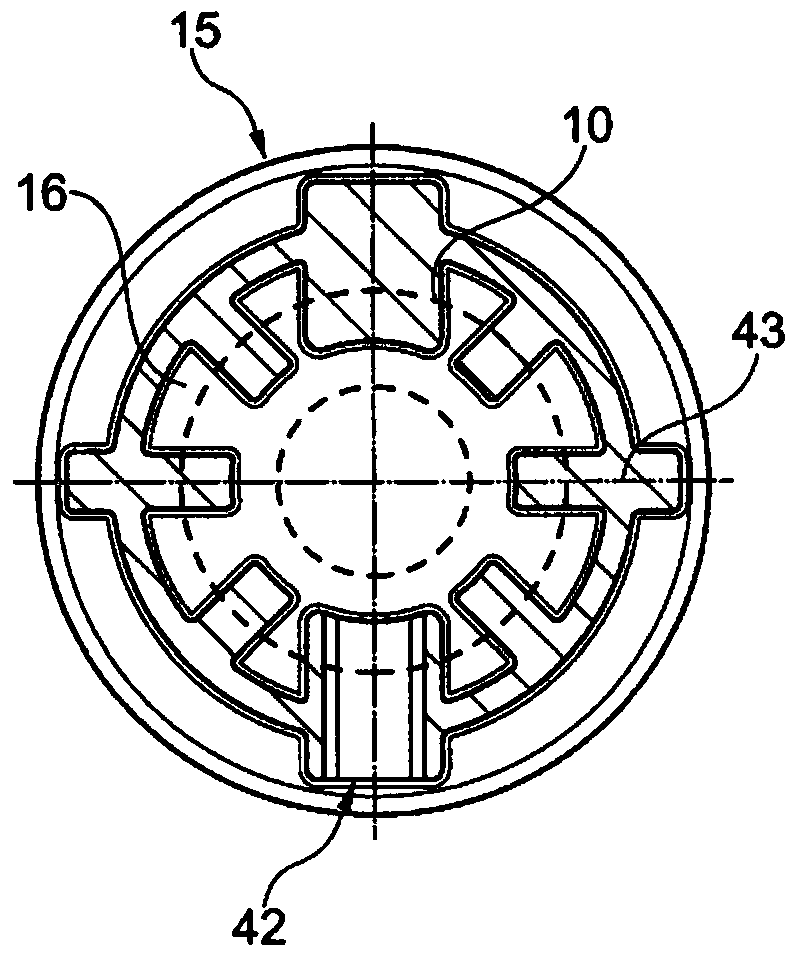

[0049] exist figure 1 A hydraulic actuator 1 is schematically shown in FIG. 1 , wherein the electronics compartment 40 is connected to the mechanical compartment 57 in which the spindle drive 35 with the spindle 36 is located. The main shaft drive 35 is fixedly connected here to the hydraulic piston 5 or its rear side 7, so that the hydraulic piston 5 can move axially in the hydraulic cylinder 3, here parallel to the main shaft 36 of the friction clutch 2 (cf. Figure 9 )move. The hydraulic cylinder 3 is sealed from the drying chamber 4 by means of an inner primary seal 38 and an outer primary seal 37 and a secondary seal 39 . In this case, the outer seal 37 is mainly provided to ensure a minimum volume in the hydraulic cylinder 3 or in the connected hydraulic system (not shown here: hydraulic line and slave cylinder). For this purpose, the hydraulic cylinder 3 is connected to a compensating container 33 in which hydraulic fluid is stored. The pressure in the compensating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com