Drying chamber

A technology of drying room and air supply room, which is applied in the field of drying room, can solve problems such as inability to adjust, and achieve simple, low-cost and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The drying chamber described below is used in particular for the production of lithium-ion batteries. However, they can also be used advantageously, for example in the pharmaceutical industry or the food industry.

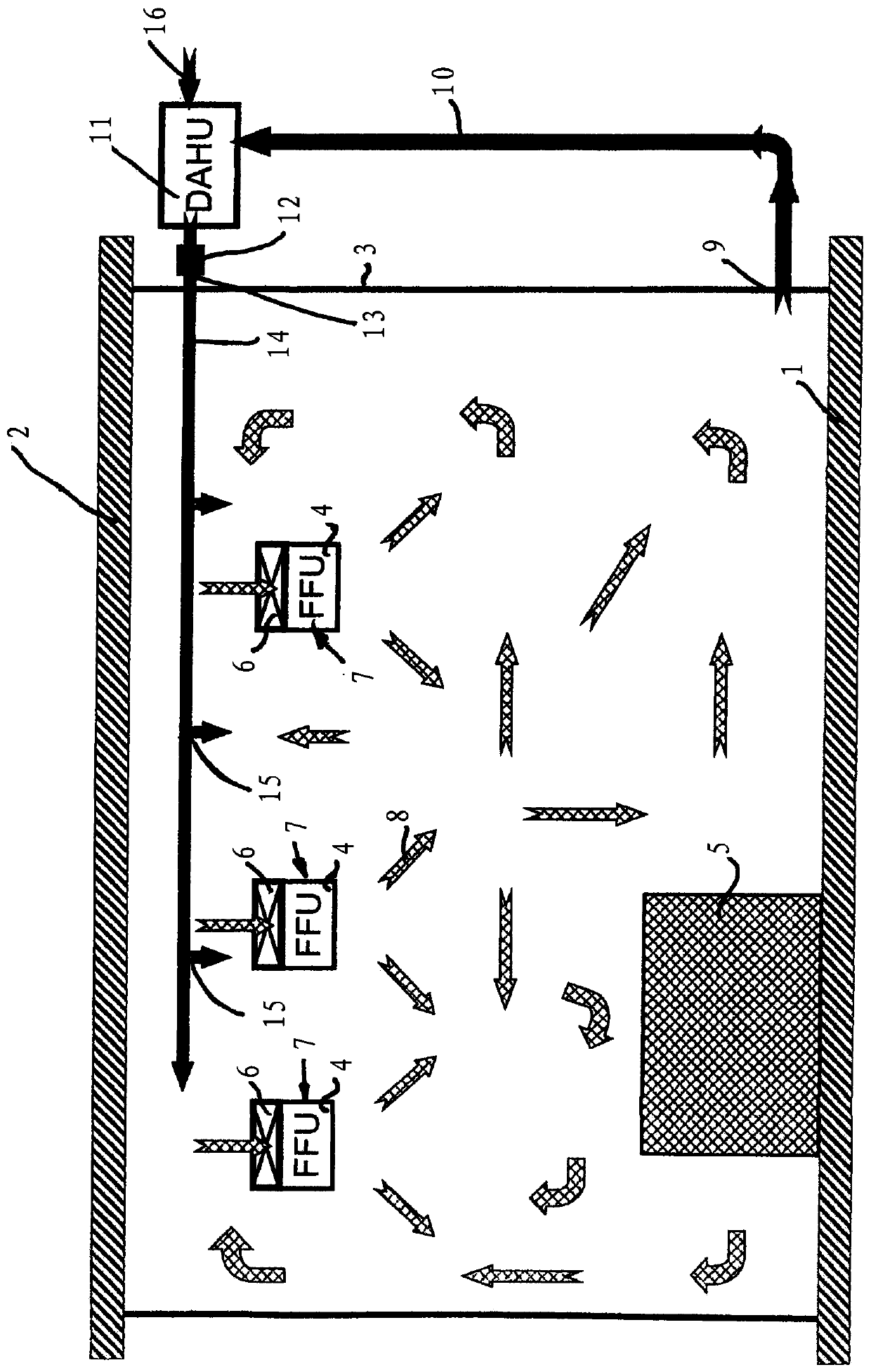

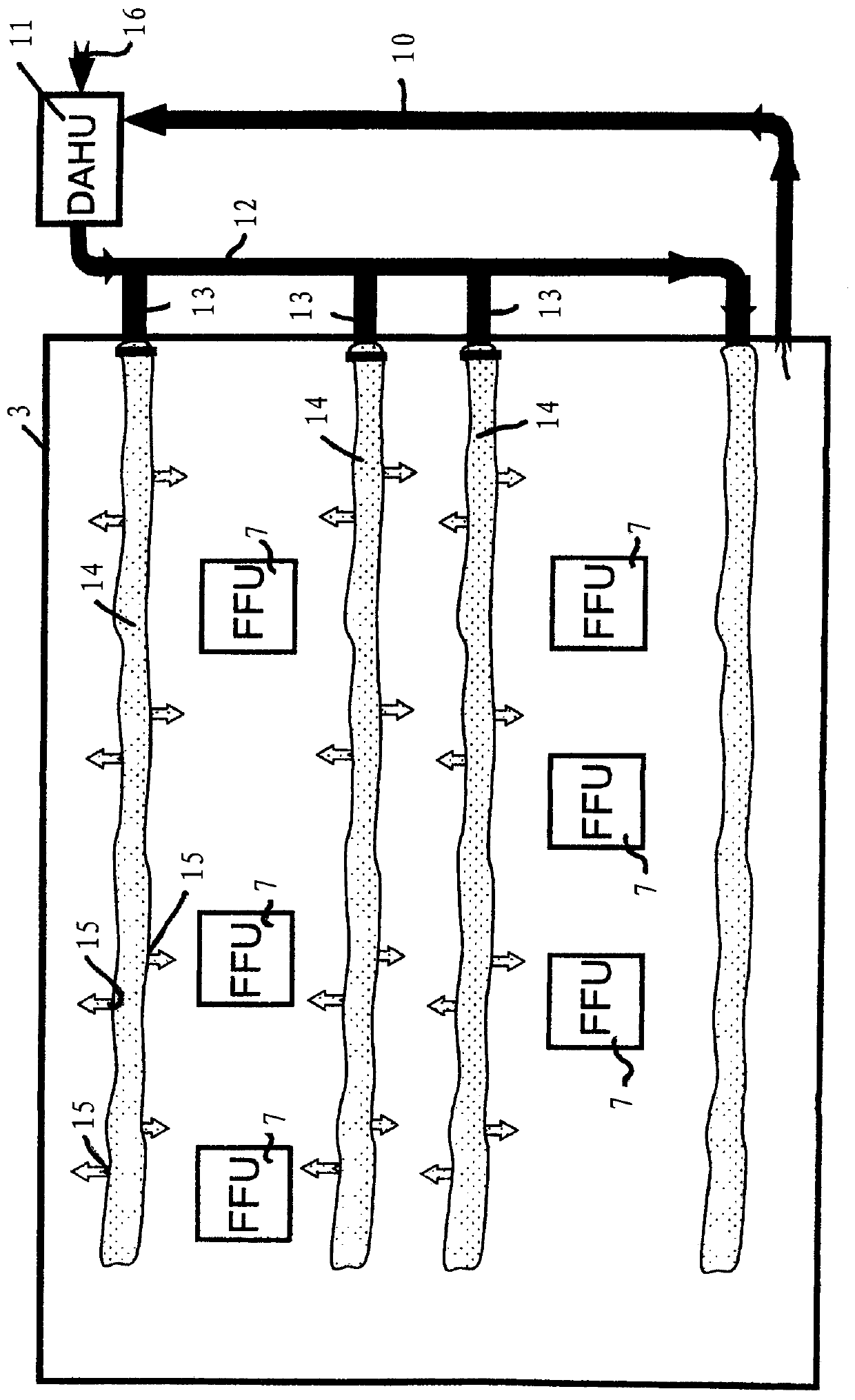

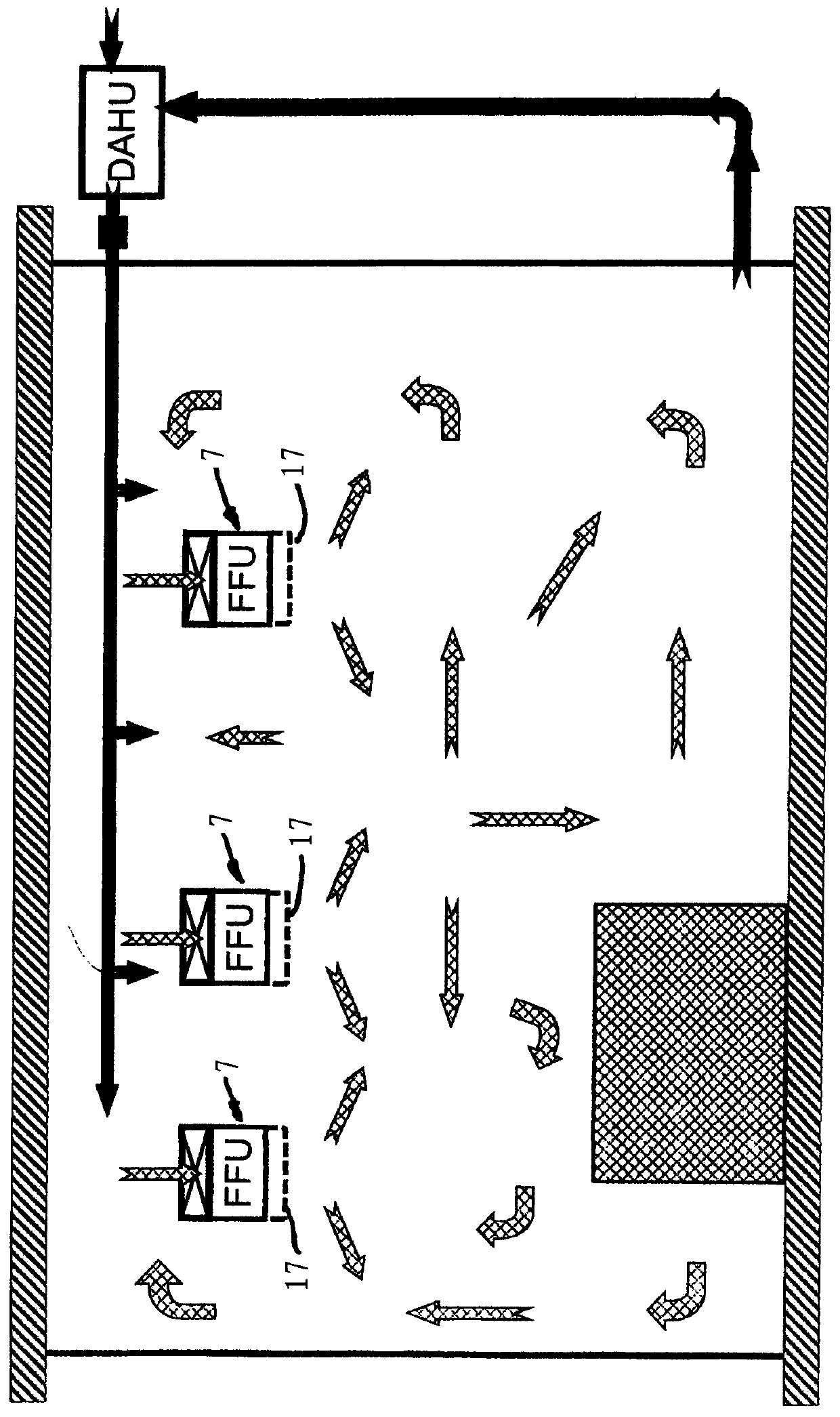

[0029] according to figure 1 with 2 The drying room has a floor 1 and a ceiling 2 supported on the floor 1 by vapor diffusion sealed side walls 3 . as by figure 2 It can be seen that the drying chamber has, for example, a rectangular outline. But the drying chamber is not limited to this cross-sectional shape. It can have, for example, a square outline, a hexagonal outline or, for example, a circular outline.

[0030] Air delivery / cooling units 7 are distributed in the drying chamber. They each include an air delivery unit 4 , which in the exemplary embodiment is formed as a filter-fan unit, and a cooling unit 6 . Here, these air delivery / cooling units 7 are only arranged in the drying chamber where filtered air is required. exist figure 1 is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com