Automatic transmission with torque converter, a dnr gear group, and a cvt unit and method of operating the same

A technology of automatic transmission and gear set, applied in the direction of belt/chain/gear, transmission device, mechanical equipment, etc., can solve the problems of high cost of automatic transmission and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

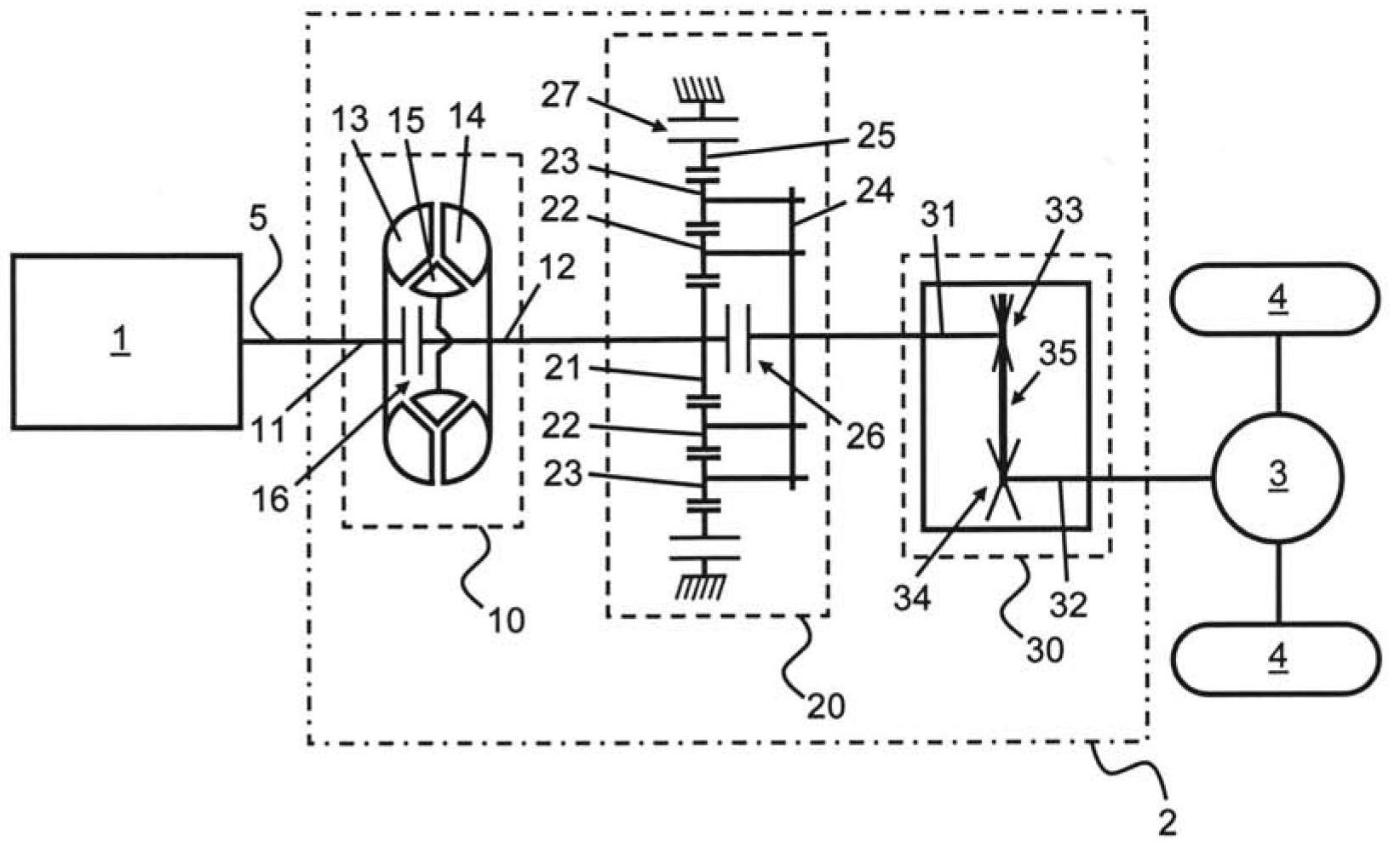

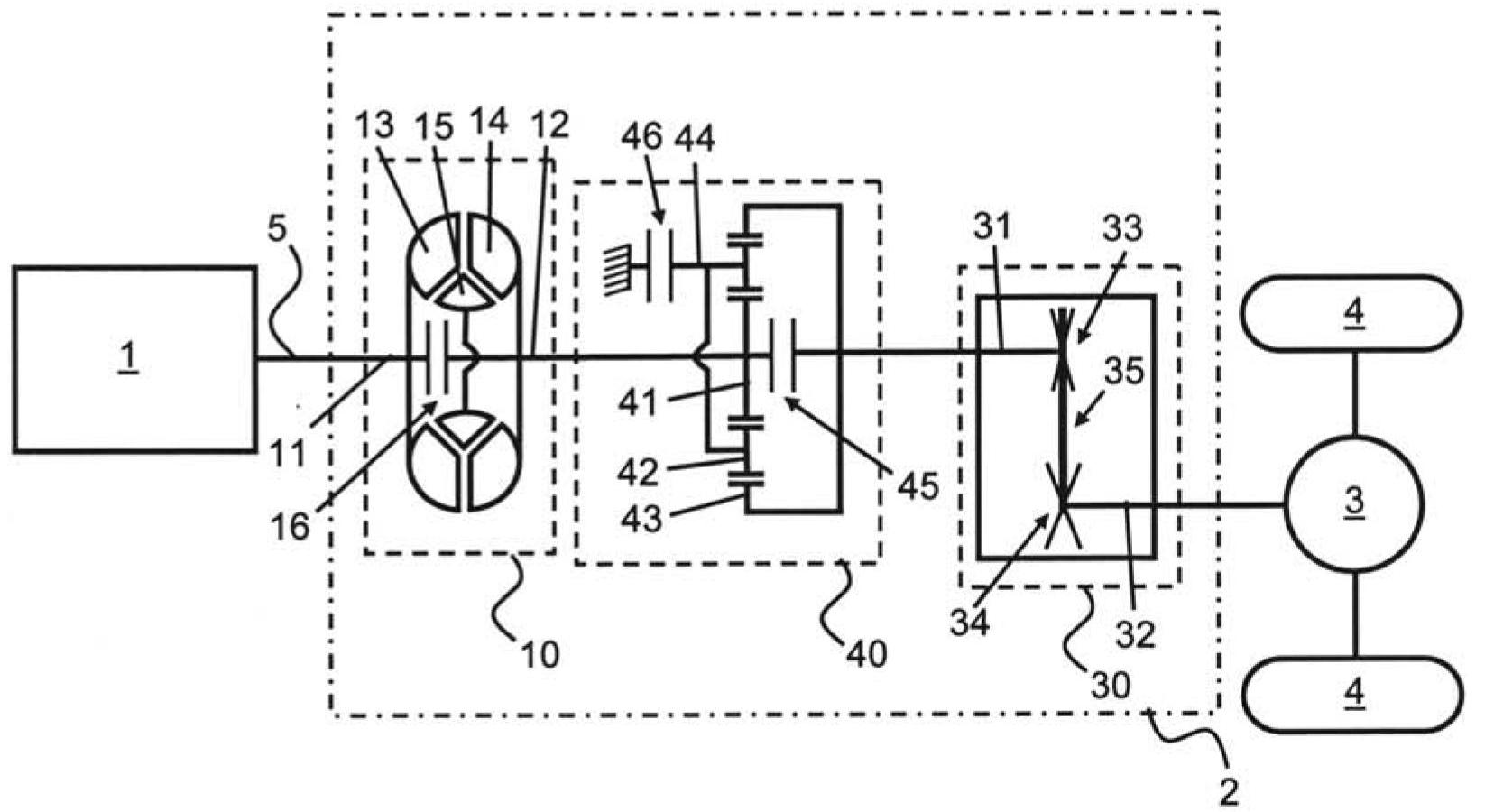

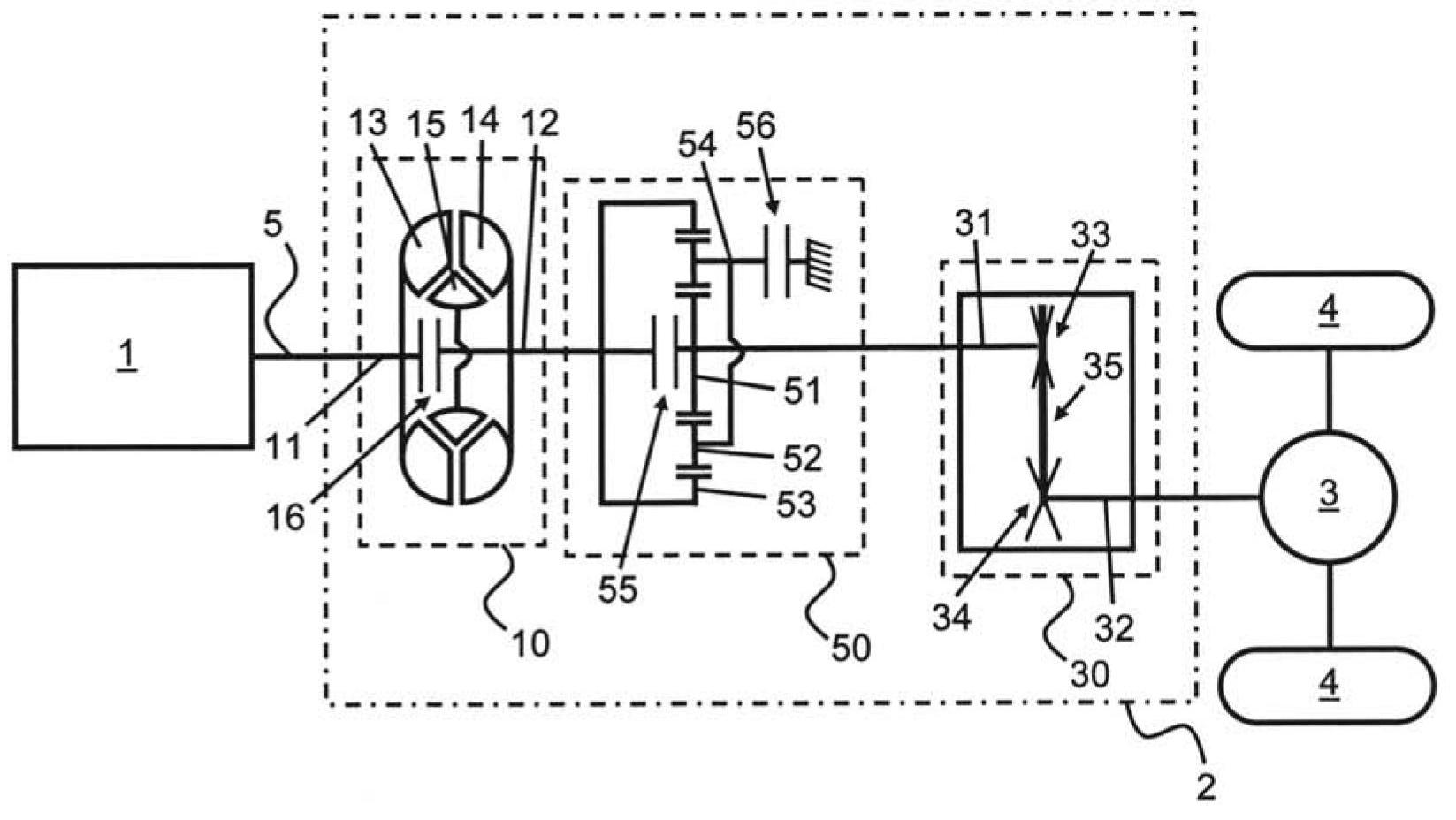

[0015] figure 1 A drive train for a vehicle is shown with a drive engine 1 , an automatic transmission 2 and with two wheels 4 driven through its differential 3 . In the driving direction, the known automatic transmission 2 successively comprises a torque converter 10 , a shiftable drive-neutral-reverse or DNR gear set 2 and a continuously variable transmission or CVT unit 30 . Typically, a final drive, that is to say a gear stage comprising two or more gears, occurs between the CVT unit 30 and the differential 3 (not shown).

[0016] A crankshaft 5 of the engine 1 is coupled to an input shaft 11 of a torque converter 10 that drives an impeller 13 . A turbine 14 of the torque converter 10 drives its output shaft 12 . In a manner known per se, the pump wheel 13 drives the turbine wheel 14 by means of the hydraulic fluid and the so-called stator 15 of the torque converter 10 , in which case the drive torque from the input shaft 11 to the output shaft 12 can be increased. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com