a cleaning system

A cleaning system and cleaning room technology, applied in the field of cleaning systems, can solve the problems of steam heat energy and waste of clean water resources, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

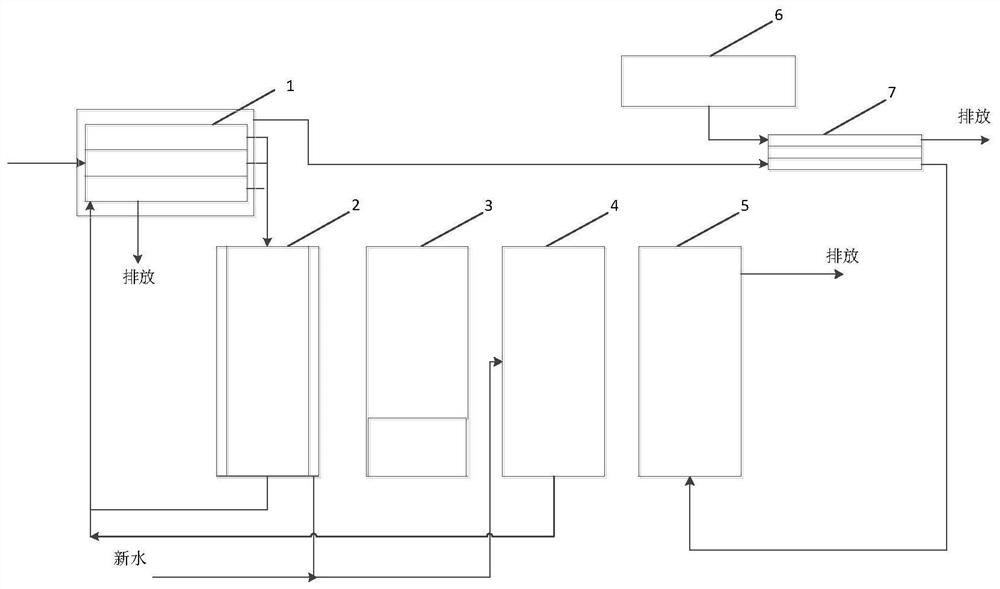

[0043] This embodiment provides a cleaning system, such as figure 1 shown, including:

[0044] Gas-fired boiler 1 is capable of feeding in natural gas and burning natural gas to heat water to form water vapor. It has a combustion chamber 11 and several steam generating chambers 12. Combustion chamber 11 has a high-temperature waste gas outlet, and each steam generating chamber 12 has a water vapor outlet;

[0045] The steam cleaning chamber 2 is cylindrical and has a collection tank at the bottom. The collection tank is divided into an intermediate collection tank for collecting the condensed water dripping from the workpiece placed in the center of the steam cleaning chamber 2, and collecting the condensed water from the four sides of the steam cleaning chamber 2. Peripheral collection troughs for condensate dripping on the interior walls;

[0046] The cleaning liquid cleaning chamber 3 is a immersion equipment, and the bottom of the cleaning liquid cleaning chamber 3 is equ...

Embodiment 2

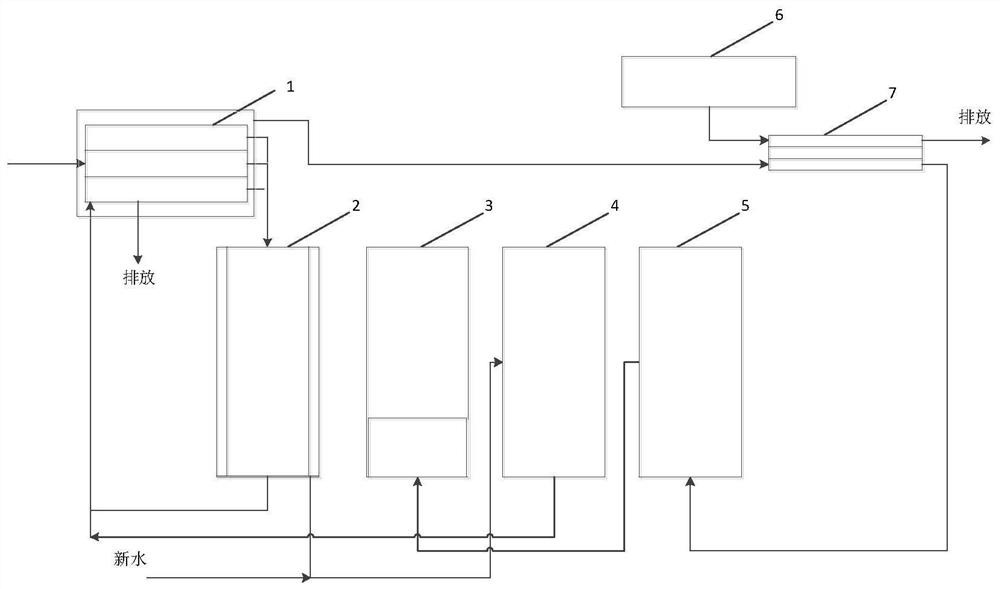

[0058] This embodiment provides a cleaning system, such as figure 2 shown, including:

[0059] On the basis of Embodiment 1, the gas flowing out of the drying chamber 5 is passed into the bubble generator 31 through the pressurization device 8, so that bubbles are generated in the cleaning liquid cleaning chamber 3 to improve the cleaning effect; it should be pointed out that the pressurization device 8 is to provide sufficient pressure for the bubbles in the cleaning liquid cleaning chamber 3 to emerge;

Embodiment 3

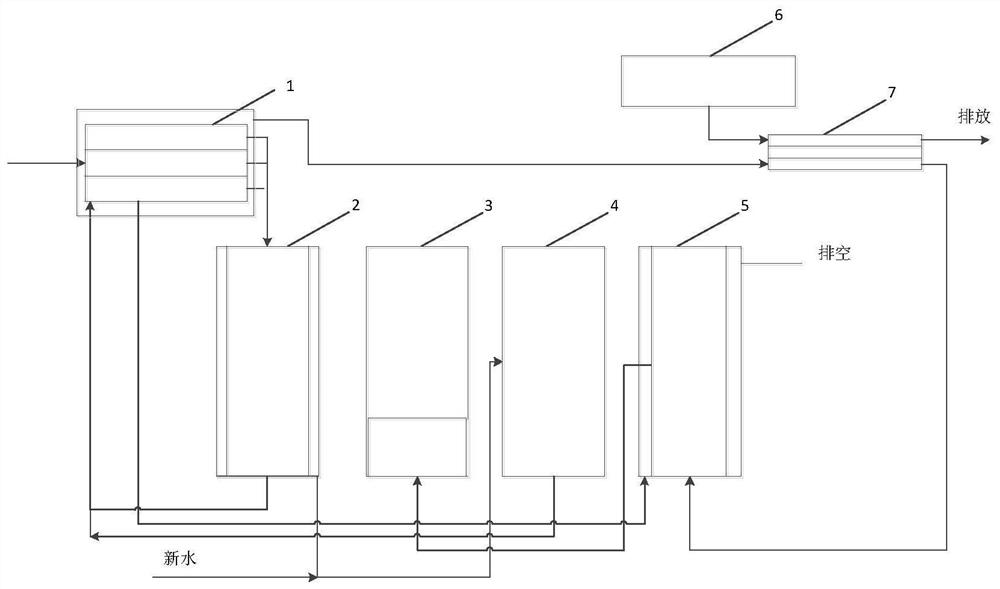

[0061] This embodiment provides a cleaning system, such as image 3 shown, including:

[0062] On the basis of embodiment 2, the side wall of drying chamber 5 has jacket or pipeline, and the jacket of drying chamber 5 or pipeline are connected with the water outlet of steam generating chamber 12, and the remaining liquid of steam generating chamber 12 and guide steam generating chamber The condensed water in the intermediate collection tank of 12 is passed into the jacket or pipeline of the drying chamber 5 to heat the drying chamber 5 and maintain the temperature of the drying chamber 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com