Device and method for drying work pieces

A drying and workpiece technology, especially in the field of wheels, drying workpieces, and wheel devices, can solve the problems of deterioration of total energy balance, increase of total equipment operating costs, and consumption, and achieve the effect of improving energy balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

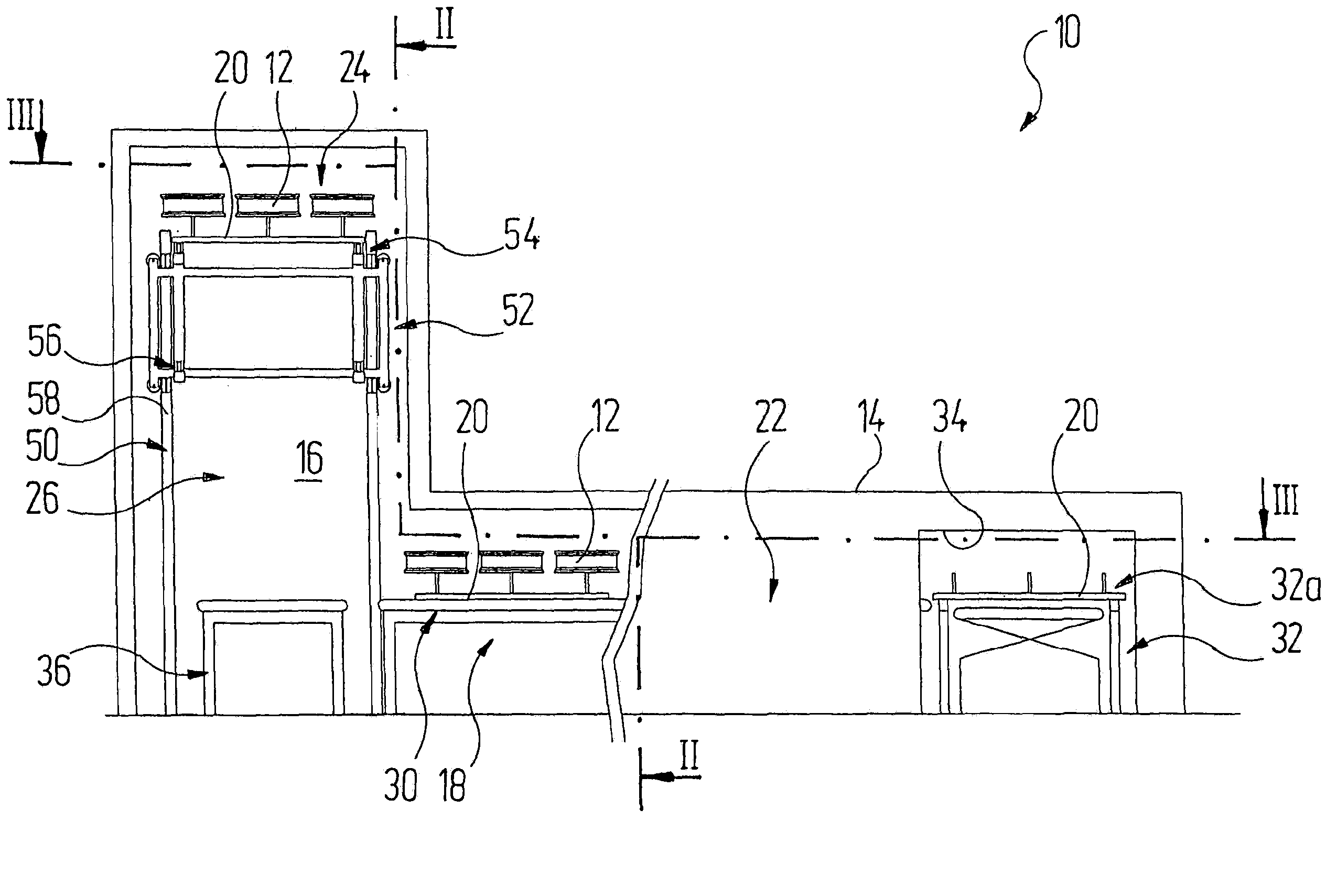

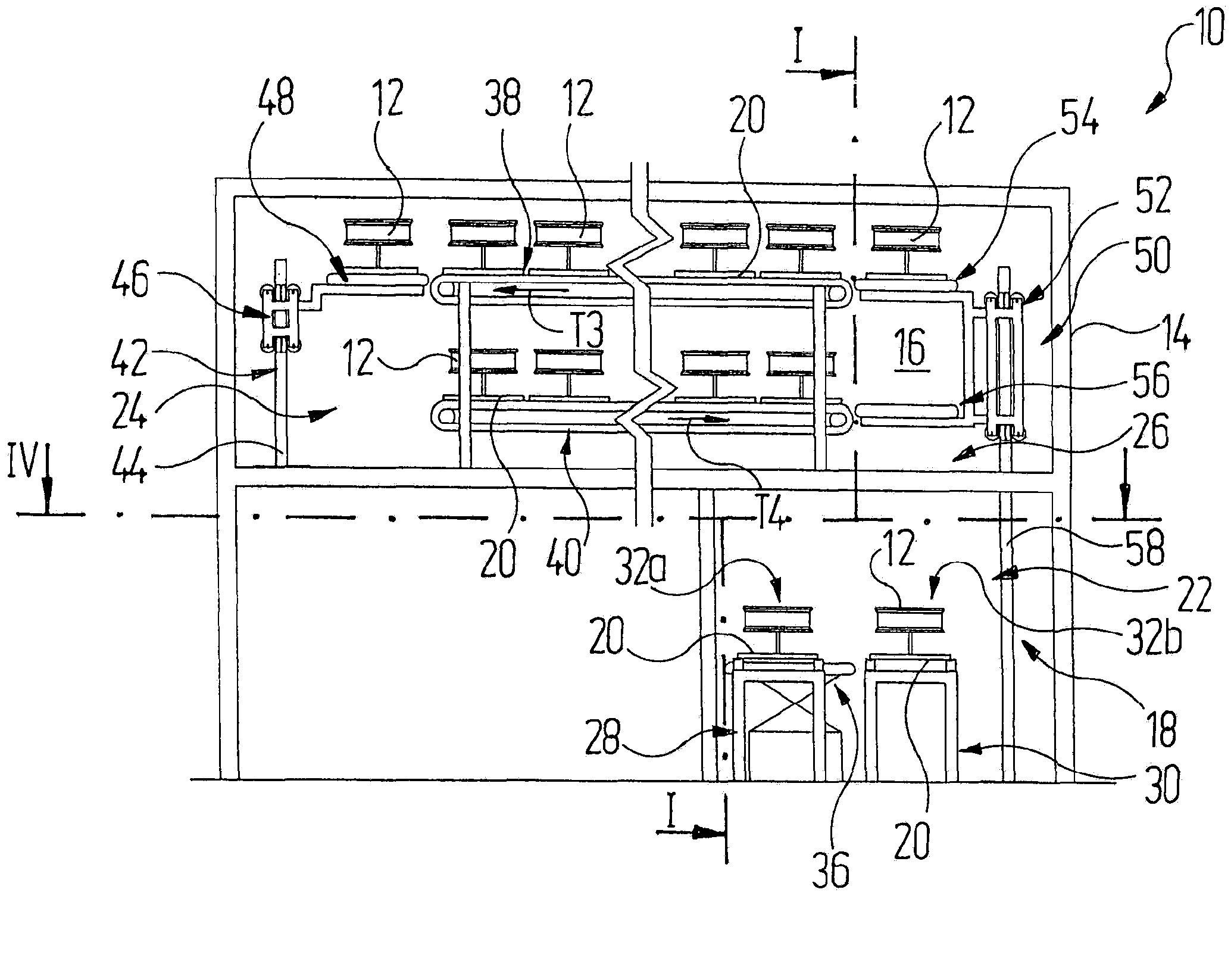

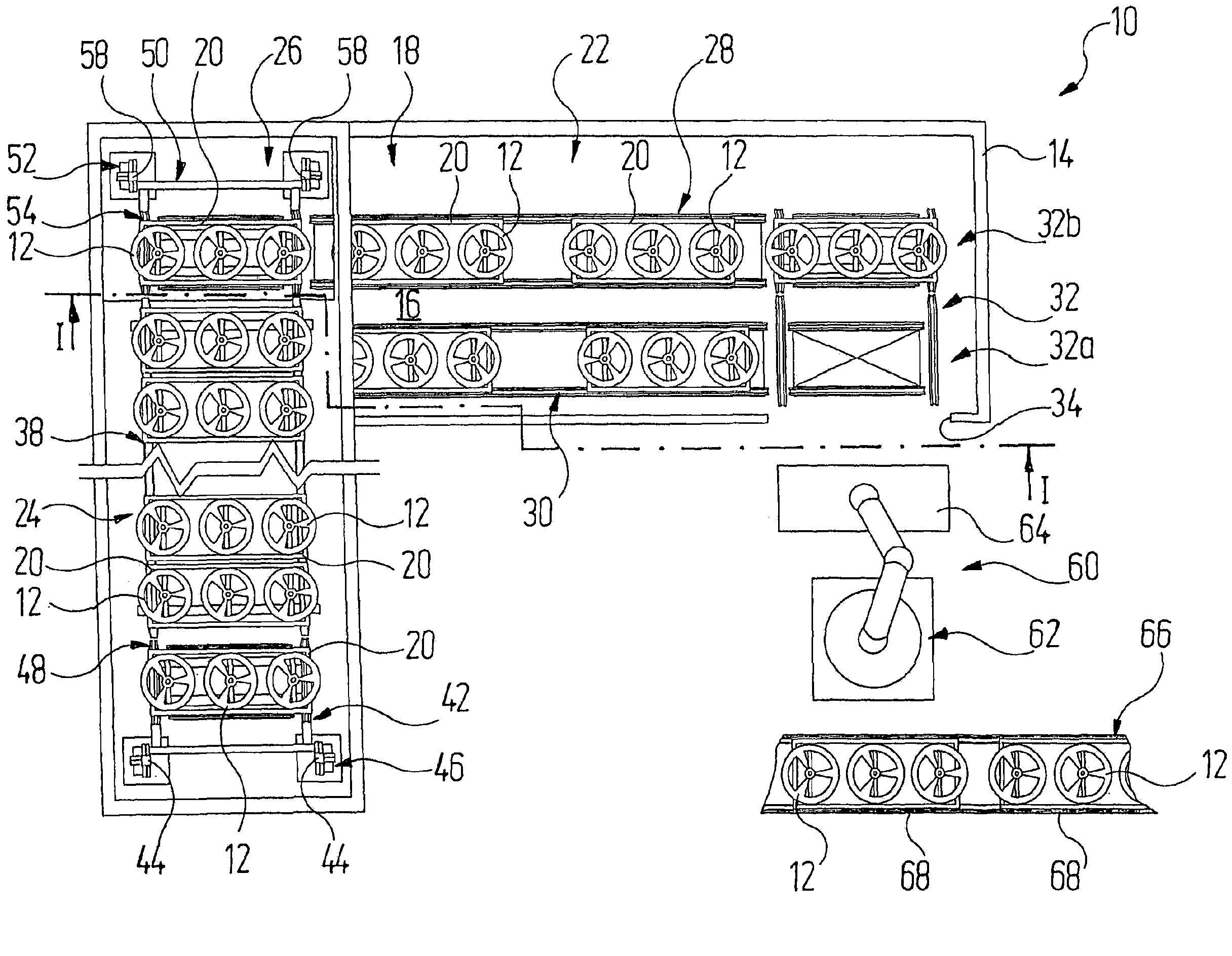

[0041] As a first embodiment of a device for drying objects, a drying oven is Figure 1 to Figure 4 The whole is represented by 10, and the workpiece is dried in a drying oven. Shown as workpiece in this exemplary embodiment is a wheel 12 for a motor vehicle, which is dried in a drying oven 10 after the wheel has been provided with an outer surface coating, such as painting, in one or more previous processing steps.

[0042] The drying oven 10 has an insulated dryer shell 14 defining a drying chamber 16 . The workpiece carrier 20 loaded with the wheels 12 is transported through the drying chamber 16 by means of a transport system generally indicated at 18 . In the embodiment shown here, each workpiece holder 20 is capable of accommodating three wheels 12 .

[0043] The drying chamber 16 of the drying oven 10 has a preheating and discharge zone 22 at a first level and a drying tunnel 24 at a second level, which is higher than the first level of the preheating and discharge zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com