Drying chamber air distribution structure capable of efficiently dehumidifying

A drying room and air distribution technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of high consumption of auxiliary fuel, low solid content, large transportation volume, etc., and achieve energy consumption reduction and simple and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

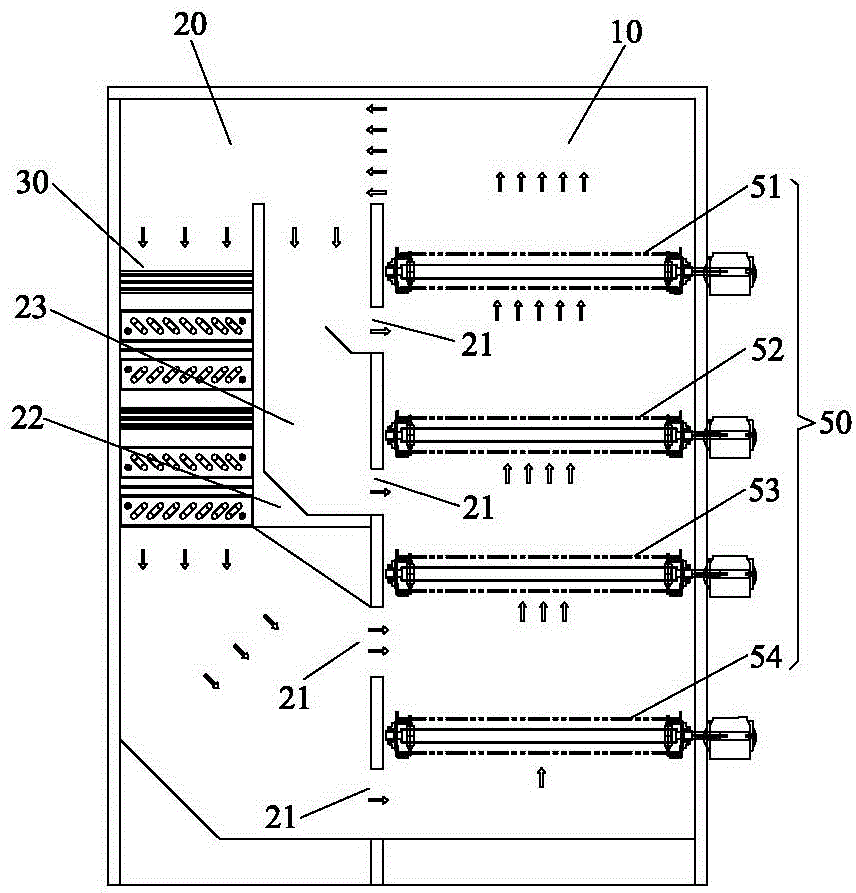

[0024] The invention is like figure 1 and figure 2 It is shown that a dry room can be efficient and dehumidified, including the first chamber 10, the second cavity room 20, the heat pump 30, the circulating fan 40, and the plural layer.in:

[0025] The first chamber 10 is connected above the second cavity room 20.

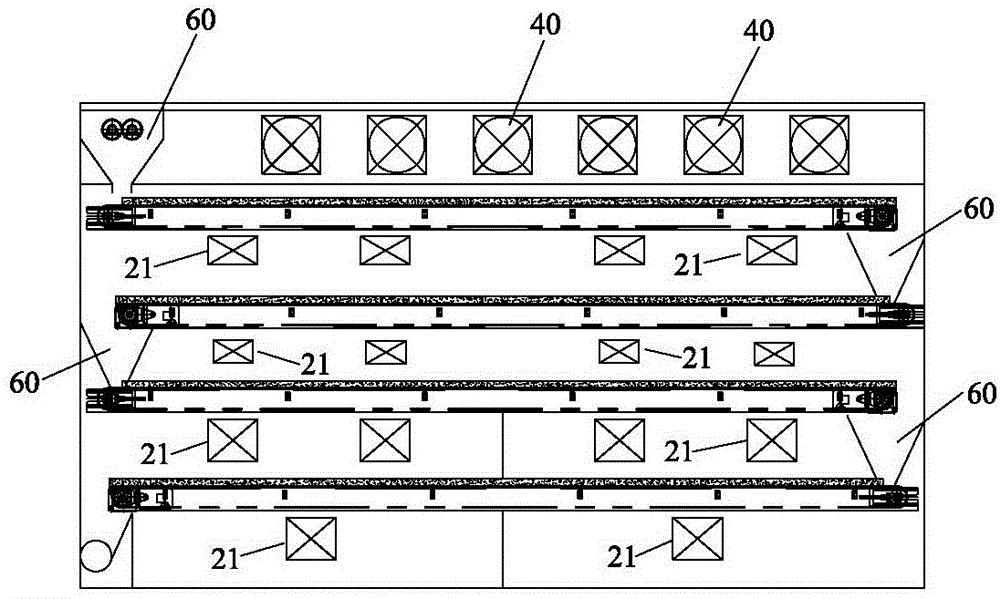

[0026] The heat pump 30 is installed on the 10 side walls of the first cavity chamber; the plural mesh zone 50 includes the first layer of the net zone 51, the second layer of the net zone 52, the third layer of the net zone 53, and the fourth layer net zone 54.The plural mesh belt 50 is installed in the second cavity room 20 in the secondary chamber, and the top of the top 50 of each net zone is set up above the top 50 of the sludge 60 that is used to put the sludge 60 on the net.

[0027] The circulating fan 40 has a total of multiple, and the plural cycle fan 40 is installed above the first layer of net zone 51.

[0028] On the side wall of the second cavity room, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com