Marine diesel-driven screw air compressor and machining method thereof

A processing method and screw-type technology, which is applied in the field of air compressors, can solve the problems of affecting the fit of parts, poor control of cooling water temperature, unfavorable operation of diesel-driven screw air compressors, etc., and achieve the effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings:

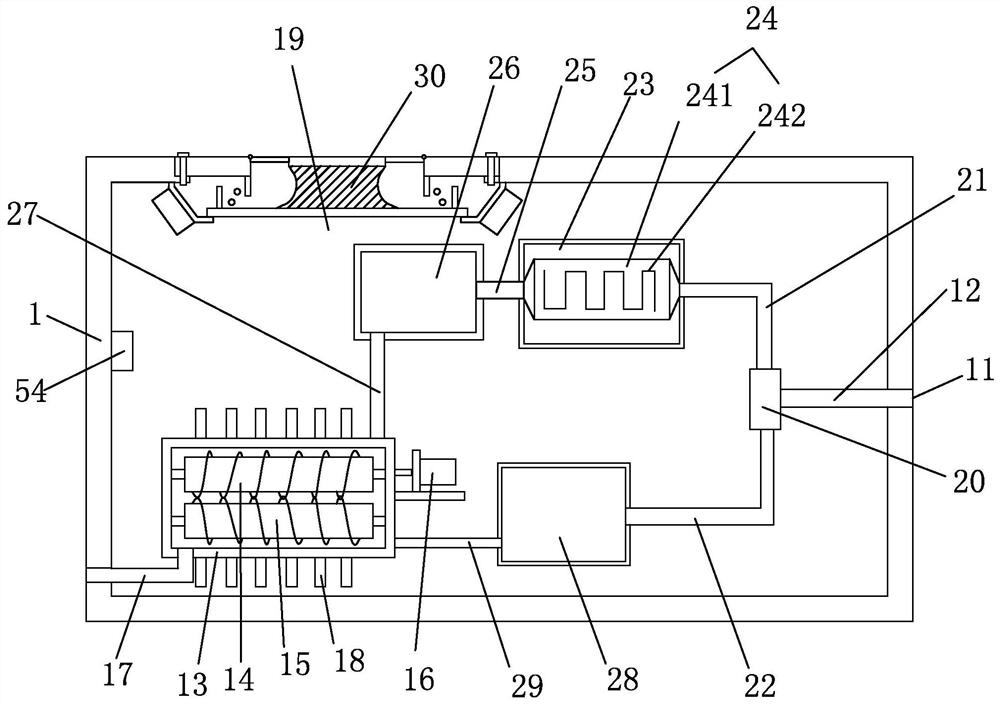

[0033] Such as figure 1 As shown, a marine diesel-driven screw air compressor includes a housing 1, an air inlet 11 is provided on the side wall of the housing 1, and a first air intake pipe 12 is provided on the air inlet 11, and the first air intake pipe The end of 12 is provided with three-way air valve 20, and the other end of three-way air valve 20 is provided with second air intake pipe 21 and the third air intake pipe 22, and the other end of second air intake pipe 21 is provided with cooling chamber 23, and cooling chamber 23 is provided with There is a condensing pipe 24, the condensing pipe 24 includes an inner pipe 242 and an outer pipe 241, the inner pipe 242 is used for cooling liquid to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com