Drying device for preparing brick body through raw bauxite

A drying device, a technology for raw bauxite, which is applied in the directions of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of reducing production efficiency, inability of continuous drying in the drying chamber, drying, etc., and achieves improved production efficiency, a simple structure, handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

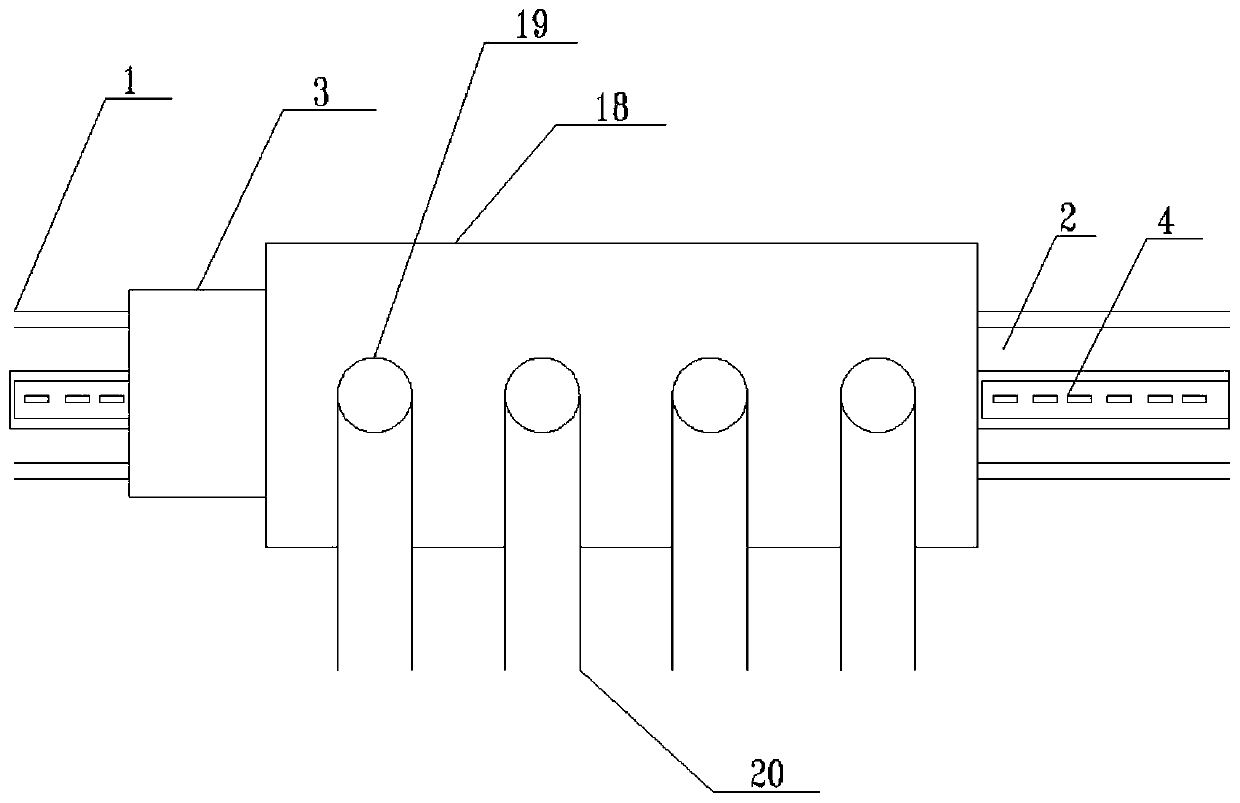

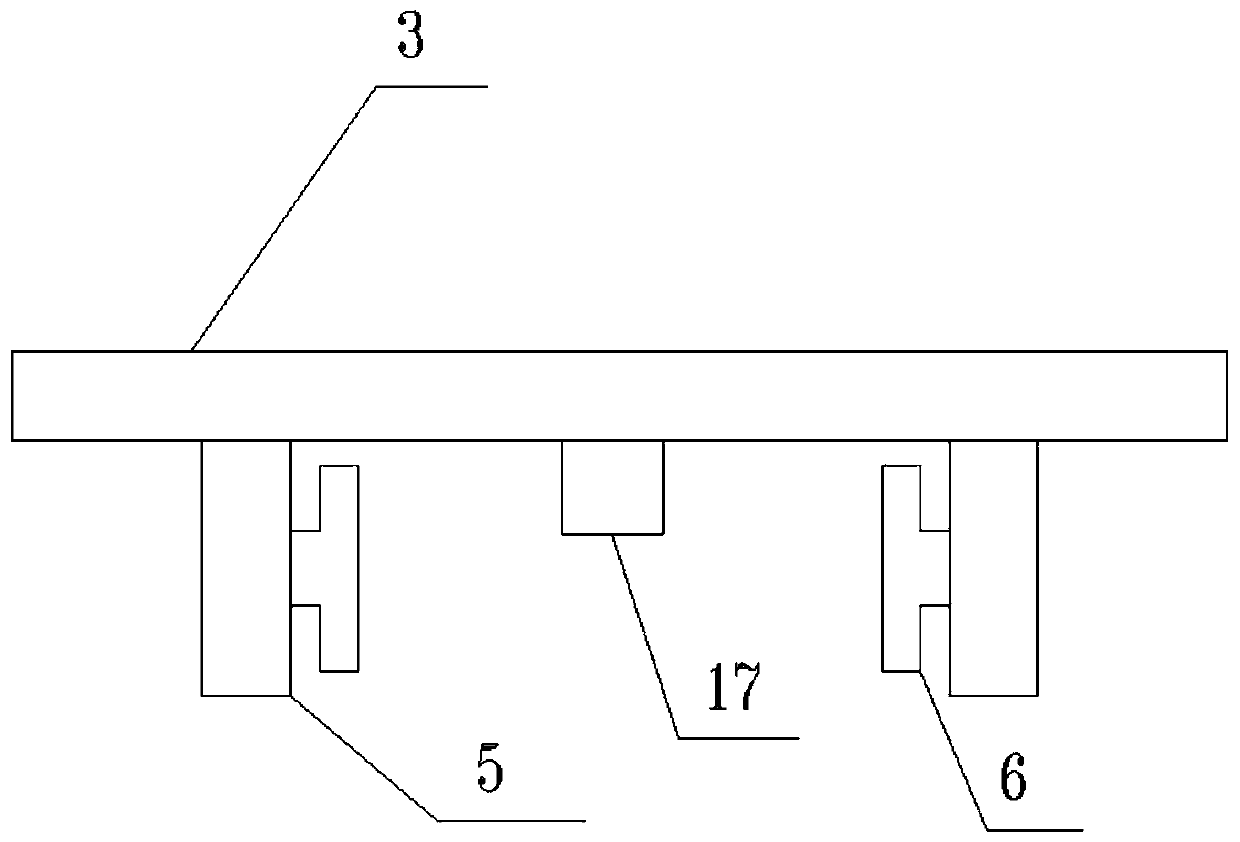

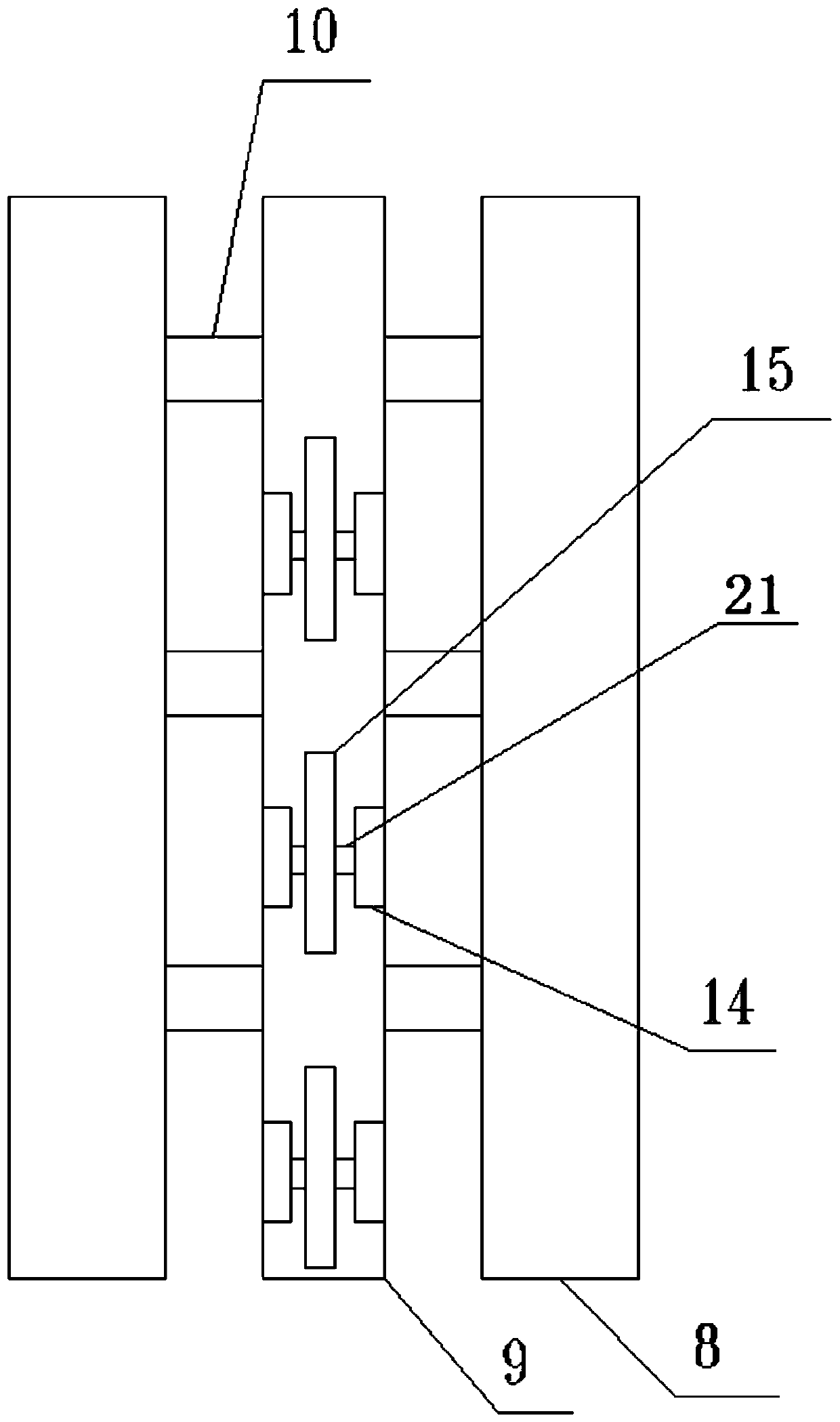

[0016] Embodiment of the present invention: a drying device for making bricks from raw bauxite, as shown in the accompanying drawings, includes a drying chamber 18, which is a hollow structure with front and rear openings, and is uniformly arranged on the top of the drying chamber 18 At least two suction holes 19, the corresponding suction pipe 20 communicates with the suction holes 19 to realize the drying of the drying chamber 18, the track 1 traverses the entire drying room 18, a hollow structure 2 is set between the track 1, and the transport plate 3 Across the track 1, the driving device 4 of the transport board 3 is set in the hollow structure 2, the outriggers 5 are arranged symmetrically on both sides of the bottom surface of the transport plate 3, and the rollers 6 are arranged inside the legs 5, and the rollers 6 and the track 1 Cooperate to realize that the transportation board 3 moves on the track 1, and the driving device 4 cooperates with the transportation board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com