Production process of a structural core material set

A production process and set technology, which is applied in the direction of wood processing appliances, layered products, manufacturing tools, etc., can solve the problems of large deviation of processing dimensions, insufficient layering fastness of stickers, and low product accuracy, and improve processing efficiency. , Save labor costs, simple maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

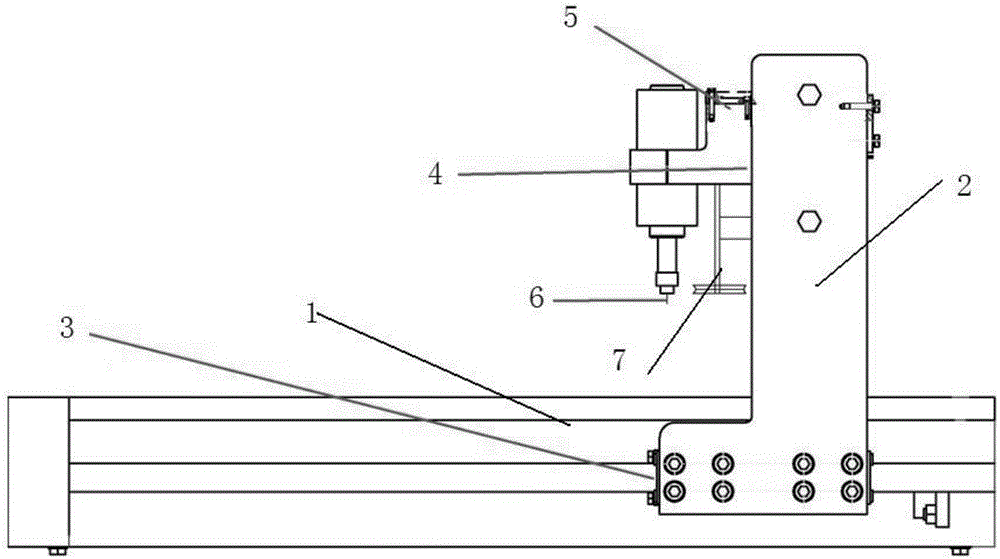

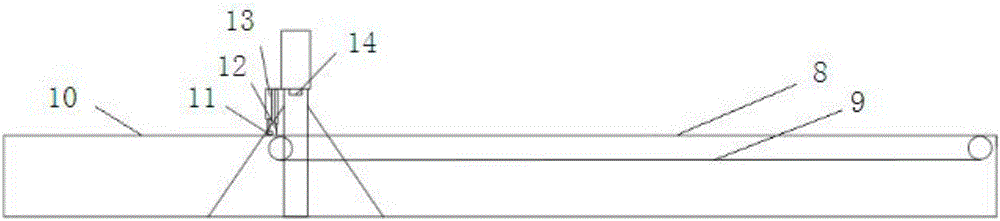

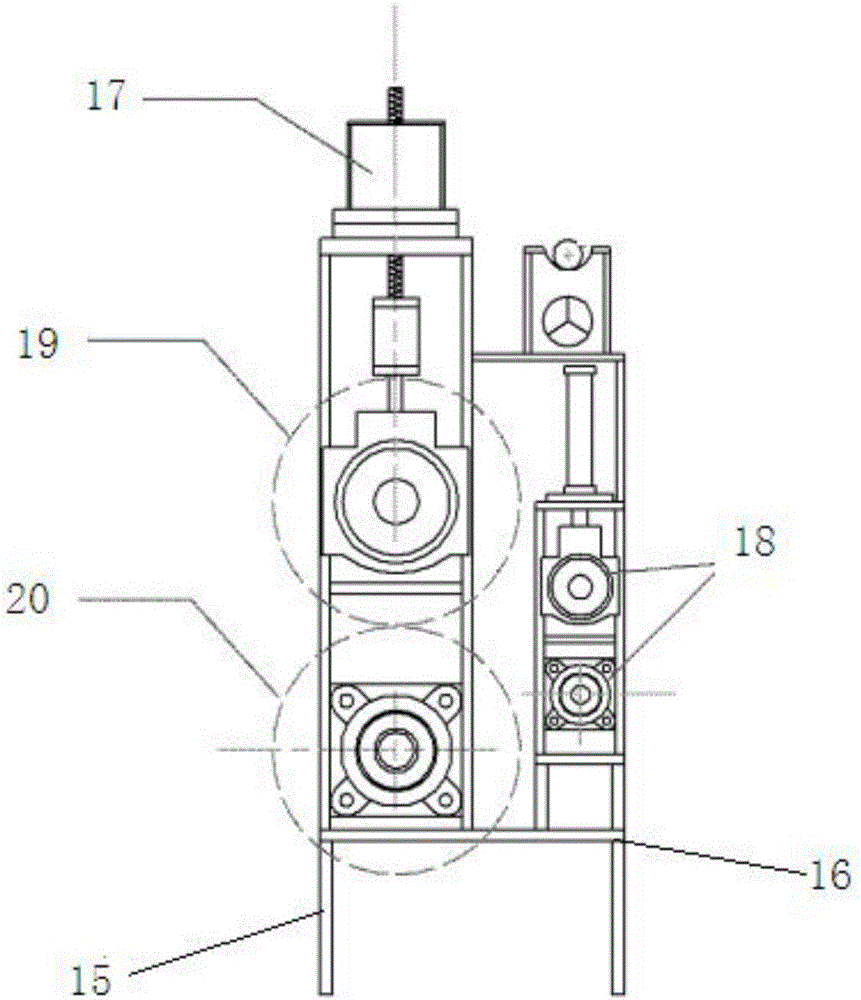

[0020] The present invention is a kind of production technology of structural core material set, comprises the following steps: (1) the processing of balsa wood; (2) the processing of PVC sheet material; (3) splicing of balsa wood and PVC sheet material; The step (1) The processing steps of balsa wood are as follows: first, process the balsa wood board according to the drawing; cut flat according to the required thickness; sanding: make the surface of balsa wood smooth; coating: apply a layer of glue on the surface of balsa wood , to reduce the penetration during the splicing process of PVC boards; pasting, using a pasting machine to paste cloth; punching; slotting; entering the CNC saw for synchronous scribing, edge trimming and angle cutting processes; soot blowing, laying and repairing to obtain light wood boards ; The processing steps of the step (2) PVC sheet are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com