Magnesium alloy electromagnetic energy heating liquid channel tube

An electromagnetic energy and magnesium alloy technology, applied in induction heating, coil devices, etc., can solve the problems of poor quality of magnesium alloy liquid, temperature difference generated by soup pipes, and high power consumption, so as to achieve the same height, less power consumption, and higher power consumption. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

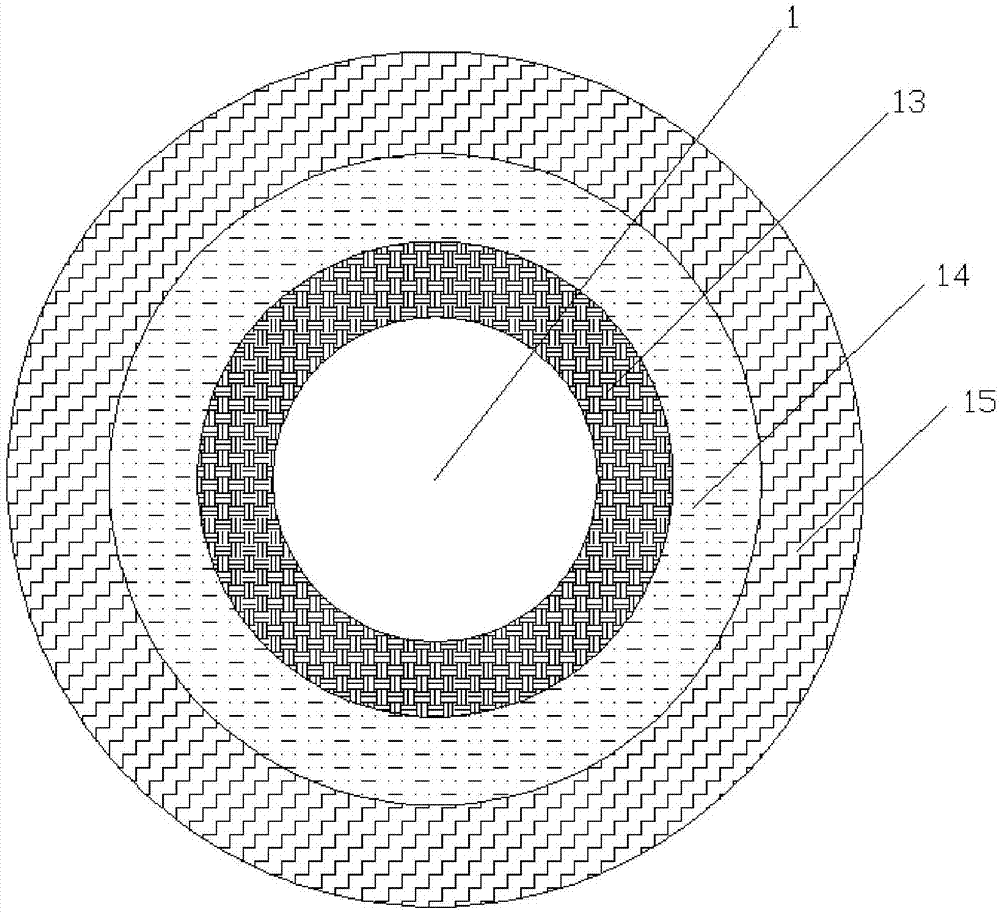

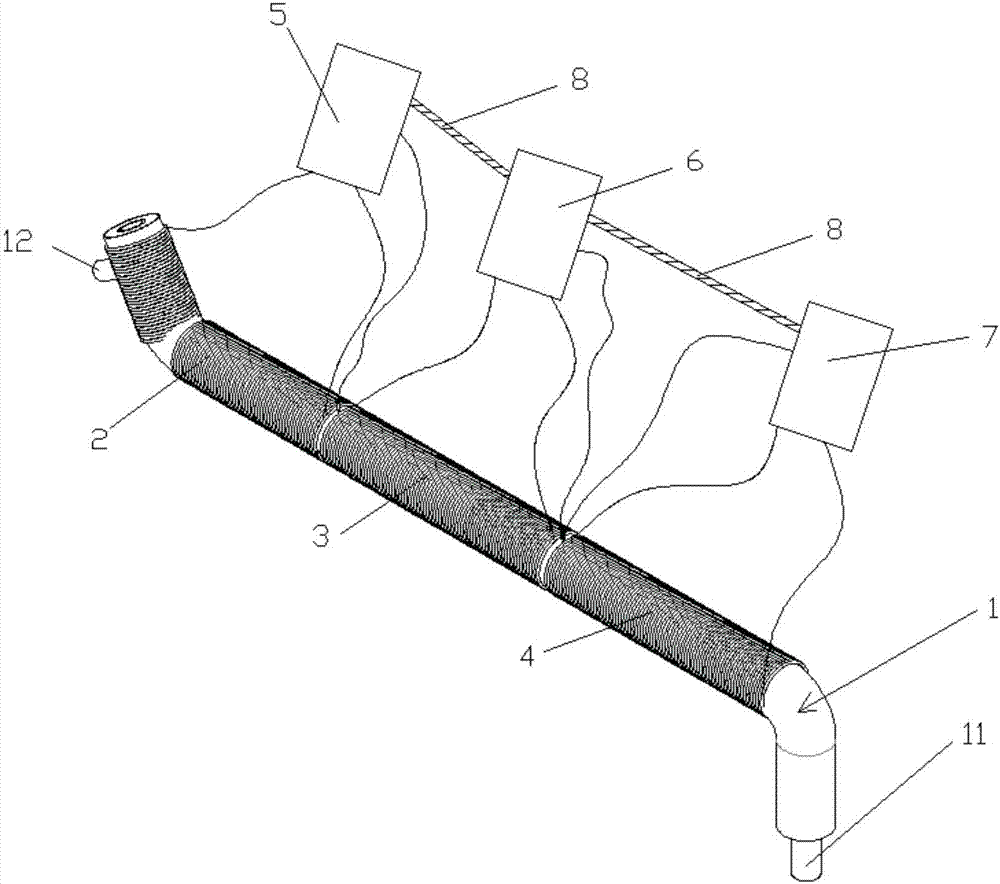

[0029] In order to achieve the purpose of the present invention, as shown in the figure, an embodiment of the present invention is: a magnesium alloy electromagnetic energy heating soup pipe, including a soup pipe body 1 and an electromagnetic generator, characterized in that the soup pipe Pipe body 1 is provided with double-sided silk blanket 13, glass fiber cloth 14 and electromagnetic induction coil 15 sequentially along the radial direction, double-sided silk blanket 13 is wound on the outer wall of Tangdao pipe body 1, and glass fiber cloth 14 is wrapped on both sides. On the silk blanket 13, the electromagnetic induction coil 15 is wound outside the glass fiber cloth 14, and the electromagnetic induction coil 14 is electrically connected with the electromagnetic generator.

[0030] The beneficial effect of adopting the above-mentioned technical solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com