Vacuum diffusion welding equipment for borosilicate glass with high light transmittance and use method of vacuum diffusion welding equipment

A technology of borosilicate glass and vacuum diffusion welding, which is applied in glass manufacturing equipment, glass forming, glass reshaping, etc. It can solve the problems of not having an accelerated cooling structure and affecting the work efficiency of staff, and achieve structural strength And the effect of high sealing performance, improving light transmittance and reducing plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

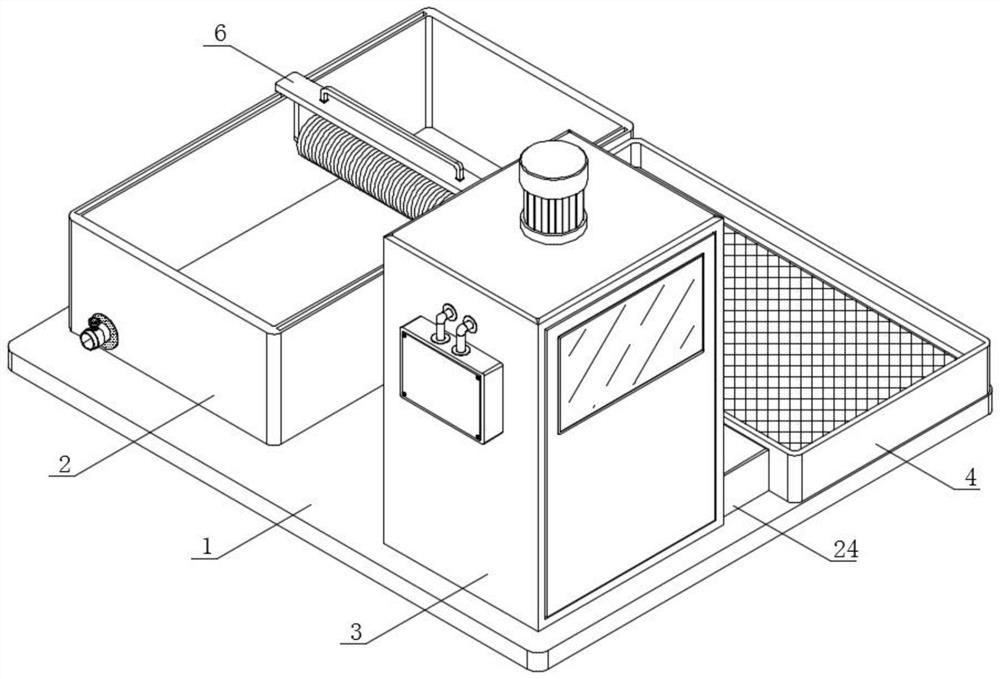

[0044] see figure 1 and Figure 9 , an embodiment provided by the present invention: vacuum diffusion welding equipment for high light-transmitting borosilicate glass and its use method, including a support base plate 1, a cleaning tank 2, a heating box 3 and a cooling tank 4, the support base plate 1 The top is respectively provided with a cleaning tank 2, a heating tank 3 and a cooling tank 4;

[0045] By using welded glass structural parts, the glass is formed into a unified whole and cannot be disassembled. The structural strength and sealing performance are high, which protects the product structure design. The light transmittance of the formed glass is consistent with that before welding, and can be used in For special applications such as photocatalytic reaction, no solder, solder and other materials are added during the molding process, which will not cause redundant or polluted internal structures of the glass. The solder resist material is 304 stainless steel, which...

Embodiment 2

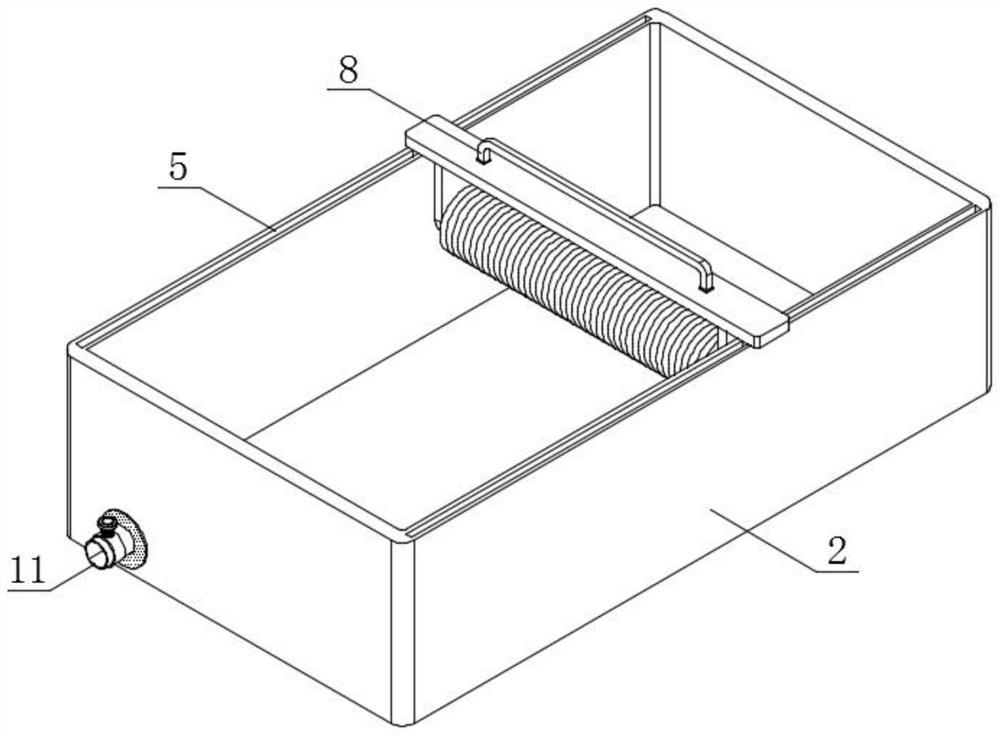

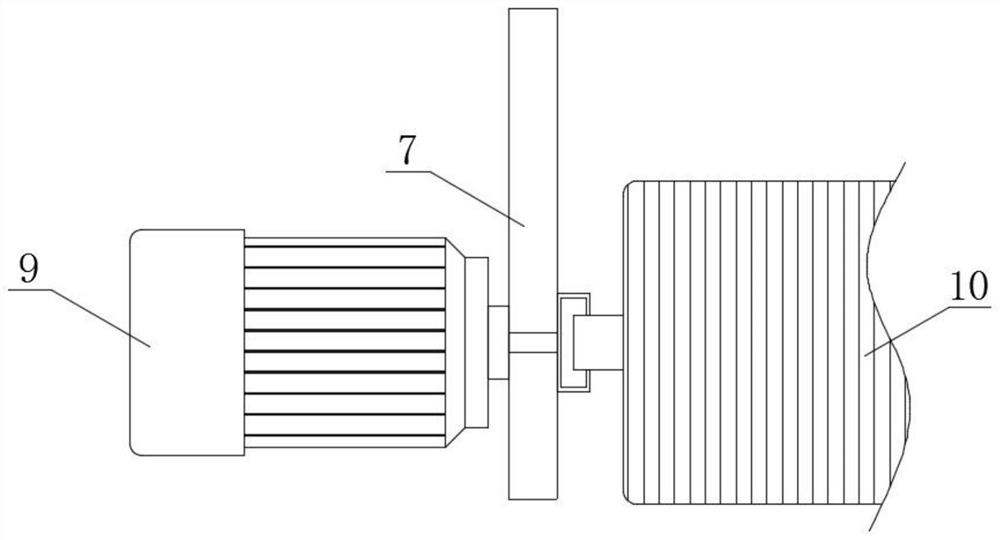

[0047] see figure 2 and image 3 , an embodiment provided by the present invention: vacuum diffusion welding equipment for high light-transmitting borosilicate glass and its use method, including a cleaning tank 2, both sides of the top of the cleaning tank 2 are provided with a limit chute 5, the limit The inside of the bit chute 5 is slidingly connected with a movable horizontal plate 6; fixed frames 7 are installed on both sides of the bottom of the movable horizontal plate 6, a handle 8 is installed in the middle of the top of the movable horizontal plate 6, and a control motor is installed on one side of the fixed frame 7 9. The output end of the control motor 9 runs through the interior of the fixed frame 7 and a cleaning brush 10 is installed. The bottom of the cleaning tank 2 side is equipped with a water outlet pipe 11. The surface of the water outlet pipe 11 is provided with a switch valve, and the water outlet pipe 11 is connected to the The intersection of the cl...

Embodiment 3

[0050] see Figure 4 , Figure 5 and Figure 6 , an embodiment provided by the present invention: vacuum diffusion welding equipment for high light-transmitting borosilicate glass and its use method, including a heating box 3, a power box 12 is installed on one side of the heating box 3, and the top of the heating box 3 The middle part of the drive motor 13 is installed, the output end of the drive motor 13 runs through the inner top wall of the heating box 3 and a transmission rod 14 is installed. Adjustment knob 16, the bottom end of adjustment knob 16 is connected with limit push plate 17, the surface of limit push plate 17 is provided with protective layer 18, both sides of heating box 3 inside are all provided with dryer body 19, and dryer The main body 19 is electrically connected to the electric box 12, and one side of the surface of the heating box 3 is connected with a switch door 20, the back of the switch door 20 is provided with a sealing strip 21, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com