Sulfide solid electrolyte based on oxygen doping and preparation method of sulfide solid electrolyt

A solid electrolyte, sulfide technology, applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of sensitivity, poor electrochemical stability of cathode and metal lithium, etc., to overcome instability, low price and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 0.4359gLi 2 S (99.999%), 0.3710gP 2 S 5 (99.999%) and 0.0323gP 2 o 5 (99.999%) and 0.1608gLiCl (99.999%) are put into a mortar and mixed fully in an inert gas-protected glove box, and the mixed powder is pressed into tablets using a tablet press, and the pressed tablets are put into a closed-ended In the quartz tube, evacuate to 0.1 Pa, and seal the quartz tube; then put the sealed quartz tube into the muffle furnace, heat it to 400 ° C at a heating rate of 0.3 ° C / min, keep it for 12 hours, and finally in the Cool in the furnace. The cooled block was taken out from the quartz tube, put into a glove box and manually ground into powder with a mortar to obtain cubic phase Li 6 P.S. 4.4 o 0.6 Cl sulfide solid electrolyte.

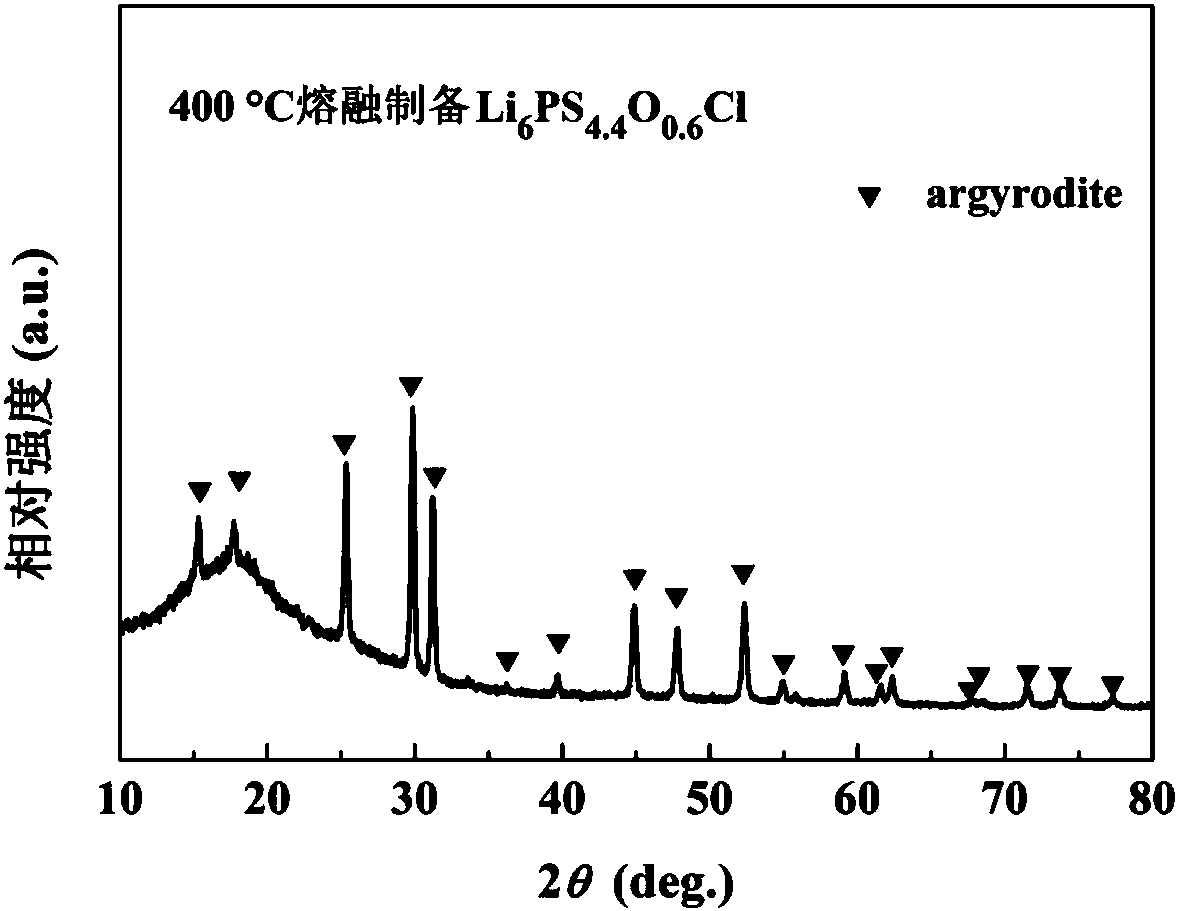

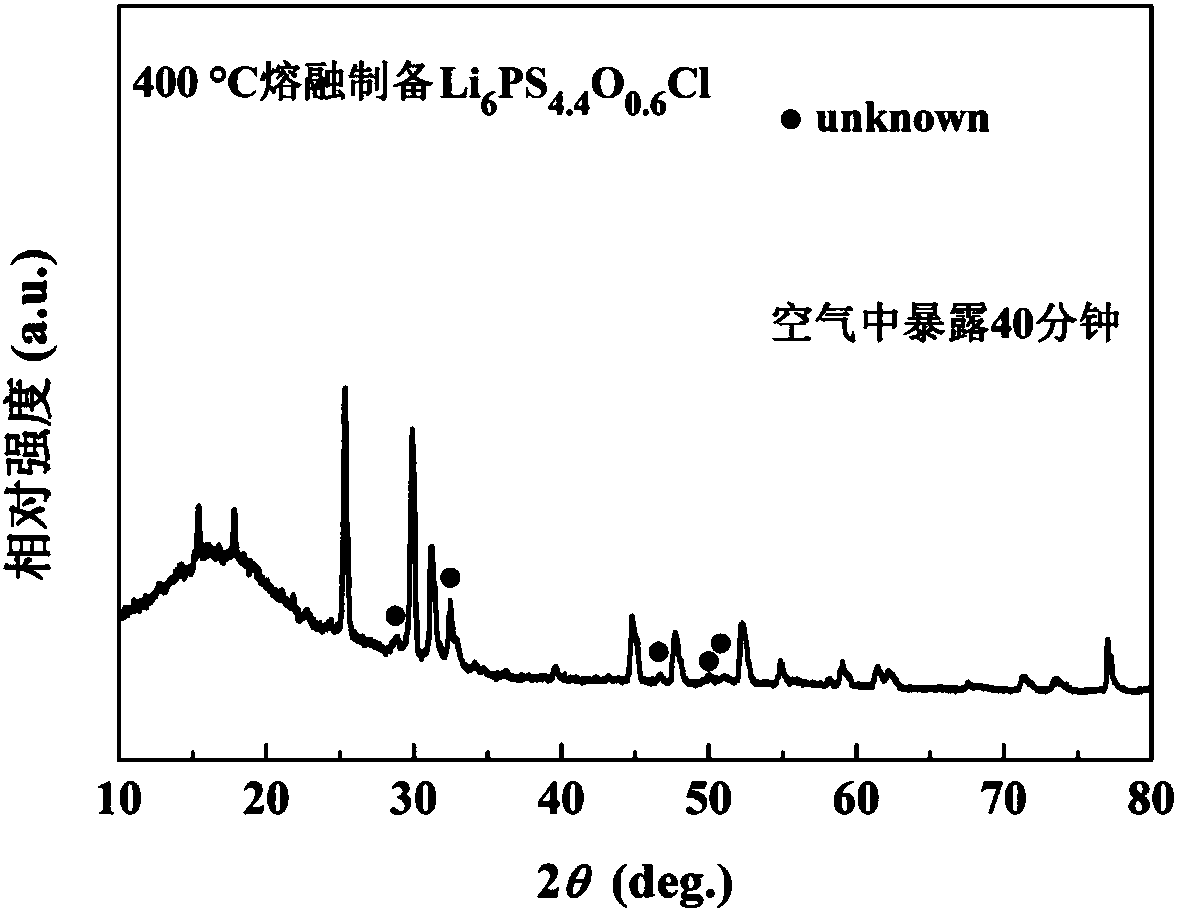

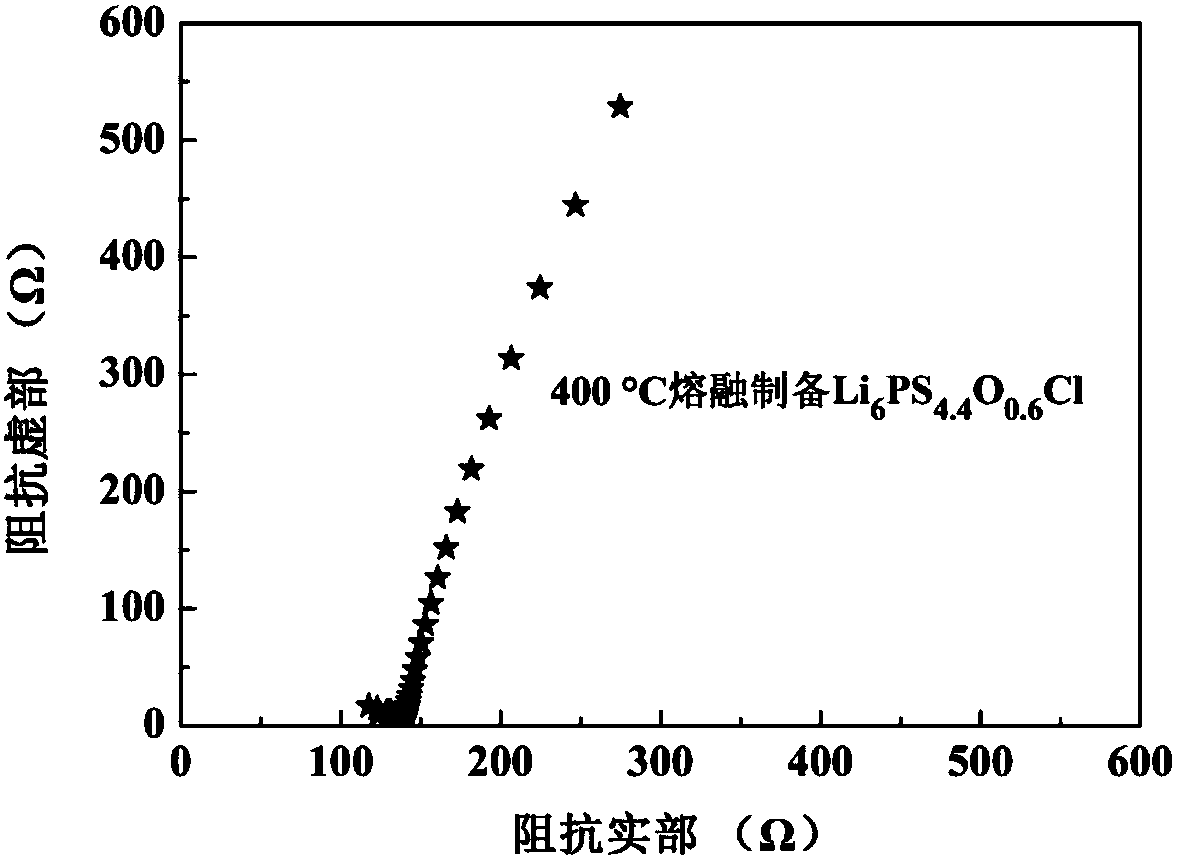

[0020] After the above-mentioned sulfide solid electrolyte is sealed with a polyimide film, X-ray diffraction (XRD) test is carried out, and the test adopts SmartLab (40kV, 40mA, Cu Ka, ), the test range is 10°~80°, and the rate is 4° / min. ...

Embodiment 2

[0025] 0.4727gLi 2 S (99.999%), 0.2365gP 2 S 5(99.999%) and 0.1404gAs 2 o 3 (99.999%) and 0.1504gLiCl (99.999%) are put into the mortar and thoroughly mixed in the glove box protected by inert gas, and the mixed powder is pressed into tablets using a tablet press, and the pressed tablets are put into a closed-end In the quartz tube, evacuate to 0.1 Pa, and seal the quartz tube; then put the sealed quartz tube into the muffle furnace, heat it to 450 °C at a heating rate of 0.3 °C / min, keep it for 12 hours, and finally furnace Internally cool to room temperature; the cooled block is taken out from the quartz tube, put into a ball mill jar, the ball mill adopts a low speed of 100 rpm, and the ball milling time is 2 hours, and ball milled under the protection of high-purity argon (99.999%), Cubic Li 6.8 As 0.4 P 0.6 S 4.4 o 0.6 Cl sulfide solid electrolyte.

[0026] The above-mentioned sulfide solid electrolyte was tested by the impedance test method described in Example...

Embodiment 3

[0028] 0.4432gLi 2 S (99.999%), 0.2218gP 2 S 5 (99.999%) and 0.1939gSb 2 o 3 (99.999%) and 0.1411LiCl (99.999%) were put into a mortar and mixed thoroughly in an inert gas-protected glove box, and the mixed powder was pressed into tablets using a tablet press, and the pressed tablets were put into a closed-ended In the quartz tube, evacuate to 0.1 Pa, and seal the quartz tube; then put the sealed quartz tube into the muffle furnace, heat it to 500 °C at a heating rate of 0.3 °C / min, keep it for 12 hours, and finally furnace Internal cooling to room temperature; the cooled block is taken out from the quartz tube, put into a ball mill jar, the ball mill adopts a low speed of 200 rpm, and the ball milling time is 2 hours, and ball milled under the protection of high-purity argon (99.999%), Cubic Li 6.8 Sb 0.4 P 0.6 S 4.4 o 0.6 Cl sulfide solid electrolyte.

[0029] The above-mentioned sulfide solid electrolyte was tested by the impedance test method described in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com