Patents

Literature

131 results about "Phosphorus pentasulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

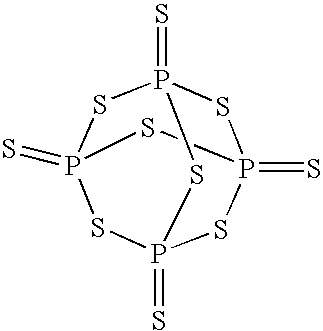

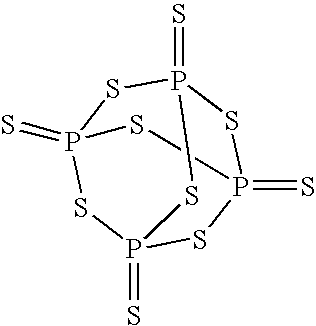

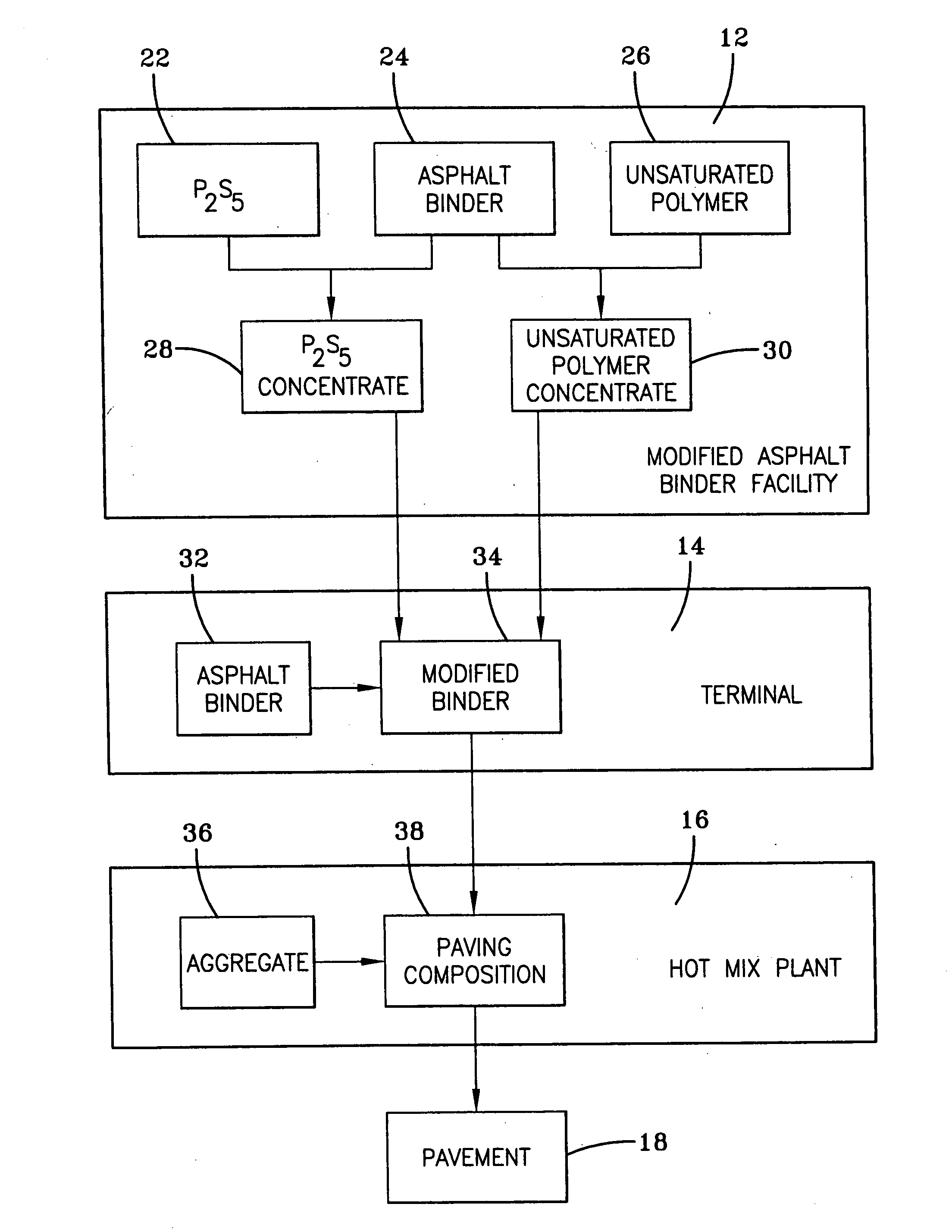

Phosphorus pentasulfide is the inorganic compound with the formula P₂S₅ or dimer P₄S₁₀. This yellow solid is the one of two phosphorus sulfides of commercial value. Samples often appear greenish-gray due to impurities. It is soluble in carbon disulfide but reacts with many other solvents such as alcohols, DMSO, and DMF.

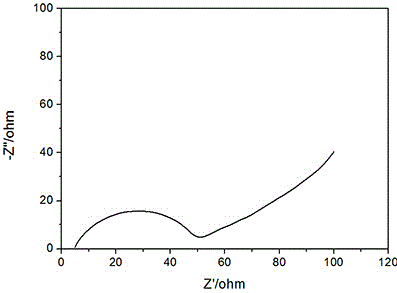

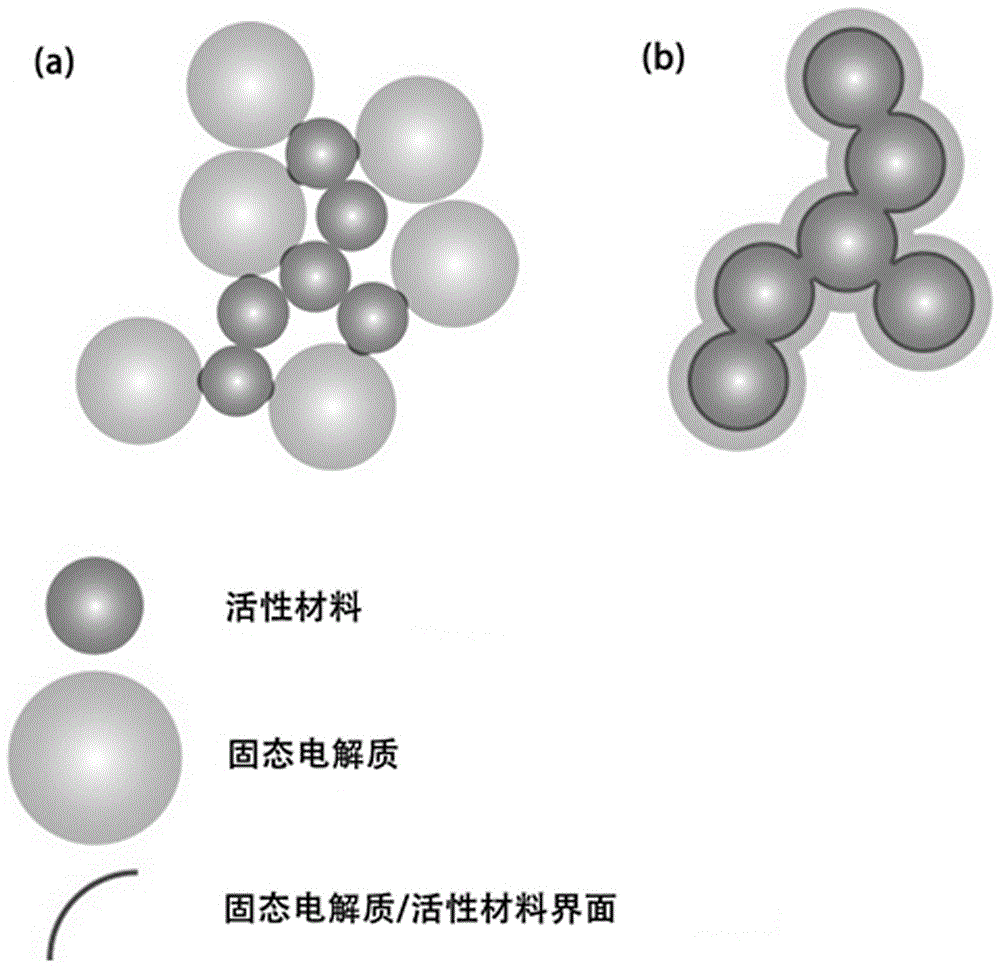

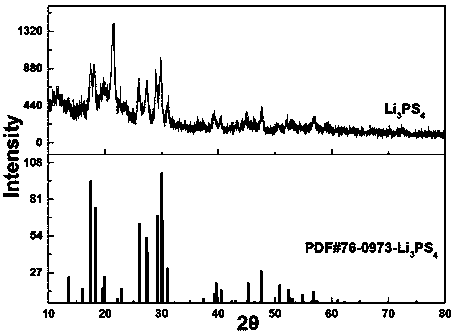

Sulfide electrolyte material and preparation method thereof

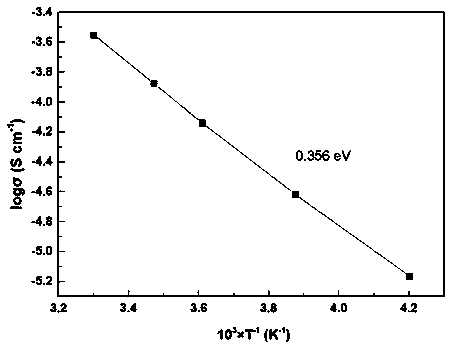

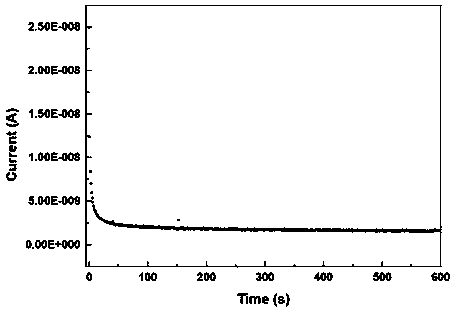

ActiveCN103500853AEasy to prepareImprove ionic conductivityFinal product manufactureElectrolytesOrganic solventPhosphorus pentasulfide

The invention provides a preparation method of a sulfide electrolyte material as shown in a formula (I). The preparation method comprises the steps of mixing lithium sulfide, phosphorus pentasulfide and an organic solution to obtain a mixed solution; stirring, centrifuging, filtering and drying the mixed solution sequentially to obtain an initial material; performing heat treatment on the initial material to obtain the sulfide electrolyte material as shown in the formula (I). In the preparation process of the sulfide electrolyte material, lithium sulfide and phosphorus pentasulfide are dissolved into an organic solvent and react to form a compound containing Li, P and S, the compound and the organic solvent form a crystalline state, and then centrifuging, filtering, drying and heat treatment processes are performed sequentially to obtain the sulfide electrolyte material, so that the preparation method of the sulfide electrolyte material, provided by the invention, is simple and easy to operate.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

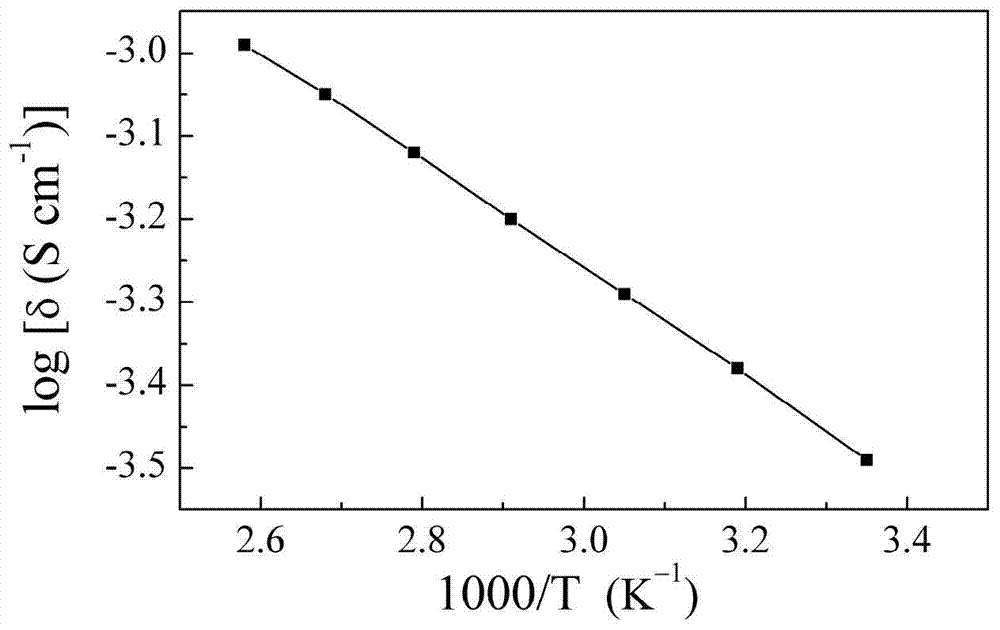

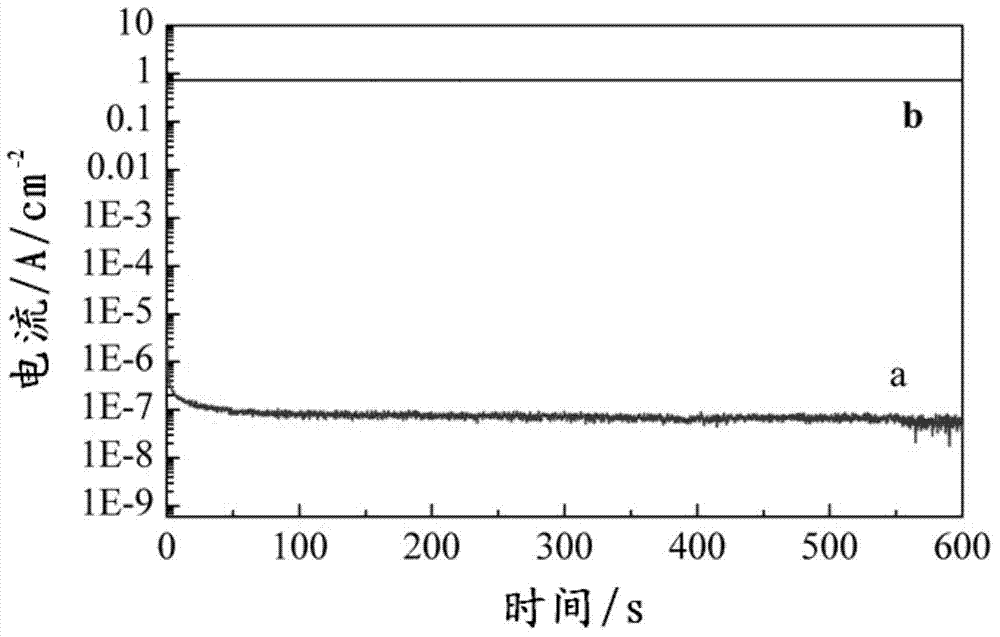

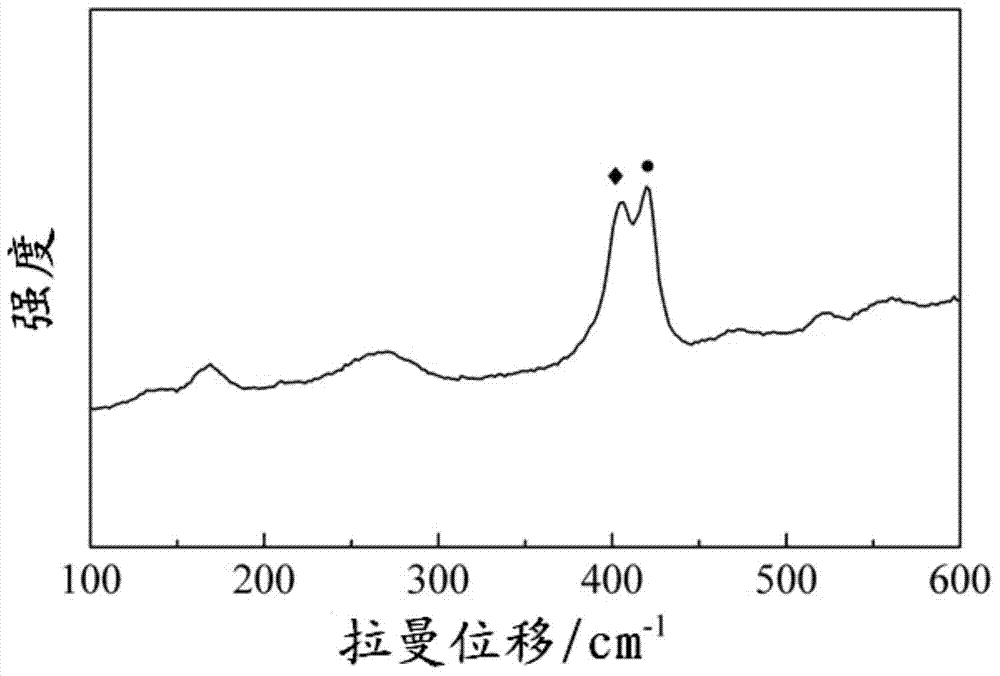

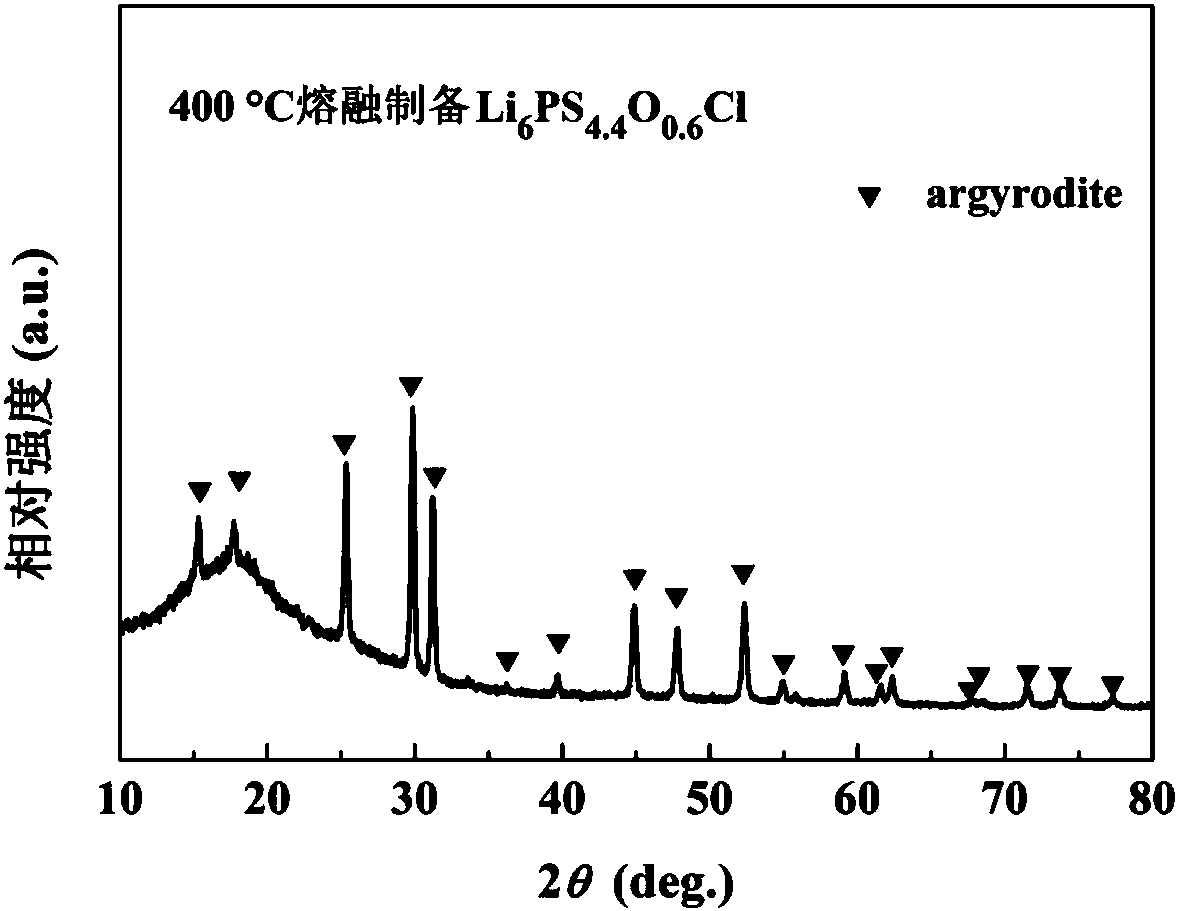

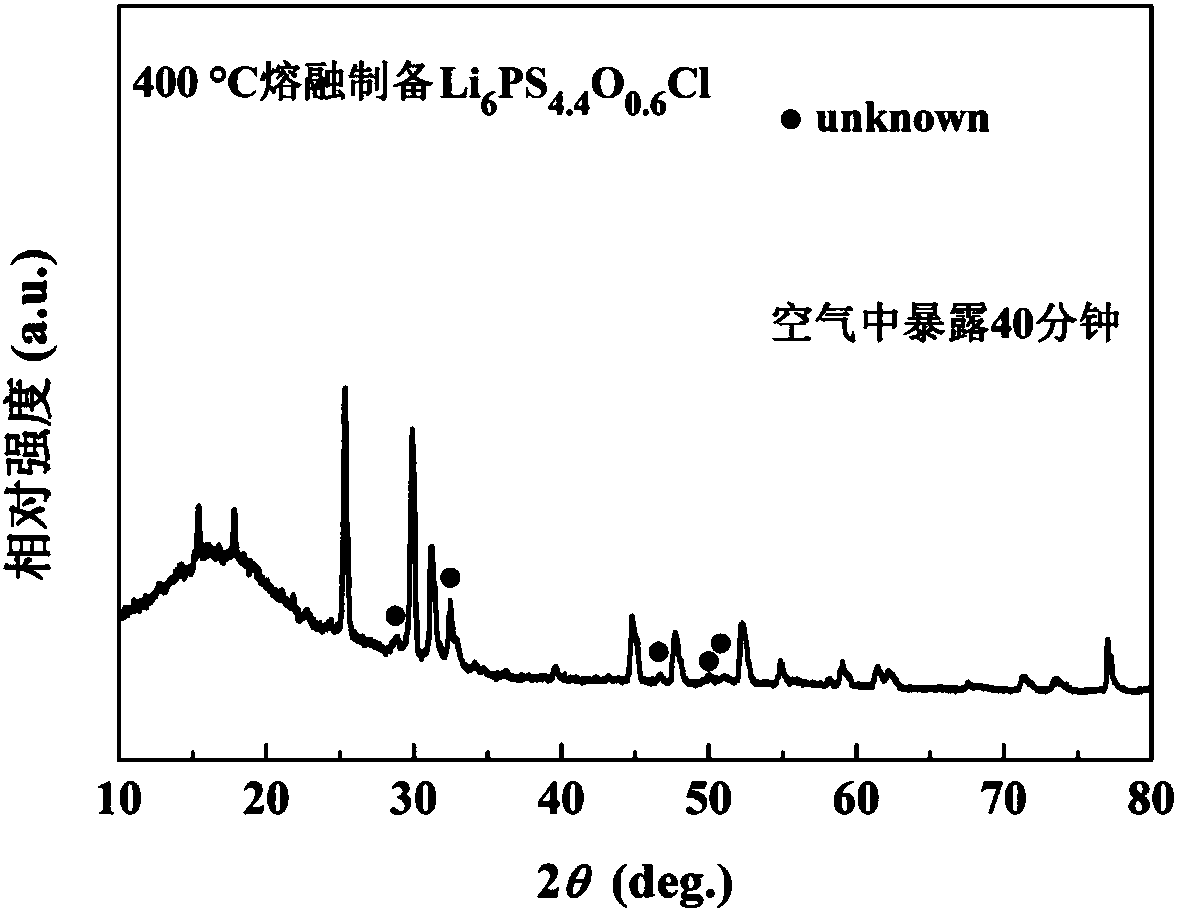

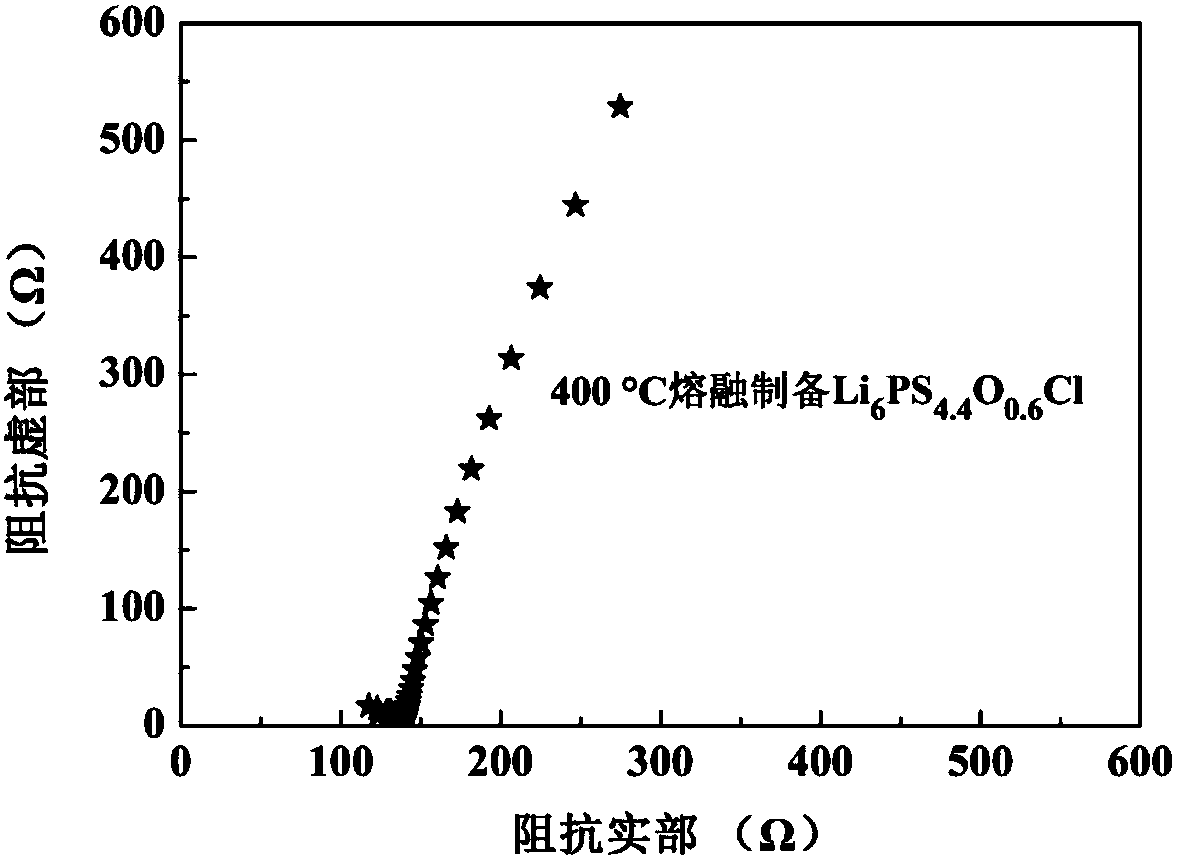

Sulfide solid electrolyte based on oxygen doping and preparation method of sulfide solid electrolyt

ActiveCN108493479AImprove stabilityImprove ionic conductivitySolid electrolytesLi-accumulatorsLithium chloridePhosphorus pentasulfide

The invention provides a sulfide solid electrolyte based on oxygen doping. The sulfide solid electrolyte is prepared from the chemical ingredients, in percentage by mass: 36-60% of lithium sulfide orlithium selenide, 18-48% of phosphorus pentasulfide or phosphorus selenide, 1-23% of metal oxide or specific nonmetallic oxide and 8-37% of lithium chloride, lithium bromide or lithium iodide. The preparation method of the sulfide solid electrolyte mainly comprises the steps that the raw materials are sufficiently blended and subjected to tabletting, then placed in a quartz tube to be burned and sealed, the product is placed in a muffle furnace and heated to be 400-600 DEG C at a slow heating rate, the optimal heating rate is 0.3 DEG C / minute, heat preservation is conducted for 12-48 hours, and then the product is cooled to reach the room temperature; and the product is ground to be powder, and the sulfide solid electrolyte based on oxygen doping is prepared. The sulfide solid electrolyteis easy to prepare and high in repeatability, the prepared solid electrolyte has the high ionic conductivity and good stability to the air and positive and negative electrodes.

Owner:YANSHAN UNIV

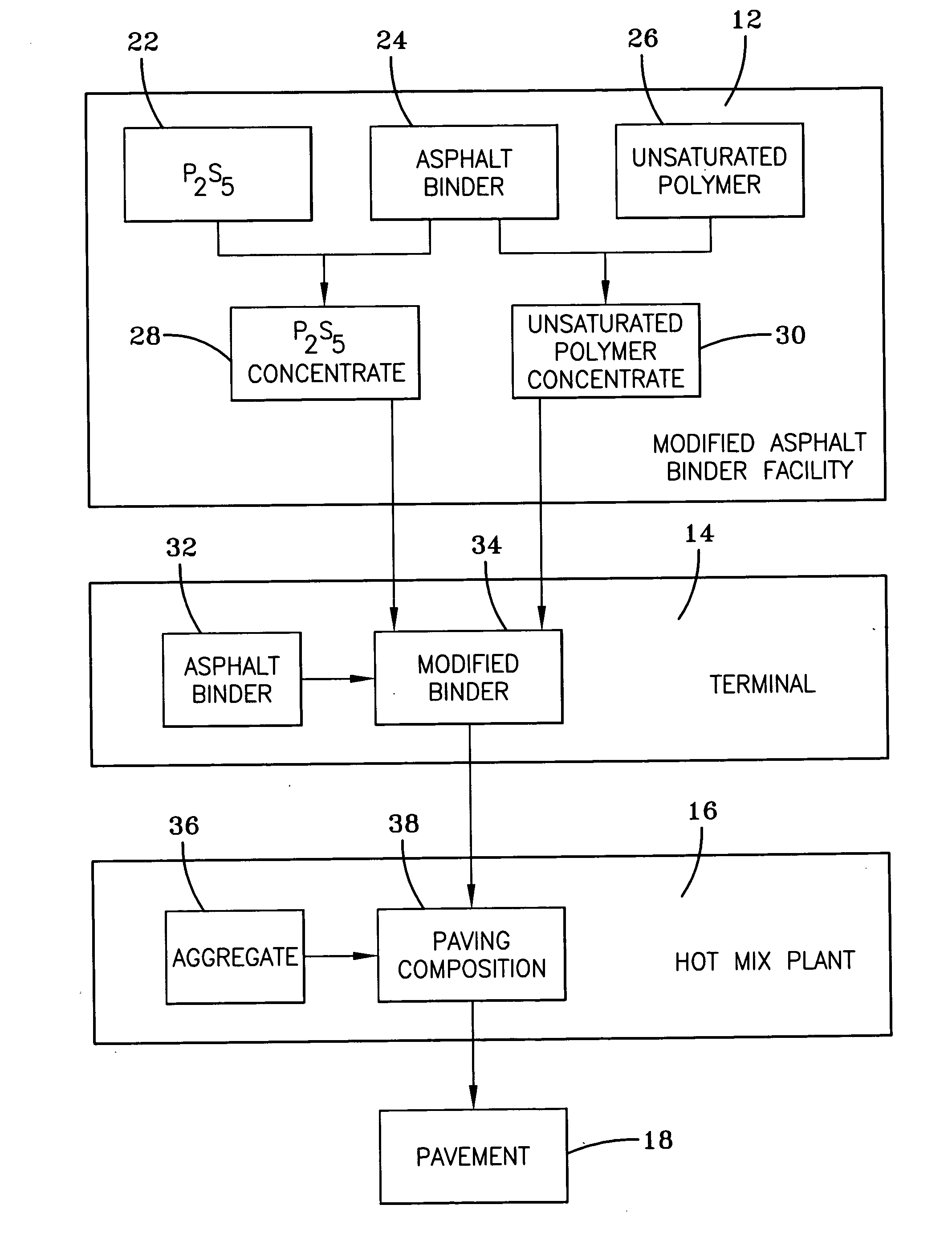

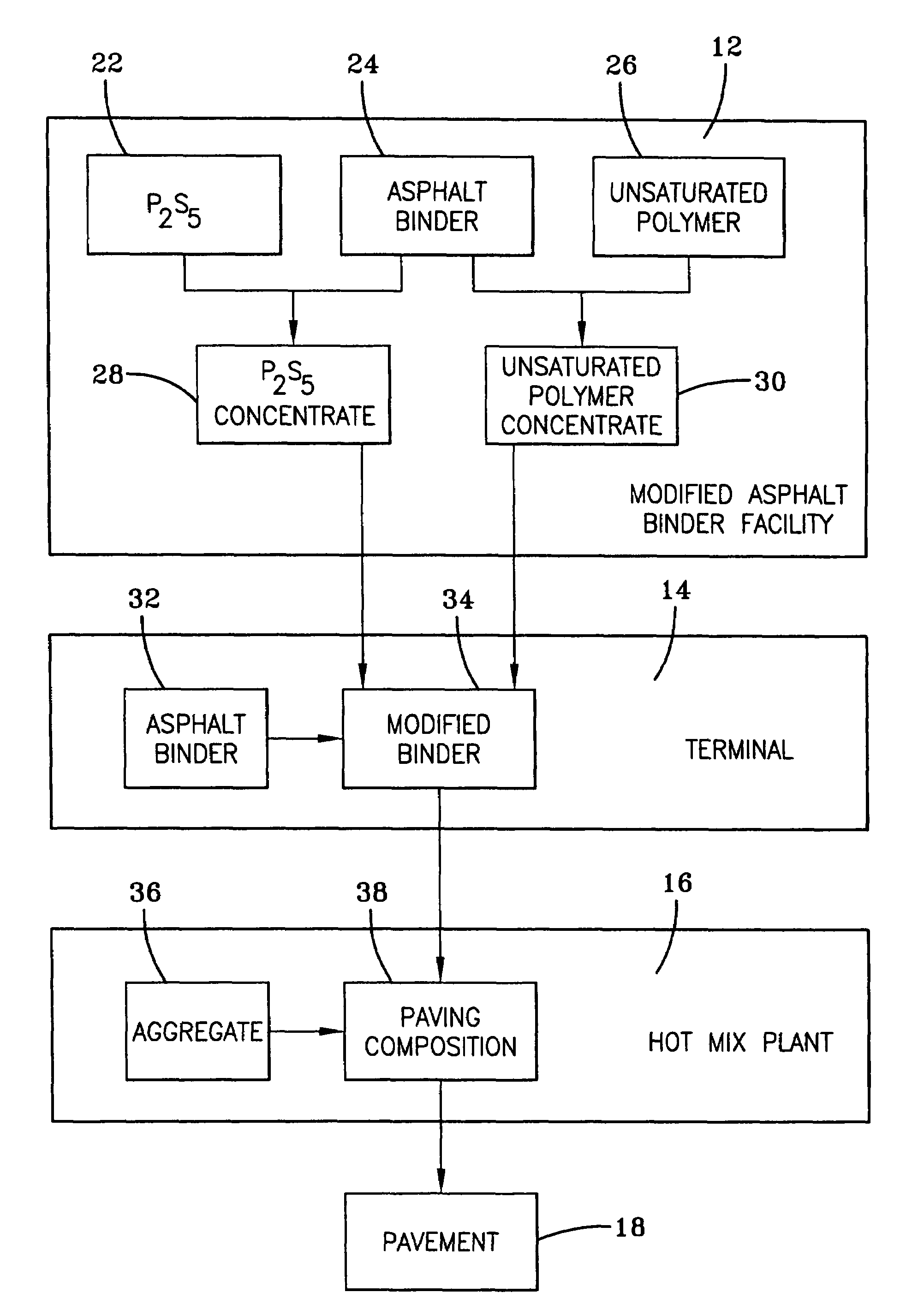

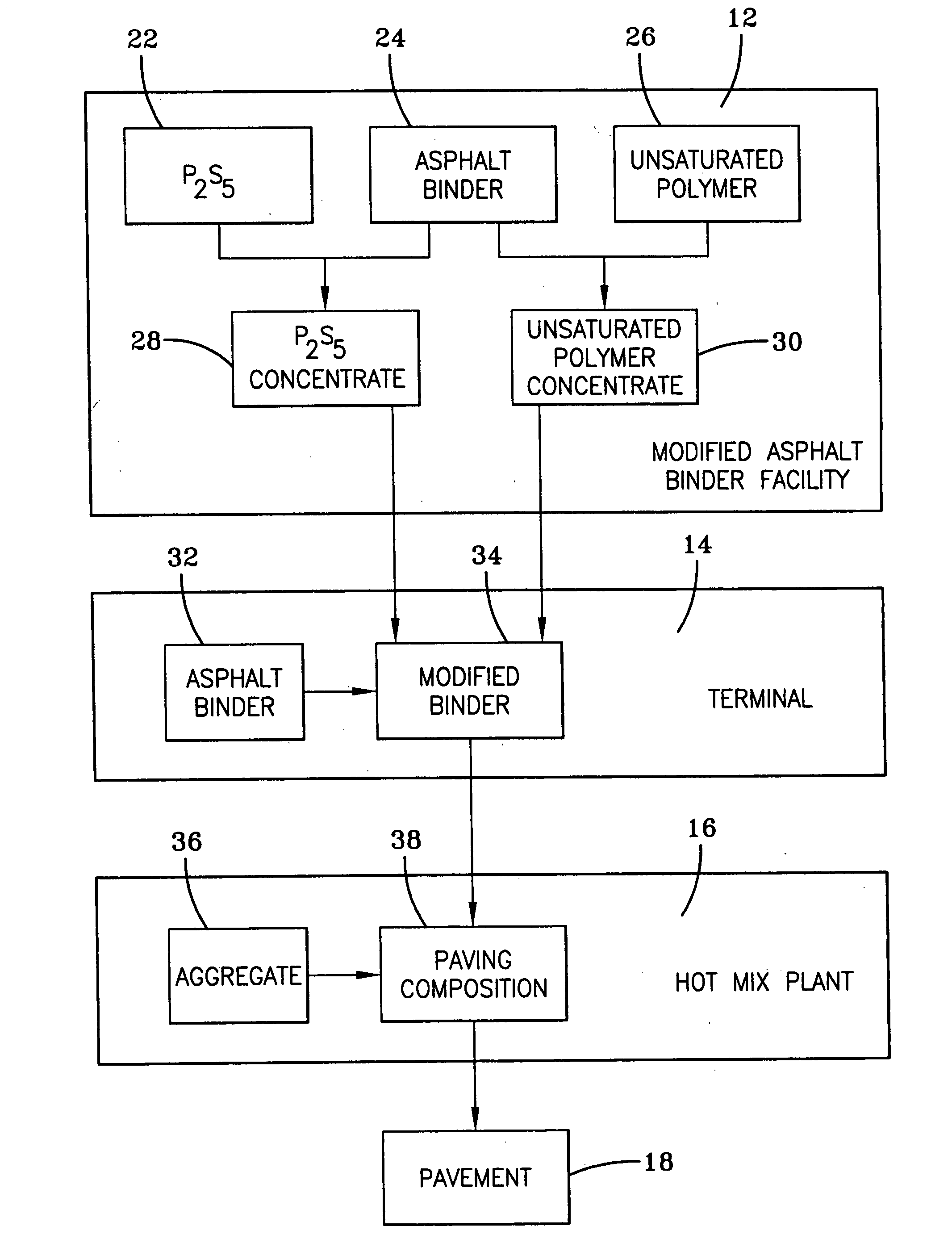

Modified asphalt binders and asphalt paving compositions

A process for preparing a modified asphalt binder composition, the process comprising mixing asphalt, an unsaturated polymer, and phosphorus pentasulfide to form a modified asphalt composition.

Owner:FIRESTONE POLYMERS LLC +1

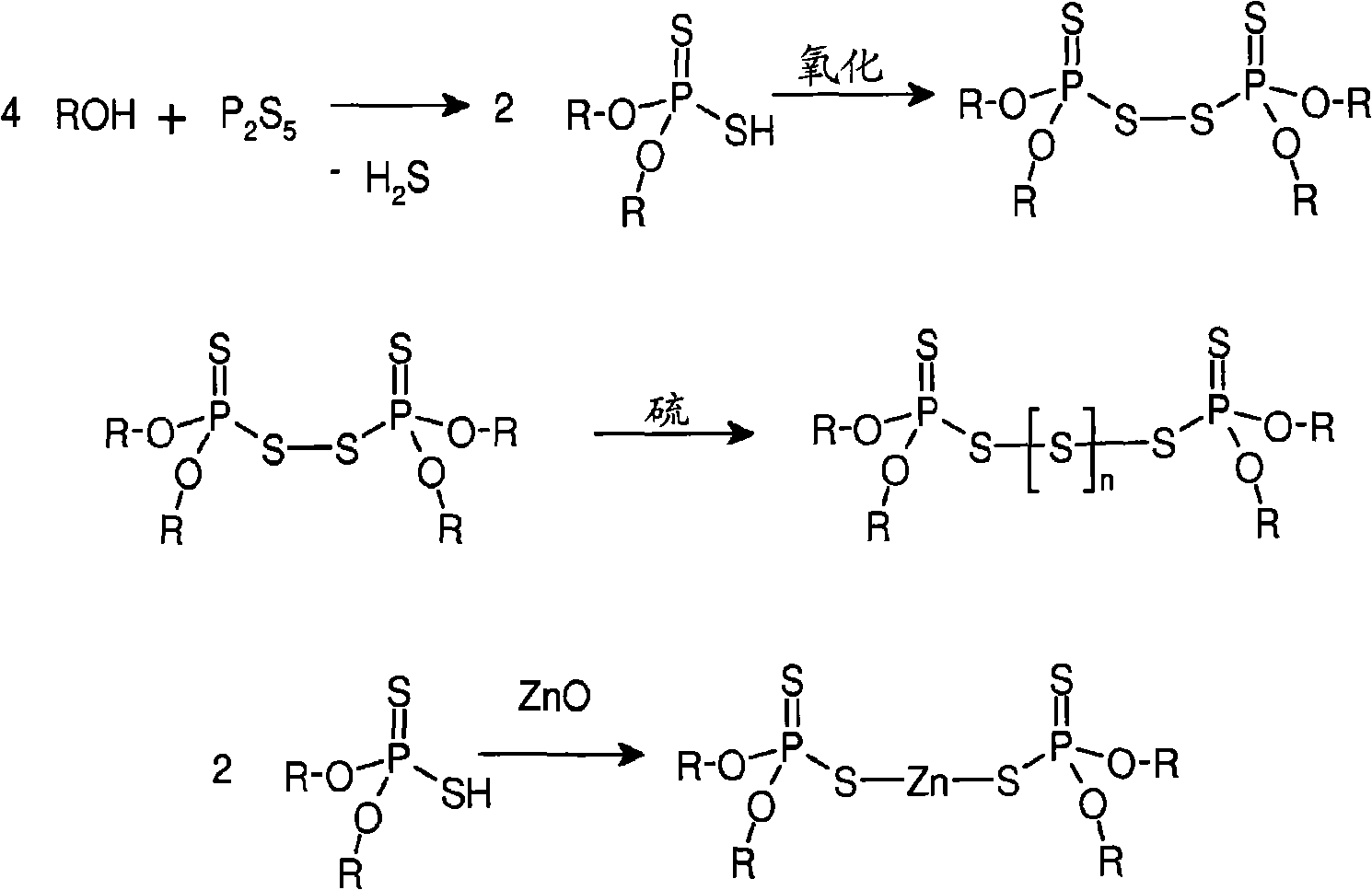

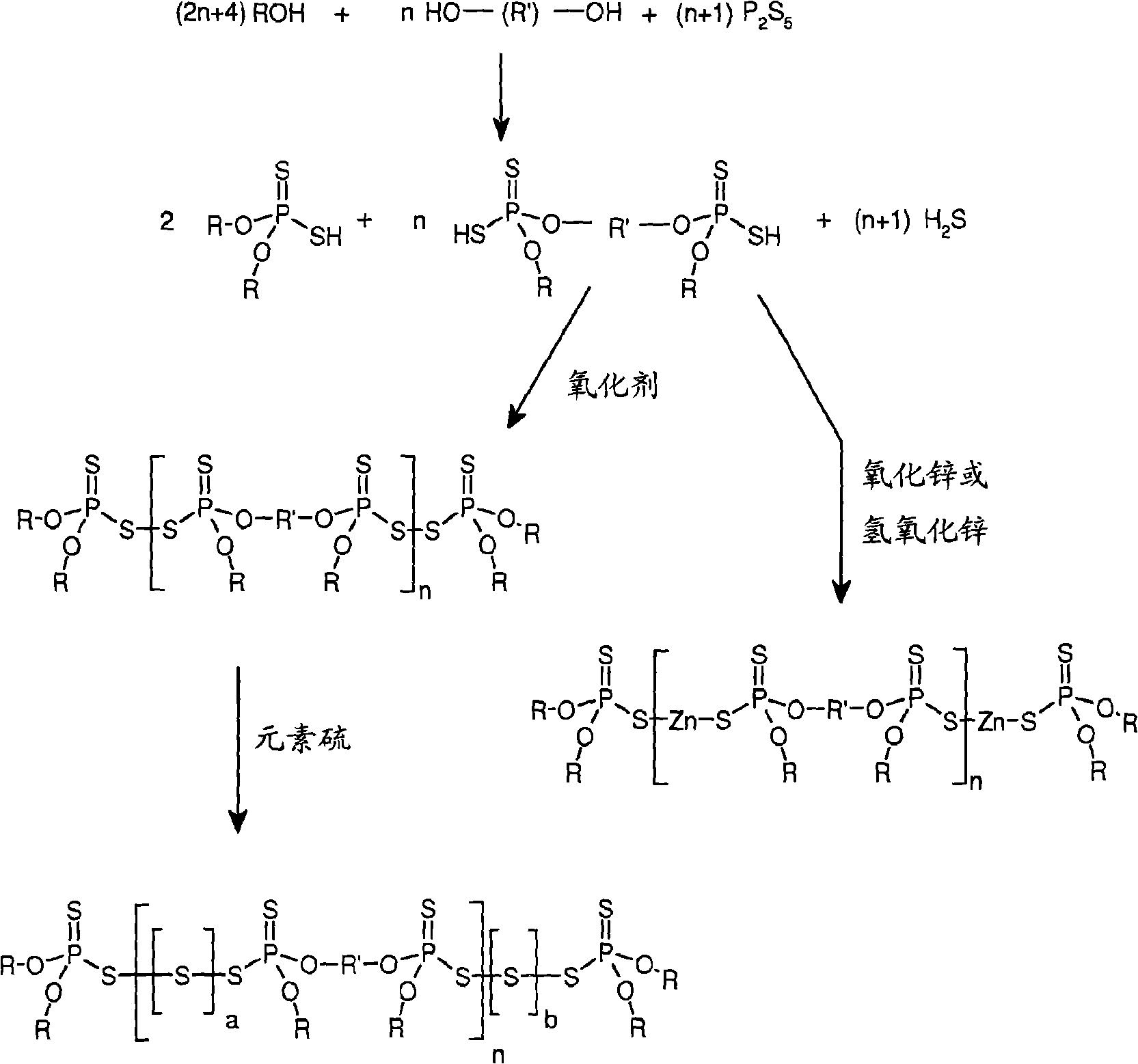

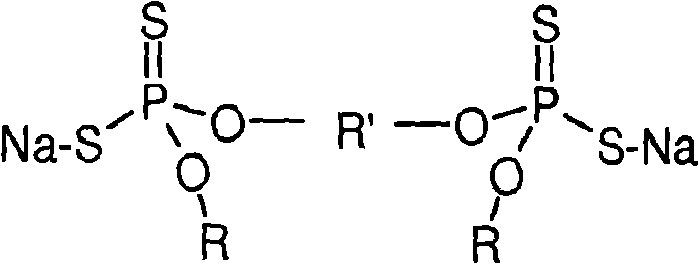

Dithiophosphate composition and utility in rubber

The present invention relates to oligomeric or polymer dithiophosphate di- or poly- sulfides and their utility in rubbers. Another aspect of the invention is a method for making oligomeric or polymeric dithiophosphates by reacting phosphorous pentasulfide with a di- or polyol and a mono alcohol to produce a dithiophosphoric acid, and then oxidizing the dithiophosphoric acid with an oxidizing agent to produce an oligomeric or polymeric dithiophosphate.

Owner:VANDERBILT CHEM LLC

A lithium sulfide battery electrolyte for improving safety and stability

InactiveCN109148956AImprove stabilityImprove securityLi-accumulatorsSecondary cells servicing/maintenanceOxalatePhosphorus pentasulfide

The invention provides a lithium sulfur battery electrolyte for improving safety and stability. The electrolyte is prepared from lithium salt, solvents and additives, The lithium salt is a mixture oflithium bis-trifluoromethanesulfonimide (LiTFSI), lithium bis-oxalate borate (LiBOB) and lithium difluorooxalate borate (LiODFB), the solvent is a mixture of dioxolane (DOL) and tetraethanol dimethylether (TEGDEM), and the additive is lithium nitrate and phosphorus pentasulfide. The phosphorus sulfide additive in the battery prepared by the electrolyte reacts with the negative electrode lithium metal to form a passivation layer, At that same time, the decomposition of lithium bis (trifluoromethanesulfonimide) on the negative electrode side can be inhibit by the action of lithium bis (oxalate)and lithium difluorooxalate, so that the stability and cycle performance of the battery can be improved. The lithium bis (trifluoromethanesulfonimide) can protect the negative electrode, effectivelyreduce the generation of lithium dendrite and improve the safety of the battery.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

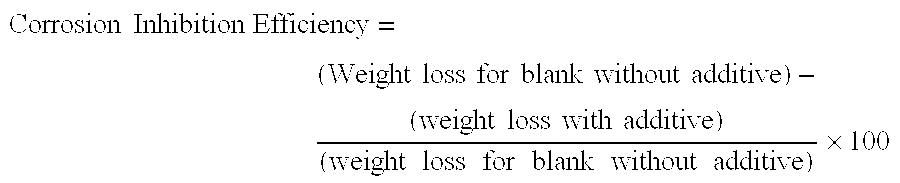

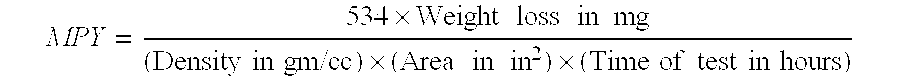

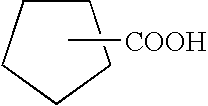

Naphthenic acid corrosion inhibition using new synergetic combination of phosphorus compounds

ActiveUS20100116718A1Low acid valueDistillation corrosion inhibitionOther chemical processesPhosphorus pentasulfidePhosphate

The present invention relates to the field of processing hydrocarbons which causes corrosion in the metal surfaces of processing units. The invention addresses the technical problem of high temperature naphthenic acid corrosion and sulphur corrosion and provides a solution to inhibit these types of corrosion. The three combination compositions are formed by three mixtures separately, with one mixture obtained by mixing compound A, which is obtained by reacting high reactive polyisobutylene (HRPIB) with phosphorous pentasulphide in presence of catalytic amount of sulphur with compound B such as trialkyl phosphate and second mixture obtained by mixing compound A with compound C such as phosphite like di-isodecyl phenyl phosphite, and third mixture obtained by mixing compound A with compound D such as a phosphonate, wherein each of these three mixtures independently provide high corrosion inhibition efficiency in case of high temperature naphthenic acid corrosion inhibition and sulphur corrosion inhibition. The invention is useful in all hydrocarbon processing units, such as, refineries, distillation columns and other petrochemical industries.

Owner:DORF KETAL CHEM (I) PTE LTD

Method for preparing O, O-diethyl chlorothiophosphate

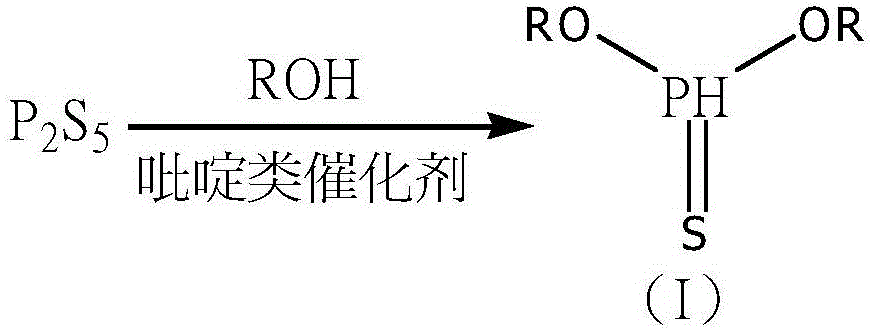

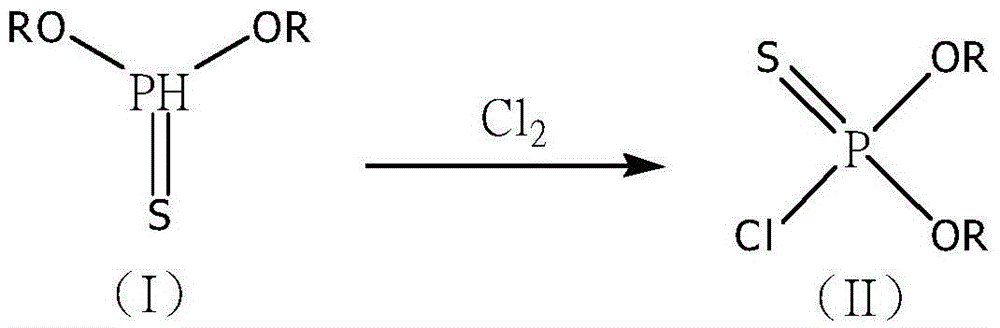

InactiveCN102584892AImprove efficiencySatisfy productivityGroup 5/15 element organic compoundsPhosphorus pentasulfideAlcohol

The invention provides a method for preparing O, O-diethyl chlorothiophosphate. The method comprises the steps of adopting phosphorus pentasulfide as raw materials, conducting reaction between the phosphorus pentasulfide and absolute ethyl alcohol to obtain O, O-diethyl dithiophosphate (ethyl sulfide for short); then reacting with fixed quantity of chlorine gas to obtain ethyl chloride crude products; adding a catalyst, conducting post-chlorination reaction to obtain ethyl chloride and crystalloid sulphur, centrifugally separating the sulphur, and distilling by a film evaporator to obtain more than 99% of a high-purity product. The method has the advantages of environmental friendliness of the production process and high product purity. The O, O-diethyl chlorothiophosphate can meet the demands of upper-end products and the requirement of export.

Owner:HUBEI XIANLONG CHEM IND

Method for preparing O,O-ethyl thioether substituted phosphorus oxychloride

InactiveCN101293897AMild desulfurization conditionsAchieve friendlyGroup 5/15 element organic compoundsPhosphorus pentasulfideSulfide

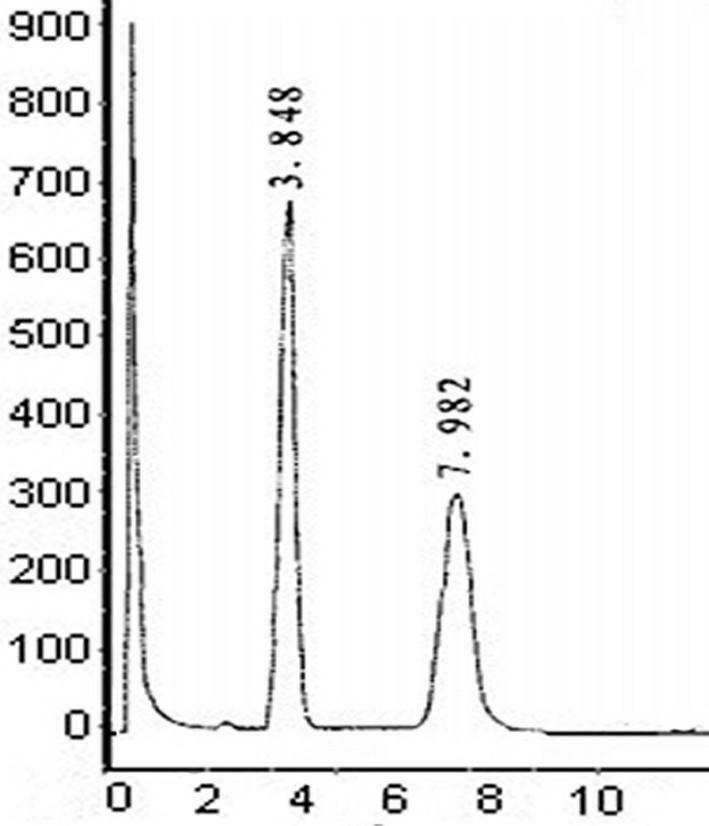

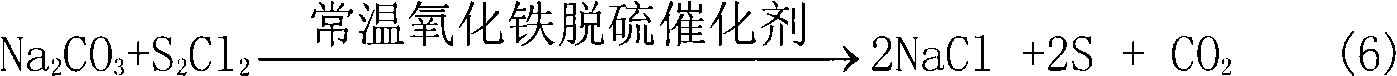

The invention relates to a method for preparing O,O-diethyl thiophosphoryl chloride (DETC), comprising the steps of reacting the raw material of phosphorus pentasulfide with anhydrous alcohol to obtain O,O-diethyl phosphorodithioate (referred to as ethyl sulfide); reacting with chlorine gas to obtain crude O,O-diethyl thiophosphoryl chloride; performing desulfuration of the crude O,O-diethyl thiophosphoryl chloride with ferric oxide desulfuration catalyst at room temperature to obtain desulfurized O,O-diethyl thiophosphoryl chloride and crystalline sulfur; and refining the desulfurized O,O-diethyl thiophosphoryl chloride by the steam distillation method to obtain O,O-diethyl thiophosphoryl chloride with high purity (over 99.5%). The method has the advantages of environmentally friendly production process, and high product purity.

Owner:湖北蕲农化工有限公司

High temperature naphthenic acid corrosion inhibition using organophosphorous sulphur compounds and combinations thereof

ActiveUS20100126842A1Inhibition is effectiveLow acid valueThermal non-catalytic crackingDistillation separationPhosphorus pentasulfideDistillation

The present invention relates to the field of processing hydrocarbons which causes corrosion in the metal surfaces of processing units. The invention addresses the technical problem of high temperature naphthenic acid corrosion and sulphur corrosion and provides a solution to inhibit these types of corrosion. The composition formed by reacting high reactive polyisobutylene (HRPIB) with phosphorous pentasulphide in presence of catalytic amount of sulphur provides high corrosion inhibition efficiency in case of high temperature naphthenic acid corrosion inhibition and sulphur corrosion inhibition. The invention is useful in all hydrocarbon processing units, such as, refineries, distillation columns and other petrochemical industries.

Owner:DORF KETAL CHEM (I) PTE LTD

Modified asphalt binders and asphalt paving compositions

A process for preparing a modified asphalt binder composition, the process comprising mixing asphalt, an unsaturated polymer, and phosphorus pentasulfide to form a modified asphalt composition.

Owner:FIRESTONE POLYMERS LLC +1

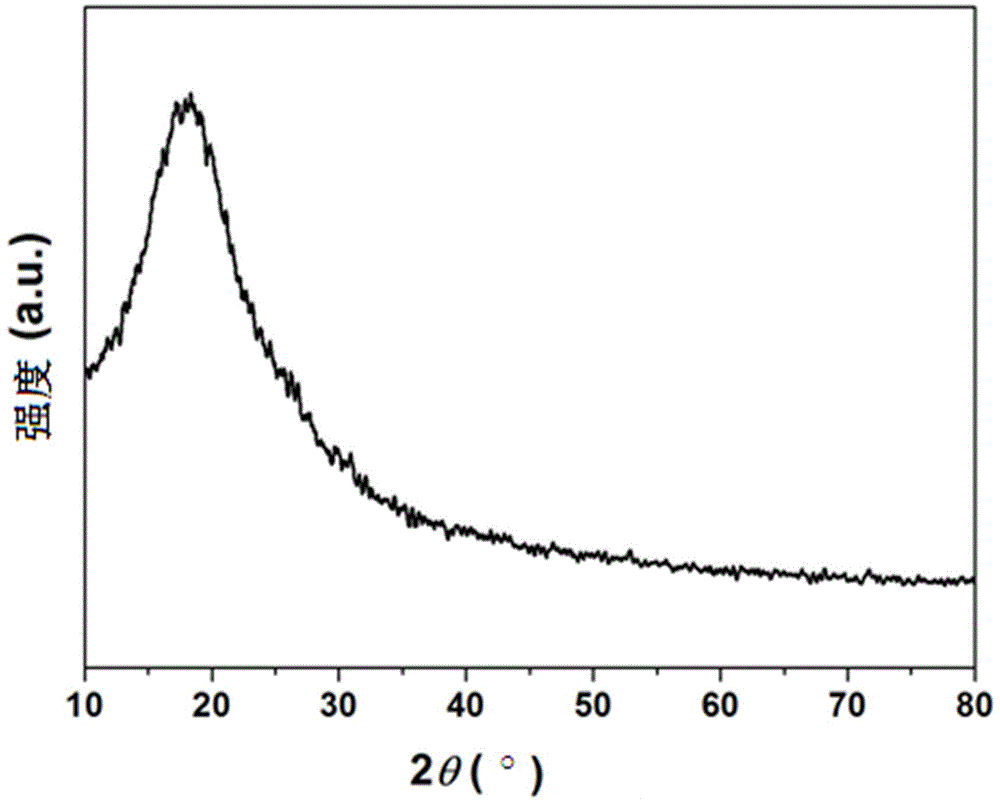

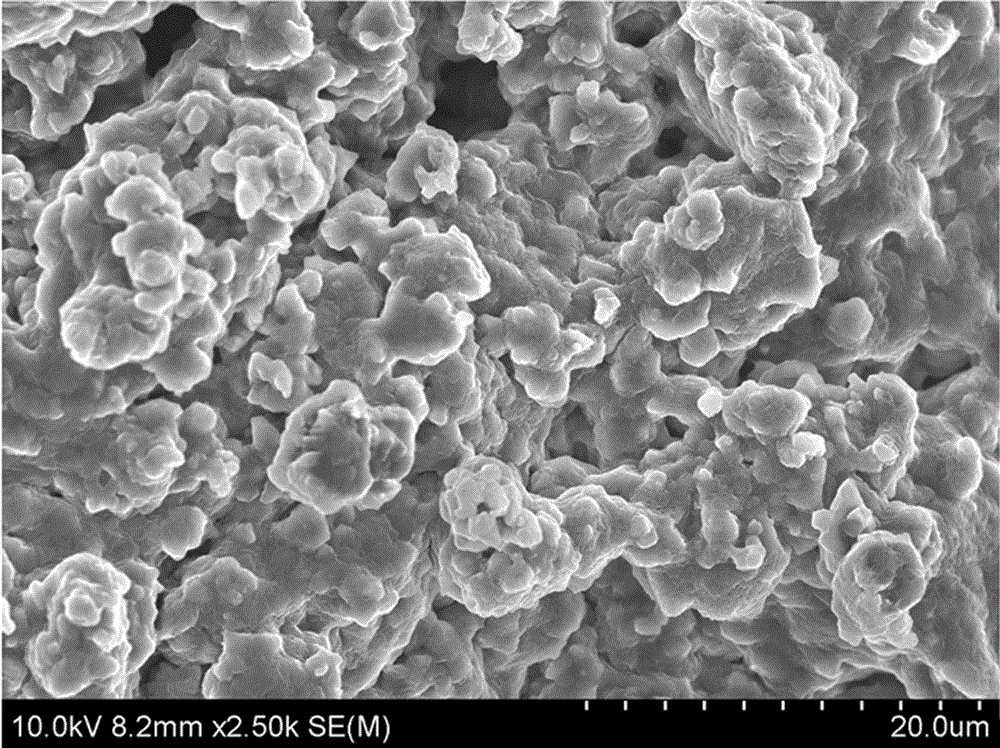

Preparation method of amorphous sulfide solid electrolyte

InactiveCN105609870APrecise control ratioSolve the problem of low puritySolid electrolytesSecondary cellsMetallic lithiumPhosphorus pentasulfide

The invention relates to the field of lithium ion batteries, in particular to a preparation method of an amorphous sulfide solid electrolyte. The preparation method of the amorphous sulfide solid electrolyte is characterized by mainly comprising the following steps: (1) putting metallic lithium, elemental sulfur, germanium sulfide and phosphorus pentasulfide in a certain proportion into a water-free and oxygen-free sealed container for mixing; and (2) mechanically grinding the raw materials mixed in the step (1) so as to prepare the amorphous sulfide solid electrolyte. According to the preparation method, the proportion of lithium, sulfur to phosphorus can be accurately controlled, and the problem that raw material volatilization in a high-temperature solid-phase method causes relatively low product purity is solved; and meanwhile, the resources of the raw materials are abundant, the process is simple, and the high-purity amorphous sulfide solid electrolyte can be obtained through a ball-milling one-step method.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

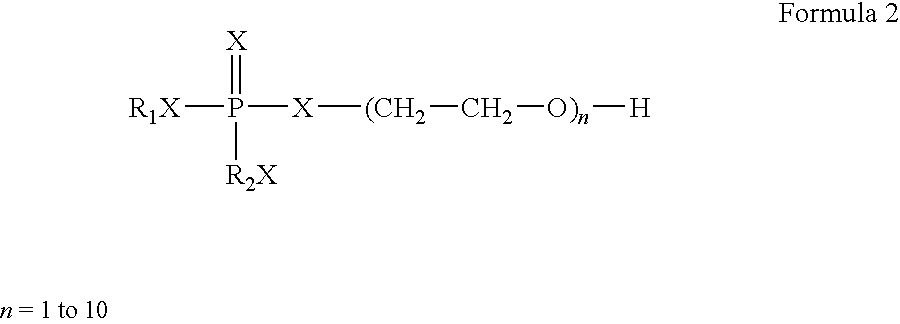

Novel additive for naphthenic acid corrosion inhibition and method of using the same

ActiveUS20100264064A1Low acid valueDistillation corrosion inhibitionOther chemical processesPhosphorus pentasulfideDistillation

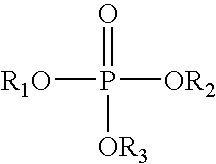

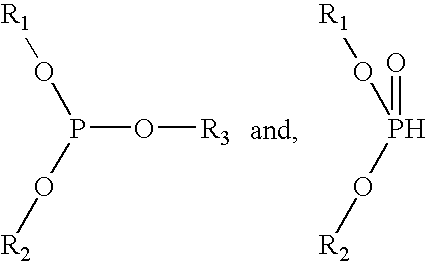

The present invention relates to the field of processing hydrocarbons which causes corrosion in the metal surfaces of processing units. The invention addresses the technical problem of high temperature naphthenic acid corrosion and sulphur corrosion and provides a solution to inhibit these types of corrosion. The three combination compositions are formed by two mixtures separately, with one mixture obtained by mixing compound A, which is obtained by reacting high reactive polyisobutylene (HRPIB) with phosphorous pentasulphide in presence of catalytic amount of sulphur with compound B which is thiophosphorous compound such as phosphorous thioacid ester of Formula (1) and second mixture obtained by mixing compound A with compound C of Formula (2) which is obtained by reacting compound B with ethylene oxide, wherein each of these two mixtures independently provide high corrosion inhibition efficiency in case of high temperature naphthenic acid corrosion inhibition and sulphur corrosion inhibition. The invention is useful in all hydrocarbon processing units, such as, refineries, distillation columns and other petrochemical industries.

Owner:DORF KETAL CHEM (I) PTE LTD

Oil additive preparation method

InactiveCN1733874AMeet the use requirementsFulfil requirementsAdditivesPhosphorus pentasulfideAlcohol

The process for preparing the disclosed oil additive capable of improving lubricating oil's wear resistance and diesel oil's oiliness comprises, reacting phosphorus pentoxide or phosphorus pentasulfide with monohydric alcohol under the conditions of normal pressure, agitating, and a reaction temperature of 50-90 deg C, obtaining the mixture of monobasic and divalent phosphate esters, then carrying out amination reaction between the phosphate ester mixture with amines under the condition of normal pressure, agitating, and a reaction temperature of 30-80 deg. C.

Owner:SHENYANG HAOWEI CHEM TECH

Method for efficiently preparing and collecting chalcogenide solid electrolyte

InactiveCN106329002AEven contactEfficient synthesisFinal product manufactureElectrolyte accumulators manufactureSolid state electrolytePhosphorus pentasulfide

The invention discloses a method for efficiently preparing and collecting chalcogenide solid electrolyte. The method comprises the following steps of 1, performing dry milling: putting lithium sulfide and phosphorus pentasulfide into a ball mill container to be subjected to ball milling mixing for preparing Li3PS4; 2, performing wet milling: adding a proton inert organic solvent into the ball mill container; performing ball milling stirring to realize the dissolution of the Li3PS4 for obtaining an Li3PS4 solution; 3, transferring the Li3PS4 solution in the ball mill container into a collecting container; performing drying to remove organic solvents. The efficient preparation and collection of the chalcogenide solid electrolyte is realized. Through the continuous ball milling, solution and deposition paths, the adhesion and residue of powdery products on the inner wall of a ball mill tank and the surface of a grinding ball in the collecting process are greatly reduced; the purity and the collection efficiency of the solid electrolyte are improved; meanwhile, the method is also suitable for being used for realizing continuous in-situ coverage on the solid electrolyte layer on the surface of active materials.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Copper-nickel sulphide ore floatation collector

The invention relates to a copper-nickel sulphide ore floatation collector, which is prepared from isobutanol, phosphorus pentasulfide, ammonia water, hydroximic acid and ethionine ester. A preparation method comprises the following steps of: adding the isobutanol into a kettle, adding the phosphorus pentasulfide with stirring, introducing steam to heat to the temperature of the between 70 and 80 DEG C, performing reaction for 2 hours, injecting water into a jacket until the temperature is reduced to 40 DEG C, adding into an ammoniation kettle, injecting water for dilution with stirring, introducing the ammonia water for ammoniation when the concentration is diluted to 70 percent, controlling the ammoniation temperature to be 45 DEG C, and stopping introducing the ammonia water when the pH value reaches 8-9; continuously stirring for 20 minutes to obtain a substance for later use; weighing the substance for later use, the hydroximic acid and the ethionine ester based on weight part; and putting into the kettle sequentially, stirring at normal temperature for 1 hour, and discharging when the pH value is over 7 to obtain the finished product. The copper-nickel sulphide ore floatation collector has the advantages of strong selectivity and high recovery rate.

Owner:磐石市鑫达化工有限责任公司

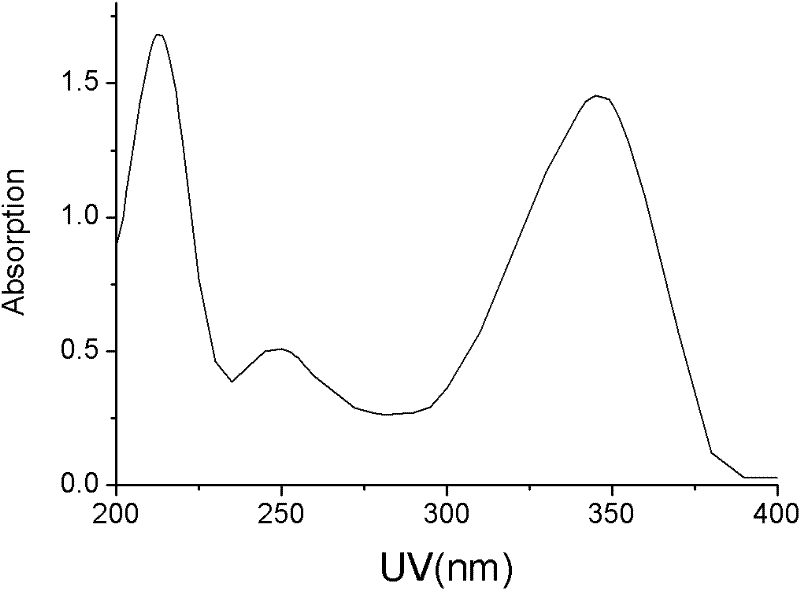

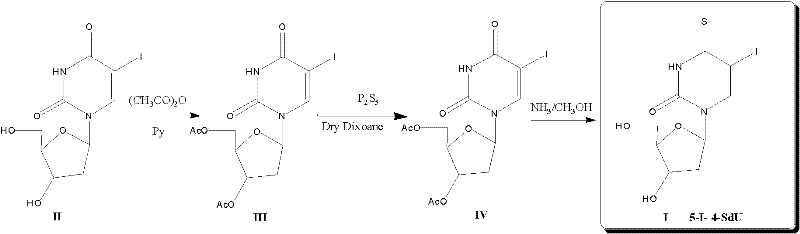

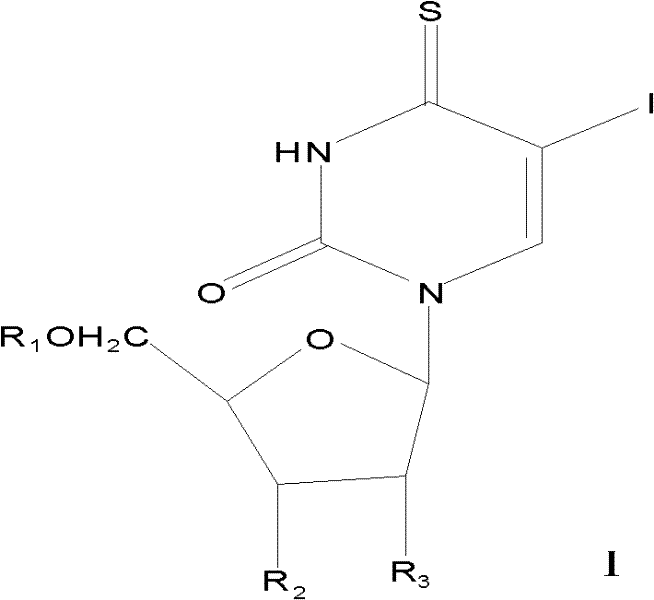

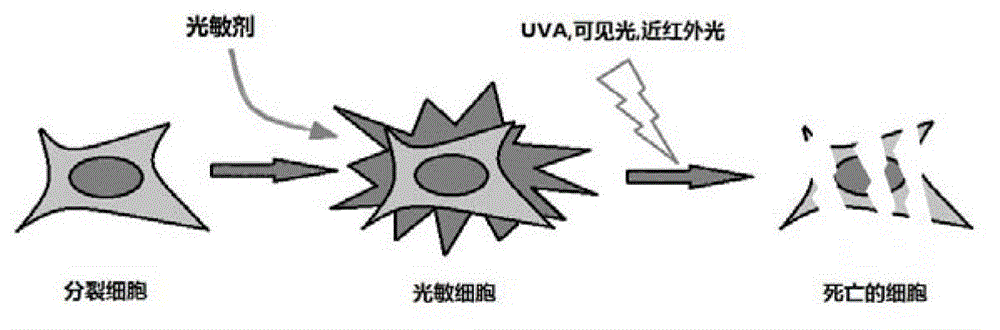

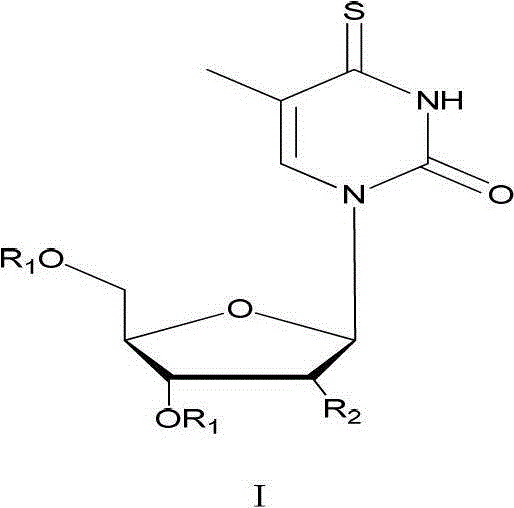

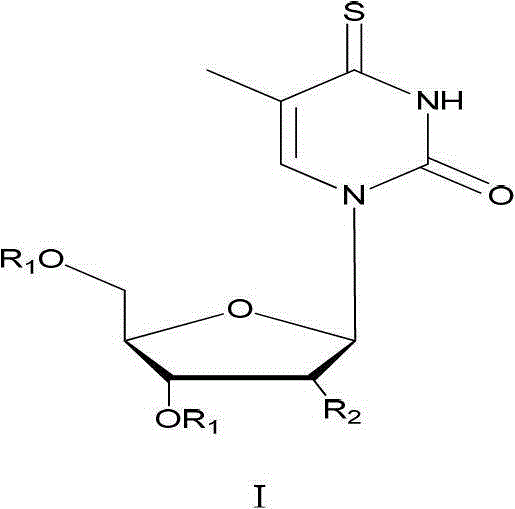

5-iodine-4-sulfur-2'-deoxyuridine, and derivatives and synthetic method thereof

ActiveCN102675389AIncreased sensitivityOvercoming the inability to act selectively on cancer cellsSugar derivativesSugar derivatives preparationPhosphorus pentasulfideAcetic anhydride

The invention discloses 5-iodine-4-sulfur-2'-deoxyuridine, and derivatives and a synthetic method of the 5-iodine-4-sulfur-2'-deoxyuridine. The synthetic method comprises the steps of using 5-iodine-2'-deoxyuridine as main raw material, treating by using acetic anhydride under a certain conditions to obtain 3', 5'-O-dioxo acetyl-5-iodine-2'-deoxyuridine, reacting under the action of phosphorus pentasulfide, then, introducing ammonia to saturated methanol solution, stirring and deprotecting at the room temperature to obtain 5-iodine-4-sulfur-2'-deoxyuridine. According to the invention, the compound and the derivatives have greatest absorption with the ultraviolet spectrum at 345 nm and stronger UVA photosensitivity. Therefore, the compound provided by the invention is a new basic base sulfur-containing nucleosides compound, can alternatively acts on cancer cells and has potential medical value; besides, the synthetic method provided by the invention has the advantages of simple reaction conditions, accessible raw material, low cost, high product yield, high purity and high efficiency.

Owner:DALIAN UNIV

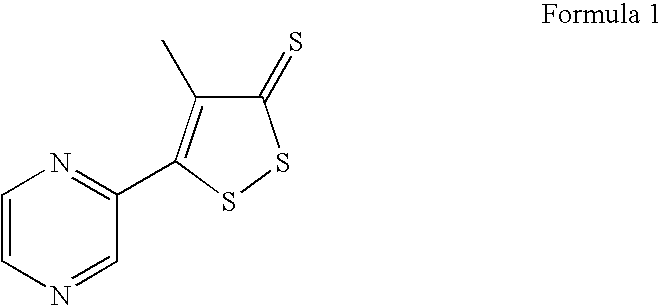

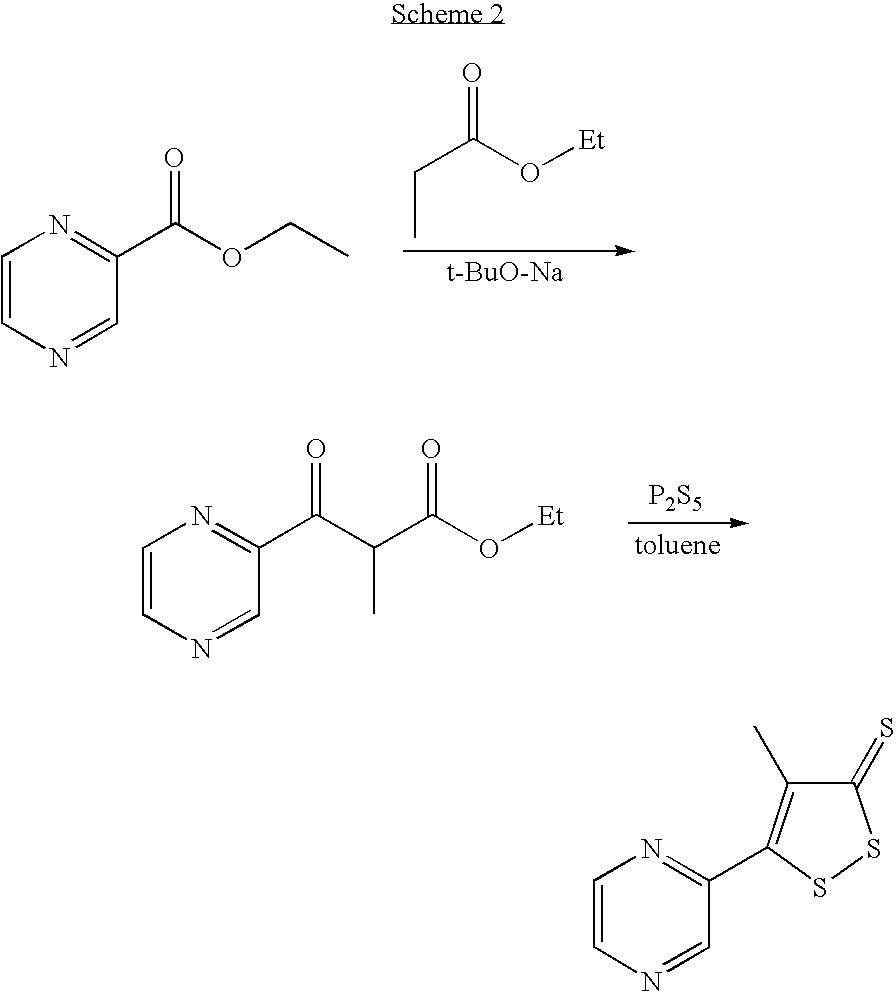

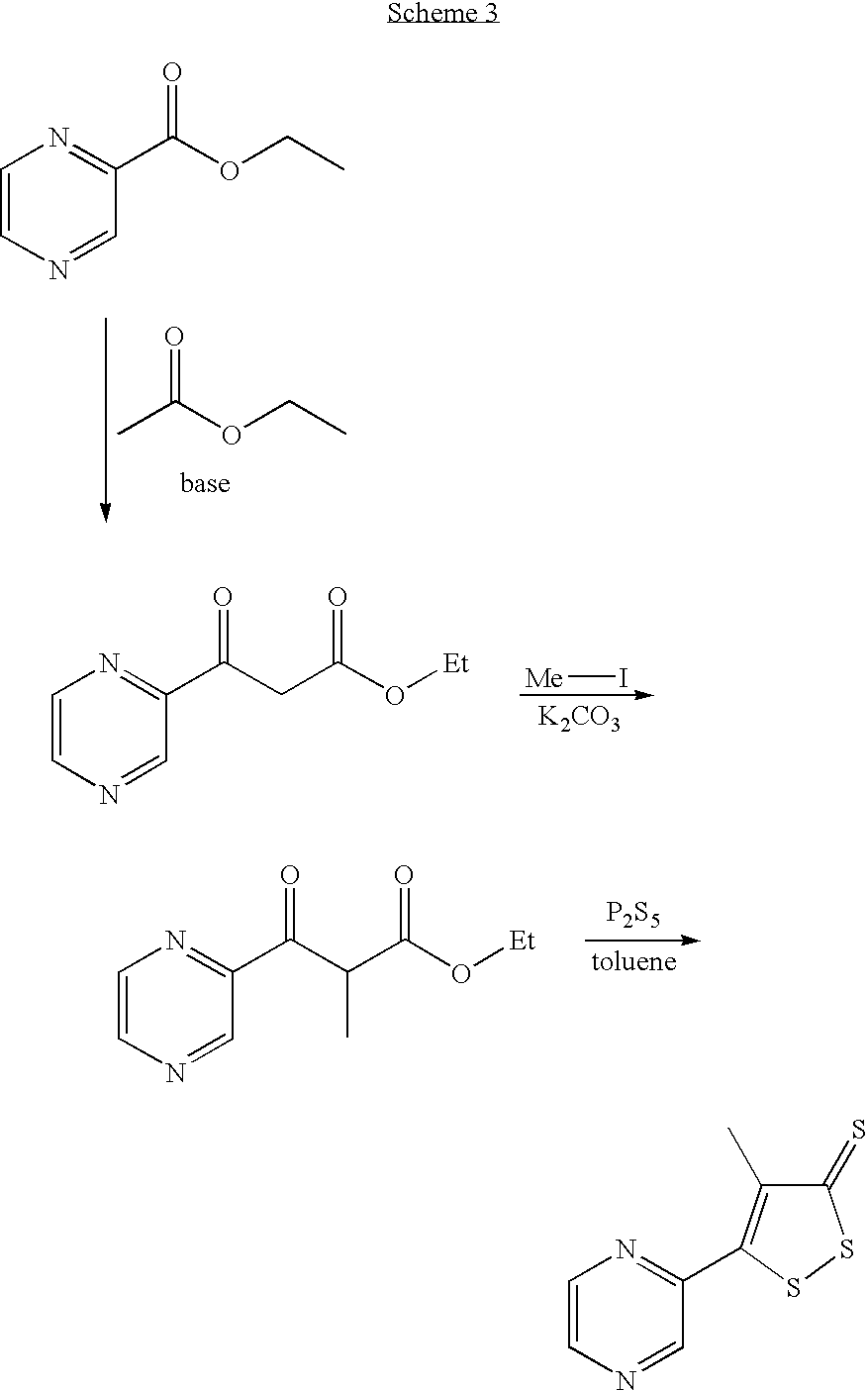

Method for preparing oltipraz

InactiveUS20060106079A1High yieldShorten the construction periodBiocideOrganic chemistryPhosphorus pentasulfideSolvent

Provided is a method for preparing oltipraz. The method includes reacting methyl 2-methyl-3-(pyrazin-2-yl)-3oxopropionate with phosphorus pentasulfide in the presence of a mixed solvent of toluene and xylene, followed by recrystallization.

Owner:PROTHERAPEUTICS INC

Synthetic method of 4-sulfur thymidine and analogues of 4-sulfur thymidine under microwave irradiation

InactiveCN102718822AShort reaction timeHigh yieldSugar derivativesSugar derivatives preparationPhosphorus pentasulfideSolvent

The invention discloses a synthetic method of 4-sulfur thymidine and analogues of 4-sulfur thymidine under microwave irradiation. Thymidine or a thymidine analogue ribothymidine are taken as raw materials; after hydroxyls on saccharide rings are protected, a reaction between reaction products of a previous step and phosphorus pentasulfide solid is carried out in a reactor; dioxane is taken as a solvent; microwave irradiation is carried out in microwaves of 80-100 watts for 7-10 minutes to obtain reaction products after a reaction of sulfur replacing oxygen is carried out; then methanol solution containing saturated ammonia gas is added into the reaction products of a previous step and stirring is carried out to remove protecting groups of hydroxyls at normal temperature; after recrystallization is carried out, the synthetic process of 4-sulfur thymidine and analogues of 4-sulfur thymidine under microwave irradiation is realized. The invention is advantaged in that the method is with short reaction time, high yield and high product purity; a traditional time-consuming and energy-consuming synthetic method with low yield is avoided; and favorable conditions are provided for development of drugs containing sulfur nucleoside analogues.

Owner:DALIAN UNIV

Preparation method of sulfide solid electrolyte

PendingCN110867606ANothing producedComposition is easy to adjustSolid electrolytesSecondary cellsSolid state electrolyteMetallic lithium

The invention provides a low-cost preparation method of a sulfide solid electrolyte composed of Li, P and S elements and with freely controllable components. The preparation method comprises the following steps: adding elemental sulfur and phosphorus pentasulfide into an organic ether solution of a metal lithium-aromatic compound, and mixing to obtain a mixed solution; and sequentially carrying out mixing reaction, separation, precipitation, drying and heat treatment on the mixed solution to obtain the sulfide solid electrolyte containing Li, P and S as constituent elements. According to the preparation method of the sulfide solid electrolyte, raw materials are cheap and easy to obtain, the process is simple, production is safe, product components are easy to adjust, and production cost can be greatly reduced.

Owner:YANGTZE RIVER DELTA PHYSICS RES CENT CO LTD +2

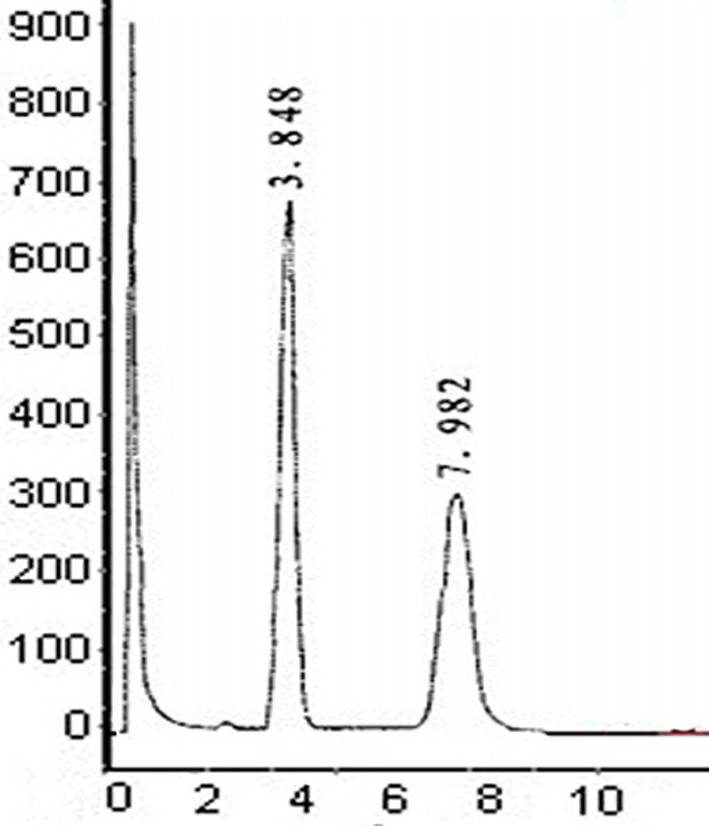

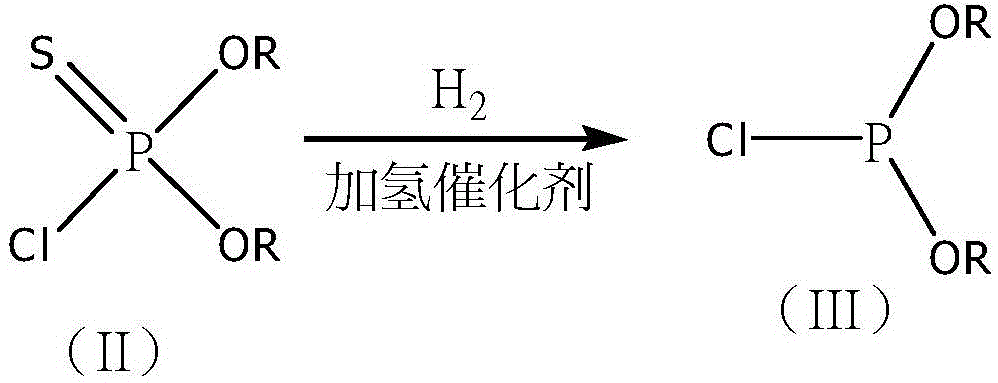

Synthetic method of methyl phosphite and glufosinate-ammonium

InactiveCN105524109AEmission reductionHigh synthetic yieldGroup 5/15 element organic compoundsGlufosinate-ammoniumVulcanization

The invention discloses a synthetic method of methyl phosphite and glufosinate-ammonium. The method comprises the steps: with phosphorus pentasulfide as a starting material, then carrying out vulcanization reaction, chlorination reaction, water washing and distillation purification, then carrying out catalytic hydrogenation to obtain chloride phosphite (III), and next carrying out Grignard reaction to obtain methyl phosphite (IV), wherein R is C1-C4 alkyl. The method comprises the steps: with phosphorus pentasulfide as the starting material, then carrying out vulcanization reaction, chlorination reaction, water washing and distillation purification, then carrying out catalytic hydrogenation to obtain chloride phosphite, next carrying out Grignard reaction to synthesize methyl phosphite (IV), and thus obtaining the final product glufosinate-ammonium through a Strecker route of the prior art. The synthetic yield is increased, methyl phosphorus dichloride and other unstable corrosive intermediates cannot be produced, the discharge of three-waste substances is reduced, and environment-friendly costs and pressure are reduced.

Owner:ANHUI COSTAR BIOCHEM CO LTD

Aliphatic amine ester boride lubricating oil additive and preparation method thereof

The invention discloses an aliphatic amine ester boride lubricating oil additive and a preparation method thereof. The method comprises the following steps: putting methyl oleate and triethanolamine in a container, reacting under the conditions of the temperature of 90 DEG C and the pressure of 80mmHg for 4-5 hours, adding oleic acid and reacting, and obtaining oleamide; mixing the oleamide and phosphorus pentasulfide and dodecanol, continuously cyclically introducing ammonia gas at high pressure, reacting at the temperature of 170-180 DEG C for 4-5 hours, and obtaining an aliphatic amine ester mixture; mixing aliphatic amine ester and boric acid, reacting under the conditions of the temperature of 100 DEG C and the pressure of 230mmHg for 4-5 hours, reducing the pressure to 30mmHg, and reacting; and reducing the temperature, filtering and obtaining the aliphatic amine ester boride lubricating oil additive. A novel low-sulfur low-phosphorus high-efficiency and boron nitride structure-containing aliphatic amine ester boride lubricating oil additive is prepared through continuous cyclic introduction of ammonia gas in a three-step reaction and a two-step pressure reduction method, and the prepared product has excellent wear resistance, antifriction property and oxidation resistance, the production method is simple, the cost is low, and the product structure is stable.

Owner:王严绪

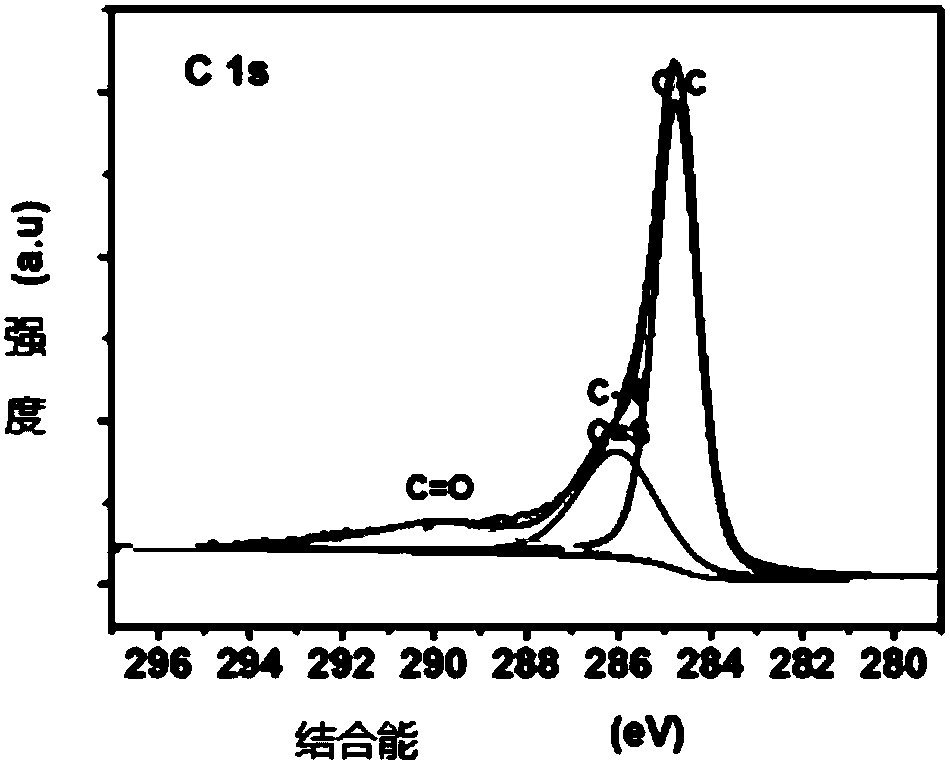

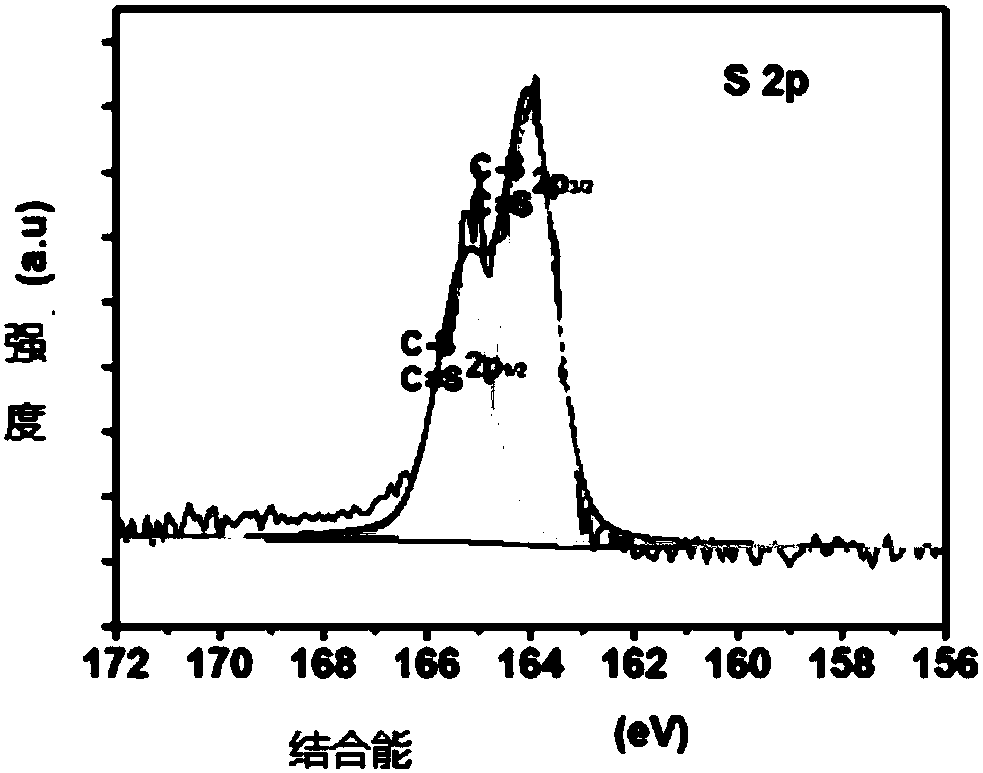

Sulfur/nitrogen co-doped graphene and preparation method thereof

InactiveCN107583664AThe method steps are simpleEasy to operateCatalyst activation/preparationPhosphorus pentasulfideDoped graphene

The invention discloses sulfur / nitrogen co-doped graphene and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing graphene oxide based on a Hummers method, secondly, adding anhydrous dimethyl sulfoxide, performing ultrasonic dispersion, adding phosphorus pentasulfide for stirring and reaction, then performing vacuum suction filtration, performingdrip washing through anhydrous tetrahydrofuran, heating obtained black powder in a tubular furnace, preserving the heat to treat the black powder under a certain gas atmosphere, and finally, naturallycooling the black powder to room temperature, thereby obtaining the sulfur / nitrogen co-doped graphene. The method is simple in step and low in cost. The sulfur / nitrogen co-doped graphene prepared through the preparation method disclosed by the invention is excellent in catalytic activity of electrocatalytic oxygen reduction reaction (ORR), and has an extreme current density of -4.7 mA cm<-2> andan electron transfer number of 3.9; the catalysis performance of the sulfur / nitrogen co-doped graphene is close to that of a commercial platinum / carbon catalyst. The sulfur / nitrogen co-doped graphenehas a great application potential in the field of green energy conversion.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing O,O-diethylthiophosphorylchloride

InactiveCN106083921AReduce generationSatisfy productivityGroup 5/15 element organic compoundsPhosphorus pentasulfideDistillation

The present invention discloses a method for preparing O,O-diethylthiophosphorylchloride, including the steps: a, preparing an intermediate by reaction of phosphorus pentasulfide with ethanol; b, synthesizing crude ethyl chloride by reaction of sulfides with chlorine; c, subjecting the crude ethyl chloride to the procedures such as crystallizing, centrifuging and distillation to obtain the required product. The invention has the advantages that esterification is carried out in the presence of a phase transfer catalyst without a solvent; chlorination byproduct S2Cl2 and an esterification product are subjected to in-situ reductive chlorination through optimal selection of chlorination catalysts and chloride depth control so that there is no byproduct S2Cl2 produced at a chlorination end point, thereby reducing chlorination and superchlorination impurities; the target product has a purity of higher than 99.5% and can meet the requirements of high-grade products for production and exporting.

Owner:JIANGSU XINNONG CHEM

Preparation method of ethyl chloride

InactiveCN104817588AReduce dosageReduce pollutionGroup 5/15 element organic compoundsSulfur preparation/purificationPhosphorus pentasulfideEthyl Chloride

The invention relates to a preparation method of ethyl chloride. The method comprises the following steps: 1, carrying out a sulfuration reaction on phosphorus pentasulfide and anhydrous ethanol under the action of a catalyst to obtain ethyl sulfide and hydrogen sulfide; 2, carrying out a chlorination reaction on ethyl sulfide and chlorine to generate crude chlorine; and 3, introducing hydrogen sulfide obtained after the sulfuration reaction into the crude chlorine, and reacting to obtain ethyl chloride and sulfur. The preparation method has the following advantages: hydrogen sulfide is adopted to remove disulfur dichloride in crude chlorine, so the consumption of an alkali liquid is reduced, and generated tail gas hydrogen chloride can be absorbed by water to prepare hydrochloric acid as a byproduct; obtained sulfur is sandy in shape, and can be directly sold as a raw material without treatment; and no wastewater is generated in the whole preparation process, so environmental pollution is maximally reduced, and the cost is saved.

Owner:湖北犇星新材料股份有限公司

Magnetic boronized phosphonate amine ester lubricating oil additive

InactiveCN104611090AImprove wear resistanceExcellent friction reductionAdditivesFriction reductionPhosphorus pentasulfide

The invention relates to a magnetic boronized phosphonate amine ester lubricating oil additive. According to the technical scheme, the preparation method comprises the following steps: putting methyl oleate and monoethanolamine into a container to react for 4-5 hours at the temperature of 90 DEG C and the high negative pressure of 80MMHg, and further adding oleic acid to react, thereby obtaining oleamide; mixing oleamide with phosphorus pentasulfide and propyl alcohol, constantly introducing an ammonia gas at high pressure to react for 4-5 hours at 170-180 DEG C, thereby obtaining a phosphonate amine ester compound; mixing phosphonate amine ester with boric acid to react for 4-5 hours at the temperature of 100 DEG C and the high negative pressure of 230MMHg, reducing the pressure to be 30MMHg for further reaction, cooling, and filtering, so as to obtain the boronized phosphonate amine ester lubricating oil additive. By continuously introducing the ammonia gas in a circulation manner by using a two-step pressure reduction method through three steps of reaction, a novel boronized phosphonate amine ester lubricating oil additive which is low in sulfur, low in phosphorus, high in efficiency and contains a boron nitride structure can be prepared, and the prepared product is excellent in wearing resistance, friction reduction and anti-oxidation property, simple in production method, low in cost and stable in product structure.

Owner:DAQING JINPU CHEM IND

Modified asphalt binders and asphalt paving compositions

A process for preparing a modified asphalt binder composition, the process comprising mixing asphalt, an unsaturated polymer, and phosphorus pentasulfide to form a modified asphalt composition.

Owner:FIRESTONE POLYMERS LLC +1

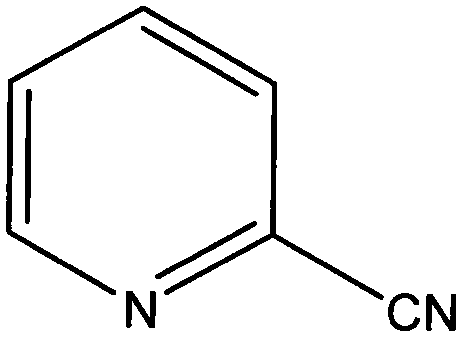

Method for preparing pyridine-2-carbonitrile by using 2-OP rectification residue

ActiveCN109251171AReduce generationEfficient use ofOrganic chemistryPhosphorus pentasulfideDistillation

According to the present invention, 2-OP rectification residue is used as a raw material, phosphorylated zeolite and / or phosphorylated silica is used as an in-situ catalytic cracking catalyst, a mixture of alumina, zinc oxide, boric acid, cobalt acetate and silica is used as a catalytic dehydration catalyst, a mixture of sulfamic acid, phosphorus pentasulfide, phosphorus pentoxide and bis(trichloromethyl)carbonate is used as a dehydration agent, and a process comprising an in situ catalytic cracking and pressure reducing distillation process, a catalytic dehydration and pressure reducing distillation process and a rectification process is performed to obtain the pyridine-2-carbonitrile product with the mass percentage of more than or equal to 99%, wherein the yield is 40-60% based on the mass of the 2-OP rectification residue.

Owner:YANCHENG INST OF TECH

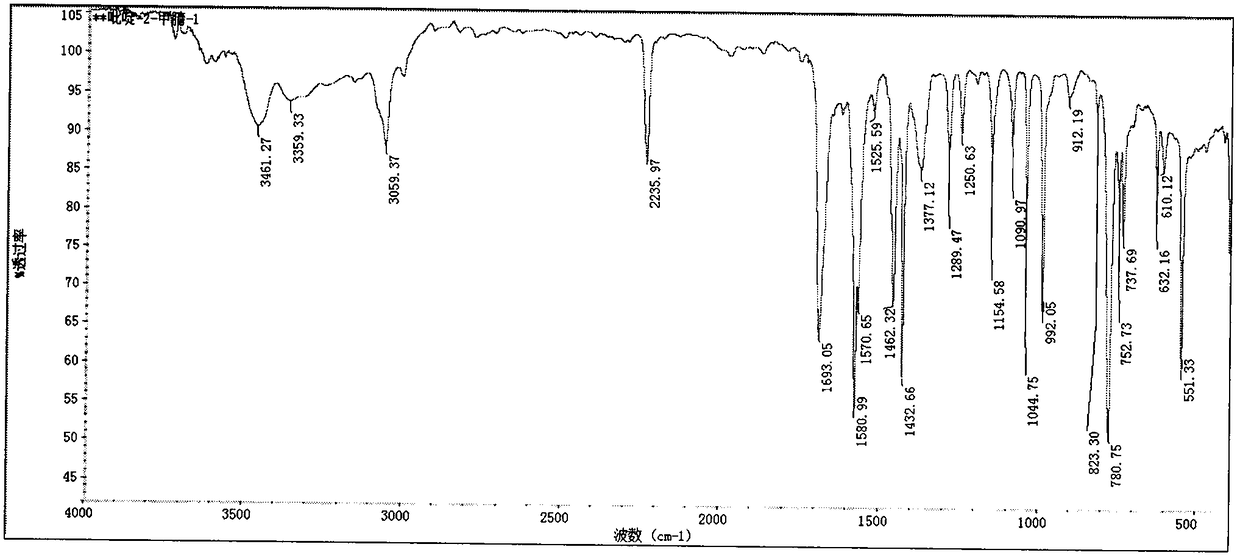

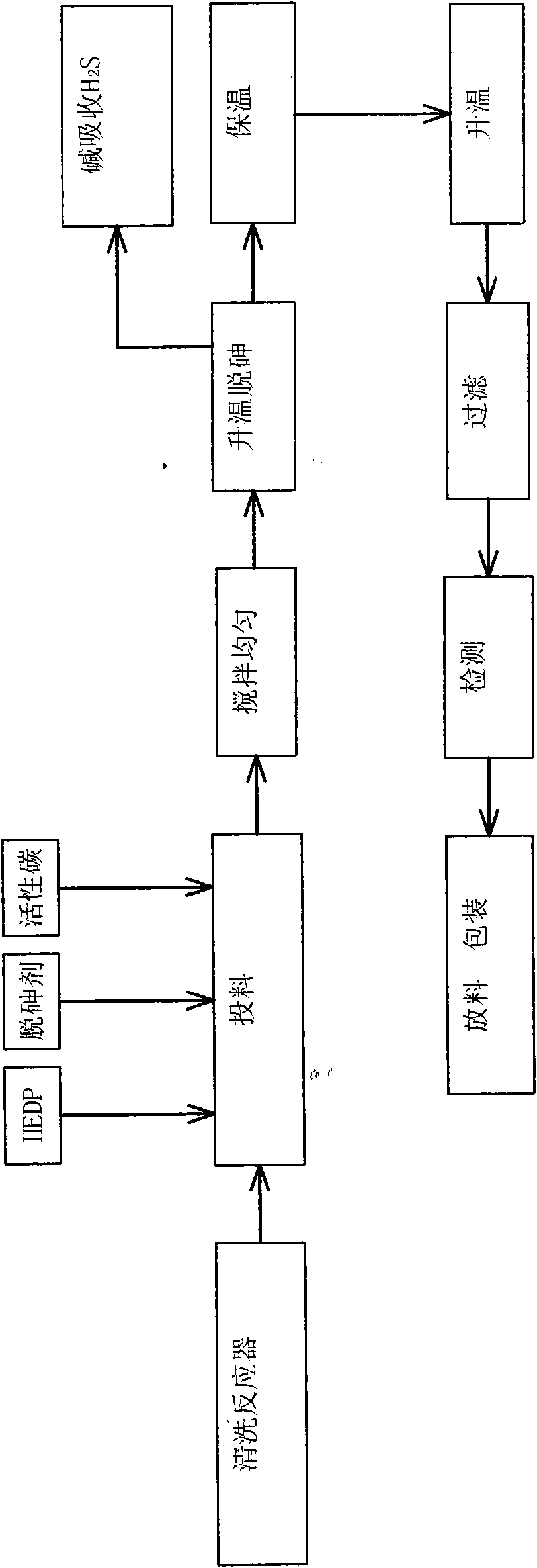

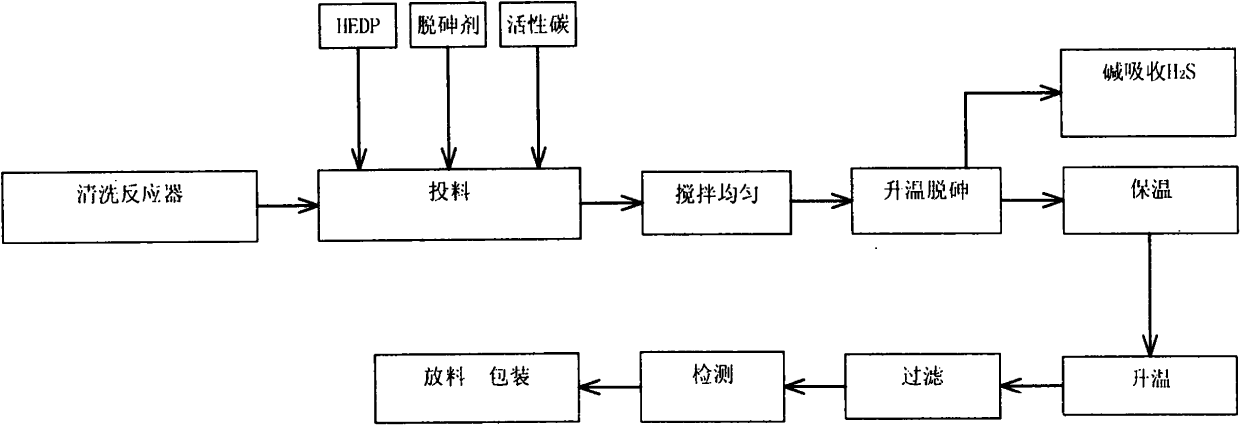

Process for arsenic removal of 1-hydroxy ethylidene-1,1-diphosphonic acid

InactiveCN102070665ALow priceLow costGroup 5/15 element organic compoundsActivated carbonPhosphorus pentasulfide

The invention discloses a process for the arsenic removal of 1-hydroxy ethylidene-1,1-diphosphonic acid, which ensures low production cost. The process comprises the following operating steps of: adding 400 to 1,000 weight parts of 1-hydroxy ethylidene-1,1-diphosphonic acid free from arsenic removal treatment into a reaction kettle, introducing vapor to adjust the temperature of the material in the kettle to 20 to 70 DEG C by using a reaction kettle clamping sleeve, adding 0.1 to 1 weight part of phosphorus pentasulfide serving as an arsenic removal agent, adding 0.2 to 2 weight parts of activated carbon, washing a charging hole by using 0.5 to 2 weight parts of pure water after the charging is finished, preserving the heat for 1 to 5 hours at the temperature of 20 to 70 DEG C, filtering the 1-hydroxy ethylidene-1,1-diphosphonic acid (HEDP), heating the filtered clean 1-hydroxy ethylidene-1,1-diphosphonic acid to 80 DEG C, performing external evaporation for 1 to 3 hours under negative pressure, and before the external evaporation is finished, performing activity analysis, adding the pure water for dilution according to an activity result, and introducing cooling water to reduce the temperature of the material in the kettle to 40 to 50 DEG C by using the reaction kettle clamping sleeve and performing discharging.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

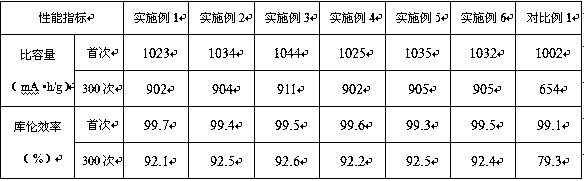

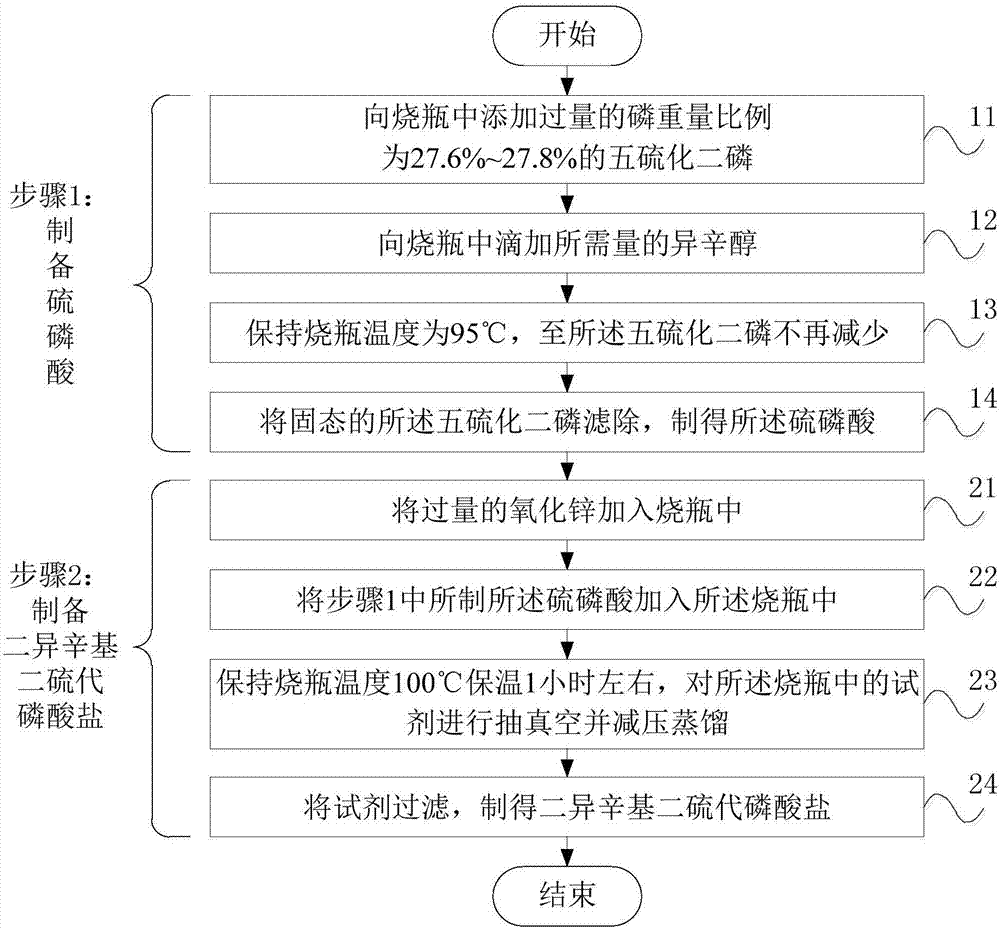

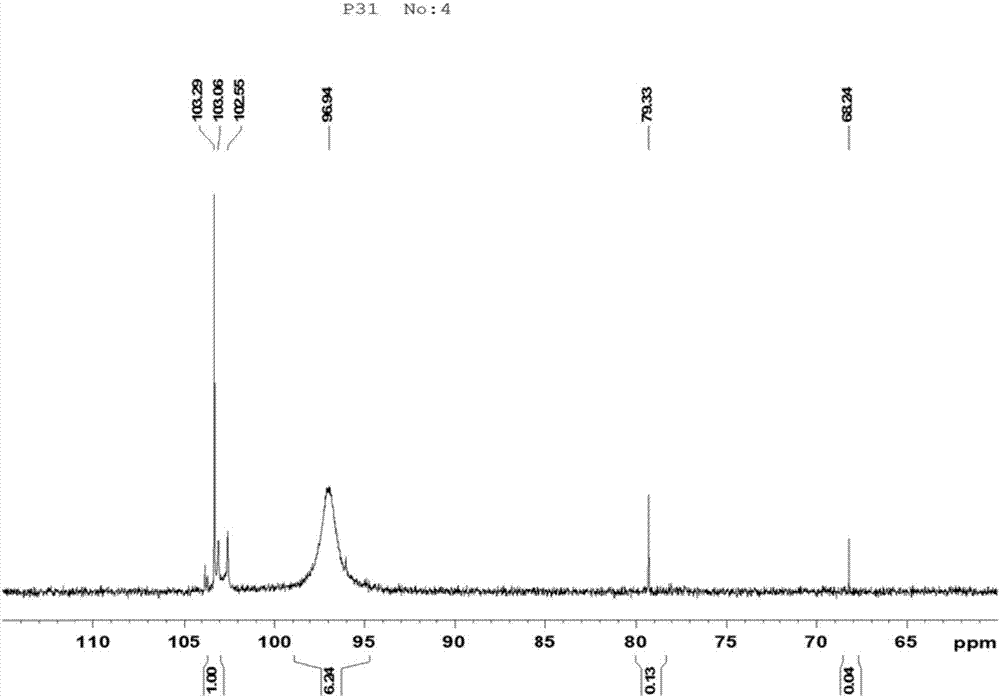

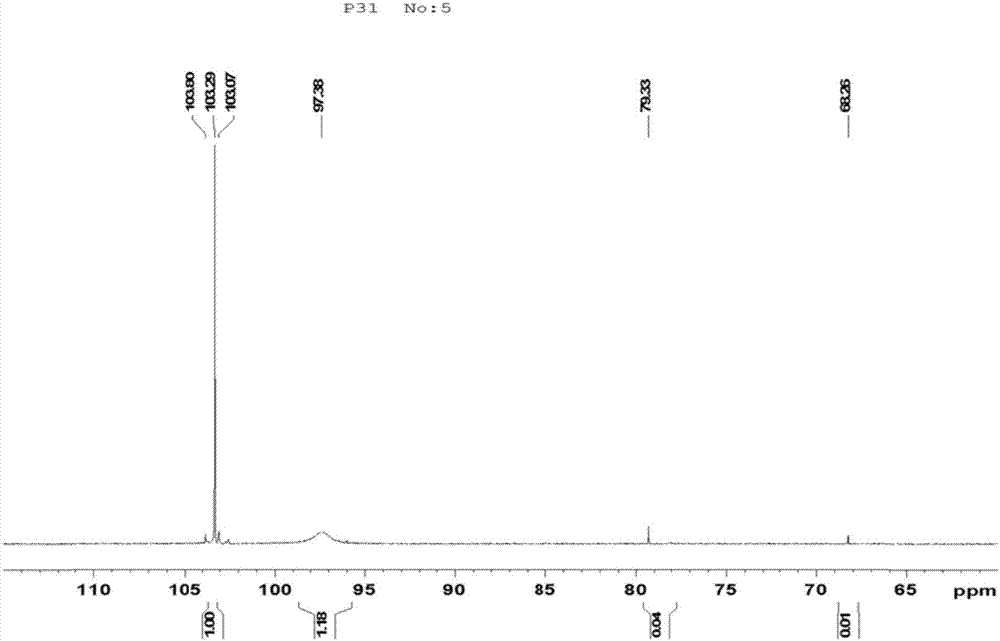

Preparation method of diisooctyl dithiophosphate additive of hydraulic oil

ActiveCN107955035AImprove water separation effectSimple production processGroup 5/15 element organic compoundsAdditivesPhosphorus pentasulfideSulfur

The invention discloses a preparation method of a diisooctyl dithiophosphate additive of hydraulic oil. The preparation method comprises the following steps: adding excessive phosphorus pentasulfide of which the weight ratio of phosphorus is 27.6%-27.8%; dropwise adding a required amount of isooctanol; maintaining the temperature of a flask to be 95 DEG C until complete reacting; filtering out solid phosphorous pentasulphur; adding excessive zinc oxide; adding prepared phosphorodithioic acid; maintaining the temperature of the flask at the temperature of 100 DEG C and insulating for about 1 hour, and vacuumizing and distilling under reduced pressure; and filtering a reagent to obtain diisooctyl dithiophosphate. The zinc oxide comprises 25-30% of direct-method zinc oxide and 70-75% of indirect-method zinc oxide, and the excessive range of the zinc oxide is 5-8%. When the diisooctyl dithiophosphate additive prepared by the technical scheme of the invention is used on the hydraulic oil, the water separation performance of the hydraulic oil is obviously improved, a production process is simple, the use amount of the zinc oxide is reduced, a catalyst is omitted, treatment of wastes in the later period is relieved, and the production cost is reduced obviously.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Preparation method of sulfo-molybdate for separating molybdenum from tungstate solution

InactiveCN102181637ALow costReduce manufacturing costProcess efficiency improvementTungstate ionVulcanization

The invention discloses a preparation method of sulfo-molybdate for separating molybdenum from tungstate solution. Phosphorus pentasulfide serves as vulcanizing agent; after the vulcanizing agent is added into molybdenum-contained tungstate solution, the vulcanizing agent is hydrolyzed to release sulphur ions; the sulphur ions and molybdate are subject to vulcanization reaction to generate sulfo-molybdate; and tungsten still exists in the form of tungstate ion. The vulcanizing agent used by the method has the advantages of high sulphur content and low price, and the preparation cost of the sulfo-molybdate can be obviously lowered.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com