Method for preparing pyridine-2-carbonitrile by using 2-OP rectification residue

A 2-OP and rectification technology, applied in organic chemistry and other fields, can solve the problems of large energy consumption and ineffective utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

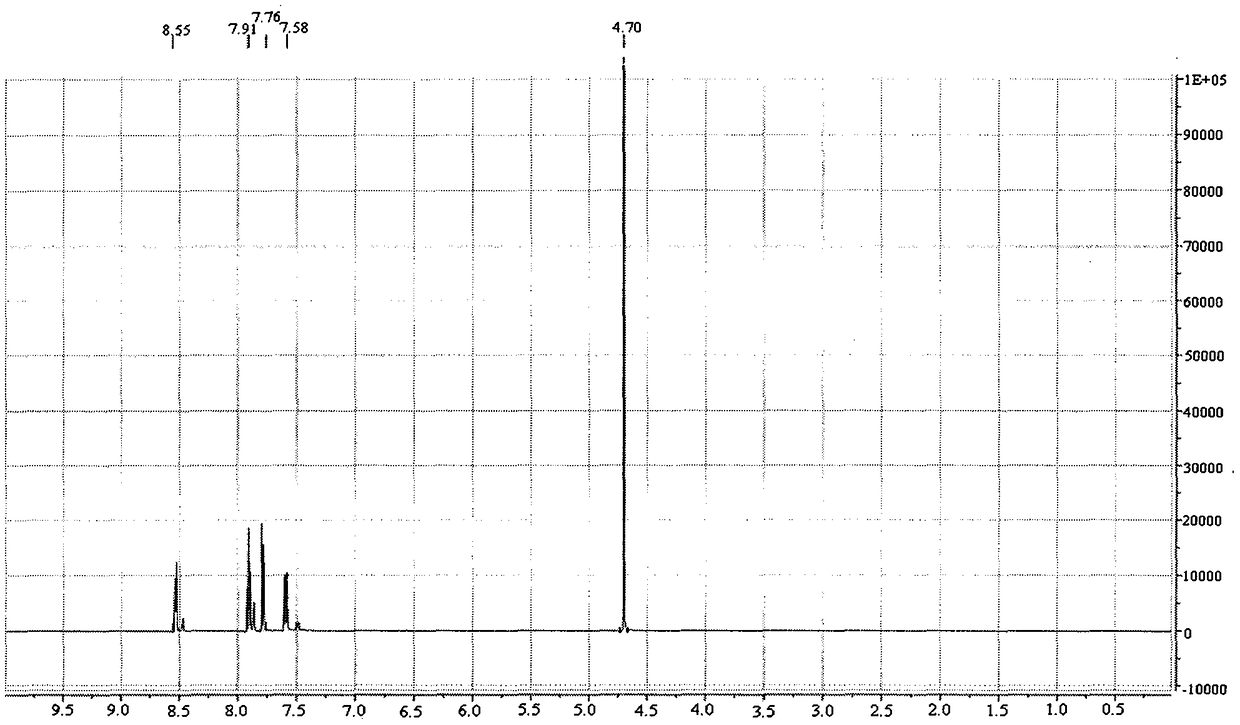

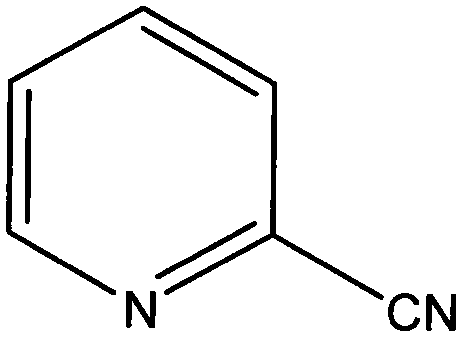

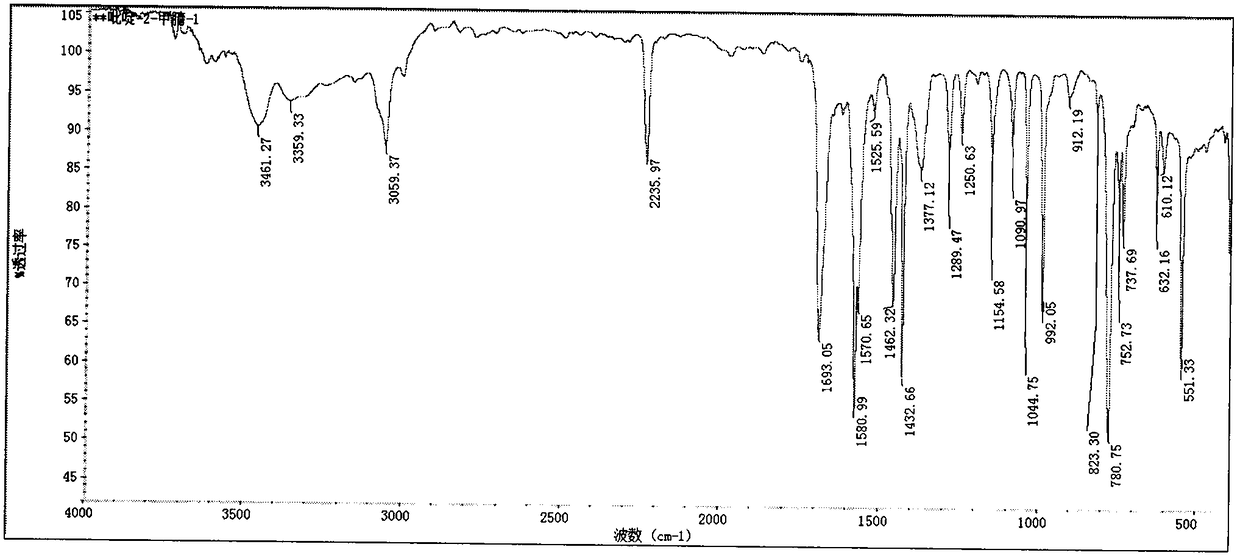

[0015] A kind of method that utilizes 2-OP rectification residue to prepare pyridine-2-carbonitrile involved in the invention is characterized in that a kind of figure 1 The pyridine-2-carbonitrile of the shown structure, by using 2-OP rectification residue as raw material, phosphorylated zeolite and / or phosphorylated silica gel as in-situ catalytic cracking catalyst, is made of aluminum oxide, zinc oxide, boric acid, cobalt acetate and The mixture composed of silicon dioxide is a catalytic dehydration catalyst, and the mixture composed of sulfamic acid, phosphorus pentasulfide, phosphorus pentoxide and bis(trichloromethyl)carbonate is a dehydrating agent. After in-situ catalytic cracking and vacuum distillation process, Processes including catalytic dehydration, vacuum distillation process and rectification process are prepared.

[0016] (1) In-situ catalytic cracking and vacuum distillation process of 2-OP rectification residue: Zeolite or silica gel is soaked in 30%~80% pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com