Sulfide electrolyte material and preparation method thereof

A technology of sulfide electrolyte and lithium sulfide, which is applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., and can solve problems such as difficult industrial scale production, complicated manufacturing methods, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Therefore, the present application provides a method for preparing a sulfide electrolyte material as shown in formula (I), comprising the following steps:

[0025] mixing lithium sulfide, phosphorus pentasulfide and an organic solution to obtain a mixed solution;

[0026] Stirring, centrifuging, filtering and drying the mixed solution in sequence to obtain the raw material;

[0027] heat-treating the initial material to obtain a sulfide electrolyte material represented by formula (I);

[0028] (100-x) Li 2 S·xP 2 S 5 (I);

[0029] Among them, 20≤x≤60.

[0030] In the process of preparing sulfide electrolyte materials, the first thing to do is the mixing process of raw materials, that is, Li 2 S, P 2 S 5 Mixed with an organic solution to obtain a mixed solution, which can also be called the first raw material. The present invention has no particular limitation on the mixing method, which may be manual mixing or mechanical mixing, and mechanical mixing is pref...

Embodiment 1

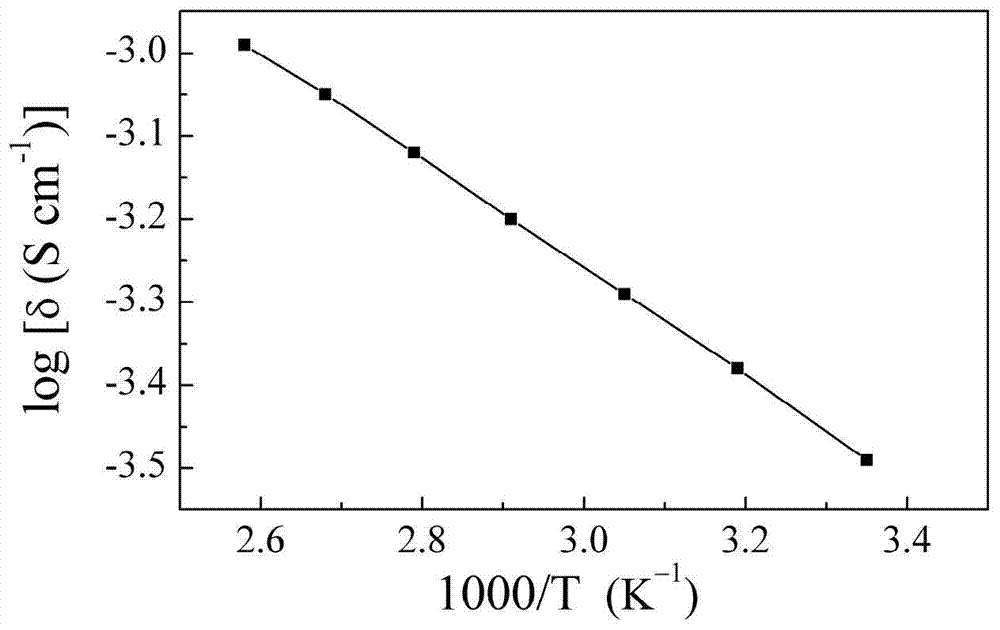

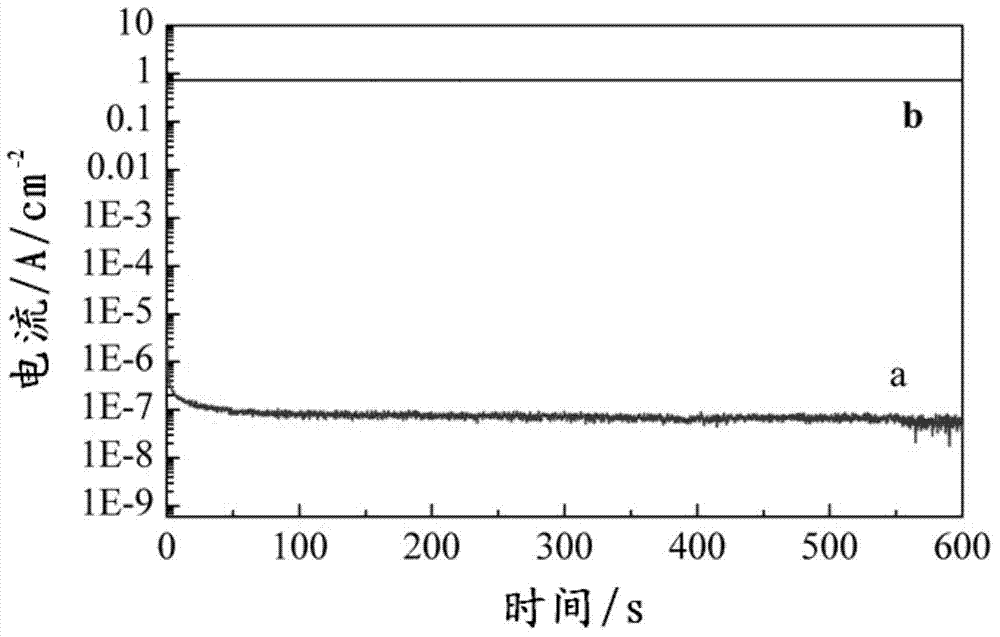

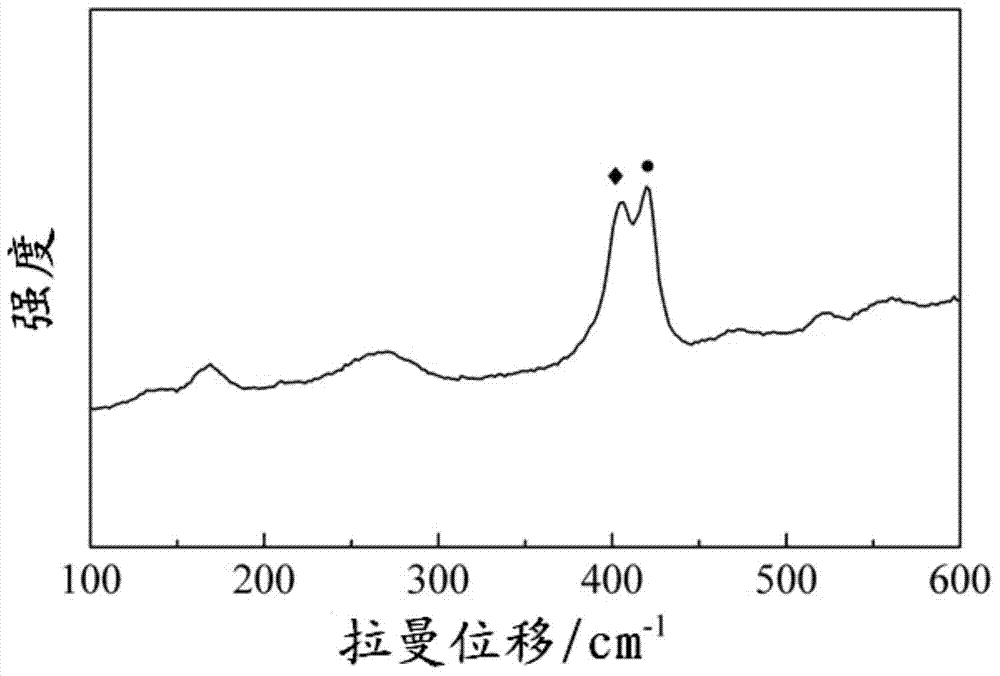

[0044] Under the protection of argon atmosphere and at room temperature, Li with a purity of more than 99% 2 S and P 2 S 5 After weighing according to the molar ratio of 70:30, put it into the reaction vessel under the condition that the water content is less than 100ppm, and then add tetrahydrofuran solution (THF) according to the mass ratio of 300%. THF needs to be distilled multiple times with a rotary evaporator to make its water content less than 1%. Add THF and mix evenly to obtain the first primary material. After the first primary material is magnetically stirred at room temperature for 24 hours, a suspension with white precipitate is obtained, which is the second primary material; Centrifuge and separate for 10 minutes, then filter and wash at room temperature, repeat this step 3 times to obtain the fourth primary material; put the fourth primary material in an oven, dry at 80°C for 6 hours to obtain a white solid, that is, the fifth primary material; The initial m...

Embodiment 2

[0050] Under the protection of argon atmosphere and room temperature, Li with a purity of more than 99% 2 S and P 2 S 5 After weighing according to the molar ratio of 80:20, put it into the reaction vessel under the condition that the water content is less than 100ppm, and then add the acetonitrile solution according to the mass ratio of 300%. Acetonitrile needs to be distilled multiple times with a rotary evaporator to make the water content less than 1%. After adding the acetonitrile solution, the first raw material is obtained, and the first raw material is magnetically stirred at room temperature for 24 hours to obtain a green light liquid with white precipitate, which is the second raw material; the second raw material is transferred into a centrifuge tube, and the rotation speed is 10000rpm Centrifuge and separate for 10 minutes, then filter and wash at room temperature, repeat this step 3 times to obtain the fourth primary material; put the fourth primary material in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com