Process for arsenic removal of 1-hydroxy ethylidene-1,1-diphosphonic acid

A technology of hydroxyethylene diphosphonic acid and process, which is applied in the field of arsenic removal technology of hydroxyethylene diphosphonic acid, can solve the problems of increasing production cost, being difficult to purchase, unfavorable for practical application, etc., and achieves low price and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

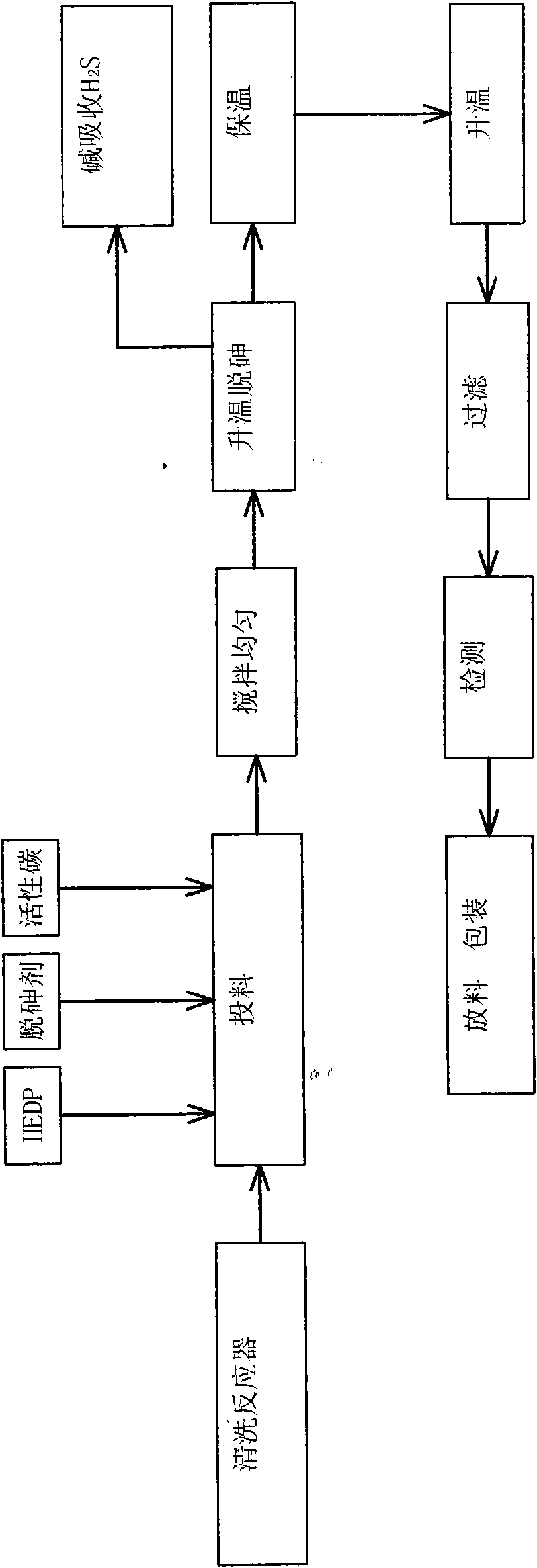

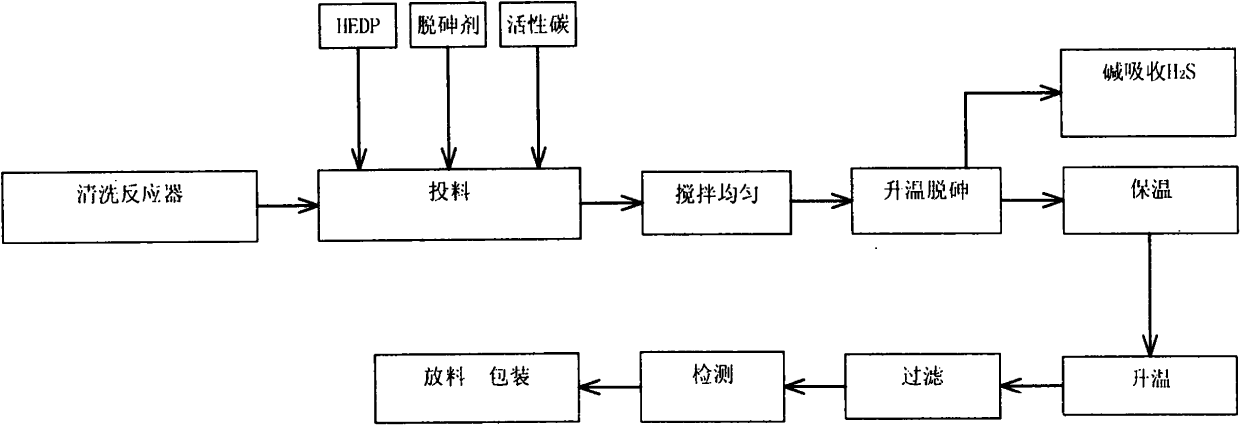

Image

Examples

Embodiment 1

[0048] The feeding amount of HEDP is 600kg, the arsenic removal agent phosphorus pentasulfide (P2S5) is 0.2kg, the amount of activated carbon is 0.6kg, the temperature is kept at 50°C, and the holding time is 2 hours.

[0049] Add 600kg HEDP into the kettle, start stirring after the addition is complete, feed steam into the reactor jacket to heat the temperature of the material in the kettle to 50±2°C, add 0.2kg of arsenic removal agent and 0.6kg of activated carbon at a time from the special feeding port, after adding Rinse the feeding port with 1kg of pure water, keep it warm for 2 hours after adding, and keep the temperature at 50±2°C; then filter the HEDP into another kettle, heat the filtered HEDP to 80°C, Steam under pressure for 2 hours, analyze the activity before the end of external steaming, dilute with pure water according to the activity content of HEDP, cool down to 50°C and discharge. The assayed arsenic content was less than 1mg / L.

Embodiment 2

[0051] The feeding amount of HEDP is 600kg, the arsenic removal agent phosphorus pentasulfide (P2S5) is 0.4kg, and the activated carbon is 0.6kg, and the temperature is kept at 25°C for 4 hours.

[0052] Add 600kg HEDP into the kettle, start stirring after the addition is complete, feed steam into the jacket of the reaction kettle to heat the temperature of the material in the kettle to 25±2°C, add 0.4kg of arsenic removal agent and 0.6kg of activated carbon at a time from the special feeding port, after adding Rinse the feeding port with 1kg of pure water, and keep it warm for 4 hours after adding, at a temperature of 25±2°C; then filter the HEDP into another kettle, heat the filtered clean HEDP to 80°C, and pull Negative pressure external steaming for 2 hours, analyze the activity before the external steaming ends, add pure water to dilute according to HEDP activity, cool down to 40°C and discharge. The assayed arsenic content was less than 1mg / L.

Embodiment 3

[0054] The feeding amount of HEDP is 600kg, the arsenic removal agent phosphorus pentasulfide (P2S5) is 0.6kg, and the activated carbon is 0.6kg, and the temperature is kept at 25°C for 2 hours.

[0055] Add 600kg HEDP into the kettle, start stirring after the addition is complete, feed steam into the jacket of the reaction kettle to heat the temperature of the material in the kettle to 25±2°C, add 0.4kg of arsenic removal agent and 0.6kg of activated carbon at a time from the special feeding port, after adding Rinse the feeding port with 1kg of pure water, and keep warm for 2 hours after adding, at a temperature of 25±2°C; then filter HEDP into another kettle, heat the filtered clean HEDP to 80°C, and pull Steam under negative pressure for 2 hours, analyze the activity before the end of external steaming, add pure water to dilute according to HEDP activity, cool down to 45°C and discharge. The assayed arsenic content was less than 1mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com