A lithium sulfide battery electrolyte for improving safety and stability

A lithium-sulfur battery and electrolyte technology, applied in the field of electrolyte and lithium-sulfur battery electrolyte, can solve the problems of poor battery stability and safety, unsatisfactory effect, etc., so as to reduce the generation of lithium dendrites, improve safety and Stability, effect of improving stability and cycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

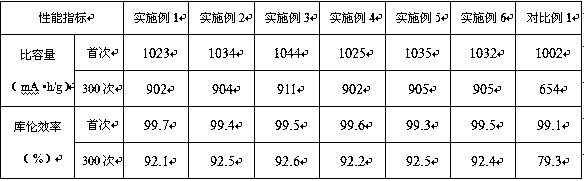

Examples

Embodiment 1

[0026] The electrolyte composition is:

[0027] Lithium-sulfur battery electrolyte consists of three parts: lithium salt, solvent and additives.

[0028] Lithium salt is a mixture of lithium bistrifluoromethanesulfonylimide, lithium bisoxalate borate, and lithium difluorooxalate borate; the concentration of lithium salt in the electrolyte is 0.7mol / L; in lithium salt, bistrifluoromethanesulfonyl The mass ratio of lithium imide, lithium bisoxalate borate and lithium difluorooxalate borate is 95:3.9:1.1;

[0029] The solvent is a mixture of dioxolane and tetraethylene glycol dimethyl ether; in the solvent, the volume ratio of dioxolane and tetraethylene glycol dimethyl ether is 1:1;

[0030] The additives are lithium nitrate and phosphorus pentasulfide; the weight percentage of lithium nitrate in the electrolyte is 1.0wt%; the weight percentage of phosphorus pentasulfide in the electrolyte is 1.0wt%.

[0031] The test method is:

[0032] The conventional components such as th...

Embodiment 2

[0035] The electrolyte composition is:

[0036] Lithium-sulfur battery electrolyte consists of three parts: lithium salt, solvent and additives.

[0037] Lithium salt is a mixture of lithium bistrifluoromethanesulfonylimide, lithium bisoxalate borate, and lithium difluorooxalate borate; the concentration of lithium salt in the electrolyte is 0.1mol / L; in lithium salt, bistrifluoromethanesulfonyl The mass ratio of lithium imide, lithium dioxalate borate and lithium difluorooxalate borate is 95:3.0:0.1;

[0038] The solvent is a mixture of dioxolane and tetraethylene glycol dimethyl ether; in the solvent, the volume ratio of dioxolane and tetraethylene glycol dimethyl ether is 1:1;

[0039] The additives are lithium nitrate and phosphorus pentasulfide; the weight percentage of lithium nitrate in the electrolyte is 1.0wt%; the weight percentage of phosphorus pentasulfide in the electrolyte is 0.4wt%.

[0040] The test method is:

[0041] The conventional components such as the...

Embodiment 3

[0044]The electrolyte composition is:

[0045] Lithium-sulfur battery electrolyte consists of three parts: lithium salt, solvent and additives.

[0046] Lithium salt is a mixture of lithium bistrifluoromethanesulfonylimide, lithium bisoxalate borate, and lithium difluorooxalate borate; the concentration of lithium salt in the electrolyte is 1.5mol / L; in lithium salt, bistrifluoromethanesulfonyl The mass ratio of lithium imide, lithium bisoxalate borate and lithium difluorooxalate borate is 95: 4.9: 2.0;

[0047] The solvent is a mixture of dioxolane and tetraethylene glycol dimethyl ether; in the solvent, the volume ratio of dioxolane and tetraethylene glycol dimethyl ether is 1:1;

[0048] The additives are lithium nitrate and phosphorus pentasulfide; the weight percentage of lithium nitrate in the electrolyte is 1.0wt%; the weight percentage of phosphorus pentasulfide in the electrolyte is 1.8wt%.

[0049] The test method is:

[0050] The conventional components such as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com