Method for efficiently preparing and collecting chalcogenide solid electrolyte

A solid-state electrolyte and sulfur-based technology, which is applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrolyte immobilization/gelation, etc., can solve the problem of low efficiency of chemical synthesis and collection, and achieve efficient synthesis and collection, high-efficiency reaction, The effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

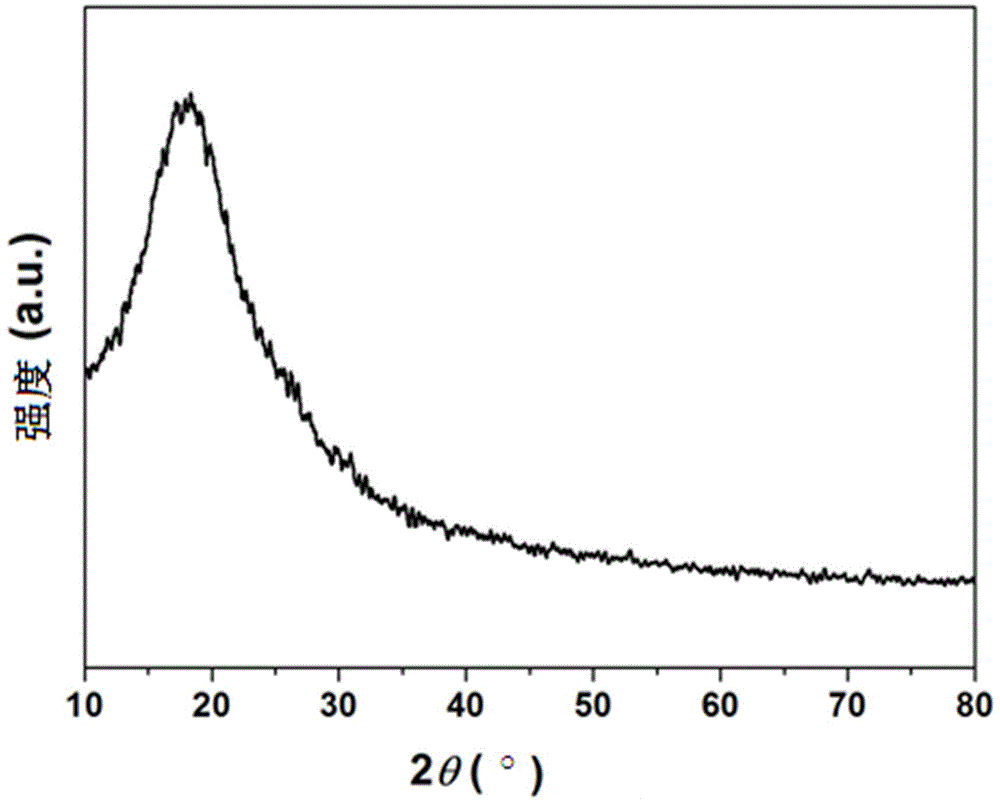

[0025] Weigh 0.4738g of lithium sulfide (99.9%) powder and 1.5262g of phosphorus pentasulfide (99%) in a glove box with an inert protective atmosphere, first grind them evenly in an agate mortar, and then add ZrO with a volume of 50ml 2 In a ball mill jar, 120 grains of ZrO with a diameter of 5 mm and 3 mL of a diameter of 2 mm 2 The grinding balls are placed in a ball mill jar, first set at a speed of 200rpm for 0.5h of ball milling, and then switch to a speed of 1000rpm for 10h of ball milling. After the ball milling is completed, put the ball milling jar in the glove box, drop 20 mL of aprotic organic solvent (eg, NMF) into the ball milling jar, seal it and ball mill it at a speed of 100 rpm for 30 min. The solution in the grinding tank was collected in a specific glass container in the glove box again, and the glass container was heated and stirred at 80° C. for 1 hour. After the solvent volatilized, the powder of the solid electrolyte was precipitated. The powder is amor...

Embodiment 2

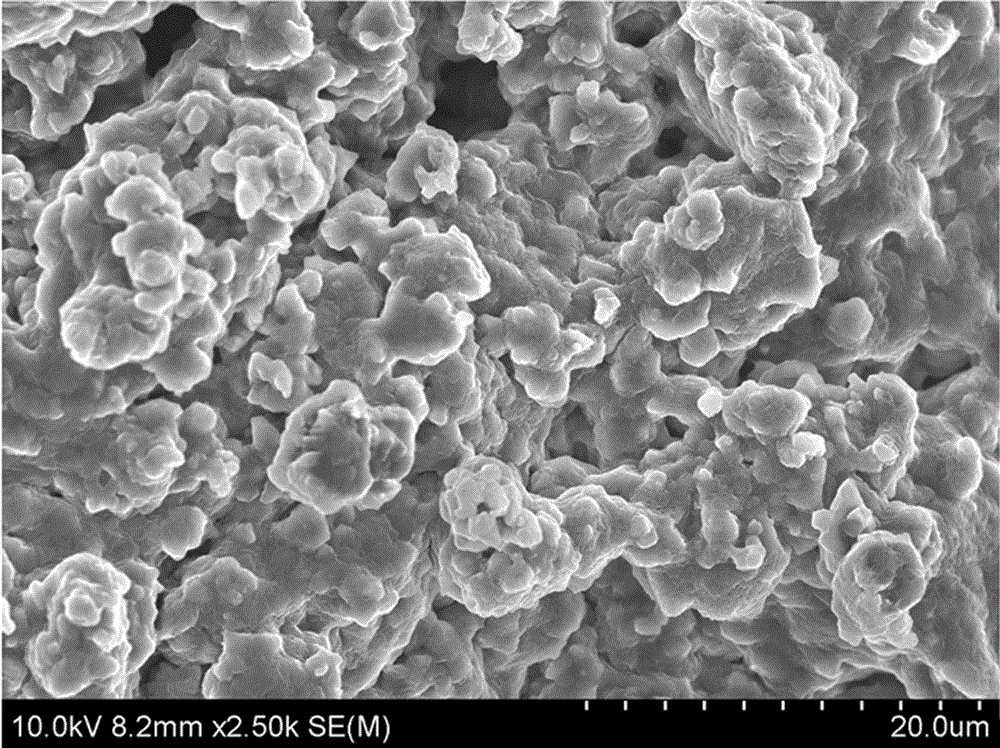

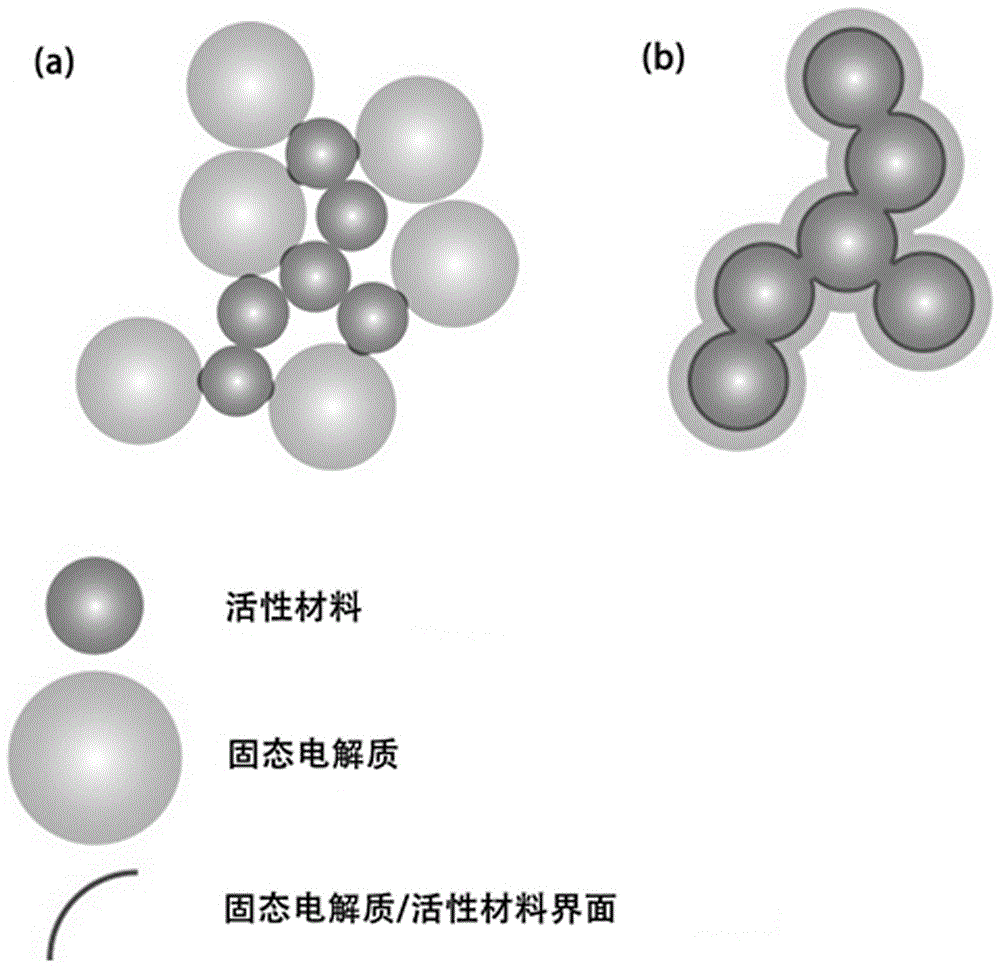

[0027] Weigh 0.2369g of lithium sulfide powder and 0.7631g of phosphorus pentasulfide in a glove box with an inert protective atmosphere, first grind them evenly in an agate mortar, then add 50ml of ZrO 2 In a grinding jar, 30 mL of ZrO with a diameter of 1 mm 2 The grinding balls were placed in a ball mill jar, and ball milled for 10 h at a speed of 1000 rpm. After the ball milling is completed, put the ball mill jar in a glove box, drop 20 mL of absolute ethanol into the ball mill jar, seal it, and ball mill it at a speed of 100 rpm for 30 min. In the glove box again, the solution in the grinding jar (and the solution after rinsing the ball milling jar with absolute ethanol) was collected in a specific glass container, and a certain amount of LiCoO 2 (as an active material) placed in a diluted solid electrolyte solution (according to the mass ratio of active material to solid electrolyte 95:5), the mixture was heated and stirred at 80°C for 3 hours, and the solid electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com