Method for preparing O,O-ethyl thioether substituted phosphorus oxychloride

A technology of ethylphosphorothioate and diethylphosphorodithioate, which is applied in the field of industrial preparation of organophosphorus fine chemicals, can solve the problem of not fundamentally achieving no sulfur-containing wastewater discharge, and achieve desulfurization conditions Gentle, yielding and high-content effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

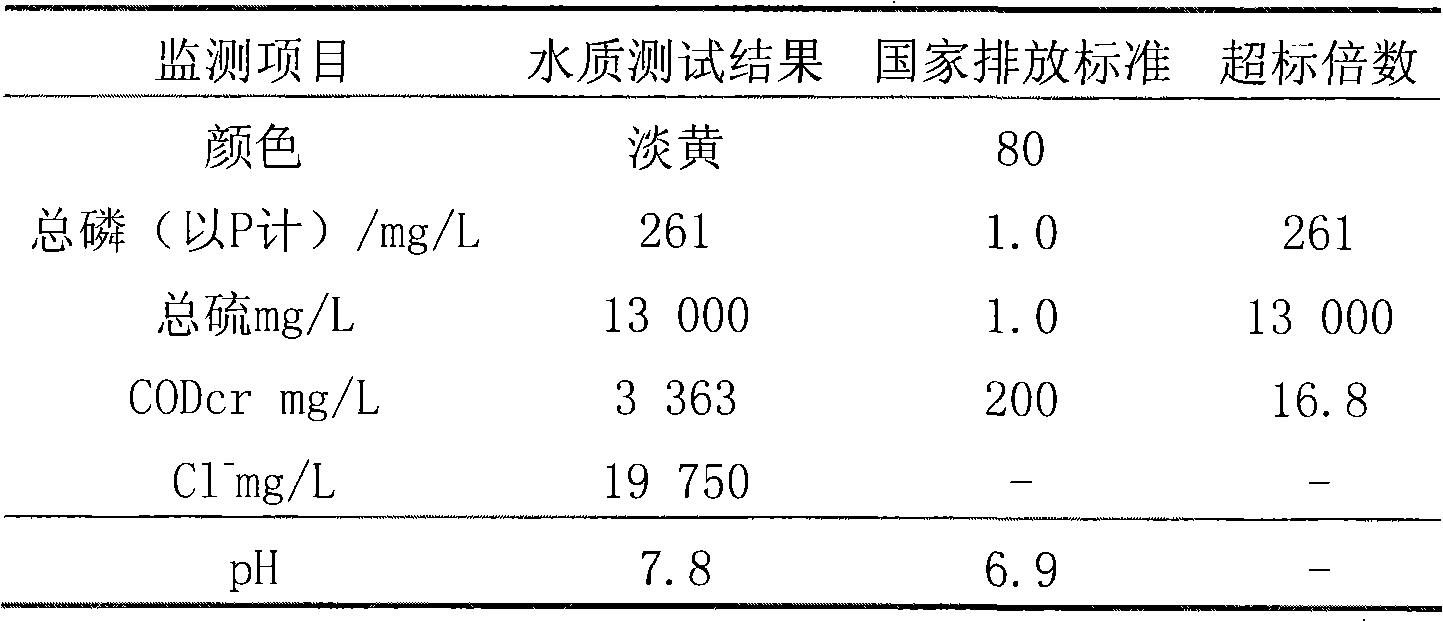

Problems solved by technology

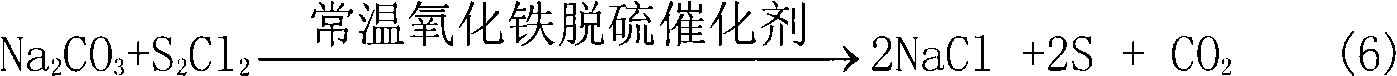

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation O, the method for O-diethyl thiophosphoryl chloride, it comprises the steps:

[0048] 1) synthesis of ethyl chloride crude product:

[0049] ①Ethylation: Add 100mL of ethyl sulfide mother liquor into a 500mL four-neck flask equipped with a stirrer, thermometer, reflux condenser and dropping funnel, and directly add 30g of phosphorus pentasulfide under stirring; The quality of the mass is 0.03% of the mass of phosphorus pentasulfide, the catalyst hydroxymethylpyridine is selected, and the temperature is controlled to add the catalyst hydroxymethylpyridine at 5° C., stirring; the molar ratio of phosphorus pentasulfide and dehydrated alcohol is 1: 4.0 to select dehydrated alcohol, dropwise Dehydrated ethanol, the temperature is controlled at 5 ° C, after the dropwise addition, keep warm for 20 minutes, cool to room temperature, filter to obtain light-colored and transparent O, O-diethyl phosphorodithioate (abbreviated as ethyl sulfide, i.e. filtrate),...

Embodiment 2

[0059] A kind of preparation O, the method for O-diethyl thiophosphoryl chloride, it comprises the steps:

[0060] 1) synthesis of ethyl chloride crude product:

[0061] ①Ethylation: Add 150mL of ethyl sulfide mother liquor into a 500mL four-neck flask equipped with a stirrer, thermometer, reflux condenser and dropping funnel, and directly add 60g of phosphorus pentasulfide under stirring; The quality of the mass is 0.1% of the mass of phosphorus pentasulfide, the catalyst hydroxymethylpyridine is selected, and the temperature is controlled to add the catalyst hydroxymethylpyridine at 25° C., stirring; the molar ratio of phosphorus pentasulfide and dehydrated alcohol is 1: 4.1 to select dehydrated alcohol, dropwise Dehydrated ethanol, the temperature is controlled at 25 ° C, after the dropwise addition, keep warm for 40 minutes, cool to room temperature, filter to obtain light-colored and transparent O, O-diethyl phosphorodithioate (referred to as ethyl sulfide, i.e. filtrate)...

Embodiment 3

[0071] A kind of preparation O, the method for O-diethyl thiophosphoryl chloride, it comprises the steps:

[0072] 1) synthesis of ethyl chloride crude product:

[0073]①Ethylation: Add 180mL of ethyl sulfide mother liquor into a 500mL four-necked flask equipped with a stirrer, thermometer, reflux condenser and dropping funnel, and directly add 80g of phosphorus pentasulfide under stirring; The quality of the mass is 0.5% of the mass of phosphorus pentasulfide, the catalyst hydroxymethylpyridine is selected, and the temperature is controlled to add the catalyst hydroxymethylpyridine at 30° C., stirring; the molar ratio of phosphorus pentasulfide and dehydrated alcohol is 1: 4.2 to select dehydrated alcohol, dropwise Dehydrated ethanol, the temperature is controlled at 40 ° C, after the dropwise addition, keep warm for 60 minutes, cool to room temperature, filter to obtain light-colored and transparent O, O-diethyl phosphorodithioate (abbreviated as ethyl sulfide, i.e. filtrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com