Preparation method and application of iron-supported titanium dioxide nanotubes with catalytic oxidation activity

A titanium dioxide, catalytic oxidation technology, applied in refining to remove heteroatoms, etc., can solve the problem of difficult removal of sulfur-containing species, and achieve the effect of high yield and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

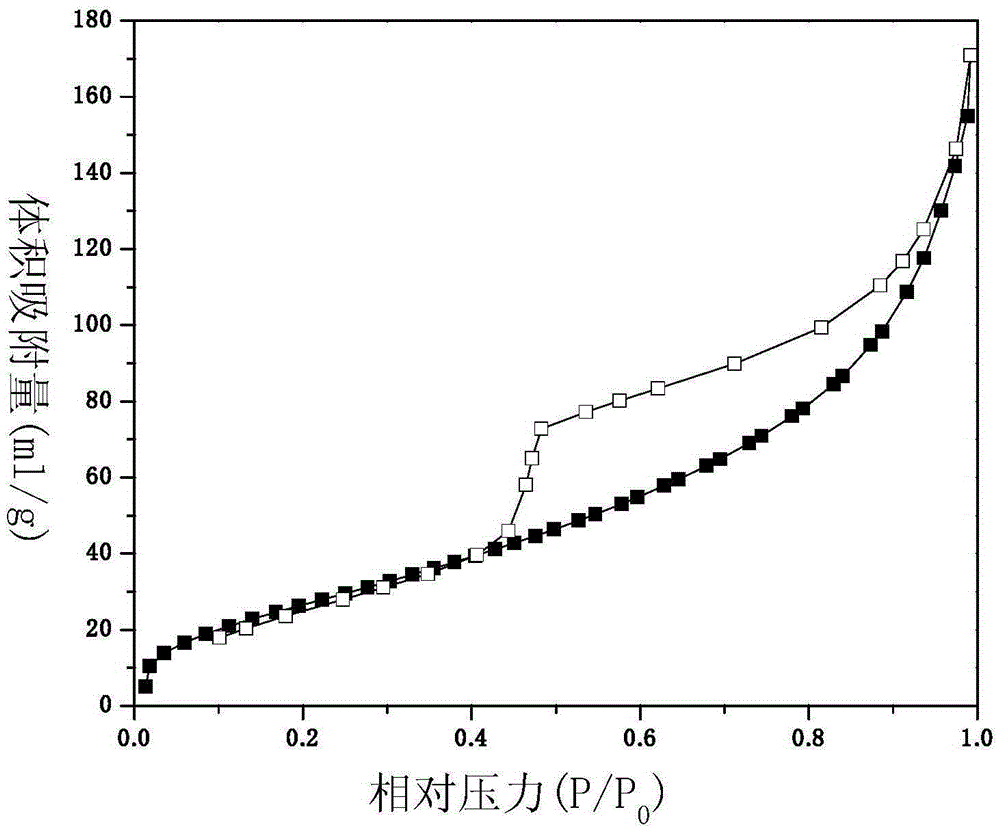

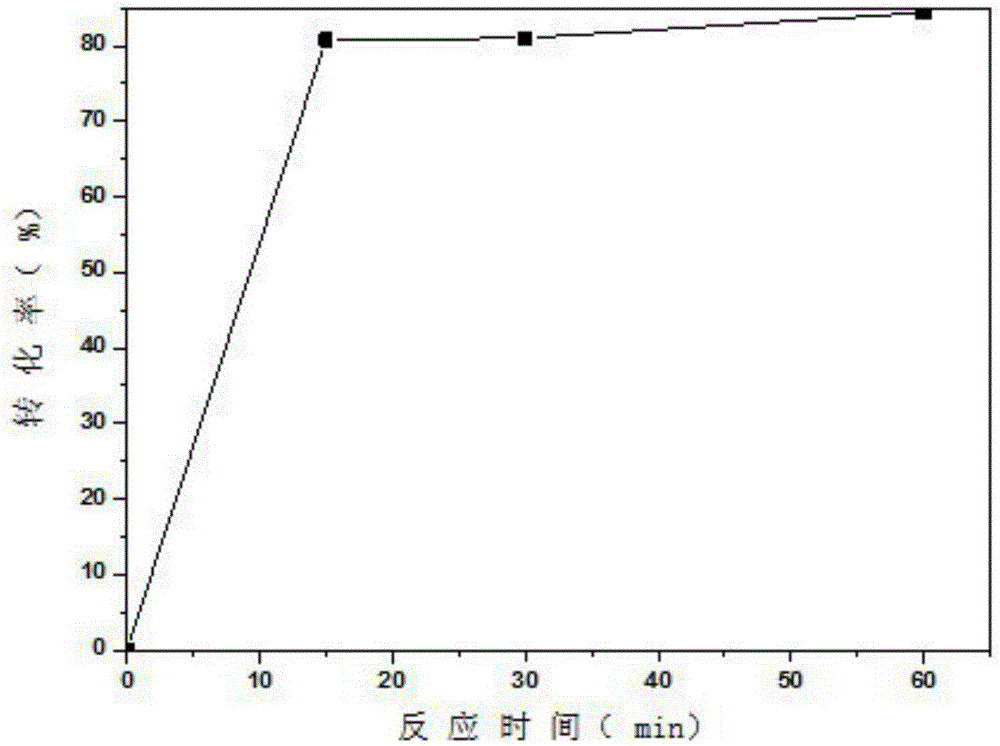

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: a kind of preparation method of the iron-supported titanium dioxide nanotube with catalytic oxidation activity of the present embodiment is carried out through the following steps:

[0021] 1. Treat the titanium source to obtain titanium dioxide crystals with anatase as the main crystal form;

[0022] 2. Weigh the titanium dioxide crystal powder obtained in the above steps, place it in the Teflon reactor lining containing 10M NaOH solution, stir it magnetically for 30 minutes at room temperature, then transfer the solution to the autoclave, and place it at 150 Under the environment of ℃, place it for 48 hours, and after the reaction, sodium-type titanium dioxide nanotubes are obtained; wherein the mass volume ratio of titanium dioxide crystals to NaOH is 1g:20-25mL;

[0023] 3. Wash the sodium-type titanium dioxide nanotubes obtained in the above step 2 repeatedly with deionized water until the pH of the solution reaches 7, filter with suction, ...

specific Embodiment approach 2

[0026] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the method for processing the titanium source described in step one is: take the titanium source, add deionized water, stir and hydrolyze, suction filter, dry, and dry at 500 Calcining at ℃ for 5 hours to obtain titanium dioxide crystals mainly in anatase crystal form; wherein, the volume ratio of titanium source to deionized water is 1:1-3; the titanium source is n-tetrabutyl titanate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass volume ratio of titanium dioxide crystals and NaOH described in step 2 is 1 g:21-24 mL. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com