Method for preparing purified petroleum benzine and concentrating thiofuran by cruden benzol

A technology for thiophene and crude benzene, which is applied in the field of preparing pure benzene and concentrated thiophene from crude benzene, can solve problems such as harsh technical conditions, equipment corrosion, environmental pollution, etc., and achieves high product quality specifications, mild desulfurization conditions, and simple process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

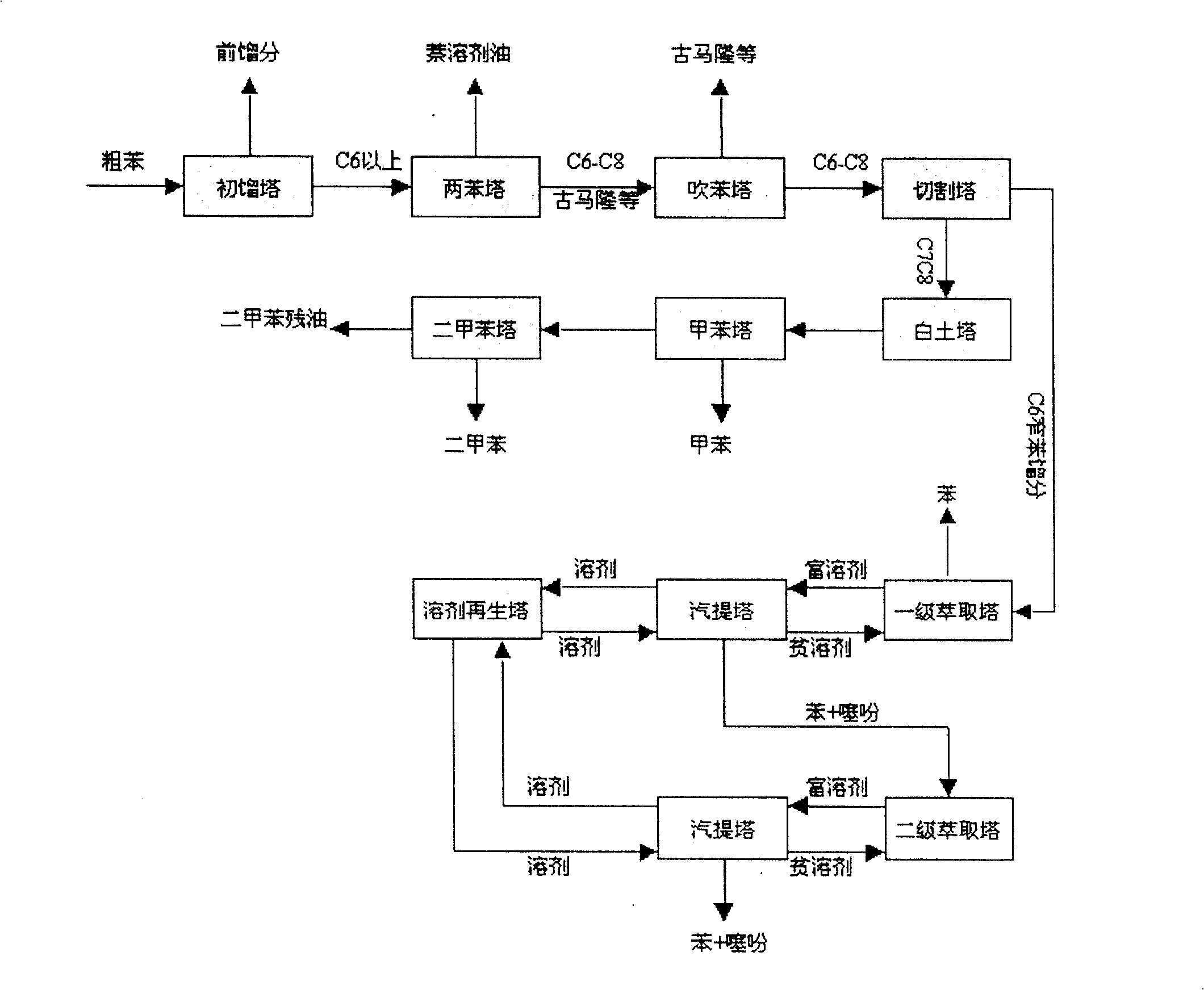

Image

Examples

Embodiment 1

[0016] Use coked light benzene containing 3350mg / L thiophene, that is, the benzene-toluene-xylene mixed fraction from the crude benzene treated by the pre-fractionation unit as raw material, which contains 80.7% of benzene, 15.4% of toluene, 3.5% of xylene, N -Methylpyrrolidone is the extraction agent, the actual number of plates in the rectification tower is 45, the solvent ratio (i.e. the ratio of the volume flow rate of the extraction agent to the raw material coking light benzene) is 3, and the reflux ratio is under the condition of 3: 1, the control The temperature at the top of the tower is 78--80°C, and the temperature at the bottom of the tower is 159--165°C, then the concentration of thiophene in the coked benzene in the overhead fraction of the extractive distillation tower drops to about 189mg / L. The bottom liquid of the tower is taken out and enters the solvent recovery tower, and the concentrate of thiophene is obtained at the top of the recovery tower, and the ben...

Embodiment 2

[0018] Use the benzene-toluene system containing 4250mg / L thiophene, that is, the fraction obtained from crude benzene through the pre-fractionation unit and benzene cutting and separation as the raw material, which contains 87.2% of benzene, 12.4% of toluene, and N,N-dimethylformamide As the extraction agent, the actual number of plates in the rectification tower is 40, the solvent ratio (i.e. the ratio of the volume flow rate of the extraction agent to the raw material) is 3, and the reflux ratio is 3:1, the temperature at the top of the control tower is 78-- 80°C, and the temperature of the tower bottom is 149--155°C, the concentration of thiophene in the coked benzene in the overhead fraction of the extractive distillation tower will drop to about 165mg / L. The bottom liquid of the tower is taken out and enters the solvent recovery tower, and the concentrate of thiophene is obtained at the top of the recovery tower, and the benzene containing thiophene concentration of 2.12%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com