Method for preparing O, O-diethyl chlorothiophosphate

A technology of diethyl phosphorothioate and diethyl phosphorodithioate, which is applied in the field of ethyl chloride, can solve the problems of high production cost, heavy pollution, complicated process, etc., so as to improve use efficiency and reduce production Cost, the effect of improving the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

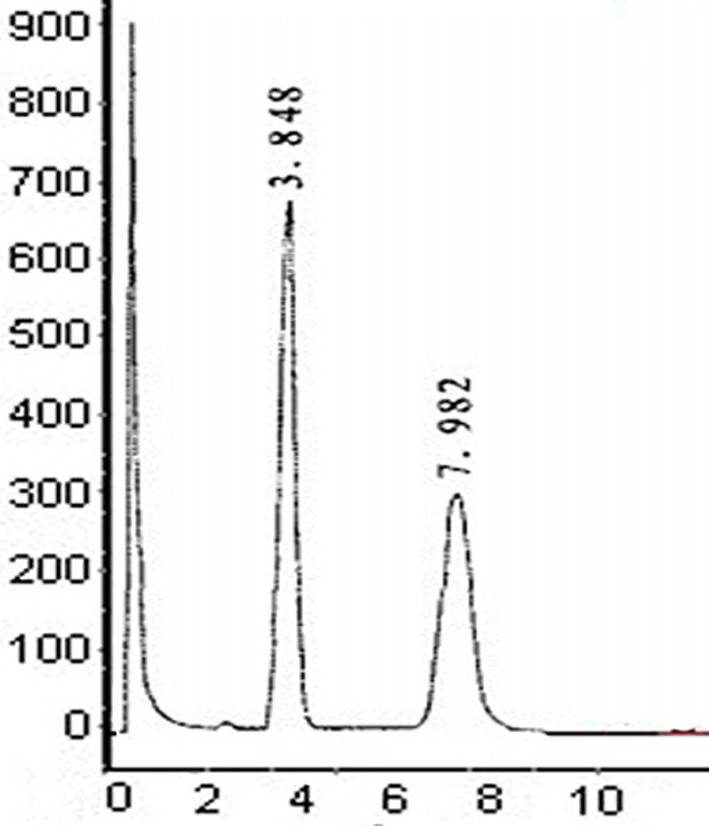

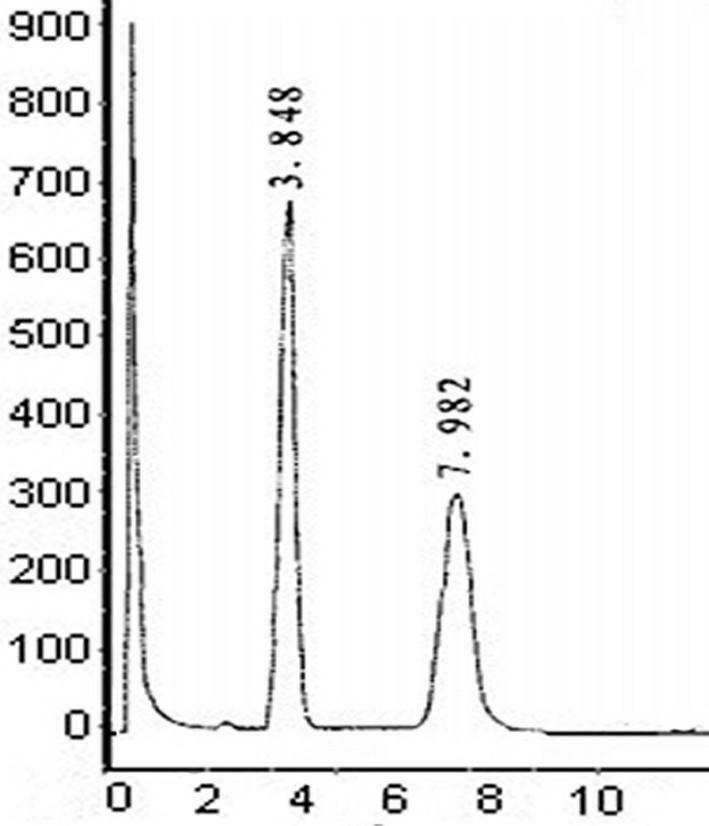

Image

Examples

Embodiment 1

[0010] Example 1: Put 400 parts of phosphorus pentasulfide into 300 parts of O, O-diethyl phosphorodithioate, add dropwise 300 parts of absolute ethanol, and keep warm for 30 minutes to obtain 1260 parts of O, O-diethyl disulfide Phosphoric acid ester, content 95%, pump 900 parts of O, O-diethyl phosphorodithioate into the chlorination kettle; lower the ethyl sulfide to below 30°C, start feeding chlorine gas, and control the temperature at Between 30 and 60°C, after feeding 300 parts of chlorine gas, check the specific gravity of the material, and control it between 1.280-1.290. After the chlorine gas is passed through, transfer all the materials into a high-temperature chlorination kettle, and add 1 part of catalyst trichlorination Phosphorus, heat up to 90°C, start to slowly feed 40 parts of chlorine gas, keep the temperature between 90 and 110°C per hour, keep warm for 2 hours after the chlorine is passed through, cool down to below 50°C, and transfer to the crystallization ...

Embodiment 2

[0011] Example 2: Put 450 parts of phosphorus pentasulfide into 350 parts of O, O-diethyl phosphorodithioate, add dropwise 350 parts of absolute ethanol, and keep warm for 30 minutes to obtain 1320 parts of O, O-diethyl disulfide Phosphoric acid ester, content 94.8%, pump 950 parts of kgO,O-diethyl phosphorodithioate into the chlorination kettle; lower the ethyl sulfide to below 30°C, start feeding chlorine gas, and control the temperature at Between 30°C and 60°C, after feeding 350 parts of chlorine gas, check the specific gravity of the material and control it at 1.283, stop the chlorine feeding, and transfer the material into a high-temperature chlorination kettle; Raise the temperature to above 60°C, start to slowly feed chlorine gas at 30 parts / hour, after 2 hours, the temperature rises to 90-110°C and keep warm for 2 hours, check the material, the sulfur is crystallized, then start to cool down to below 50°C, transfer to In the crystallization kettle; after transferring ...

Embodiment 3

[0012] Example 3: Put 500 parts of phosphorus pentasulfide into 450 parts of O, O-diethyl phosphorodithioate, add dropwise 460 parts of absolute ethanol, and keep warm for 30 minutes to obtain 1380 parts of O, O-diethyl disulfide Phosphoric acid ester, content 95.6%, pump 1000 parts of O, O-diethyl phosphorodithioate into the chlorination kettle; lower the ethyl sulfide to below 30°C, start feeding chlorine gas, and control the temperature at Between 30 and 60°C, after feeding 400 parts) of chlorine gas, check the specific gravity of the material, control it between 1.283, stop the chlorine feeding, and transfer the material into a high-temperature chlorination kettle; after the transfer is completed, put in 5 parts of catalyst C 1 -C 10 Fatty alcohol, when the temperature is raised above 60°C, 30 parts / hour of chlorine gas is introduced slowly. After 2 hours, the temperature rises to 90-110°C and is kept for 2 hours. After testing the material, the sulfur is crystallized and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com