Tunnel inverted arch construction die carrier and tunnel inverted arch construction process

The technology of a formwork and a tunnel is applied in the field of tunnel inverted arch construction formwork and tunnel inverted arch construction technology, and can solve problems such as long time required for supporting formwork, difficult construction quality assurance, and difficulty in formwork installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

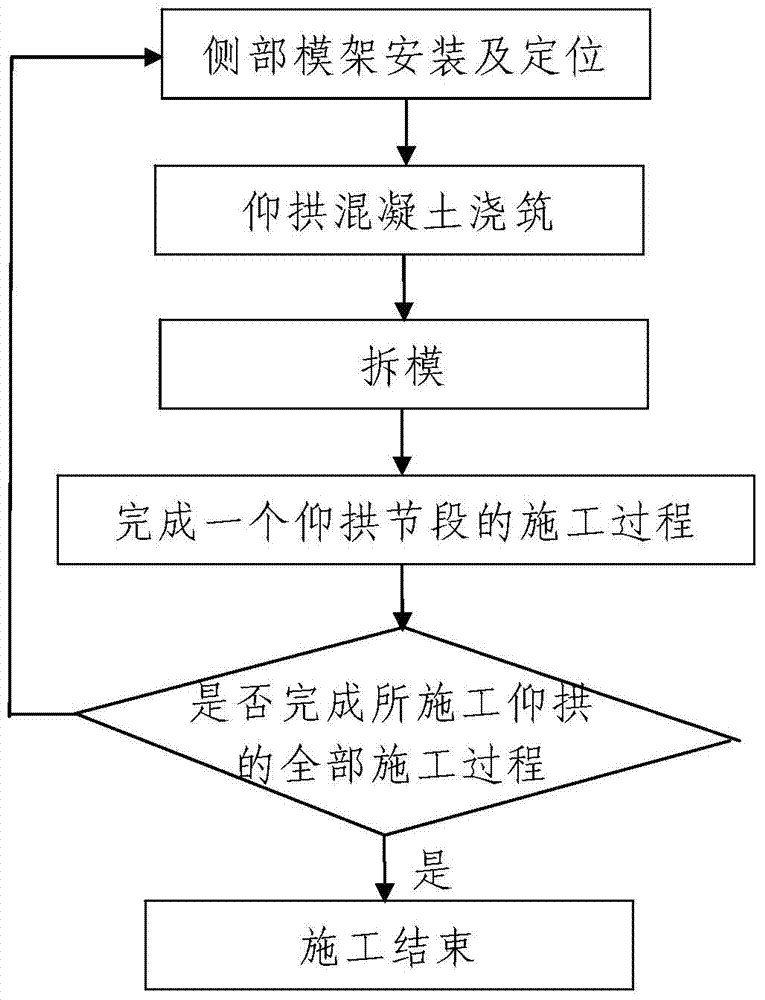

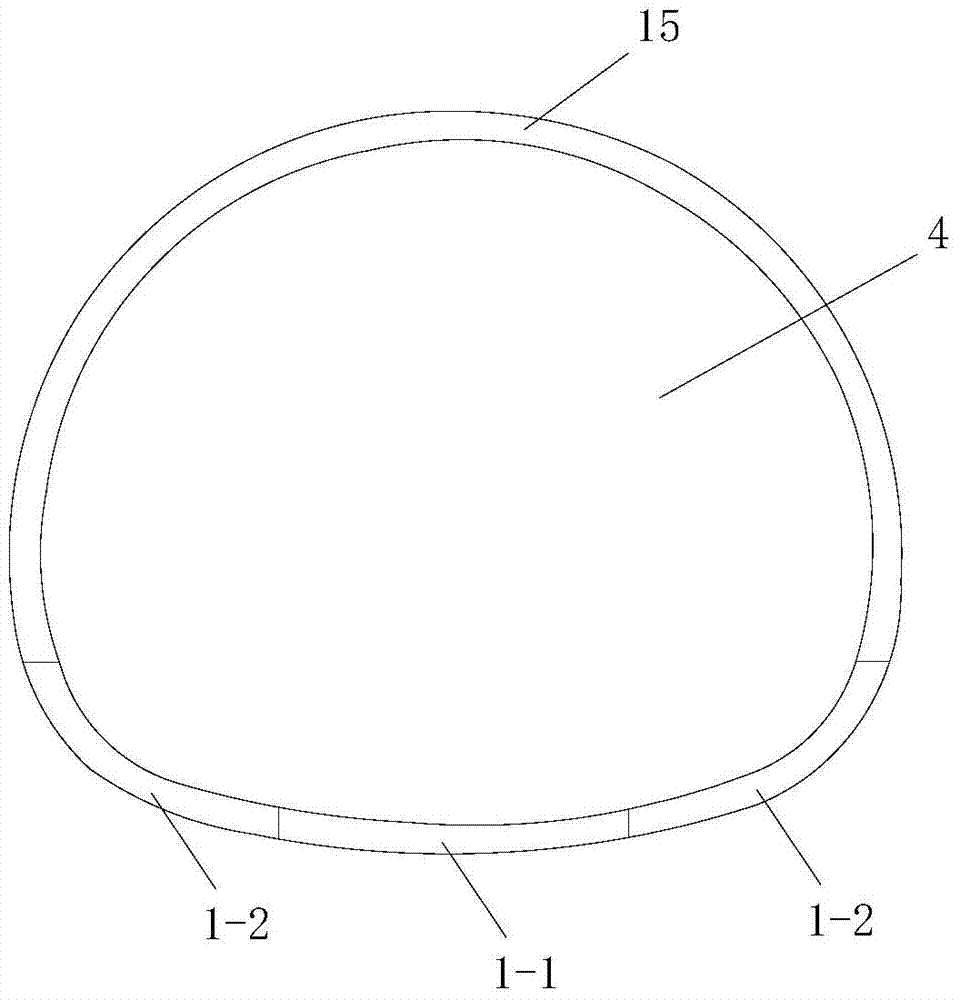

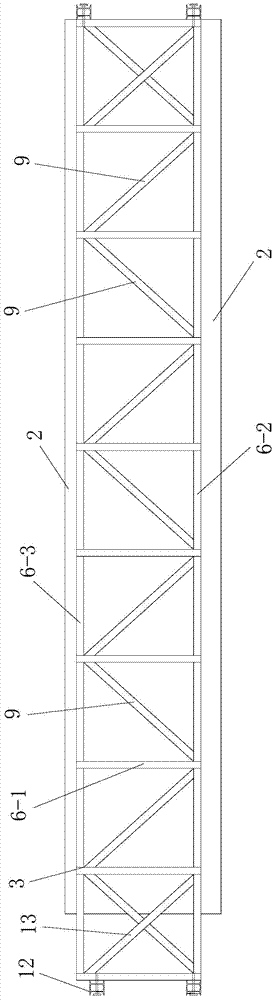

[0082] Such as figure 1 , figure 2 and image 3As shown, the constructed inverted arch is divided into a central arch section 1-1 and two side arch sections 1-2 respectively located on the left and right sides of the central arch section 1-1 along the transverse width direction of the constructed tunnel hole 4. The structures of the side arch sections 1-2 are the same and they are arranged symmetrically. The construction formwork of the tunnel invert arch according to the present invention includes two side arch sections 1 respectively for the inverted arch to be constructed. -2 the side formworks for construction, the two side formworks have the same structure and are arranged symmetrically, and the two side formworks are arranged along the longitudinal direction of the tunnel hole 4 to be constructed. The side formwork includes an arc-shaped steel formwork 2 for shaping the upper surface of the side arch section 1-2, a formwork support frame 3 that is positioned above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com