Gallery separating type steel formwork trolley

A separate, steel formwork technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as poor operational flexibility, inapplicability, and lack of steering functions, and achieve fast masonry speed, easy maintenance, and increased mobility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

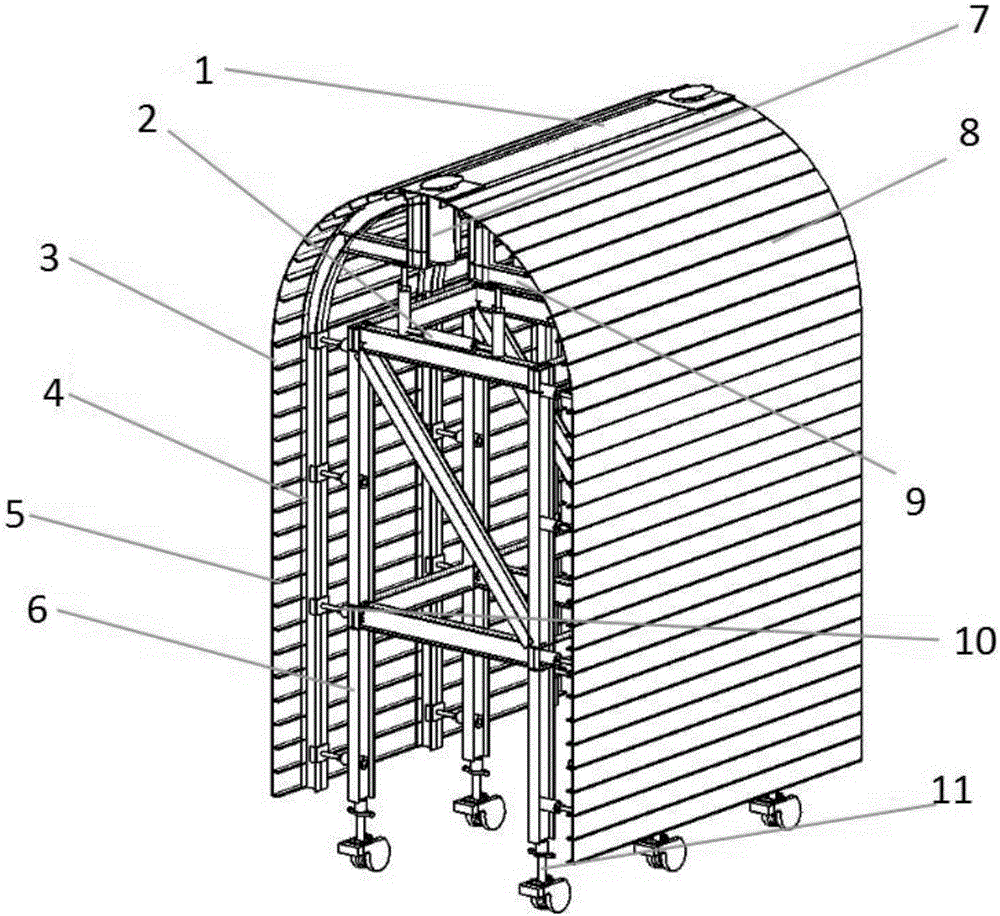

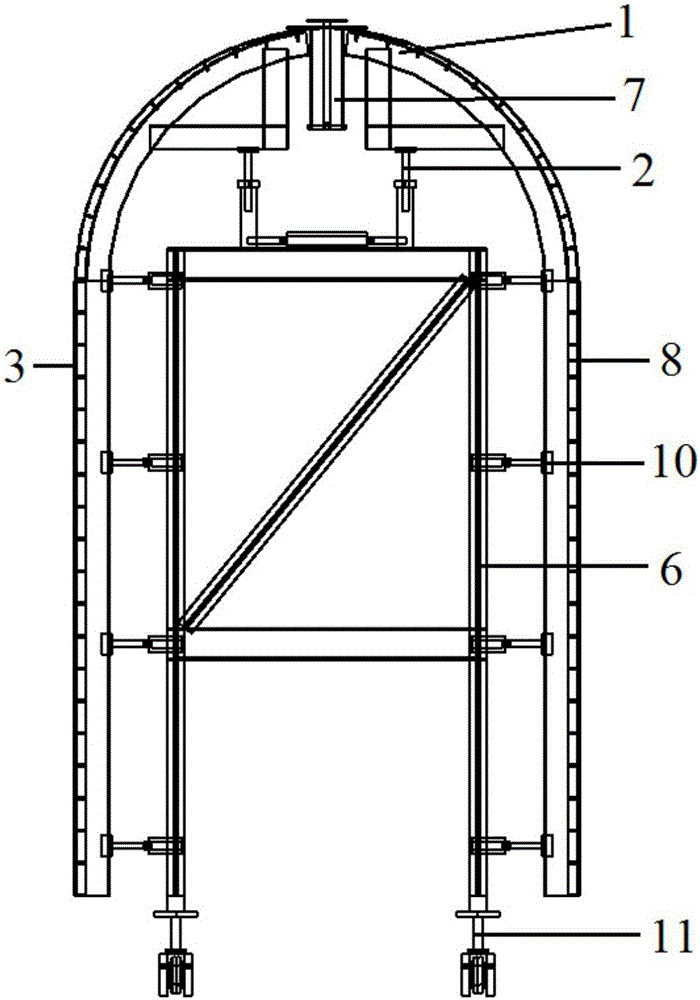

[0030] Corridor separated steel formwork trolley, its structure is as follows Figure 1-2 As shown, it includes a door frame body 6 and a top formwork 1 and a side formwork positioned on the door frame body 6. The side formwork is provided with two pieces, including a left formwork 4 and a right formwork 8, and a left formwork 4 and a right formwork 8. It is connected with the door frame body 6 through the side formwork hydraulic device 10 and the vault hydraulic device 2. The top formwork 1 is embedded in the middle of the upper part of the left formwork 4 and the right formwork 8. The top formwork 1 is equipped with a detachable grouting valve 7, and the gantry The hydraulic traveling device 11 is housed under the body 6, including rollers and a hydraulic mechanism for adjusting the height of the mast body.

[0031] The door frame body 6 adopts the I-shaped steel beams welded by steel plates to be connected by bolts. Hydraulic traveling device 11 is installed on the column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com