Patents

Literature

39results about How to "Masonry is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powder ash air-entrained concrete building block and preparation method thereof

InactiveCN101913902ALose weightSmall sizeSolid waste managementCeramic shaping apparatusFire protectionEnergy consumption

The invention discloses a powder ash air-entrained concrete building block and a preparation method thereof. The powder ash air-entrained concrete building block is prepared by adding water to 100-200kg of cement, 350-380kg of lime, 1350-1550kg of powder ash, 1.4-1.5kg of aluminite powder and 0.195-0.205kg of foam stabilizers. The preparation method comprises the following steps of raw material preparation, metering, stirring, pouring in a mould, standing for procuring, demoulding, swinging to cutting parts for cutting, steaming and curing in a reactor and finished product warehousing. The building block has the advantages of light weight, good heat insulation, machinability, convenient construction, wide source of raw materials, high production efficiency, low production energy consumption and good fire protection and sound insulation, wherein the dry volume density of the building block is 500-700kg / m3 and amounts to one third of a clay brick; as a large quantity of air holes and micro holes are arranged inside the building block, the building block has favorable heat insulation; as coarse aggregates are not used, the building block has favorable machinability, can be sawn, dug,drilled and nailed and bonded by bonding materials, thereby providing beneficial conditions for building construction; and the building block belongs to a green environmental-protection product.

Owner:舟山市宇锦新型墙体材料有限公司

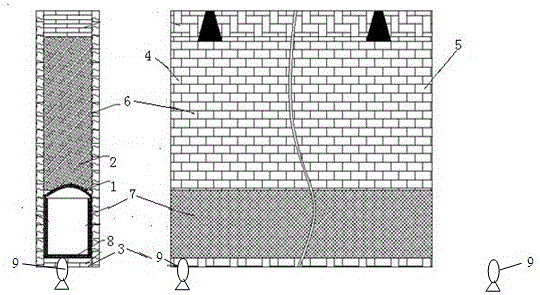

Heat-insulating double-layered wall for buildings

InactiveCN101775860AImprove thermal insulationImprove integrityWallsClimate change adaptationBrickEngineering

The invention discloses a heat-insulating double-layered wall for buildings, which consists of hollow building blocks, heat-insulating boards, reinforcing steel bars and concrete. The double-layered wall has the following characteristics that: the longitudinal reinforcing steel bars are arranged in top building block slab grooves of the double-layered wall, and are tied together by the latitudinal reinforcing steel bars. The heat-insulating double-layered wall is built with the hollow building blocks, the hollow building block comprises a top slab, two supporting legs and a reinforcing rib, and the top slab is provided with two or more ribs, between which a top slab groove is formed. When the heat-insulating double-layered wall is built, the longitudinal reinforcing steel bars are arranged in the top building block slab grooves of the wall body every 3 to 5 bricks, and are tied together by the latitudinal reinforcing steel bars, the concrete is poured in the top building block slab grooves to form reinforced concrete belts, and the inner and the outer wall bodies are connected, so that the heat-insulating double-layered wall is formed. The heat-insulating boards can be inserted in the hollow building blocks and between the two wall bodies in order to meet the requirement on the thermal performance of the energy-saving wall body. because the hollow building block is a light building block, the overall load of the building can be effectively reduced, and the cost of the building can be reduced.

Owner:吴方伯

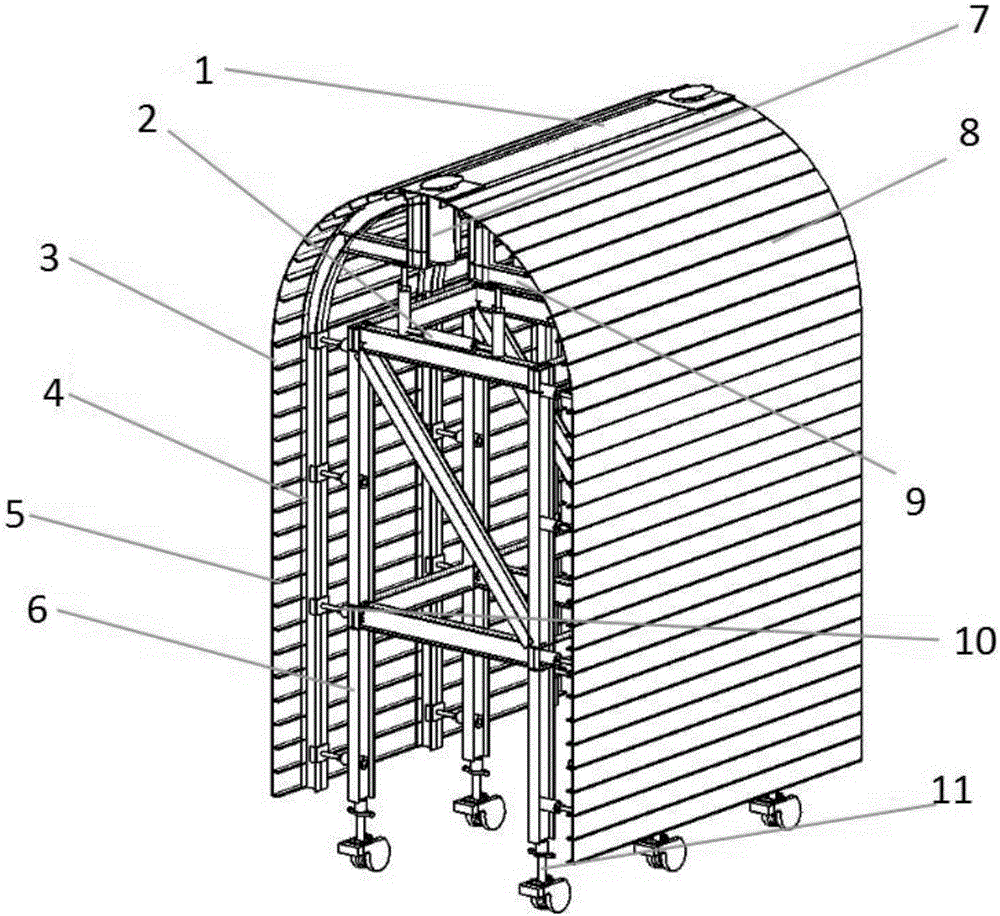

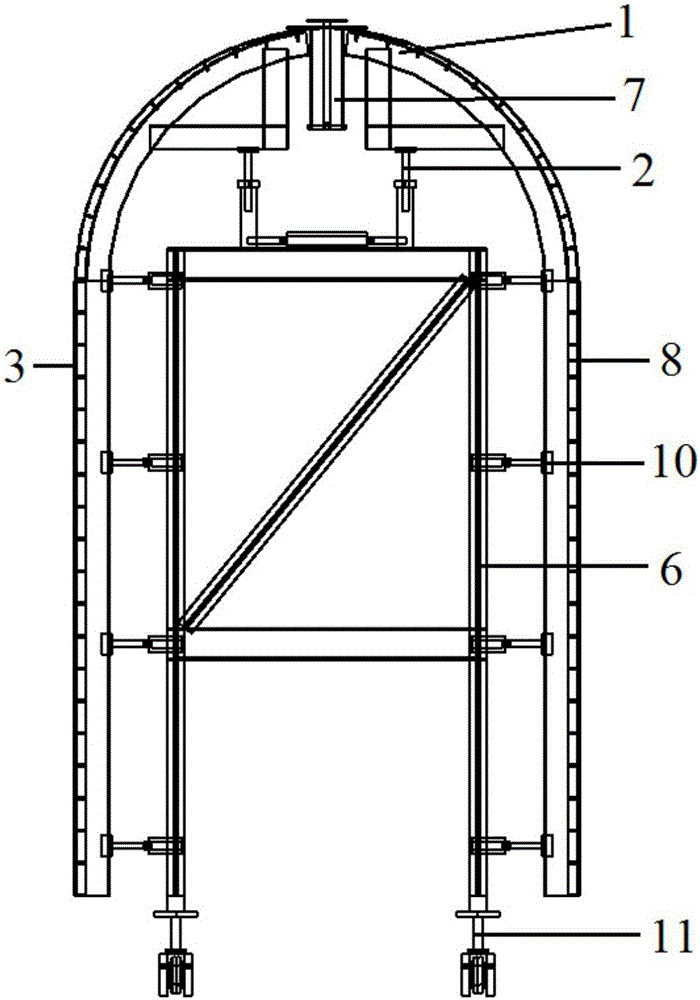

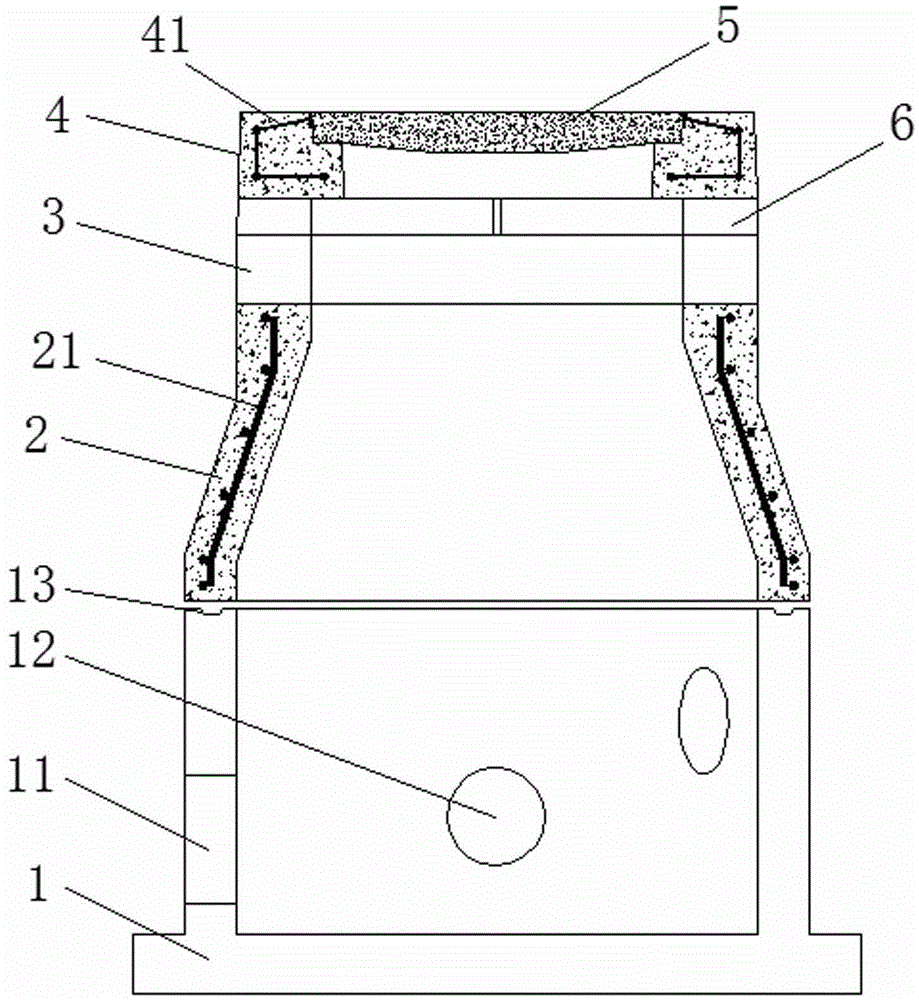

Gallery separating type steel formwork trolley

InactiveCN106640138AImprove the finishGuaranteed integrityUnderground chambersTunnel liningUltimate tensile strengthClerestory

The invention relates to a gallery separating type steel formwork trolley which comprises a portal body, a top formwork and two side formworks. A hydraulic traveling device is installed below the portal body; the top formwork and the two side formworks are located on the portal body; the side formworks are connected with the portal body through a side formwork hydraulic device and a vault hydraulic device; and the top formwork is embedded between the upper portions of the two side formworks. Compared with the prior art, the large steel formworks are adopted, so that the gallery separating type steel formwork trolley is simple in structure, high in strength, low in weight, and adjustable and high in lining quality; the mechanization construction degree is high, labor intensity is relieved, and work efficiency is improved; the two side formworks shrink inwards, the deformation space is large, collision is effectively reduced during demoulding and movement, and the movement speed is increased; and detachable grouting valves are arranged on the top formwork, so that the pouring quality is improved and the demoulding difficulty is reduced.

Owner:中国人民解放军63926部队

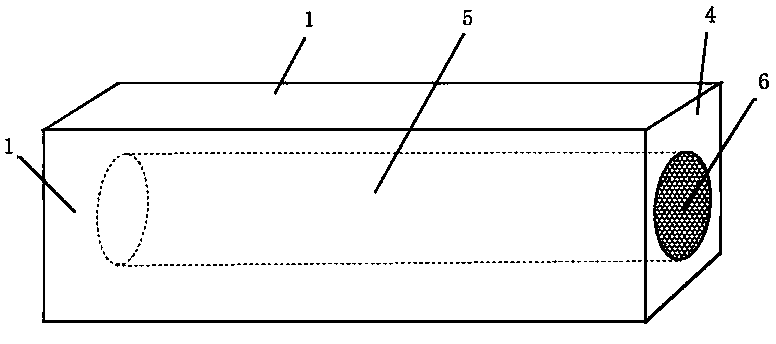

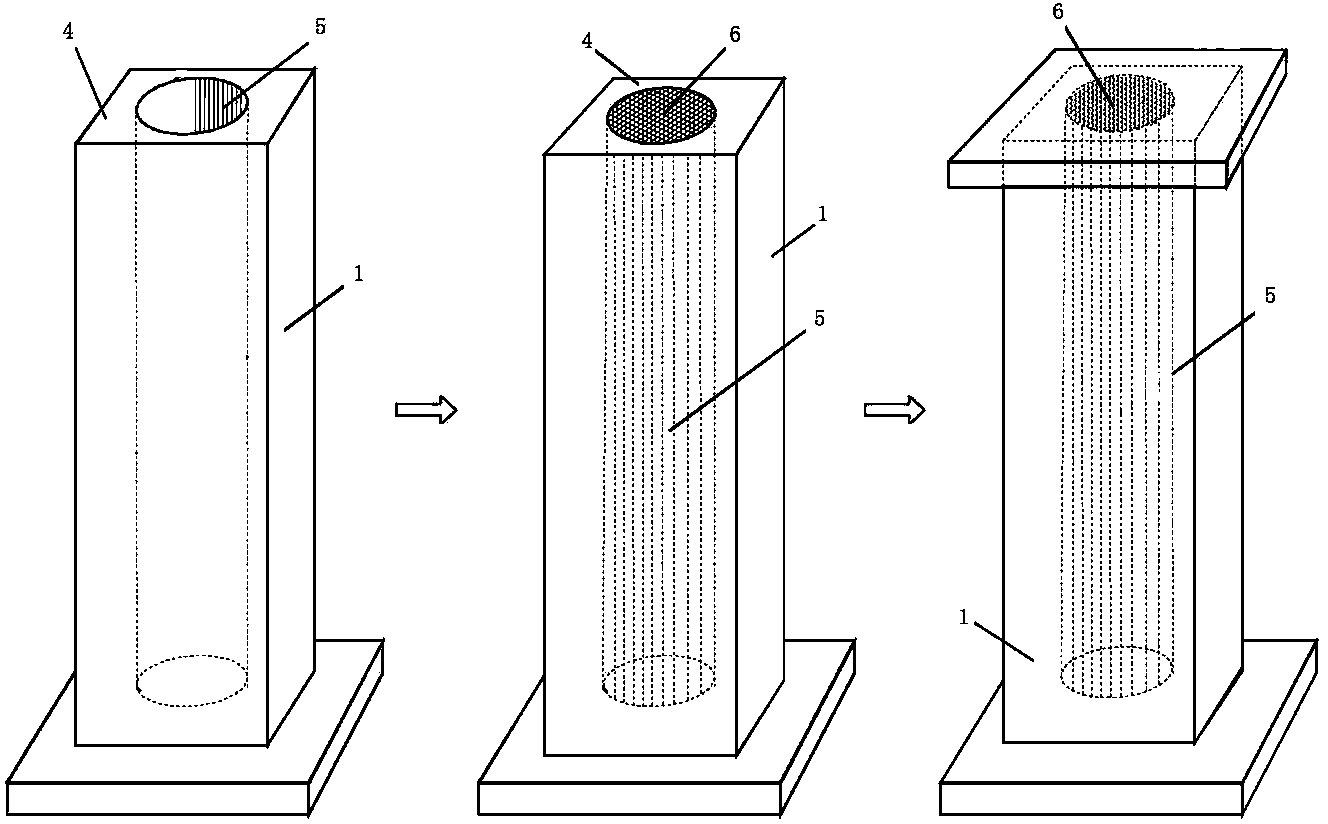

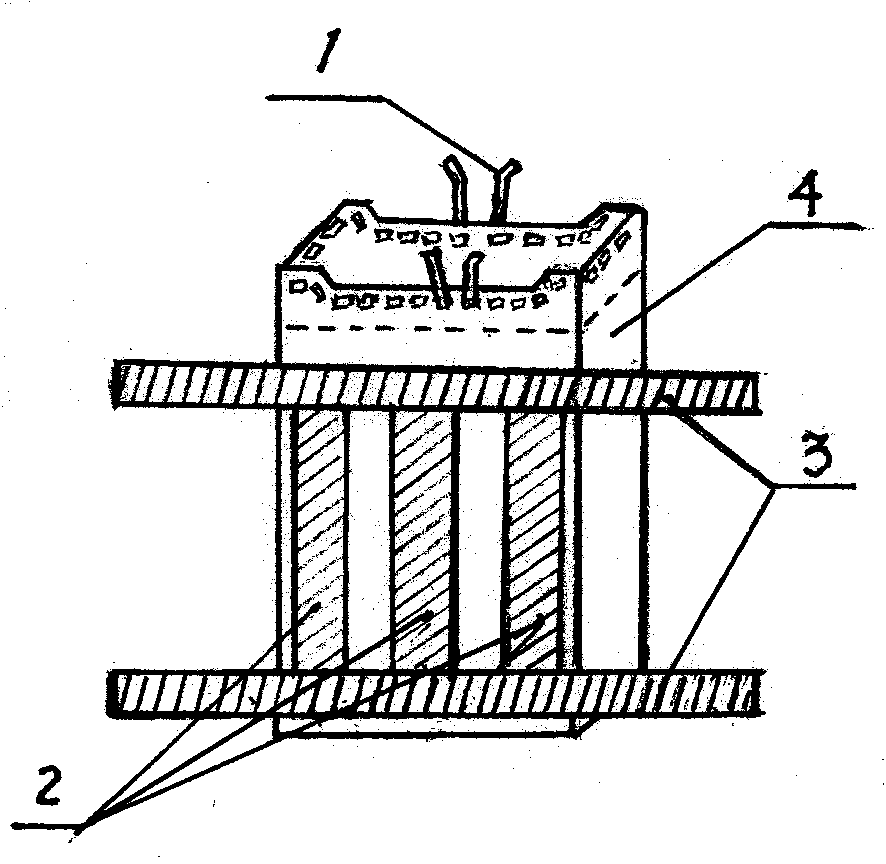

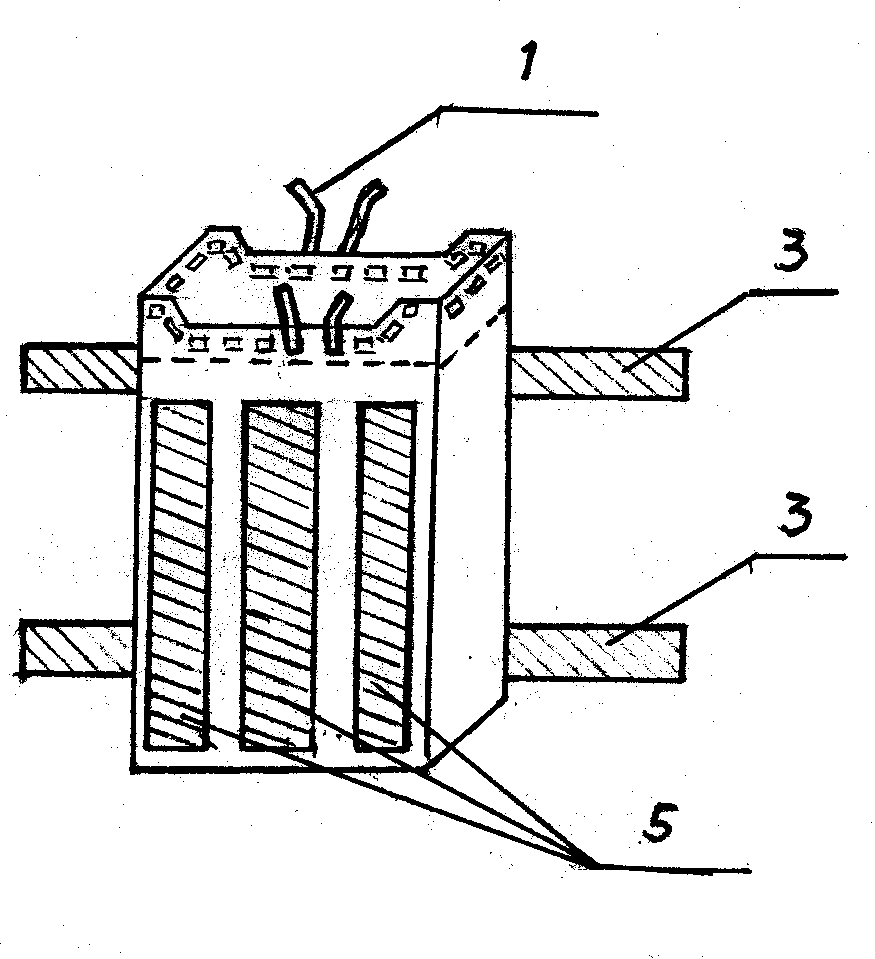

Multifunctional foamed concrete composite self-heat-preservation block and forming method thereof

ActiveCN103628614ADouble the effect of self-insulation and energy savingUnder the premise of being ecological,Construction materialFoam concreteMaterials science

The invention relates to a multifunctional foamed concrete composite self-heat-preservation block and a forming method thereof. The center of a block body is provided with a middle cavity for filling or pouring foamed materials, and the hollow cavity is a through hole with openings located in end faces of double sides, or a blind hole with an opening located in the end face of one side or a blind hole with an opening located in the side wall of one side; the middle cavity is filled with the foamed materials to form a double-foamed block, or the middle cavity is filled with the foamed materials and naturally shrinks to form a double-foamed block with a hollow chamber. The forming method comprises the steps: firstly, making a die box of the block as required, then, sorting, stirring, foaming and pouring in the die box, and distilling by using an autoclave to obtain a hollow shell, wherein the hollow shell is solid outside and is provided with the middle cavity; and (2) pouring the foamed materials into the middle cavity of the hollow shell in a physical or chemical foaming way according to the ratio of less than 300kg / cubic capacity, and then, forming through natural curing or secondary distilling, wherein the hollow shell is prepared in the step (1). The inner hole of the block provided by the invention is subjected to hollow treatment, so that the heat self-preservation and energy saving effects are good.

Owner:段志祥

Heat insulation building material

InactiveCN103641416AQuality assuranceGuaranteed mechanical strengthSolid waste managementFoam concreteBuilding product

The invention relates to a heat insulation building material which comprises the following raw materials by mass percent: 20-40% of fine sand, 30-50% of cementing material, 10-40% of heat insulation material, 10-30% of mineral admixture and 5-10% of other auxiliary materials. A production technology of the heat insulation building material comprises the steps of mixing and stirring a shell cementing material, producing foam concrete, cutting and fixing the foam concrete and a heat insulation core body of a polystyrene foam plastic board, pouring, vibrating and molding shell slurry, and maintaining building blocks. The heat insulation building material can be used for replacing a great deal of solid clay bricks, thus saving a great deal of energy and land for China, being capable of consuming a great deal of industrial solid wastes and being beneficial to the environmental protection. The produced construction product has the excellent characteristics of being good in heat insulation property, light in self weight, high in strength, waterproof, impervious, low in shrinking percentage, long in service life, simple in construction and the like, thus being beneficial to the development of building energy conservation.

Owner:肖新颖

Aerated concrete block and preparation method thereof

InactiveCN101913903ALose weightSmall sizeCeramic shaping apparatusCeramicwareSteam pressurePolymer science

The invention discloses an aerated concrete block and a preparation method thereof. The aerated concrete block is prepared from the following components: 250-320kg of cement, 350-400kg of lime, 1400-1600kg of silica sands, 1.45-1.6kg of aluminium powder, 0.195-0.205kg of foam stabilizers and water. The preparation method comprises the following steps: raw material preparing, metering, stirring, pouring into molds, standing and procuring, demolding, lifting to a cutting part for cutting, steam pressure curing in a kettle and finished product warehousing. The block has the advantages of light weight, good thermal insulation property, processability, convenient construction, wide raw material sources, high preparation efficiency, low preparation energy consumption, environment-friendliness and good fireproofing and soundproofing properties, specifically, the bulk density of the block is 500-700kg / m3, which is equivalent to 1 / 3 of the bulk density of the clay bricks; the block is provided with plentiful pores and micropores inside, thus having good thermal insulation property; the block dispenses with coarse aggregates, thus having good processability, being capable of being sawed, planed, drilled and stapled, being capable of being bonded by bonding materials and providing favorable conditions for building construction.

Owner:舟山市宇锦新型墙体材料有限公司

Lightweight building gypsum building block and production method thereof

InactiveCN107352933AMeet the production process requirementsSmooth production processCeramicwareCellulosePore distribution

The invention discloses a lightweight building gypsum building block and a production method thereof. The lightweight building gypsum building block is molded by mixing the following raw materials in parts by weight: 75-85 parts of phosphogypsum, 10-15 parts of fly ash, 32-45 parts of water, 0.5-1.0 parts of cellulose, and 8-10 parts of a comprehensive foaming delayed coagulant. Compared with the prior art, the gypsum solidification time is 8-12 min, the production technology requirement of the gypsum building block can be satisfied, and the smooth operation of the production technology is guaranteed. The aperture of a foaming plasterboard is 0.1-0.18 cm, the pore distribution is uniform, the enough intensity and breaking-resistant strength of the plasterboard can be guaranteed, and the surface is flat and smooth. Through multiple tests, the compressive strength of the product is 3.9-4.1 MPa, the flexural intensity is 2.0-2.1 MPa, the softening coefficient is 0.68, the unit solid weight is decreased by 20-30%, the heat conduction coefficient is between 0.086W( / m.k) and 0.13W( / m.k), sound insulation and heat insulation performances are obviously increased, through detection, the compressive strength is increased by 18.3%, and the flexural intensity is increased by 51.2%.

Owner:南充市高坪区江峰石膏有限公司

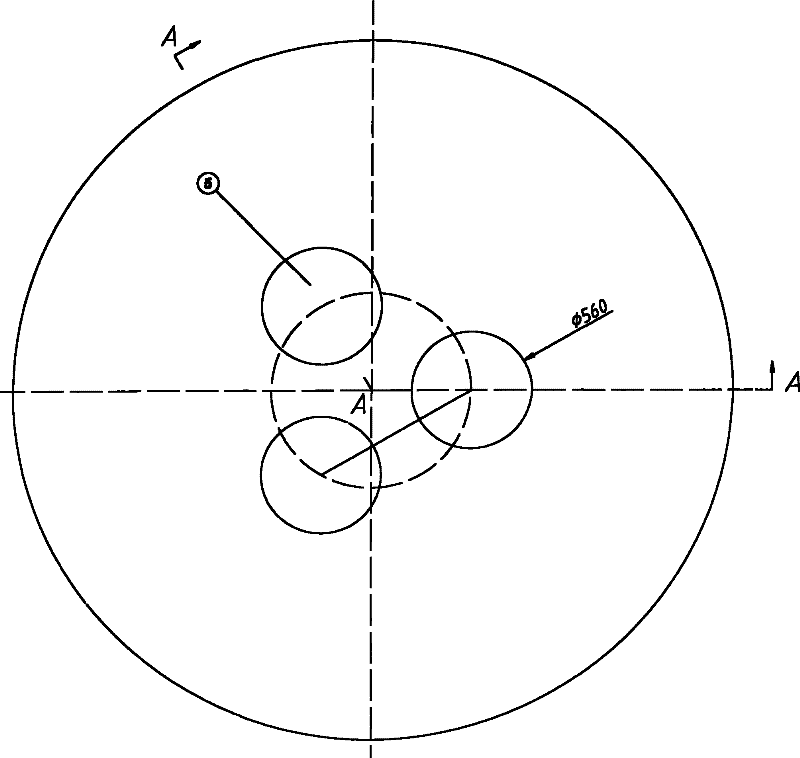

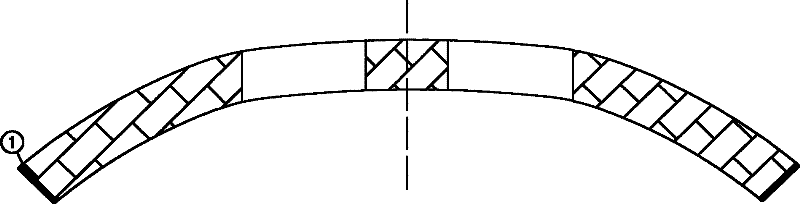

Combined arc furnace cover

InactiveCN102213545AEasy to manufactureSimple masonryLighting and heating apparatusElectric arc furnaceBrick

The invention discloses a combined arc furnace cover, which is assembled by two parts, namely a small furnace cover and a peripheral prefabricated part. Therefore, the small furnace cover on the top of the furnace, which is rapidly damaged, is convenient to replace directly on line. The traditional furnace cover is built by combining phosphate and high-alumina bricks. Compared with the traditional furnace cover, the arc furnace cover has the advantages of long comprehensive service life, convenience in building, simple replacement, simple production process and low production energy consumption.

Owner:张小旭

Steel ladle working lining building method

ActiveCN104384489AInhibition of hydrationService life is not affectedMelt-holding vesselsSlurryWater temperature

The invention relates to a steel ladle working lining building method, which sequentially comprises the following steps that 1, a steel ladle bottom working lining is built by magnesia calcium bricks or magnesia calcium carbon bricks in a dry way, and a steel ladle wall working lining is built by the magnesia calcium bricks or the magnesia calcium carbon bricks or using magnetite chrome fire clay or magnesia fire clay as bonding materials in a wet way; 2, after the steel ladle bottom working lining and the steel ladle wall working lining are built, the operation enters a baking stage within two hours. Further, before the steel ladle bottom working lining building in the first step, the magnetite chrome fire clay or the magnesia fire clay is uniformly mixed: dry mixed slurry materials are stirred by a slurry stirring machine for 3 to 5 minutes, then, water is added, the water adding quantity is 13+ / -2 percent, the water temperature is 20+ / -5 DEG C, the stirring is carried out while the water is added, and the stirring time is not less than three minutes after the water adding. The steel ladle working lining building method has the advantage that the building speed is high.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

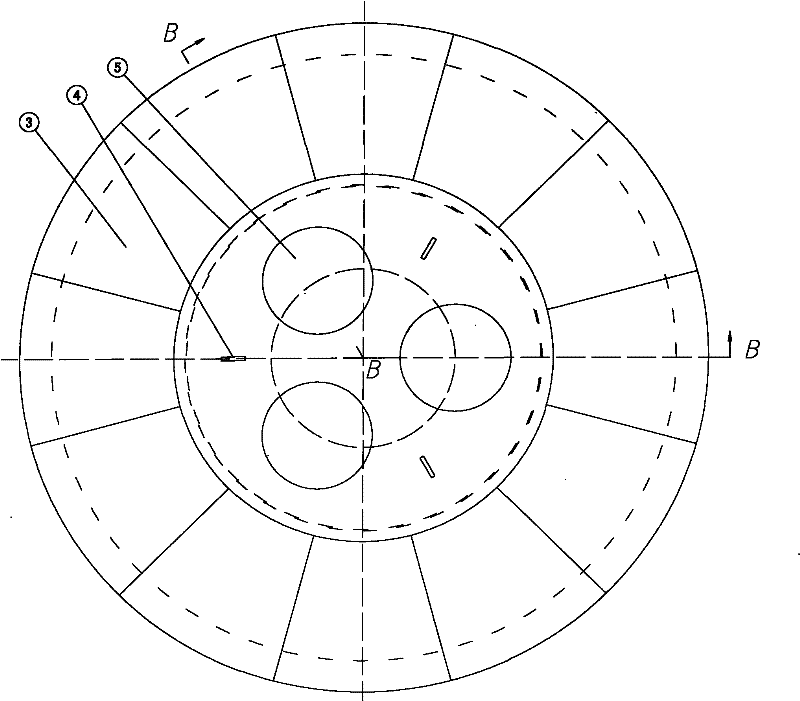

Split furnace cover

The invention provides a split furnace cover. The split furnace cover is composed of a furnace cover body and a detachable furnace cover center core body, wherein the furnace cover body is a chrome-corundum prefabricated member added with steel fibers; when the furnace cover core body is prefabricated, three electrode holes are reserved, the furnace cover body and the furnace cover core body are sealed by corundum castable, and three devices fixed with a furnace body are uniformly distributed on the furnace cover body. When the split furnace cover is used, the working capacity of all parts of the furnace cover can be maximized by replacing the furnace cover core body, waste is avoided, and continuous operation of smelting is promoted.

Owner:洛阳双兴电气科技有限公司

Inspection well

InactiveCN105386506AReduce labor intensitySimple preparation processSewerage structuresButt jointEngineering

The invention discloses an inspection well. The inspection well comprises a base, wherein the base is provided with a main pipe hole and multiple output holes communicated with users, a height adjusting part is arranged above the base, a top joint is arranged above the height adjusting part, a well lid is arranged on the top joint, and any two adjacent surfaces of the base, the height adjusting part and the top joint are connected through concrete; the height adjusting part comprises a reducing joint used for adjusting the diameter of the well, an adjusting joint used for increasing the height and an adjusting gasket. The assembly concrete inspection well is scientific and reasonable in design, convenient to construct, quick and flexible in installation, high in strength, good in anti-seeping performance, safe and reliable in well body quality, capable of facilitating butt joint of sewage pipes in units of a community and suitable for check of gathered sewage.

Owner:保定市华光市政建材有限公司

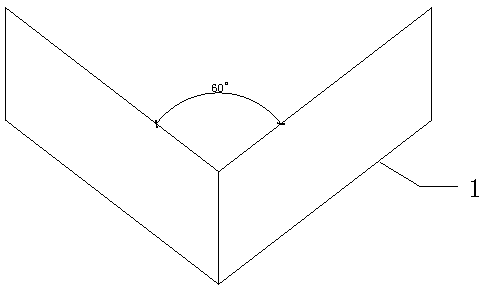

Masonry construction method of crown bricks among wall body beam, floor slab bottom and infilled wall

InactiveCN110206214AAdvantages of masonry construction methodsSimple structureCeramic shaping apparatusBuilding componentsFloor slabBrick

The invention provides a masonry construction method of crown bricks among a wall body beam, a floor slab bottom and an infilled wall, and the masonry construction method is suitable for sloping bondof the crown bricks of a housing building wall body. The masonry construction method is characterized by comprising the following steps that a, triangular concrete prefabricated block molds of the crown bricks among the wall body beam, the floor slab bottom and the infilled wall are manufactured; b, triangular concrete prefabricated block concrete is poured into steel plate frame molds and is compacted and leveled; c, the steel plate frame molds are removed, and triangular concrete prefabricated blocks are cured; and d, during masonry construction of the crown bricks among the wall body beam,the floor slab bottom and the infilled wall, the triangular concrete prefabricated blocks are filled in an inverted mode, and thus the crown bricks of the wall body can be closely combined. The masonry construction method of the crown bricks among the wall body beam, the floor slab bottom and the infilled wall has the advantages that the triangular concrete prefabricated block molds are simple instructure and convenient to manufacture, the triangular concrete prefabricated blocks are high in compactness, the masonry speed of the crown bricks among the wall body beam, the floor slab bottom andthe infilled wall is increased, the working efficiency is improved, and the engineering cost is lowered.

Owner:MCC5 GROUP CORP SHANGHAI

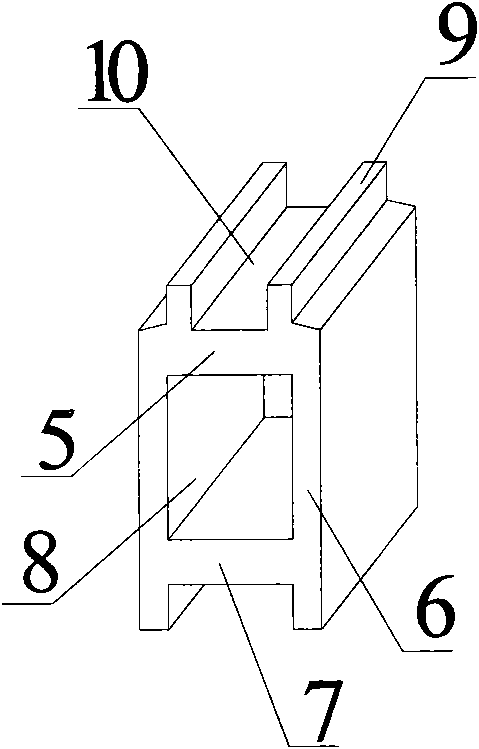

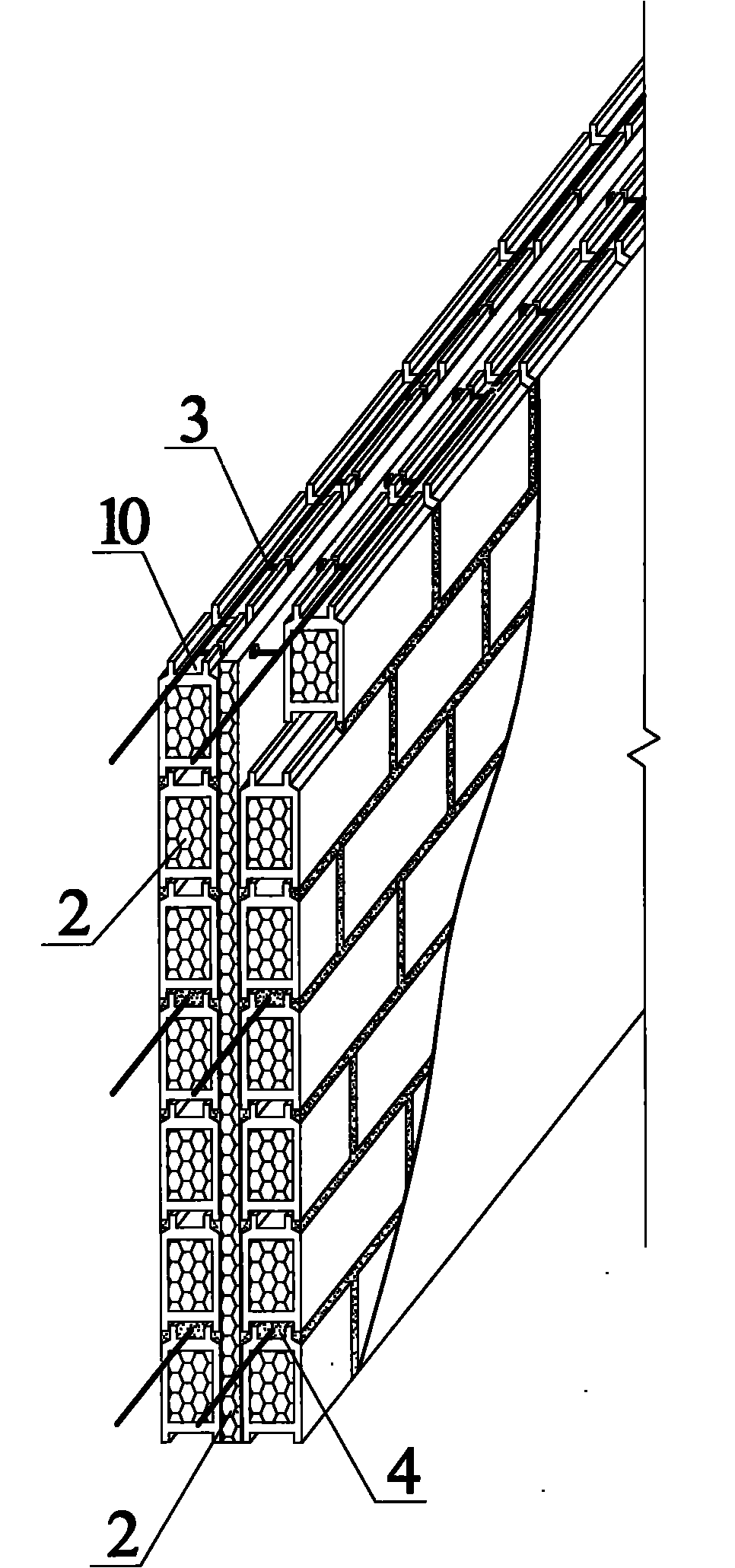

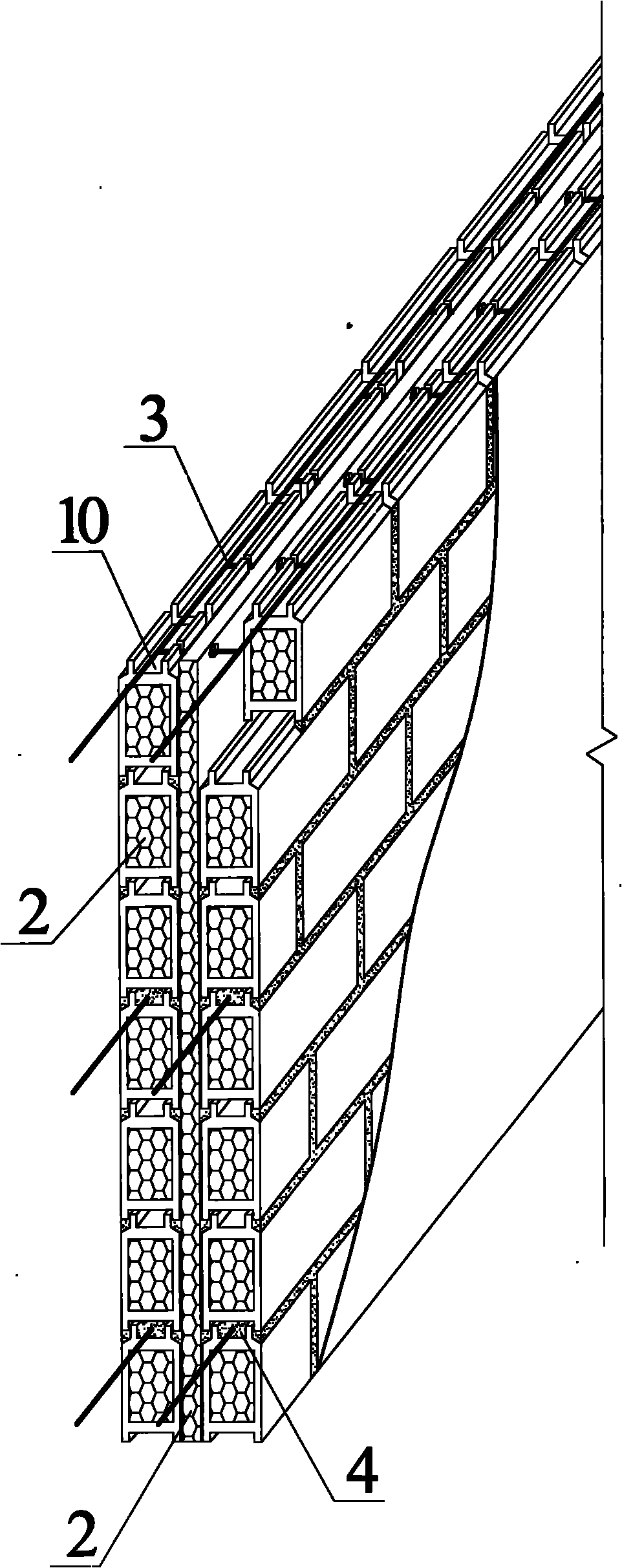

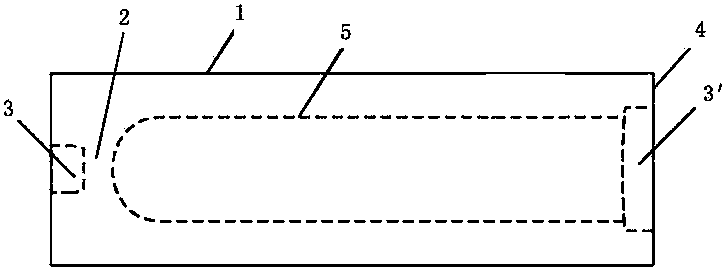

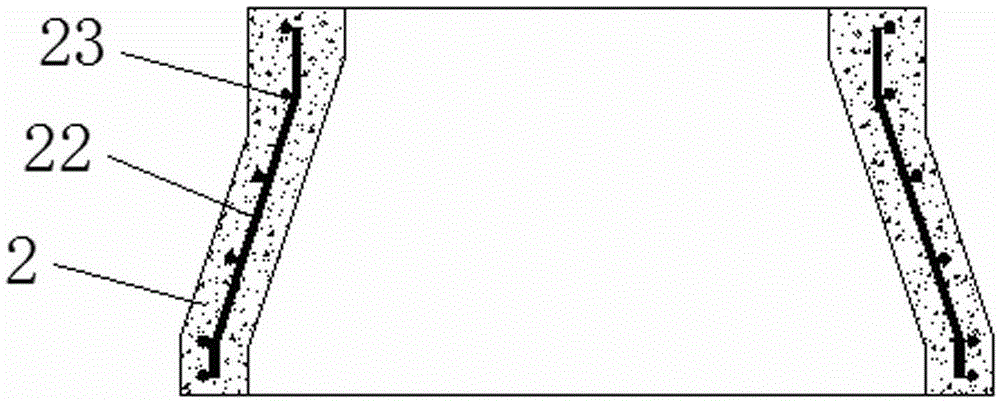

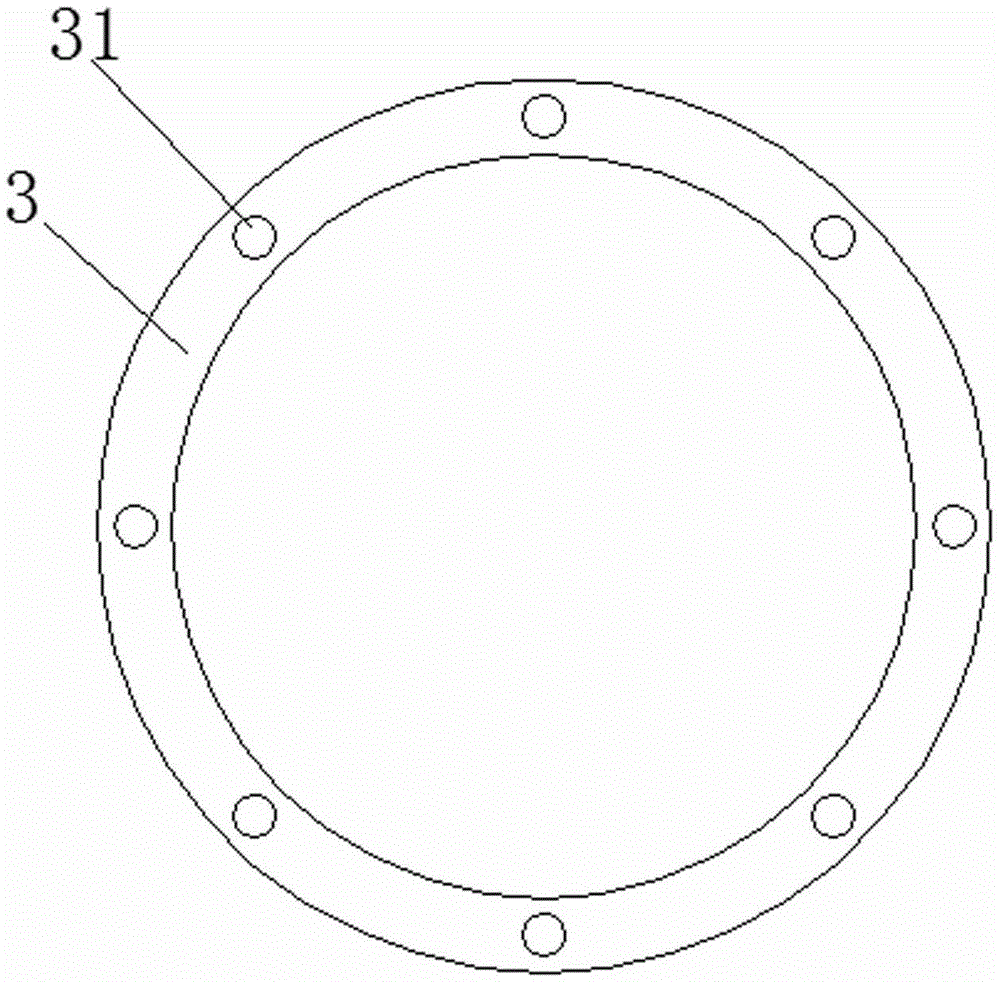

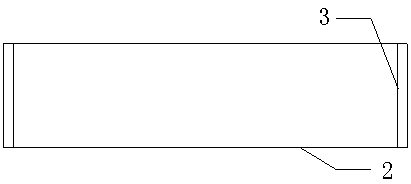

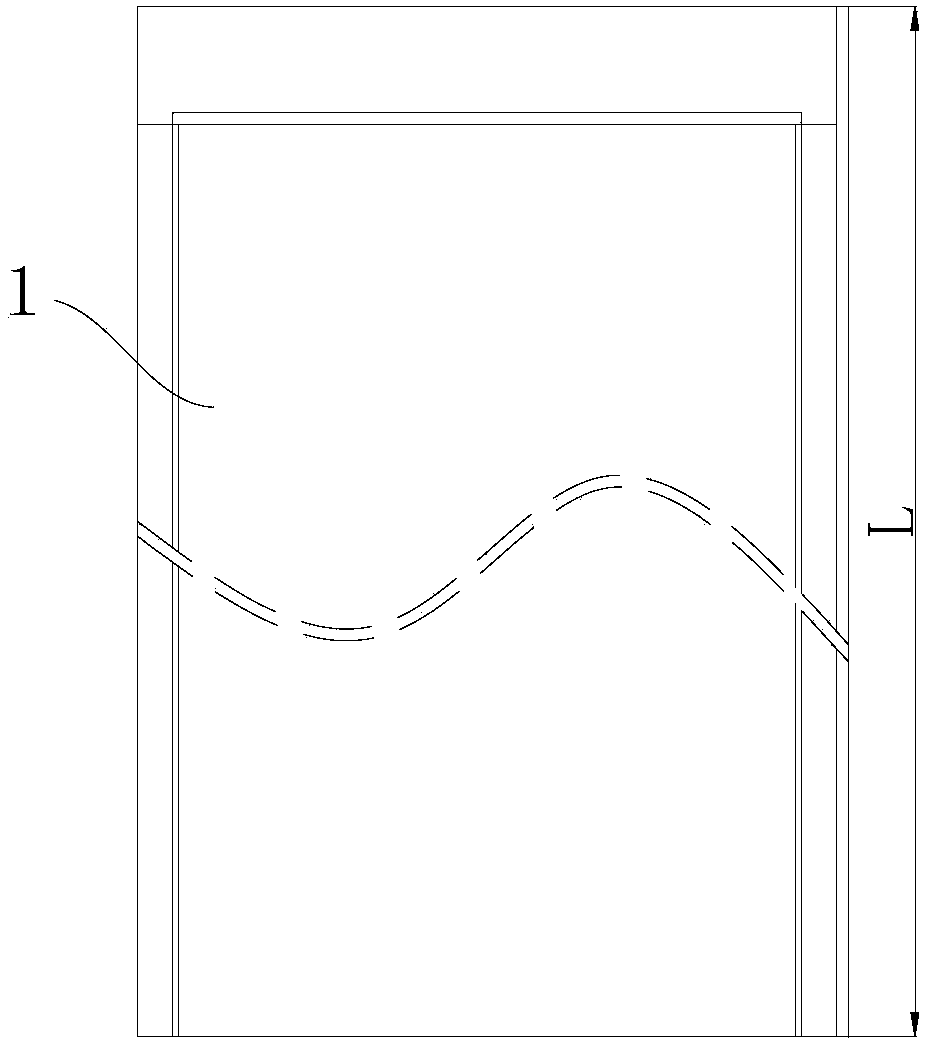

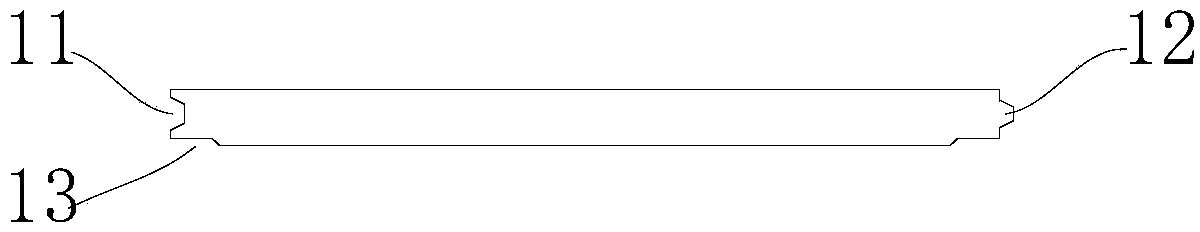

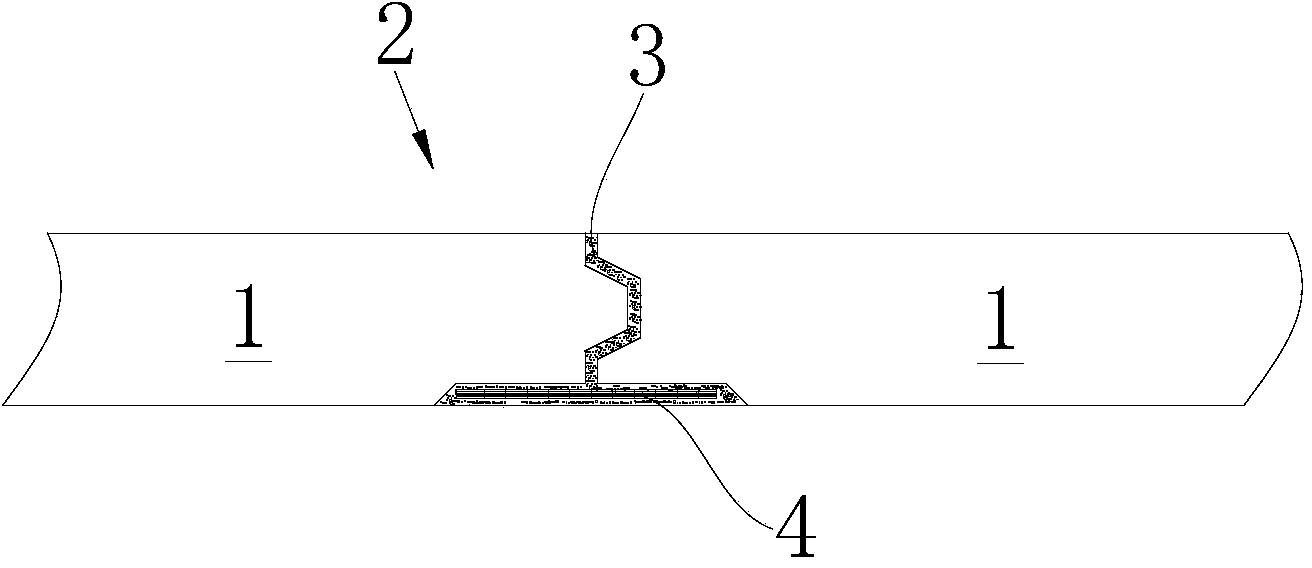

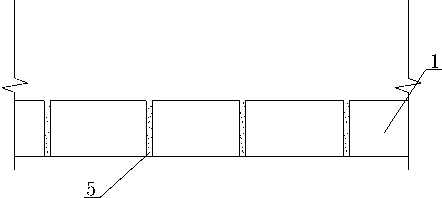

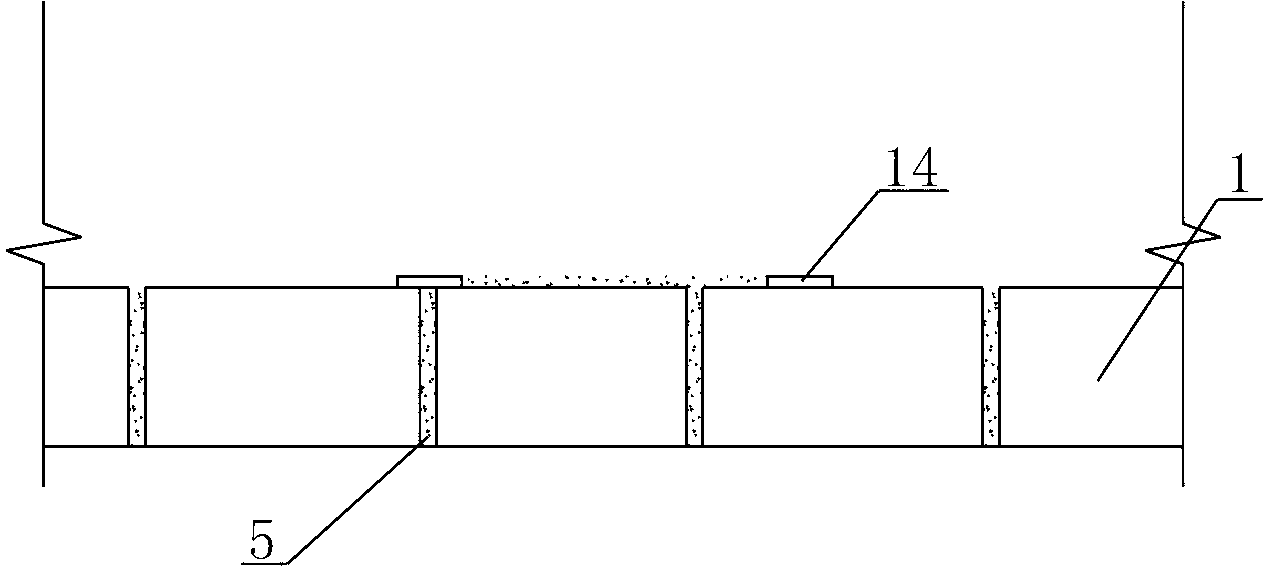

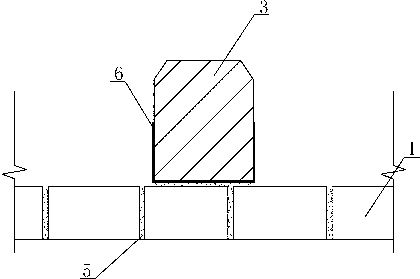

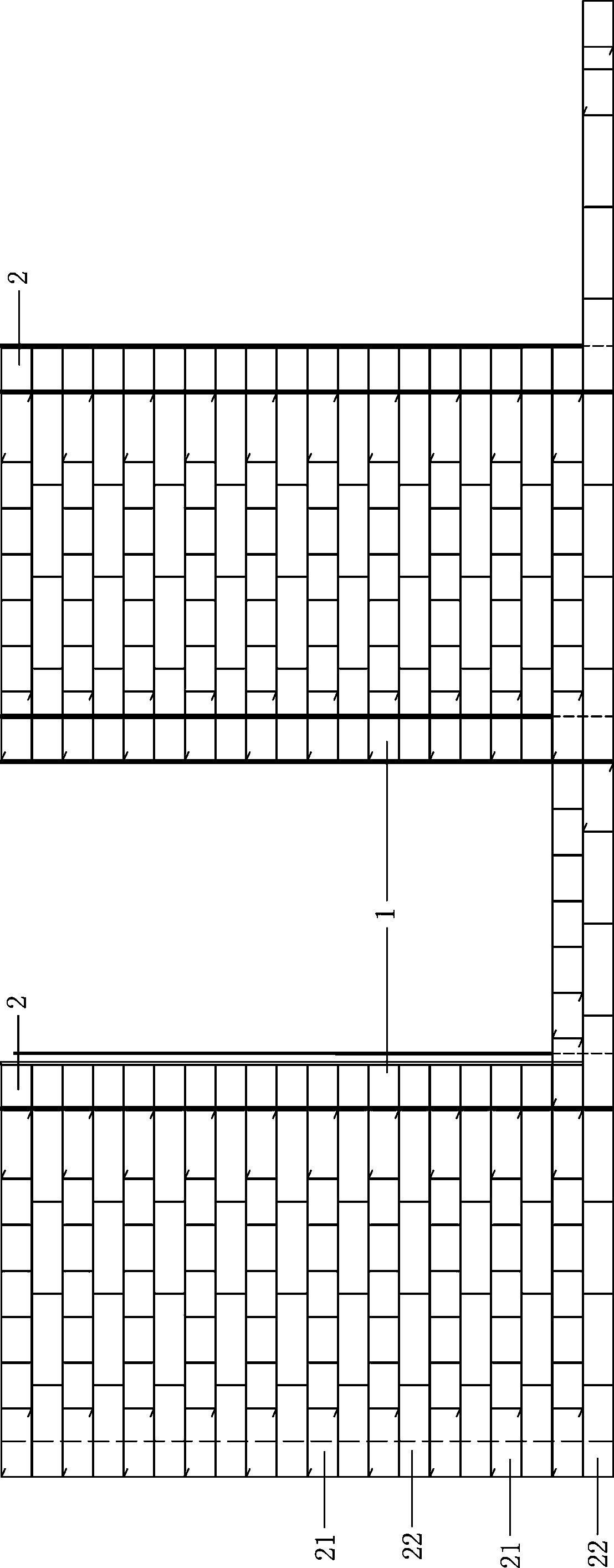

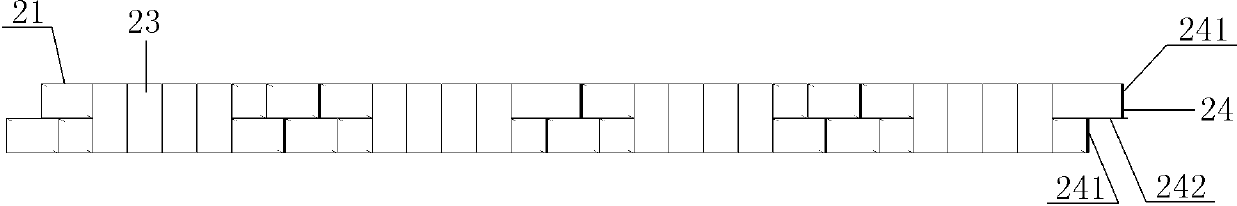

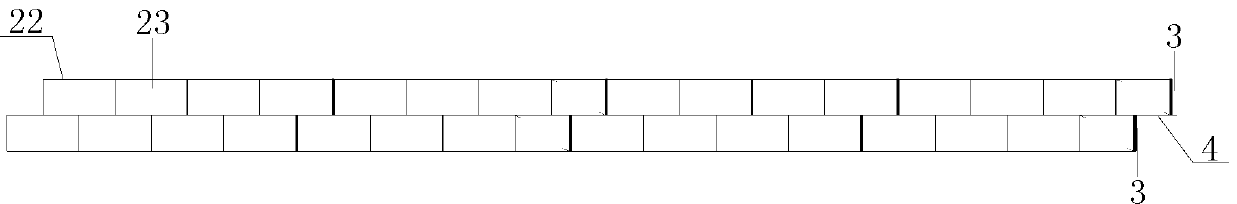

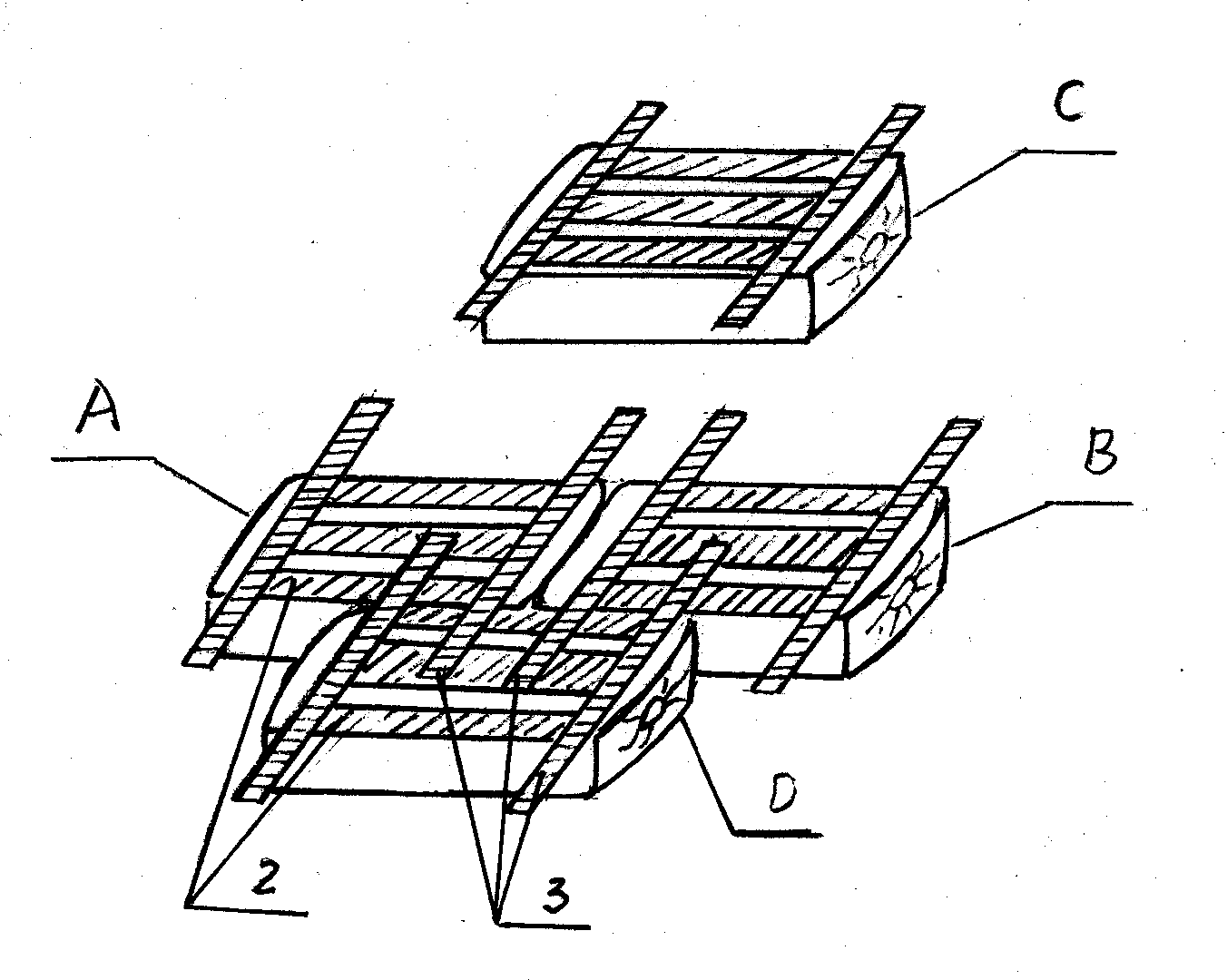

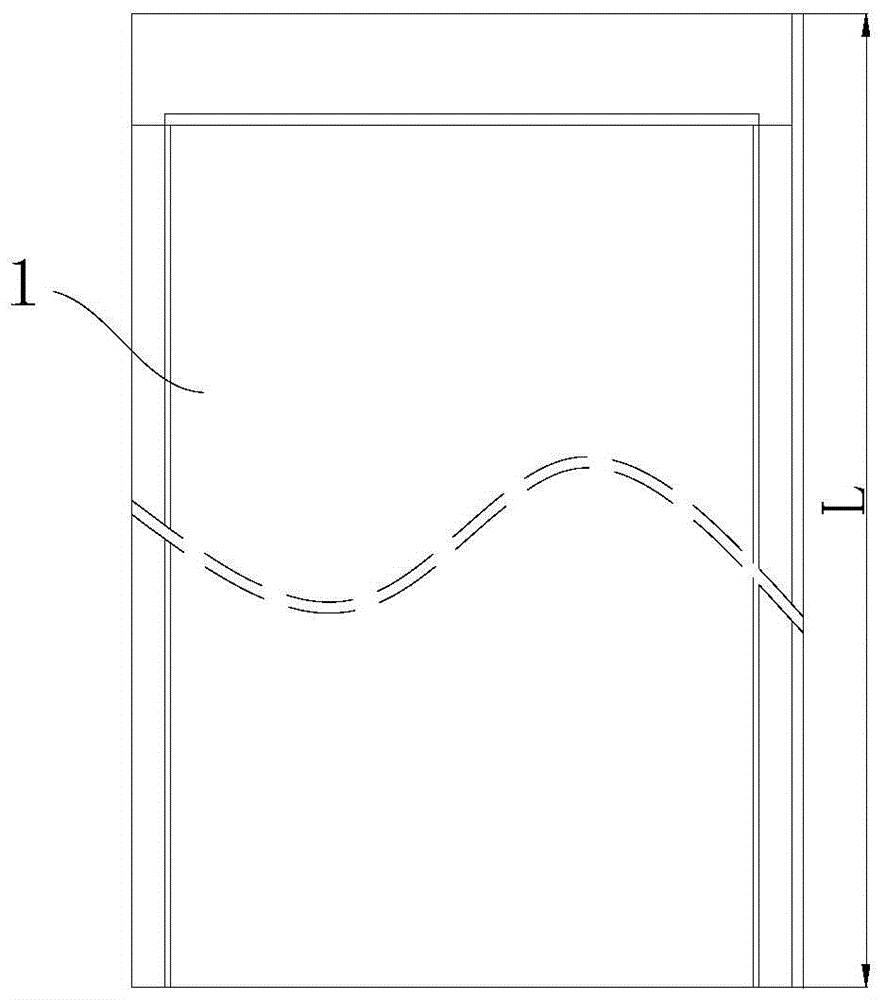

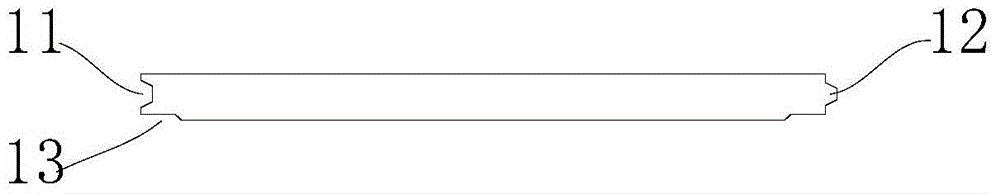

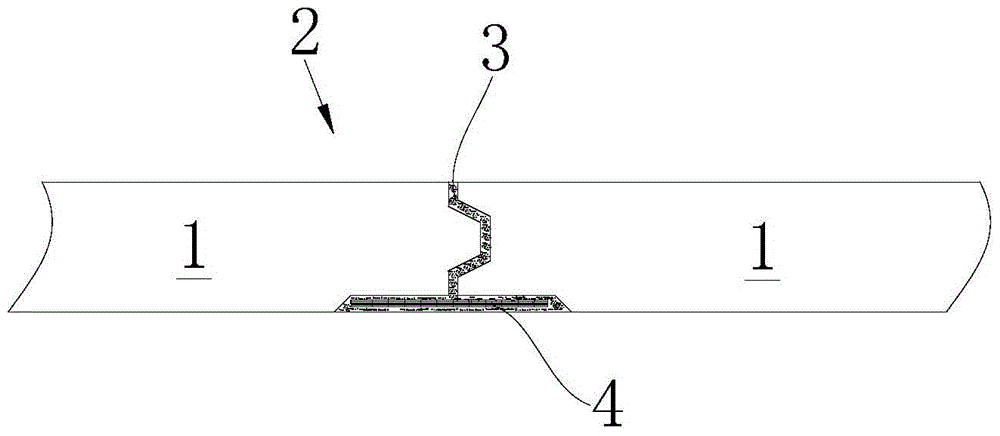

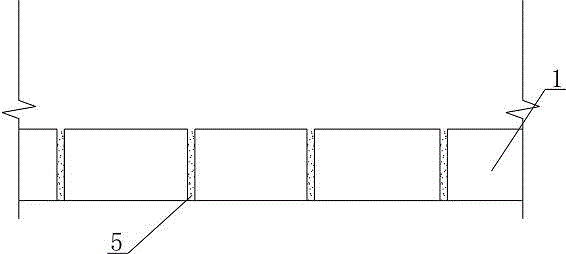

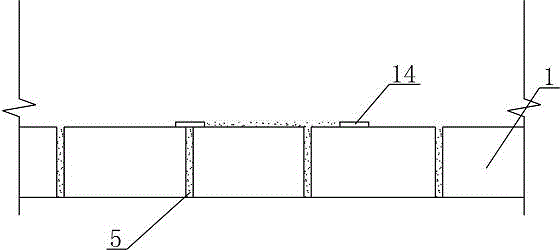

Thin wallboard and composite wall thereof

ActiveCN103806575AOvercoming quality problems such as cracking and leakageMasonry is fastConstruction materialWallsExpanded clay aggregateWall plate

The invention provides a thin wallboard which comprises an integral type wallboard formed by pouring ceramsite concrete, the length of the wallboard is smaller than a distance between the ground and the bottom surface of a top structure beam or soffit by 30-50 mm, a through chase mortise is arranged on one of two side edges in the length direction of the wallboard, and a tenon matched with the chase mortise is arranged on the other side edge. The invention provides a composite wall simultaneously, the composite wall comprises at least two thin wallboards which are upwards placed vertically in the length direction and linearly distributed, and the composite wall body is formed by clamping the tenon of one thin wallboard into the chase mortise of the other thin wallboard in a splicing manner. According to the thin wallboard and the composite wall thereof, the quality problems of cracking, leakage and the like of a conventional wall are solved, simultaneously, mortar rendering can be prevented, the construction speed is increased, and accordingly, the construction period is remarkably shortened.

Owner:广州永万预制构件有限公司 +2

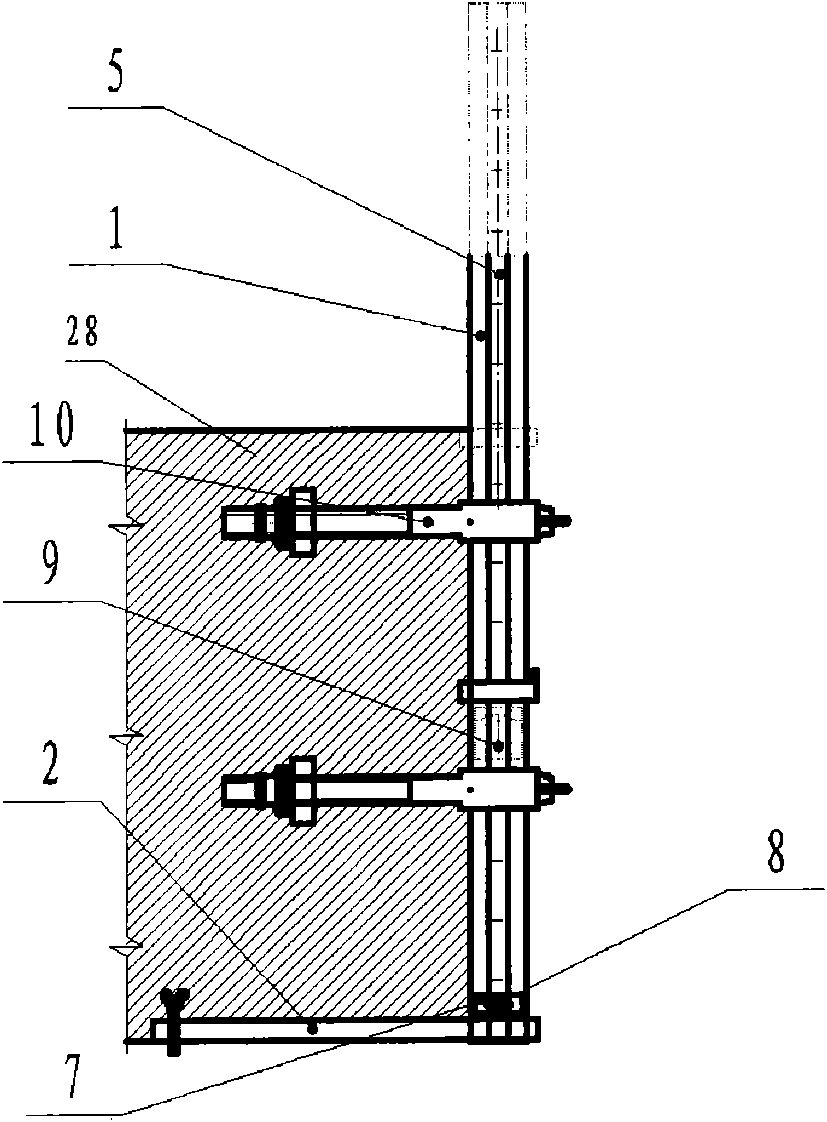

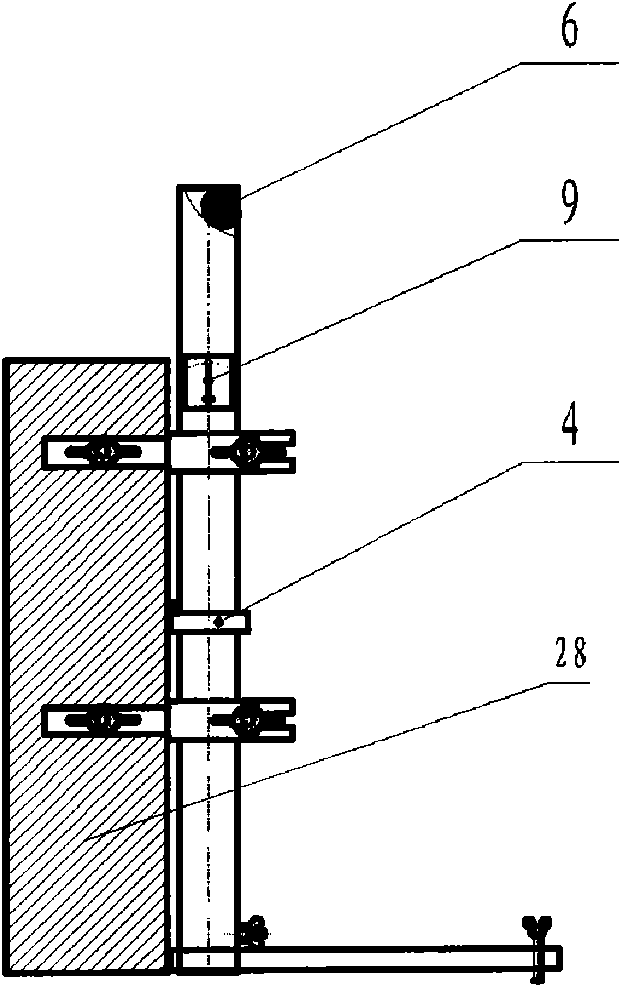

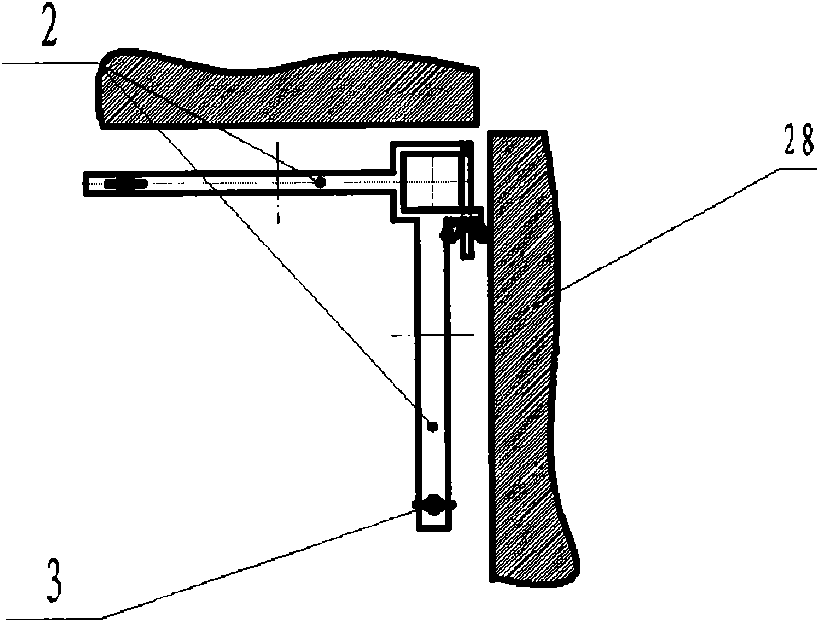

Construction method and used construction tool

InactiveCN102418421AModerate biteConsistent ash thicknessBuilding material handlingCompressive strengthUltimate tensile strength

The invention relates to a construction method and a used construction tool. An old method which has been used for thousands of years is still used for building a wall at present; and a height pole is erected, a seat angle is set, and a line is suspended at the corner of the wall. The old method has higher requirements on level of technician skill; and verticality, axiality, flatness, horizontal seam, various elevations and the like are difficult to master. In the invention, a straight pole is erected at the corner of the wall and is vertically adjusted and stabilized; a line is suspended on the straight pole to build the wall; layer strips are arranged on the straight pole; and a line suspension part of a line suspender is aligned with layer scales all the time, so that no error in elevation is guaranteed. A building formed by the construction method does not have error in verticality or axiality of the wall, and has square rooms, accurate width, flat and vertical double planes, a uniform and consistent horizontal seam, accurate lintel height, no error of wall height and an accurate ring beam; structural performance, tensile strength and earthquake resistant behavior are all greatly improved; and due to the vertical wall, the plaster is thin and quick, materials are saved, use space is expanded, hollowing of plaster is avoided, and falling phenomenon is reduced. The construction tool comprises the straight pole, an adjusting supporting piece and the line suspender on the straight pole.

Owner:黄增明

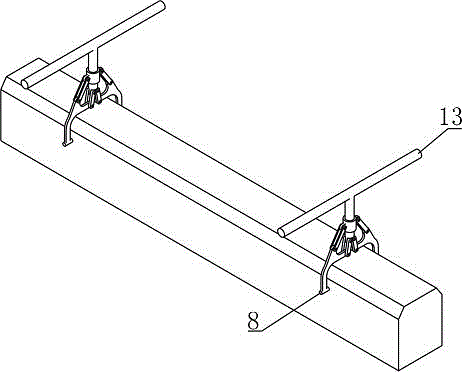

Construction method using hoisting clamp

The invention provides a construction method using a hoisting clamp. The construction method using a hoisting clamp comprises the following steps of: constructing a first-layer masonry; placing a mortar ash template on the first-layer masonry; flatly paving mortar ash joints in the limited area of mortar ash template, and then paving an acid-resistant rubber layer on the mortar ash joints; clamping the hoisting clamp on the sidewall of a filling block, and horizontally lifting the filling block and placing the filling block on the acid-resistant rubber layer; removing the mortar ash template and tightly bonding the acid-resistant rubber layers at the both sides of the filling block on the both sides of the filling block; and paving mortar ash joints at one side of a second-layer masonry material, closely combining the mortar ash joints with the acid-resistant rubber layers at the both sides of the filling block, and finishing construction for a second-layer masonry. With the adoption of the construction method provided by the invention, heavy-weight beams can be accurately and conveniently installed, the construction speed is fast, and the construction quality is guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

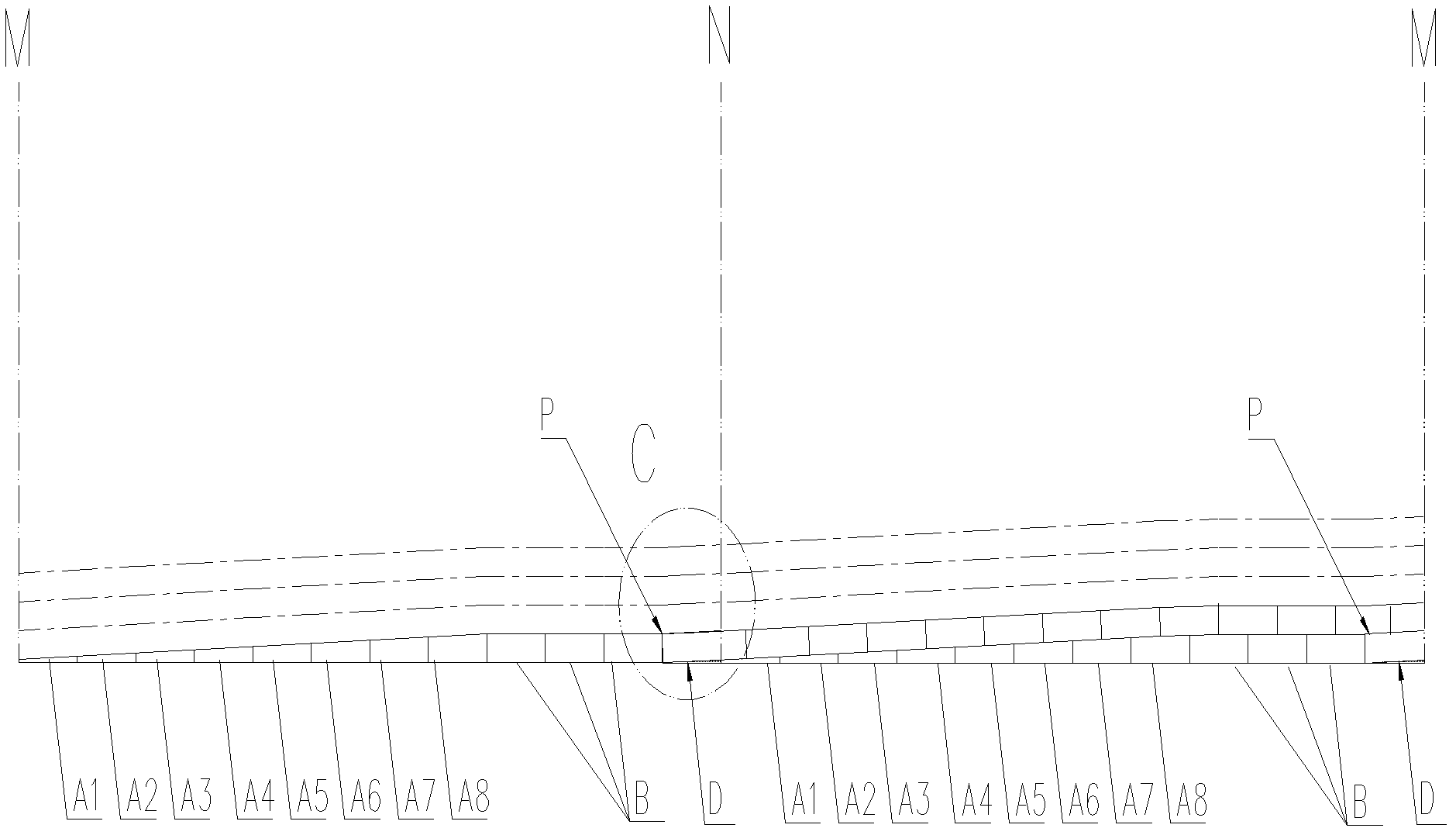

Jumping bin bricklaying method of light-weight brick furnace wall of annealing furnace

The invention relates to the field of bricklaying of a light-weight brick structure furnace wall lining of an industrial furnace, in particular to a jumping bin bricklaying method of a light-weight brick furnace wall of an annealing furnace. The jumping bin bricklaying method of the light-weight brick furnace wall of the annealing furnace is characterized in that the method is carried out according to the following steps of (1) preparation; (2) assembly and bricklaying of wall plates; (3) laying and adhesion; (4) jumping bin bricklaying; and (5) bricklaying of an upper layer in sequence. The jumping bin bricklaying method of the light-weight brick furnace wall of the annealing furnace is high in bricklaying quality, high in bricklaying speed, low in cost, little in environmental pollutionand long in service life.

Owner:CHINA MCC20 GRP CORP

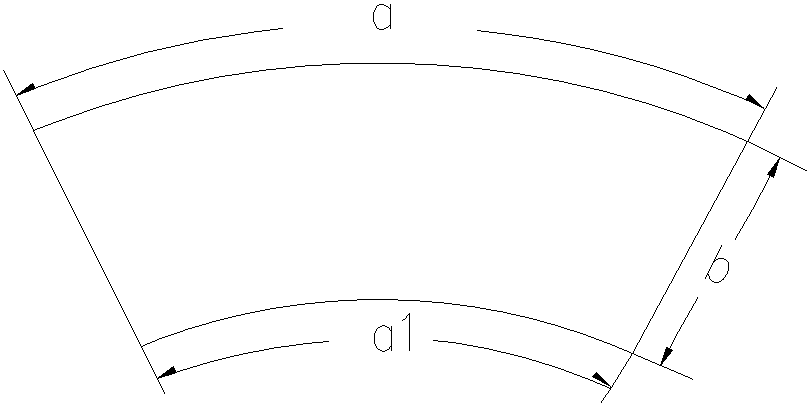

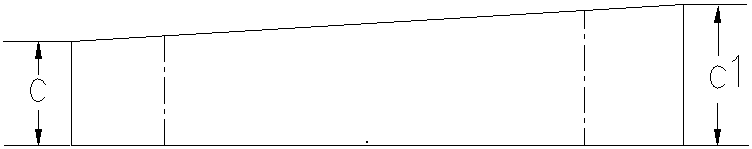

Skew brick and steel ladle wall construction method using the same

The invention relates to a skew brick and a steel ladle wall construction method using the same. The lower surface of the skew brick is a plane, the cross section in parallel with the lower surface of the brick is fan-shaped, and the upper surface of the skew brick is an inclined surface which is tangentially inclined along the fan shape. When the skew brick and the steel ladle wall construction method are used for constructing steel ladles, as door closing is not needed during a steel ladle construction process, operation is simple and construction speed is high compared with a traditional construction method.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Powder ash air-entrained concrete building block and preparation method thereof

InactiveCN101913902BLose weightSmall sizeSolid waste managementCeramic shaping apparatusFire protectionEnergy consumption

The invention discloses a powder ash air-entrained concrete building block and a preparation method thereof. The powder ash air-entrained concrete building block is prepared by adding water to 100-200kg of cement, 350-380kg of lime, 1350-1550kg of powder ash, 1.4-1.5kg of aluminite powder and 0.195-0.205kg of foam stabilizers. The preparation method comprises the following steps of raw material preparation, metering, stirring, pouring in a mould, standing for procuring, demoulding, swinging to cutting parts for cutting, steaming and curing in a reactor and finished product warehousing. The building block has the advantages of light weight, good heat insulation, machinability, convenient construction, wide source of raw materials, high production efficiency, low production energy consumption and good fire protection and sound insulation, wherein the dry volume density of the building block is 500-700kg / m3 and amounts to one third of a clay brick; as a large quantity of air holes and micro holes are arranged inside the building block, the building block has favorable heat insulation; as coarse aggregates are not used, the building block has favorable machinability, can be sawn, dug,drilled and nailed and bonded by bonding materials, thereby providing beneficial conditions for building construction; and the building block belongs to a green environmental-protection product.

Owner:舟山市宇锦新型墙体材料有限公司

Bulking brick

The invention provides an energy-saving and environment-friendly swelling brick, which relates to a material for building. In order to overcome the deficiency caused by common clay red bricks which consumes a great land resources and energy, and has serious pollution, small size but heavy deadweight, poor heat insulation performance, and increase of the total construction cost; the swelling brick of the invention takes argillo-arenaceous rock as main material, which enters a high temperature rotary furnace to charge oxygen and pressure for swelling after crushing and screening, then a secondary heating is performed after producing the swelling body, finally the shape is formed by mechanical squeezing. The swelling body after shaped by squeezing also can be mixed with the cement, the fly ash and the concrete additive. After mechanically agitating and watering, the swelling body is conveyed to a silo for squeezing to form the swelling brick which is characterized by light weight, rigid body, heat insulation, and fire resistance, nontoxic and being durable, thus being an ideal energy-saving building brick.

Owner:黑龙江省三江君合新材料科技开发有限公司

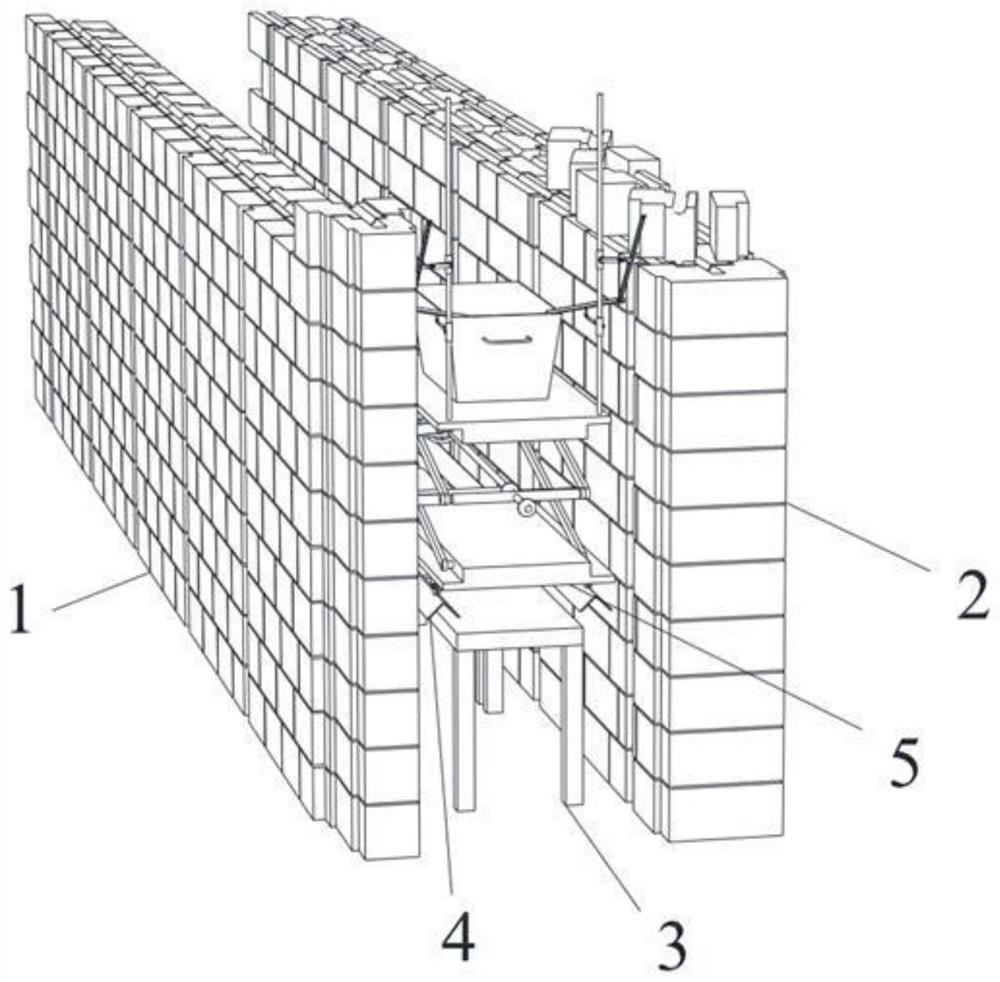

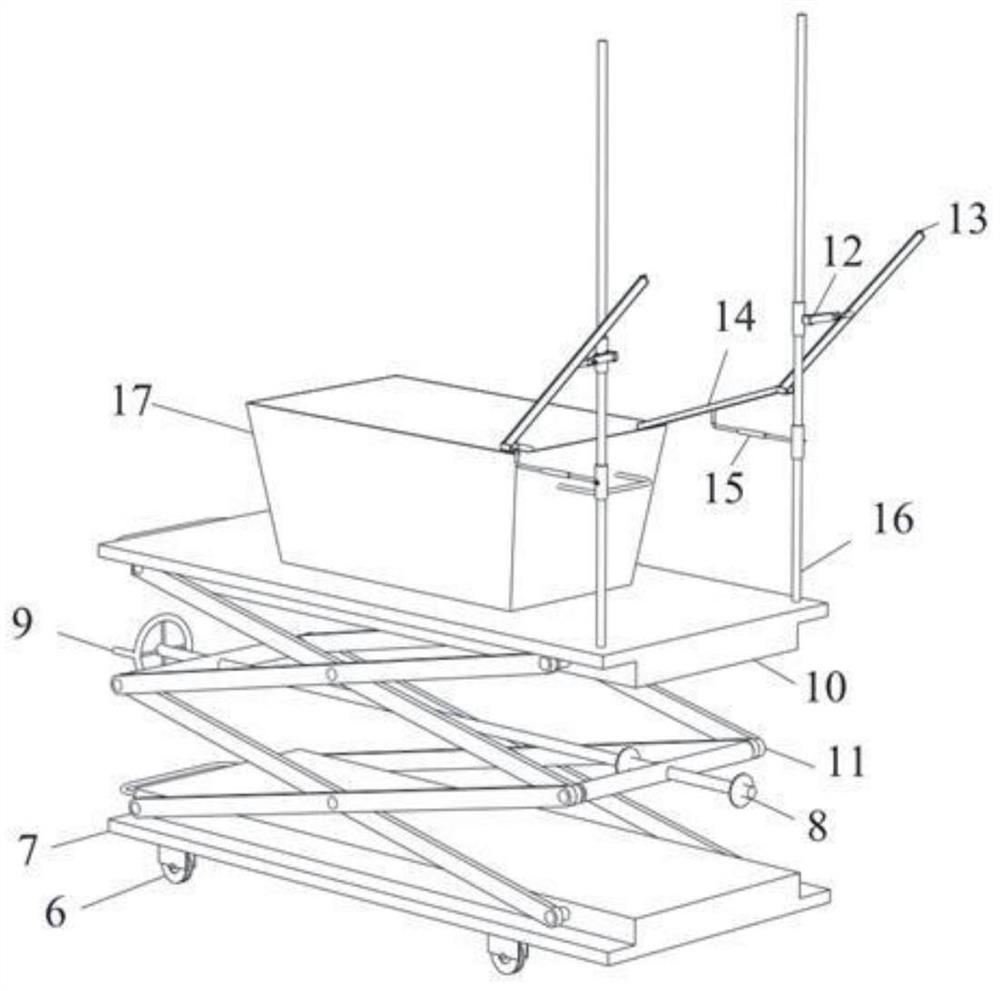

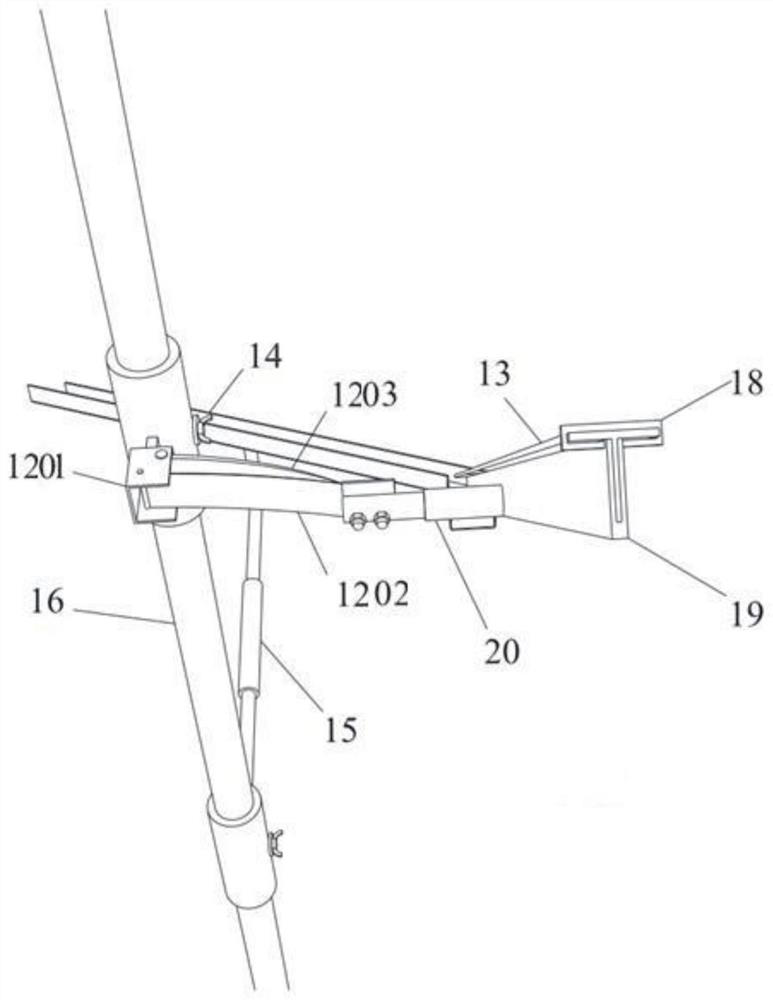

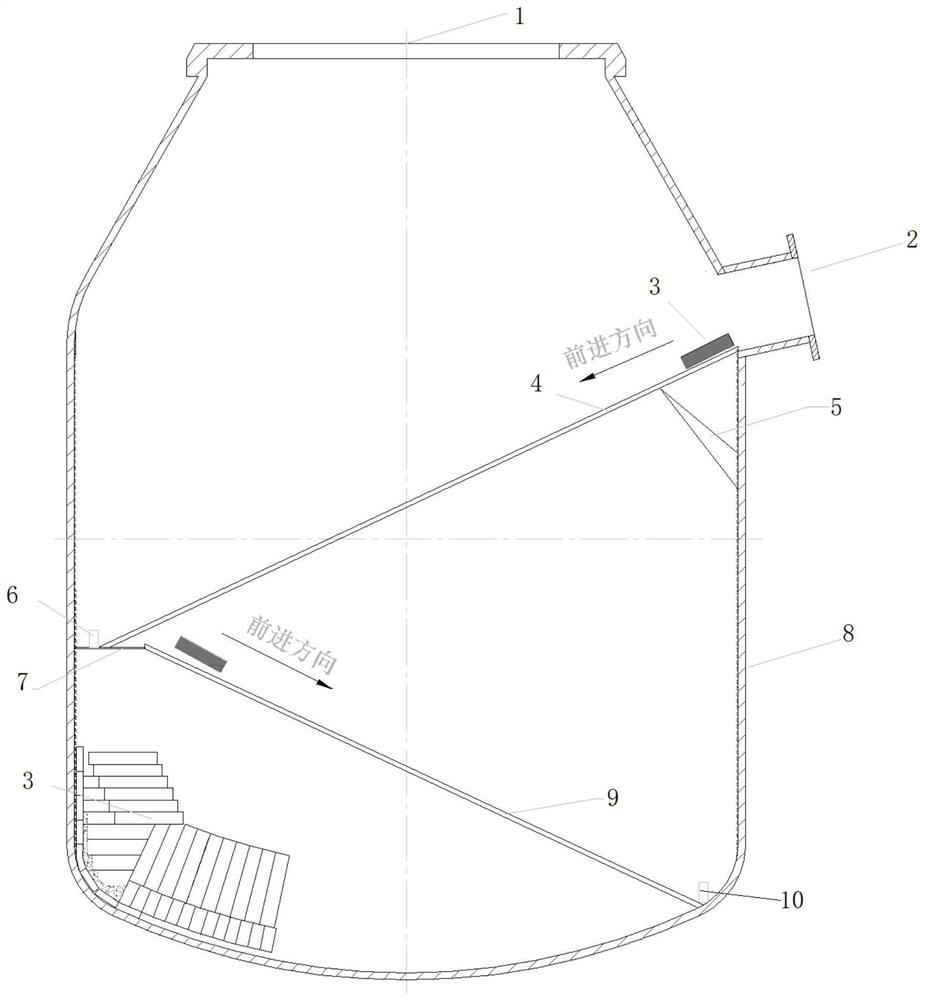

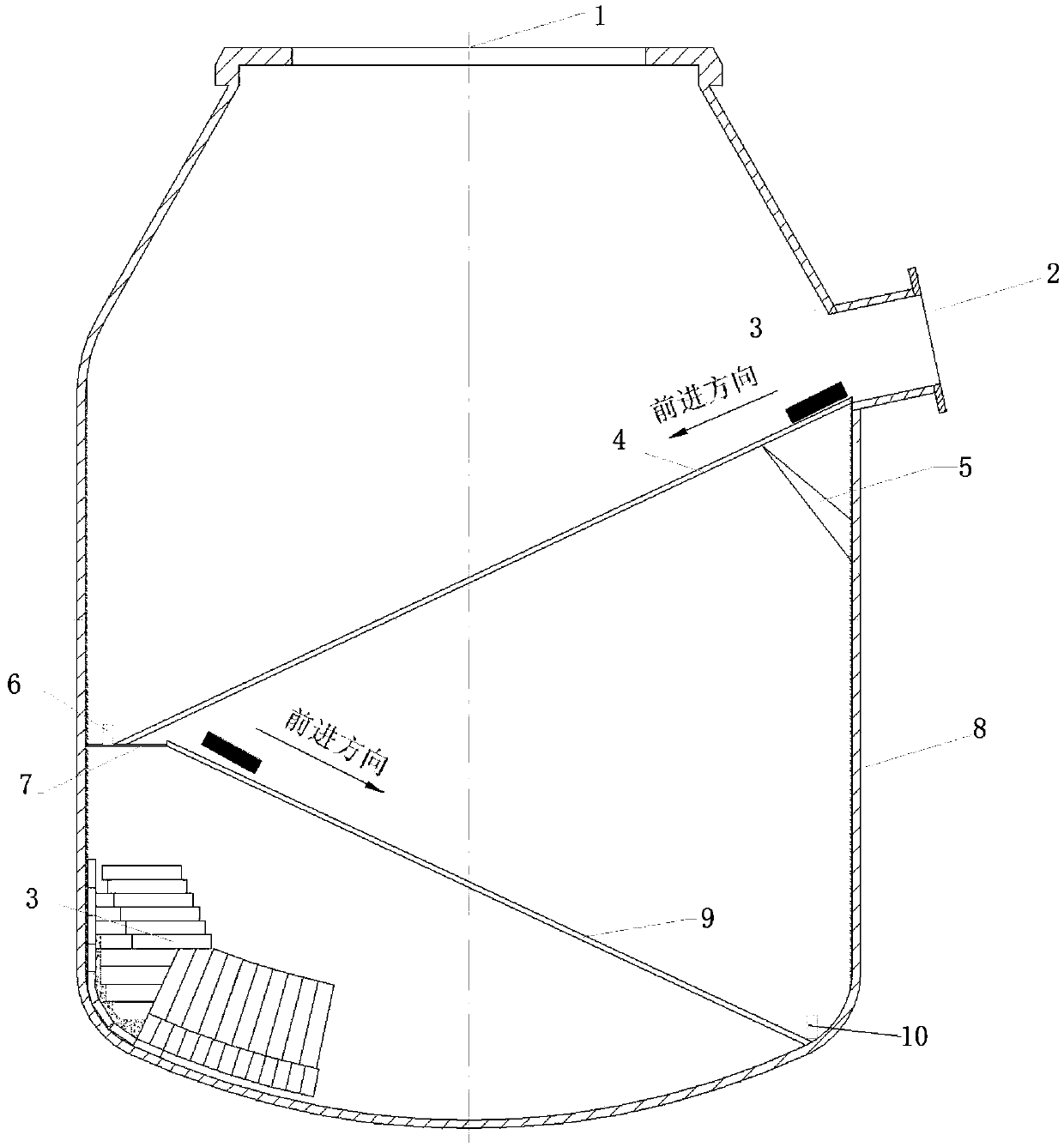

Multifunctional trolley auxiliary device for coke oven masonry

ActiveCN113122286ASave energyAvoid the problem of flying pollution to the construction environmentCoke oven brickworkCoke burnerStructural engineering

The invention discloses a multifunctional trolley auxiliary device for coke oven masonry, which comprises masonry bodies. A gangplank is arranged between the masonry bodies, an ash scraping trolley is arranged above the gangplank, a rail is arranged between the ash scraping trolley and the gangplank, a groove wheel is arranged at the bottom of the ash scraping trolley, the groove wheel and the rail are mounted in a matched manner, the ash scraping trolley moves forwards or backwards on the rail in the rolling process of the groove wheels, the ash scraping trolley is provided with an ash scraping mechanism, the ash scraping mechanism removes and collects ash scars on the opposite inner side surfaces of the masonry bodies, and the technical problems that in the prior art, the ash scar removing difficulty is large, and operation of workers is not comfortable due to the change of the ash beating height are solved.

Owner:CHINA FIRST METALLURGICAL GROUP

Ladle working lining construction method

ActiveCN104384489BInhibition of hydrationService life is not affectedMelt-holding vesselsBrickSlurry

The invention relates to a steel ladle working lining building method, which sequentially comprises the following steps that 1, a steel ladle bottom working lining is built by magnesia calcium bricks or magnesia calcium carbon bricks in a dry way, and a steel ladle wall working lining is built by the magnesia calcium bricks or the magnesia calcium carbon bricks or using magnetite chrome fire clay or magnesia fire clay as bonding materials in a wet way; 2, after the steel ladle bottom working lining and the steel ladle wall working lining are built, the operation enters a baking stage within two hours. Further, before the steel ladle bottom working lining building in the first step, the magnetite chrome fire clay or the magnesia fire clay is uniformly mixed: dry mixed slurry materials are stirred by a slurry stirring machine for 3 to 5 minutes, then, water is added, the water adding quantity is 13+ / -2 percent, the water temperature is 20+ / -5 DEG C, the stirring is carried out while the water is added, and the stirring time is not less than three minutes after the water adding. The steel ladle working lining building method has the advantage that the building speed is high.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

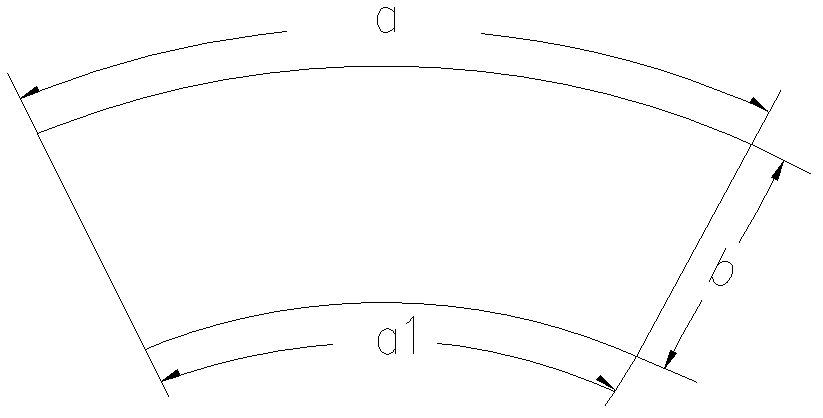

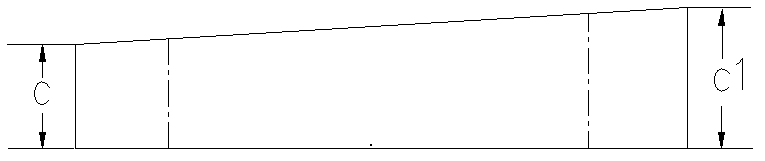

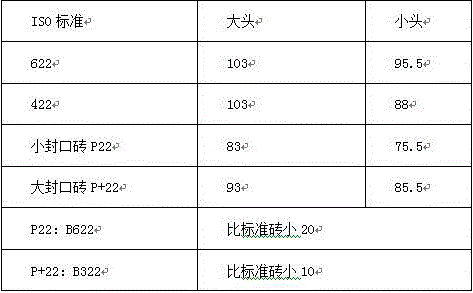

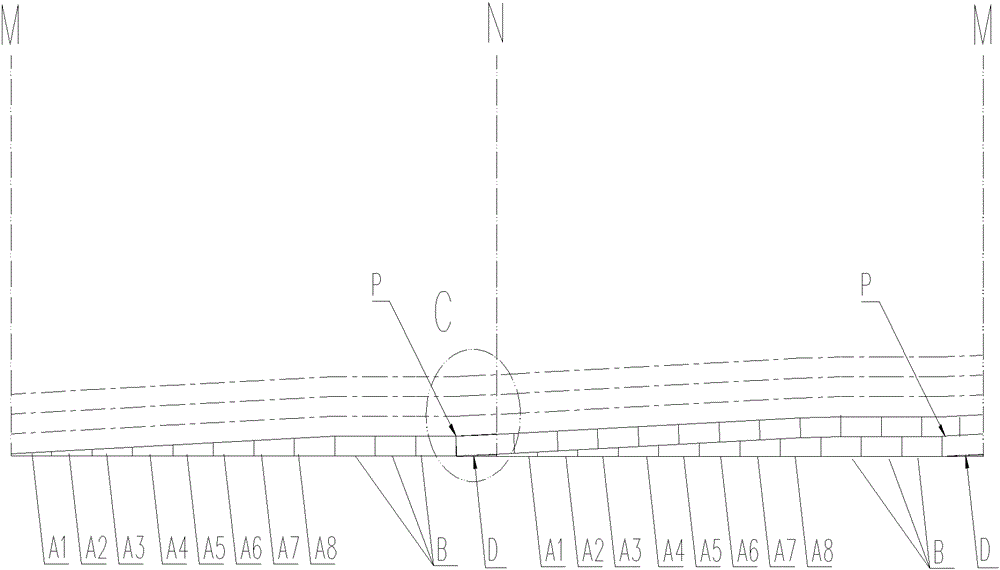

Calculating method of number of masonry sealing bricks of firebricks of rotary kiln

InactiveCN106643130AReduce the number of adjustmentsReduce adjustment time and manpowerRotary drum furnacesRotary kilnEngineering

The invention relates to a calculating method of the number of masonry sealing bricks of firebricks of a rotary kiln. The calculating method of the sealing bricks is characterized by comprising a calculating method of VDZ standard bricks and a calculating method of ISO standard bricks, wherein in the calculating method of the VDZ standard bricks, the VDZ standard bricks are equal-middle bricks, the middle width of a BP22 brick is 10mm less than that of the VDZ standard brick, the middle width of a BP+22 brick is about 8mm higher than that of the VDZ standard brick, so that the middle width of the BP22 brick and the BP+22 brick is about 2mm less than that of the two VDZ standard bricks; in the calculating method of the ISO standard bricks, the ISO standard bricks are equal-big-head bricks, the big-head width of a P22 brick is 20 mm less than that of the ISO brick, and the big-head width of a P+22 brick is 10mm less than that of the ISO standard brick; generally, the dimension of eight standard bricks is used as a reference number, then the dimension of nine standard bricks is measured, and the data, namely the difference between measured data and the data of the eight standard bricks is the data of the sealing bricks; and then the using number of the sealing bricks is calculated in a manner that the large-head width of the P22 brick is 20 mm less than that of the standard brick and the large-head width of the P+22 brick is 10mm less than that of the standard brick. The calculating method disclosed by the invention has the beneficial effects that a sealing area can be measured in advance, the number of the sealing bricks is also accurately calculated out, in the process of masonry, the adjusting number of the firebricks in the sealing area is reduced, massive human resources are reduced, adjusting time is shortened, and the sealing masonry speed is improved.

Owner:ANHUI WUHU CONCH CONSTR & INSTALLATION ENG

Deep Maintenance Method of Coke Oven Carbon Bottom Brick

ActiveCN104073269BEnsure safetySolve the pop-up puzzleCoke oven brickworkBrickwork leakage repair/preventionFurnace temperatureThermal insulation

The invention relates to a deep maintenance method for coke oven carbon bottom bricks. The method includes the following steps: 1) furnace temperature control, 2) heat insulation at 850°C, 3) interval roof protection; 4) safety protection technology for construction personnel in a limited space , 5) Quality control of carbon bottom brick masonry, 6) Thermal insulation and gap treatment technology of silica bricks at the furnace head, masonry and grouting at the furnace head on both sides of the carbonization chamber machine and coke; 7) Buffer protection of full carbon bottom bricks technology, maintenance and temperature rise control after construction; 8) buffer protection control for the first production operation after construction. This method solves the problem that operators cannot safely enter the narrow, high-temperature space, and uses zero-expansion silica bricks to replace the original silica bricks to solve the problem that ordinary silica bricks are prone to bursting at high temperatures; at the same time, it can avoid large fluctuations in furnace temperature and ensure The quality of bricklaying prolongs the life of the coke oven body, the speed of masonry is fast, the maintenance time is greatly shortened, the labor intensity is reduced, and the safety of construction workers is ensured.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Sand bag brick capable of realizing mutual adhesion and connection

InactiveCN104074302AMasonry is fastGood strength and toughnessCoastlines protectionBuilding componentsPolypropyleneBuilding material

The invention belongs to a novel building material, and relates to a sand bag brick capable of realizing mutual adhesion and connection. The sand bag brick is characterized in that a braided bag is made into a cuboid shape from polyethylene or polypropylene materials; the edge of a bag opening is in a groove shape; two tightening ropes are arranged along the edge of the bag opening in a trapezoidal shape; the front side of the rectangular braided bag is provided with hook and loop magic tapes; double-sided magic tapes are arranged on the hook and loop magic tapes; the back side of the rectangular braded bag is provided with round hoop magic tapes; after the braided bag is fully filled with sand and soil, the two tightening ropes are simultaneously and tightly pulled; the bag opening is tightened, and the two tightening ropes are knotted and tightly tied; and the sand bag brick is formed. The sand bag brick is a shape of a regular cuboid; local materials of the sand and the soil can be used and filled into the bag; and the sand bag brick is obtained. The sand bag brick has an adhesion and connection structure, so the building speed is high; a built body has good intensity and good toughness and can be conveniently dismounted; the repeated use can be realized; and the consumption is low. The sand bag brick belongs to a novel building material, has the building characteristics of high speed and convenience, has wide purposes and can be favorably popularized and applied.

Owner:初东

A kind of oblique bricklaying and ladle-clad wall masonry method using the oblique bricklaying

InactiveCN103157784BEasy to operateShorten the timeMelt-holding vesselsBrick masonryMaterials science

The invention relates to a skew brick and a steel ladle wall construction method using the same. The lower surface of the skew brick is a plane, the cross section in parallel with the lower surface of the brick is fan-shaped, and the upper surface of the skew brick is an inclined surface which is tangentially inclined along the fan shape. When the skew brick and the steel ladle wall construction method are used for constructing steel ladles, as door closing is not needed during a steel ladle construction process, operation is simple and construction speed is high compared with a traditional construction method.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Aerated concrete block and preparation method thereof

InactiveCN101913903BLose weightSmall sizeCeramic shaping apparatusBuilding componentsEnvironmental resistanceSteam pressure

The invention discloses an aerated concrete block and a preparation method thereof. The aerated concrete block is prepared from the following components: 250-320kg of cement, 350-400kg of lime, 1400-1600kg of silica sands, 1.45-1.6kg of aluminium powder, 0.195-0.205kg of foam stabilizers and water. The preparation method comprises the following steps: raw material preparing, metering, stirring, pouring into molds, standing and procuring, demolding, lifting to a cutting part for cutting, steam pressure curing in a kettle and finished product warehousing. The block has the advantages of light weight, good thermal insulation property, processability, convenient construction, wide raw material sources, high preparation efficiency, low preparation energy consumption, environment-friendliness and good fireproofing and soundproofing properties, specifically, the bulk density of the block is 500-700kg / m3, which is equivalent to 1 / 3 of the bulk density of the clay bricks; the block is providedwith plentiful pores and micropores inside, thus having good thermal insulation property; the block dispenses with coarse aggregates, thus having good processability, being capable of being sawed, planed, drilled and stapled, being capable of being bonded by bonding materials and providing favorable conditions for building construction.

Owner:舟山市宇锦新型墙体材料有限公司

Thin wall panels and their composite walls

ActiveCN103806575BOvercoming quality problems such as cracking and leakageMasonry is fastConstruction materialWallsFloor slabExpanded clay aggregate

The invention provides a thin wallboard which comprises an integral type wallboard formed by pouring ceramsite concrete, the length of the wallboard is smaller than a distance between the ground and the bottom surface of a top structure beam or soffit by 30-50 mm, a through chase mortise is arranged on one of two side edges in the length direction of the wallboard, and a tenon matched with the chase mortise is arranged on the other side edge. The invention provides a composite wall simultaneously, the composite wall comprises at least two thin wallboards which are upwards placed vertically in the length direction and linearly distributed, and the composite wall body is formed by clamping the tenon of one thin wallboard into the chase mortise of the other thin wallboard in a splicing manner. According to the thin wallboard and the composite wall thereof, the quality problems of cracking, leakage and the like of a conventional wall are solved, simultaneously, mortar rendering can be prevented, the construction speed is increased, and accordingly, the construction period is remarkably shortened.

Owner:广州永万预制构件有限公司 +2

Masonry method using lifting clamp hook

The invention provides a construction method applying a lifting clamp hook. The method comprises the steps that: a first layer of masonry is constructed; a cement mortar template is arranged on the first layer of masonry; a cement mortar joint is flatly paved on an area restricted by the cement mortar template, and an acid-resistant rubber layer is paved on the mortar joint; mounting holes are processed on two sides of a filling block; the lifting clamp hook is hooked on the mounting holes of the filling block, and the filling block is horizontally lifted and placed on the acid-resistant rubber layer; the cement mortar template is removed; acid-resistant rubber layers on two sides of the filling block are closely adhered to the two sides of the filling block; a cement mortar joint is paved on one side of the second layer of the masonry material, and the cement mortar joint is closely combined with acid-resistant rubber layers on two sides of the filling block; and the construction of the second layer of masonry is completed. With the construction method, construction speed is high, and construction quality is ensured.

Owner:CHINA FIRST METALLURGICAL GROUP

Brick conveying device for lining bricks used in converter masonry

Owner:SHANDONG IRON & STEEL CO LTD

Conveying device of furnace lining bricks for converter construction

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com