Brick conveying device for lining bricks used in converter masonry

A furnace lining brick and converter technology, applied in the manufacture of converters, etc., can solve problems such as mutual interference, many obstacles, and prolonging the delivery time of furnace lining bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described now in conjunction with accompanying drawing.

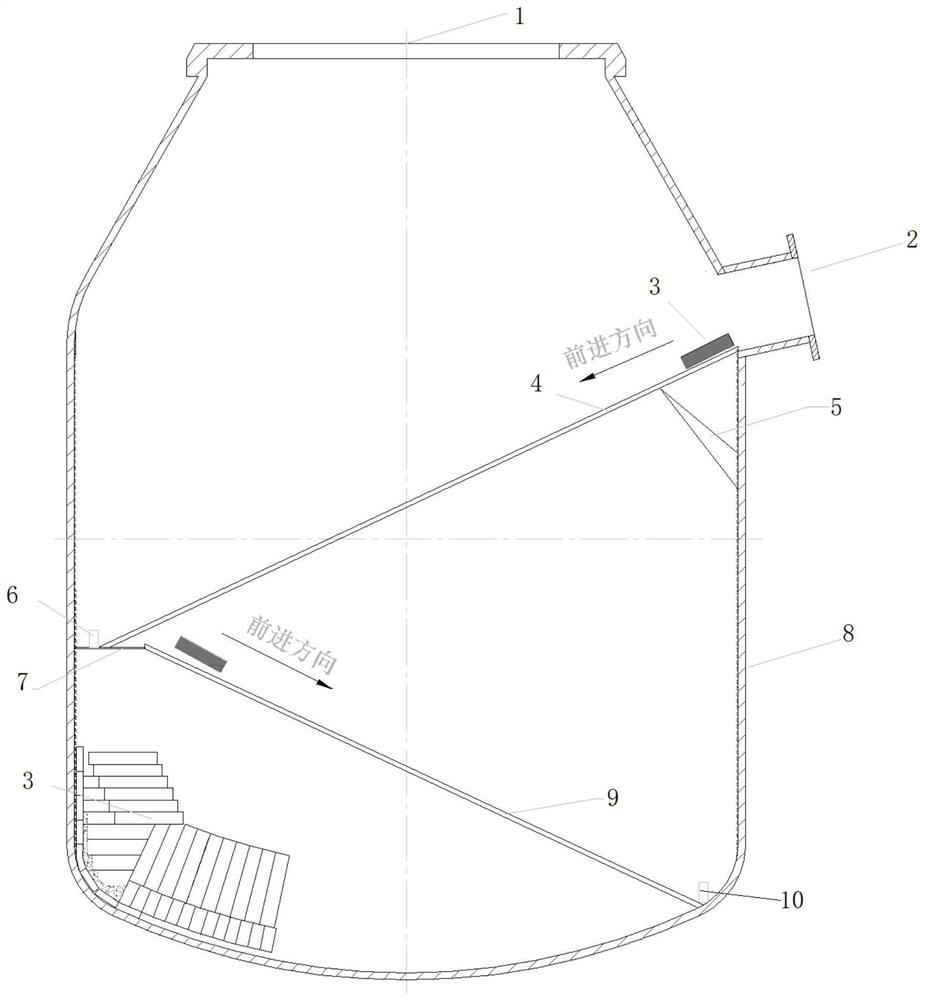

[0022] Such as figure 1 As shown, the present invention proposes a brick transporting device for lining bricks used in converter masonry, which includes: a first slide rail 4, a second slide rail 9, a first support seat 5, a second support seat 7 and a first support seat 7. A block 6; a first support seat 5 is fixed on the inner wall of the converter with the tap hole 2 of the converter, and the first support seat 5 is close to the tap hole 2 of the converter 8; and the tap hole 2 with the converter 8 A second support seat 7 is fixed on the opposite inner wall of one side of the inner wall, and the first support seat 5 and the second support seat 7 are placed up and down; the first stopper 6 is fixed on the second support seat 7, and the converter The first slide rail 4 is placed obliquely and fixedly between the tapping hole 2 of 8 and the first stopper 6, and is used to dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com