Combined arc furnace cover

An electric arc furnace and combined technology, which is applied in the field of combined electric arc furnace cover, can solve problems such as brick loosening, falling off, poor integrity of the furnace cover, and failure to work normally, and achieves fast building speed, reduced on-site workload, and build simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Take the thickness of the original furnace cover as 230mm as an example to illustrate:

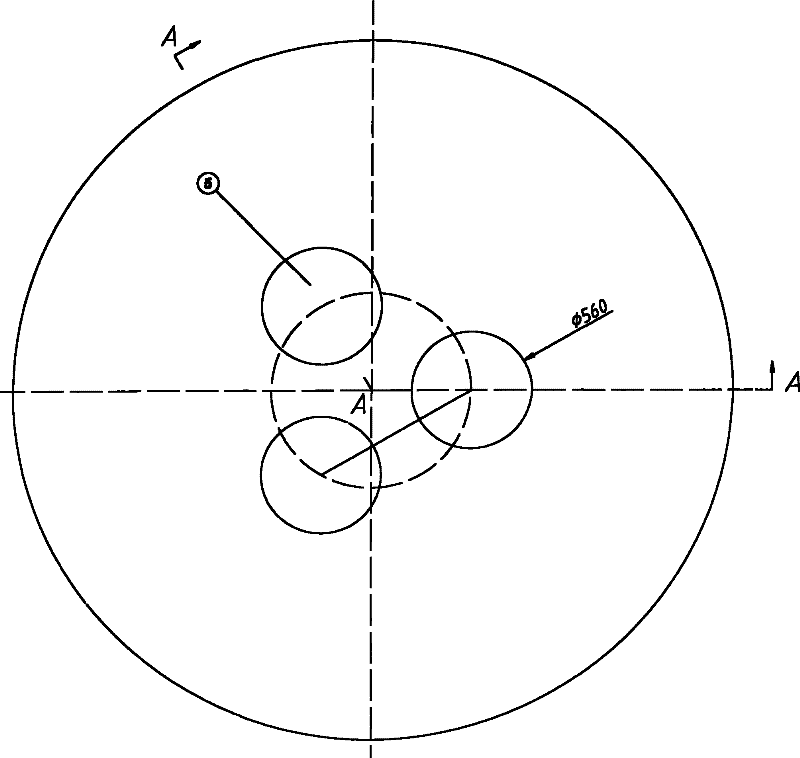

[0028] 1, press image 3 and Figure 4 As shown, carry out drawing conversion: K=150mm, α=75°, H=300mm, Q=50mm, arch height 1 takes 35mm, arch height 2 takes 25mm.

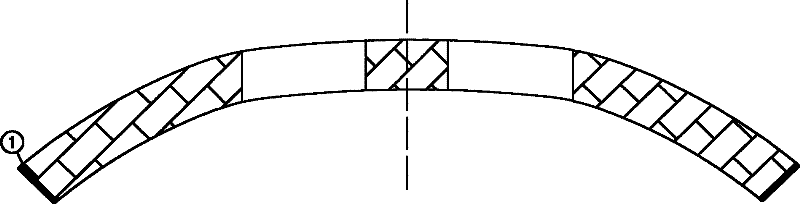

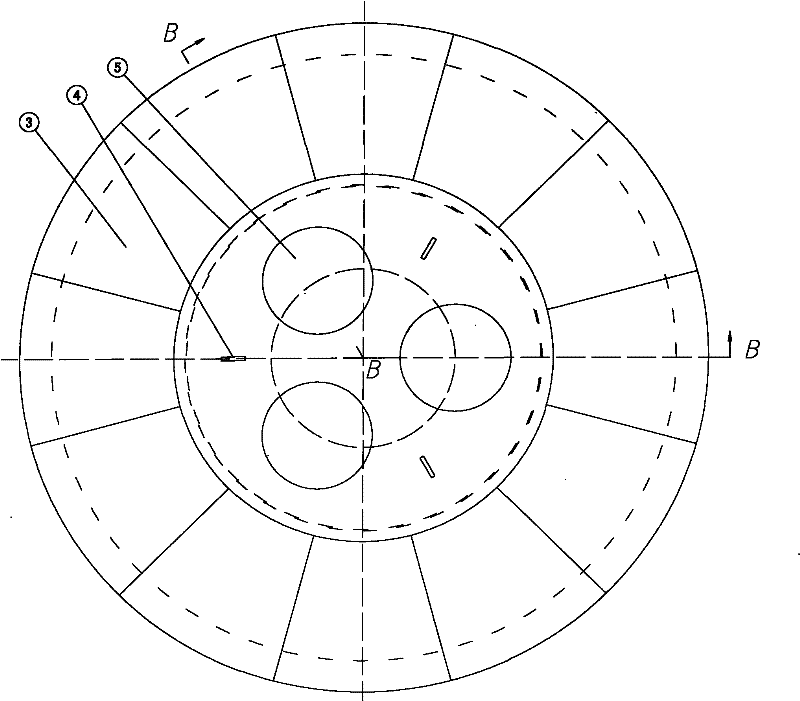

[0029] 2, press Figure 5 , Figure 6 , Figure 7 , Figure 8 Make the prefabricated parts of the furnace top small furnace cover ② and the surrounding furnace cover ③ respectively, and the selection of prefabricated materials is as follows:

[0030] Castable for furnace top small furnace cover ②

[0031]

[0032] Castables for surrounding furnace cover ③

[0033]

[0034]

[0035] The manufacturing process and process of the prefabricated part of the furnace cover are the same as those of the general prefabricated part, and the small furnace cover on the furnace top needs to pre-embed the hook ④.

[0036] 3. Press the prefabricated parts of the surrounding furnace cover ③ Figure 9 Assemble on the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com