Patents

Literature

85results about How to "Promote ongoing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

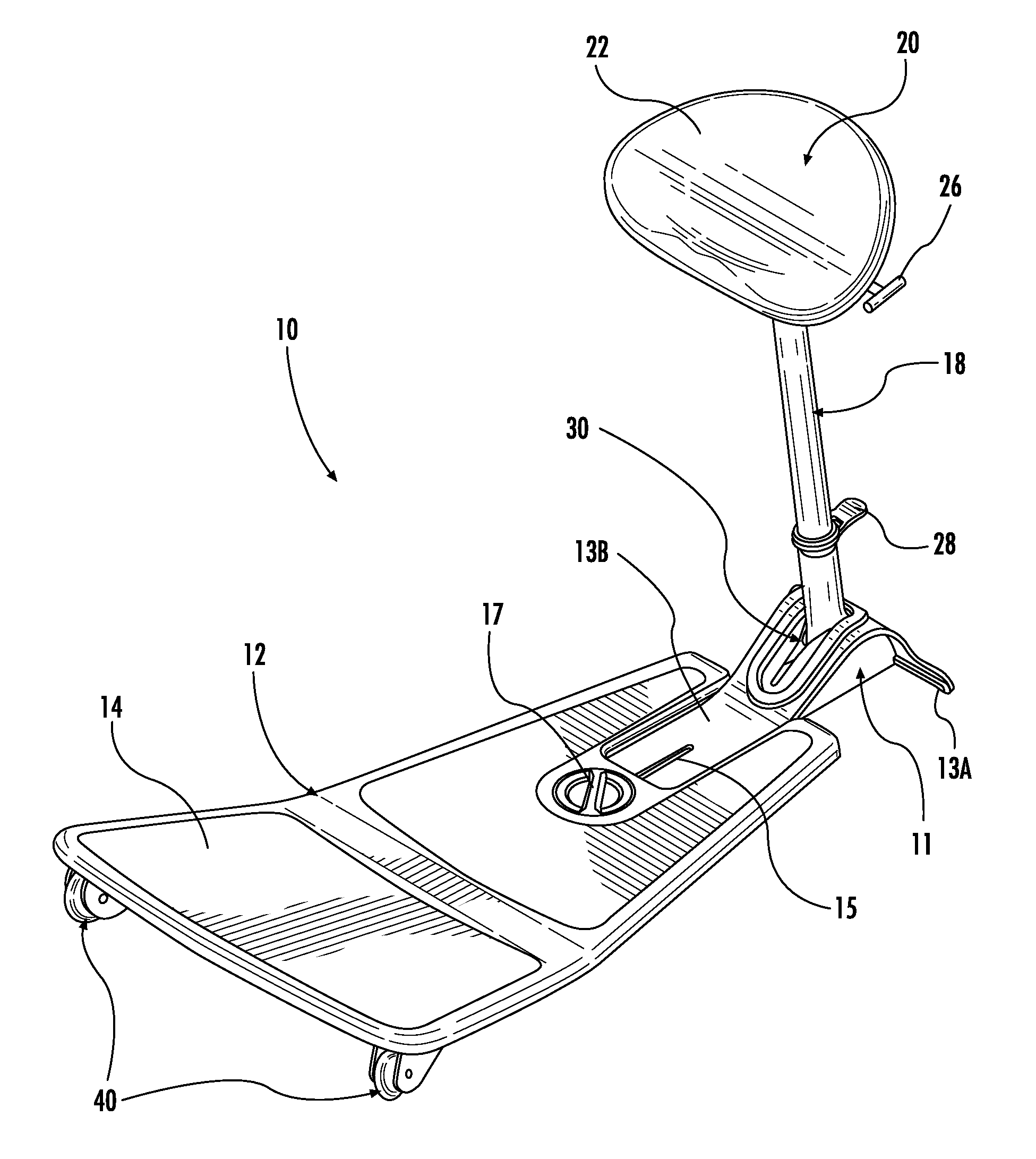

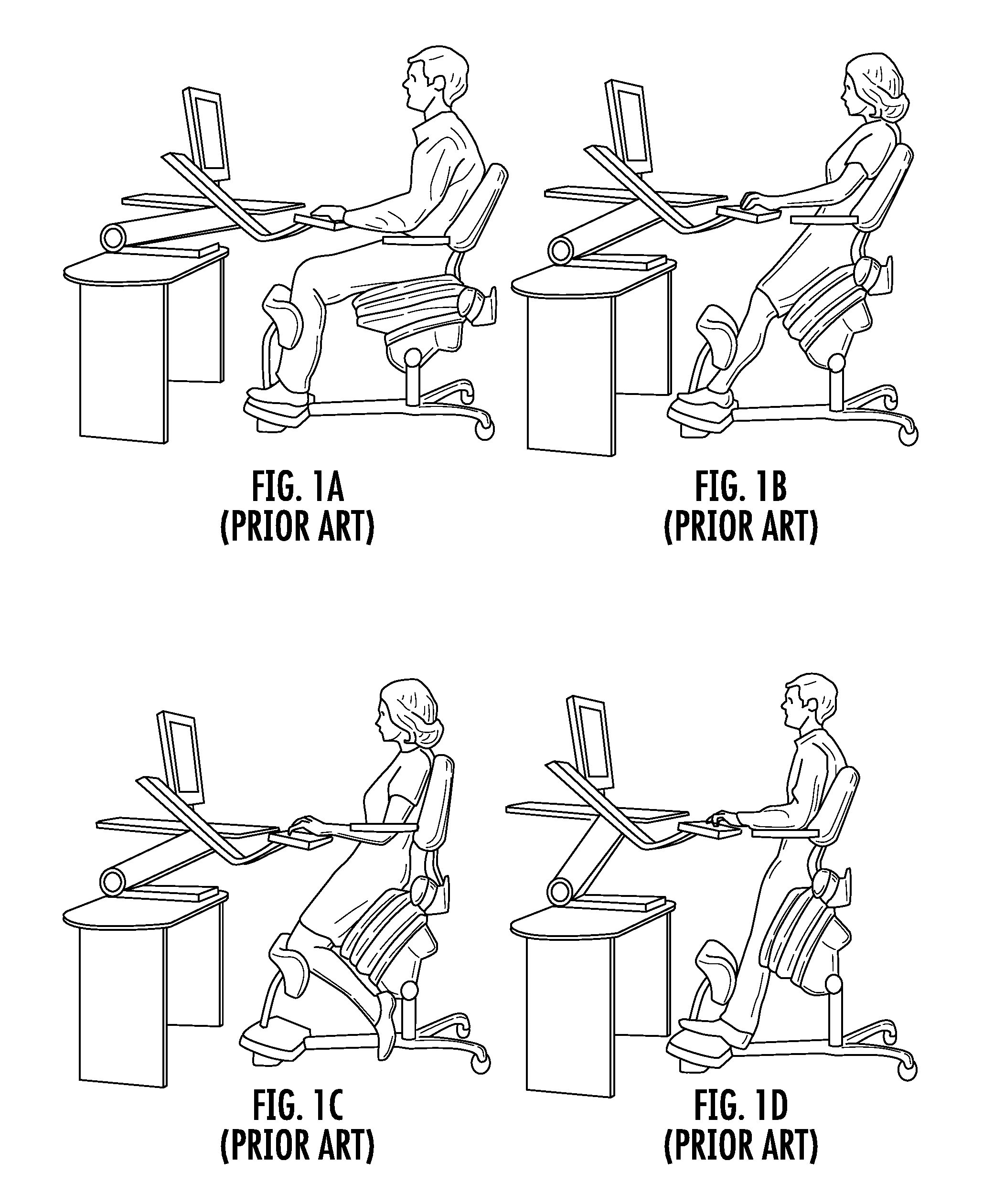

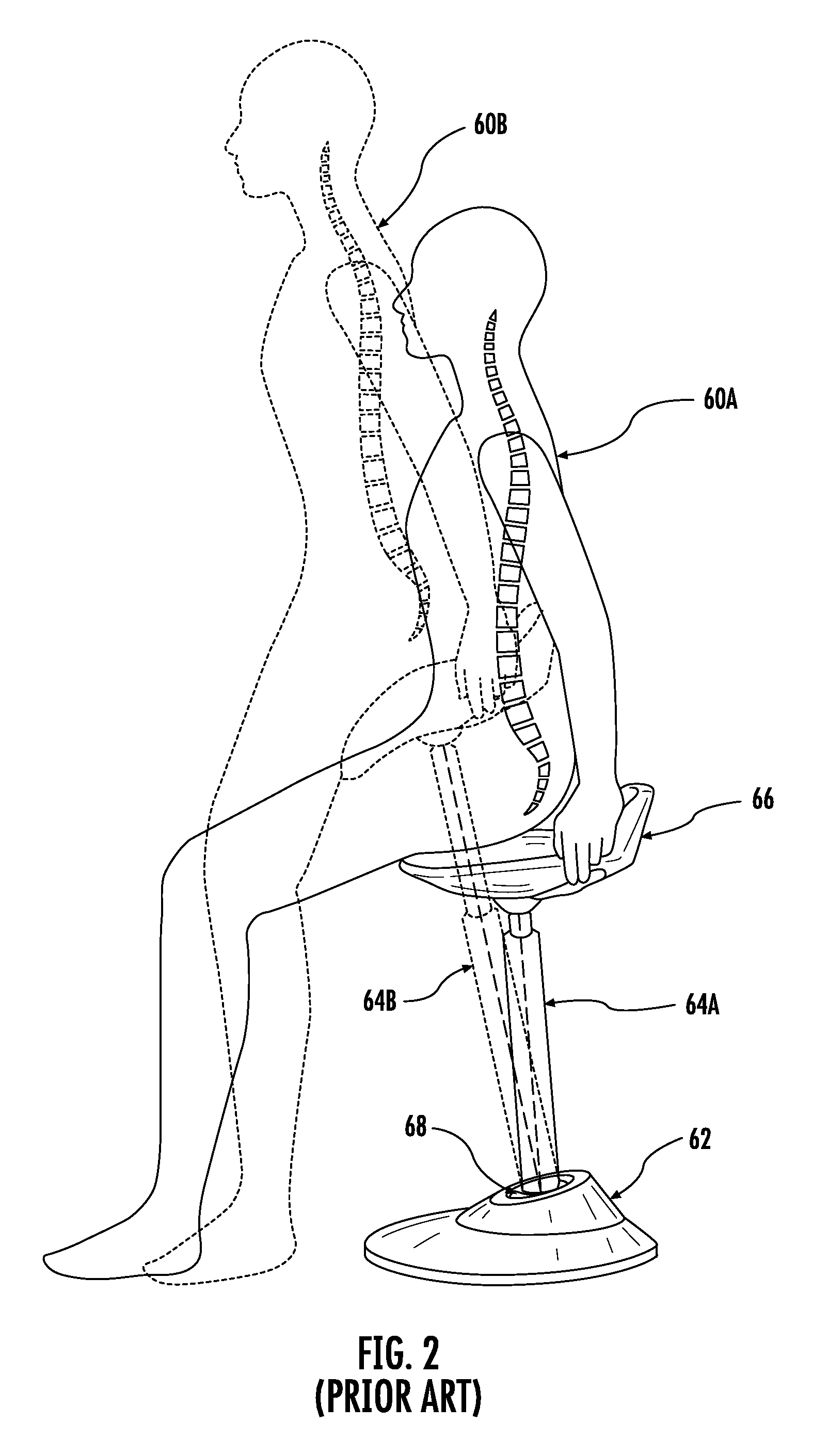

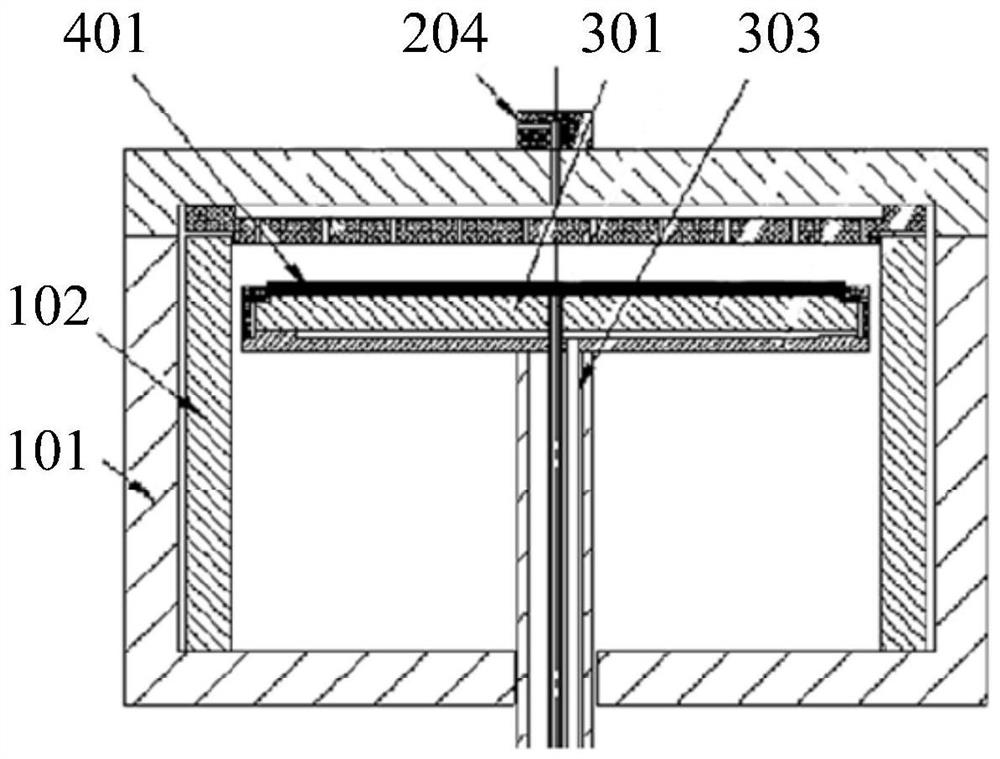

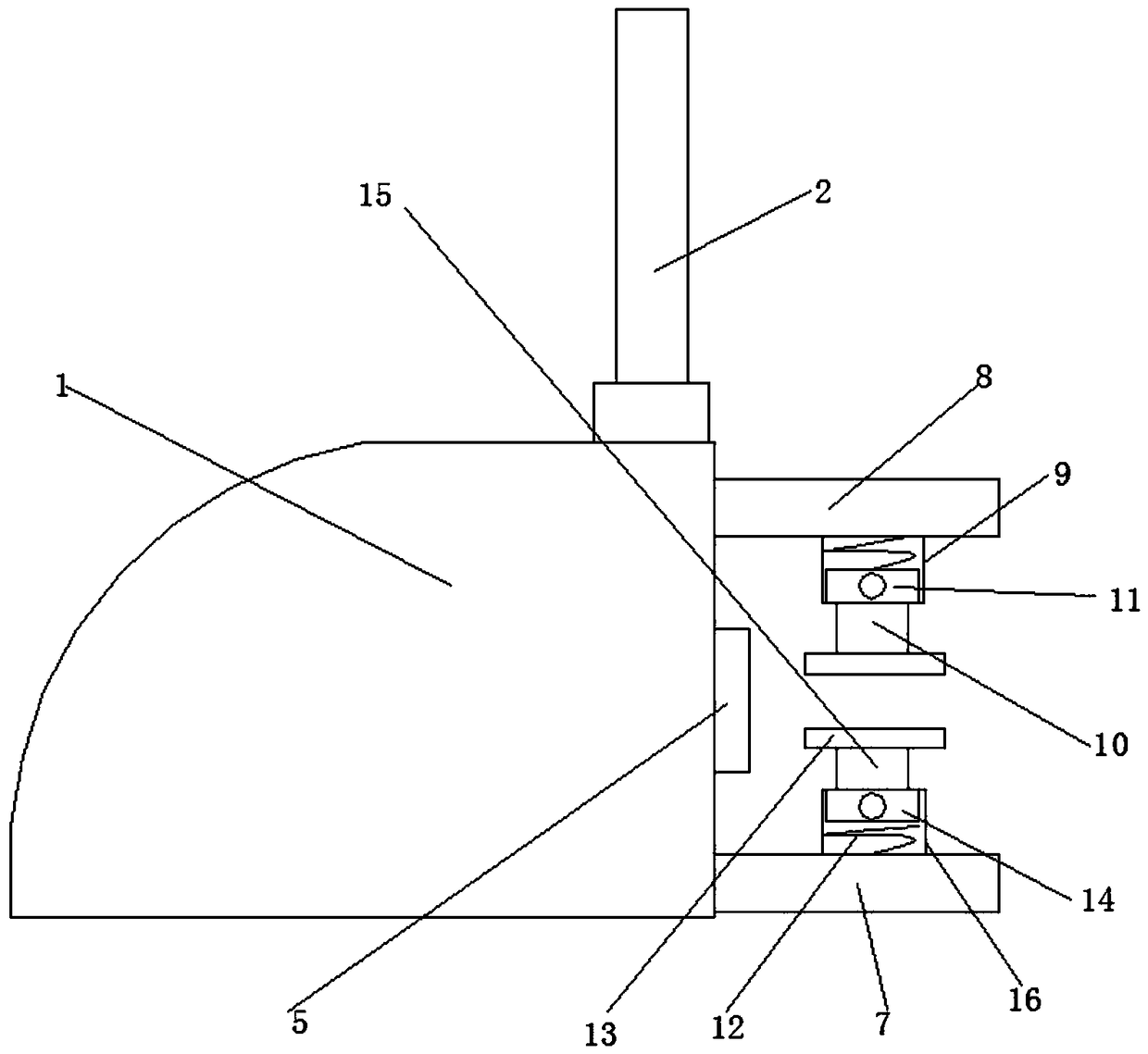

Upright active-sitting seat

ActiveUS20130306831A1Freedom of movementPromote ongoingOffice stoolsYielding couplingCoil springEngineering

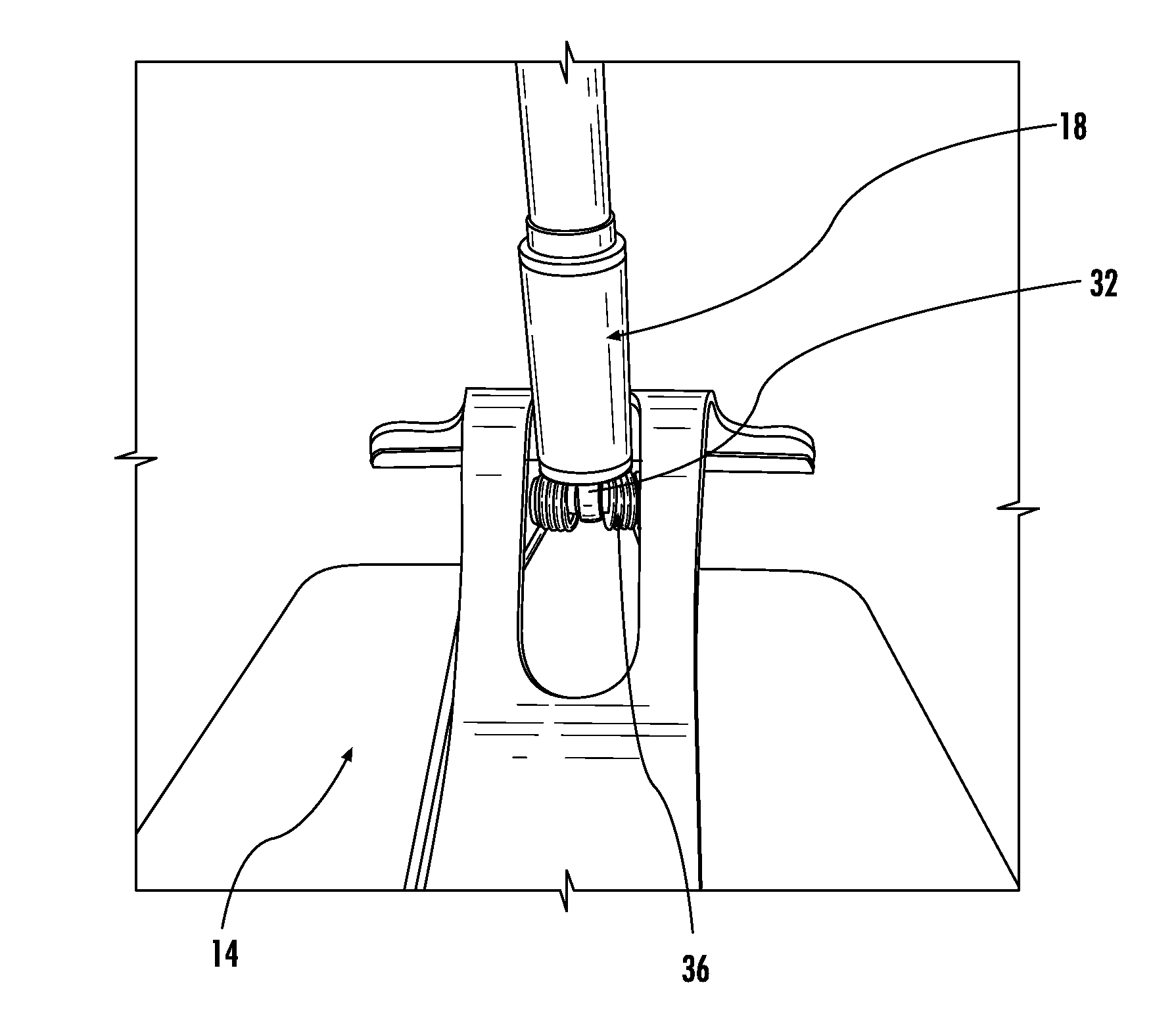

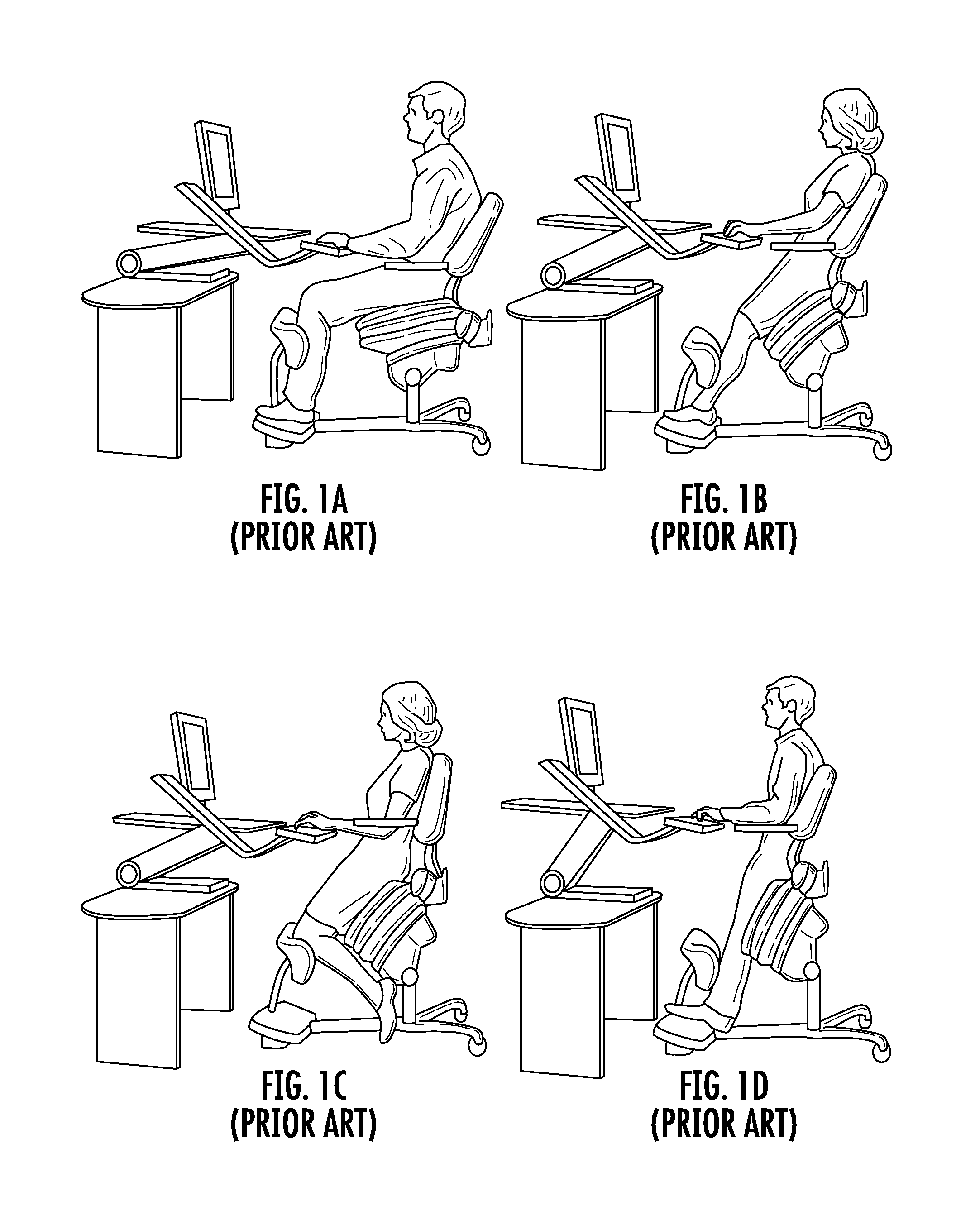

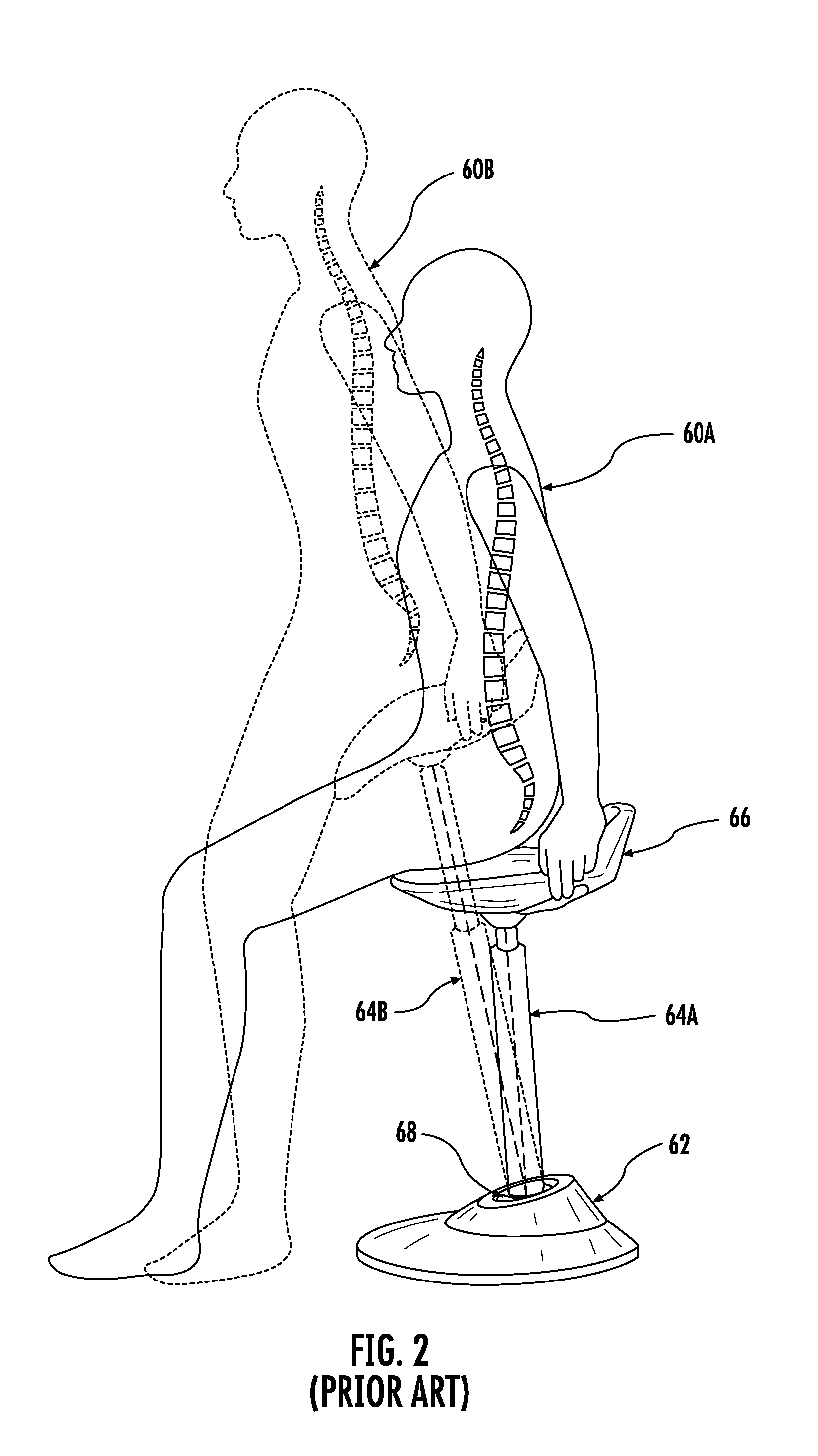

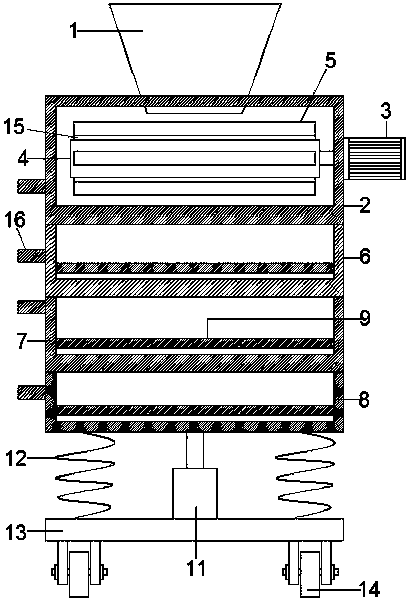

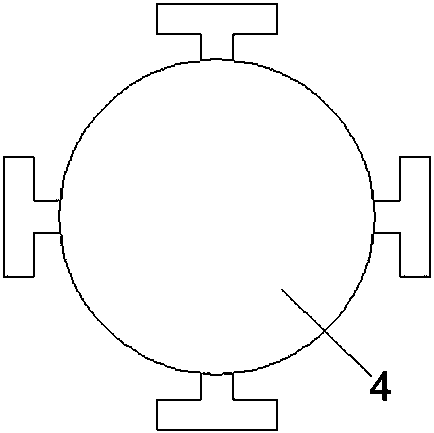

An upright active-sitting seat provides a connection of a seating leg to a base through an articulating joint that allows the user to move a seat front to back and side to side, allowing a more active sitting that encourages blood circulation. The chair includes a seat supported by a post that is connected to a mount via a ball joint rod by a transverse rod that is routed through the ball joint rod end. By way of a coil spring that engages with the mount and the post, the post is spring biased to a home position relative to the mount. When using the chair, a person may move the seat from the home position to a comfortable seating position. When the person stands from the chair after using it, the chair returns to its spring biased home position.

Owner:SAFCO PRODS

Nanometer enhanced type fluorosilicone rubber long-acting anti-fouling flashing coating

ActiveCN101338159AIncreased hydrophobic migration speedIncreased durability of hydrophobic migrationAntifouling/underwater paintsPaints with biocidesInsulation layerElectric power system

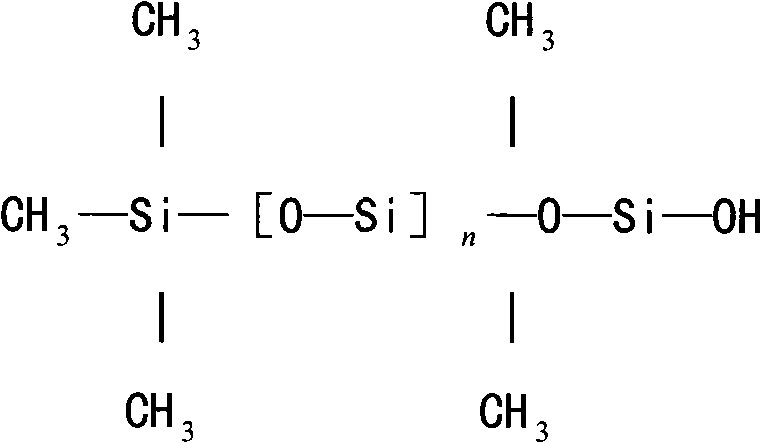

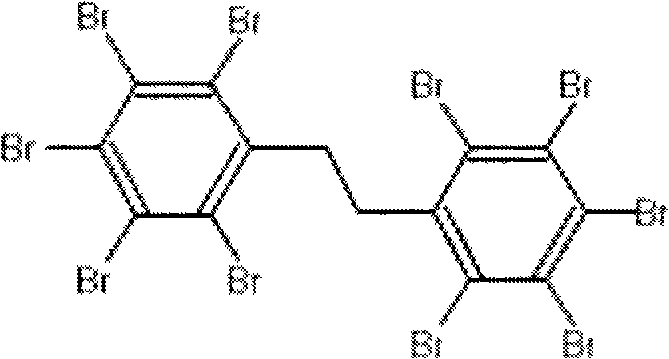

The invention provides a nanometer strengthening fluoride silicone rubber long-acting anti fouling and flashing coating material (nano PRTV coating material) which is used on an external insulation layer of a power system high pressure transmission and transformation device. The coating is composed of the following compositions (weight portion) of 20-40 percent of hydroxyl-fluoride containing polysiloxane, 2-5 percent of small molecular siloxane, 1-6 percent of cross linker, 0.02-1 percent of catalyst, 2-6 percent of nano silicon dioxide, 4-6 percent of decabromodiphenyl ethane, 1-2 percent of pigment and 30-50 percent of solvent. The coating provided by the invention is provided with perfect flame retardancy, solvent resistance, oil resistance, high and low temperature resistance and good self-cleaning performance. The surface of the coating material is smoother than dirt flash preventing coating material. Compared with the dirt flash preventing coating material, the coating material of the invention is greatly improved in aspects of hydrophobic migration speed, proportionality, sustainability, etc. Once filming can be realized. With the service life of more than 20 years, the coating material can be used permanently.

Owner:XIAN TAIPING ELECTRONICS TECH & DEVCO

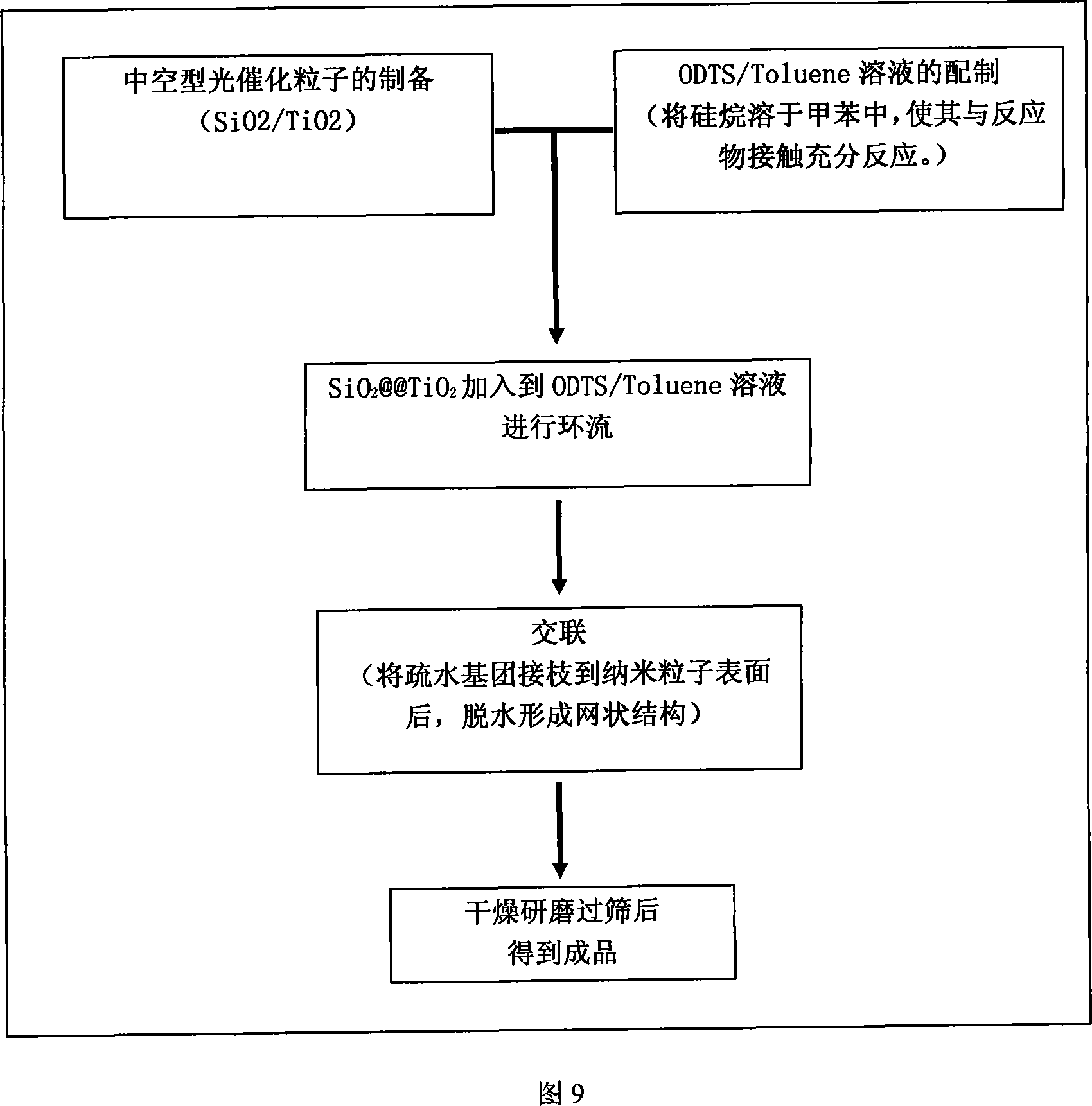

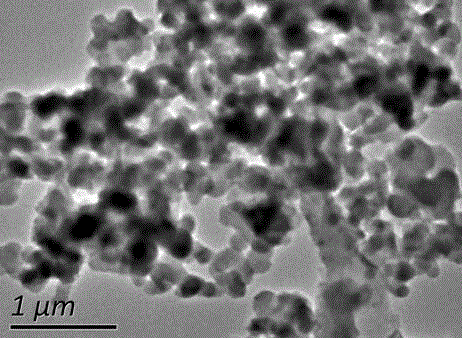

Method for preparing interface optical catalyst

ActiveCN101099929AAvoid direct contactSpread as soon as possibleCatalyst activation/preparationCross-linkPhotocatalytic reaction

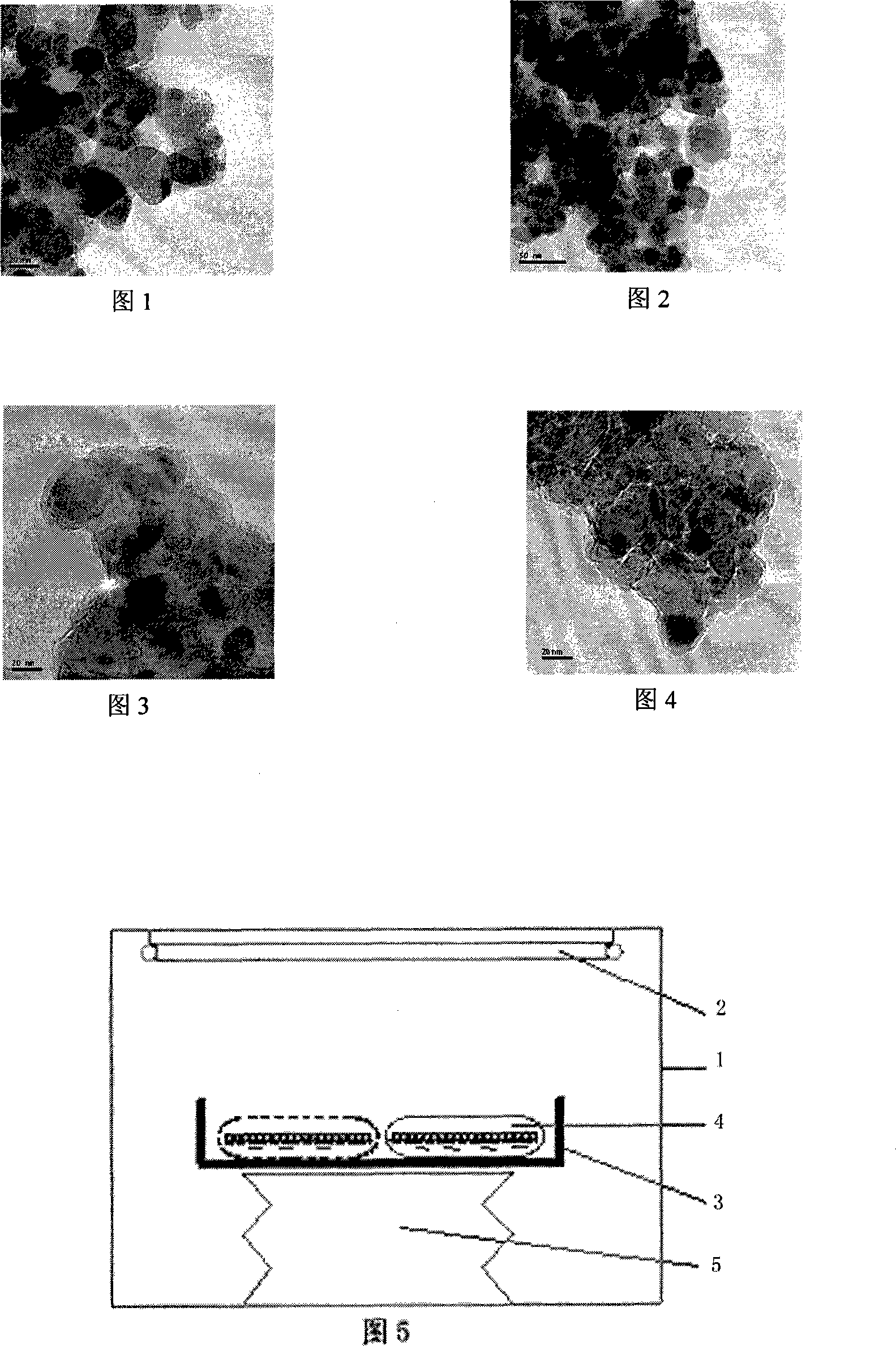

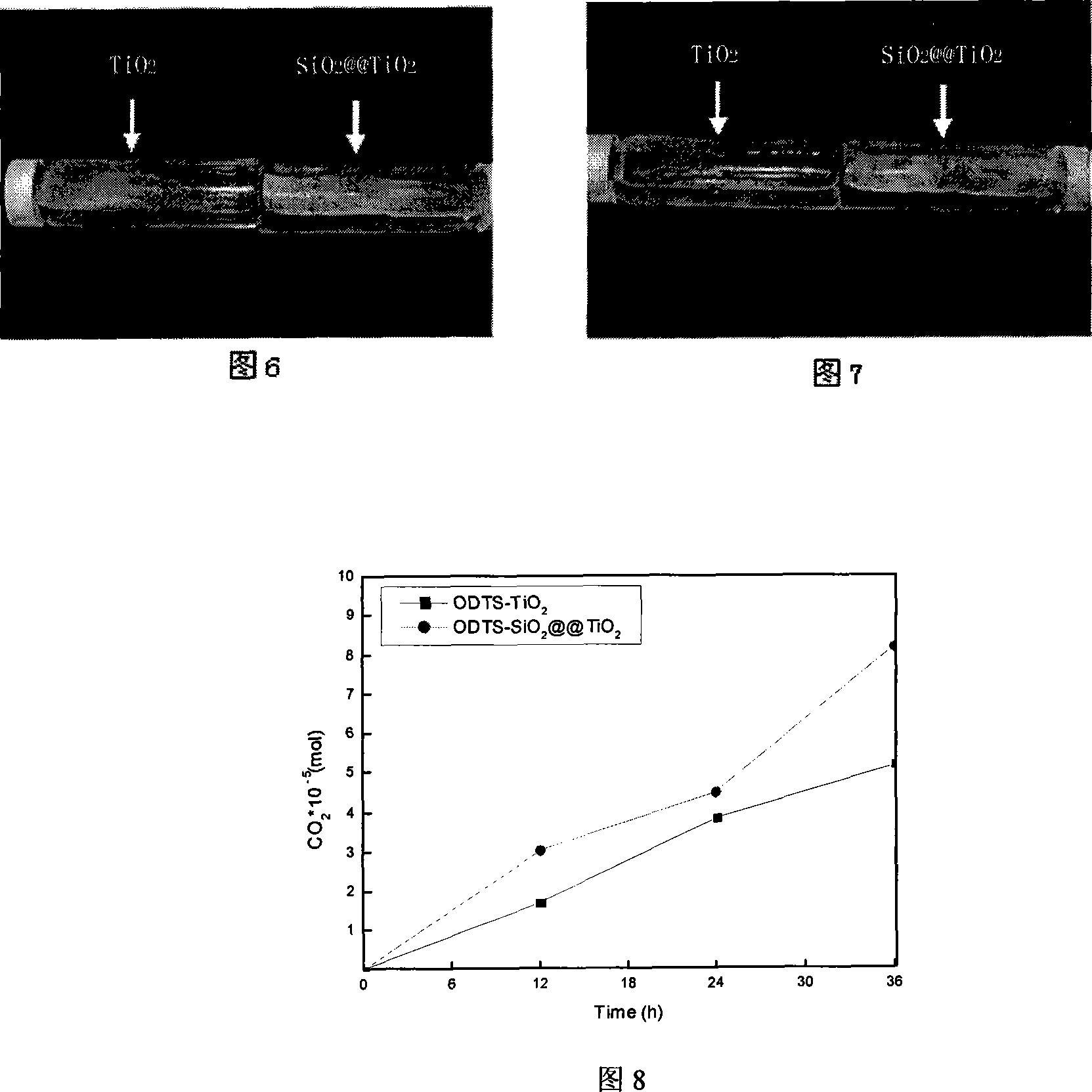

The present invention relates to one kind of interface photocatalyst, and solves the technological problem of preparing one interface photocatalyst capable of floating on water surface for photocatalytic reaction and with lasting photocatalytic activity. The interface photocatalyst floating on water surface can utilize sunlight well for photocatalysis to decompose pollutant and may be recovered easily, with the decomposition produced CO2 being dispersed to the air directly. It is prepared through the following steps: 1. preparing photocatalyst particle in SiO2-hollow layer-TiO2 structure and with nanometer core; 2. preparing hydrophobic solution; 3. preparing hydrophobic hollow nanometer photocatalyst particle; and 4. cross-linking hydrophobic groups of hollow nanometer photocatalyst particle. The present invention is applied in degrading toxic pollutant to protect environment.

Owner:ZHEJIANG SCI-TECH UNIV

Upright active-sitting seat

An upright active-sitting seat provides a connection of a seating leg to a base through an articulating joint that allows the user to move a seat front to back and side to side, allowing a more active sitting that encourages blood circulation. The chair includes a seat supported by a post that is connected to a mount via a ball joint rod by a transverse rod that is routed through the ball joint rod end. By way of a coil spring that engages with the mount and the post, the post is spring biased to a home position relative to the mount. When using the chair, a person may move the seat from the home position to a comfortable seating position. When the person stands from the chair after using it, the chair returns to its spring biased home position.

Owner:SAFCO PRODS

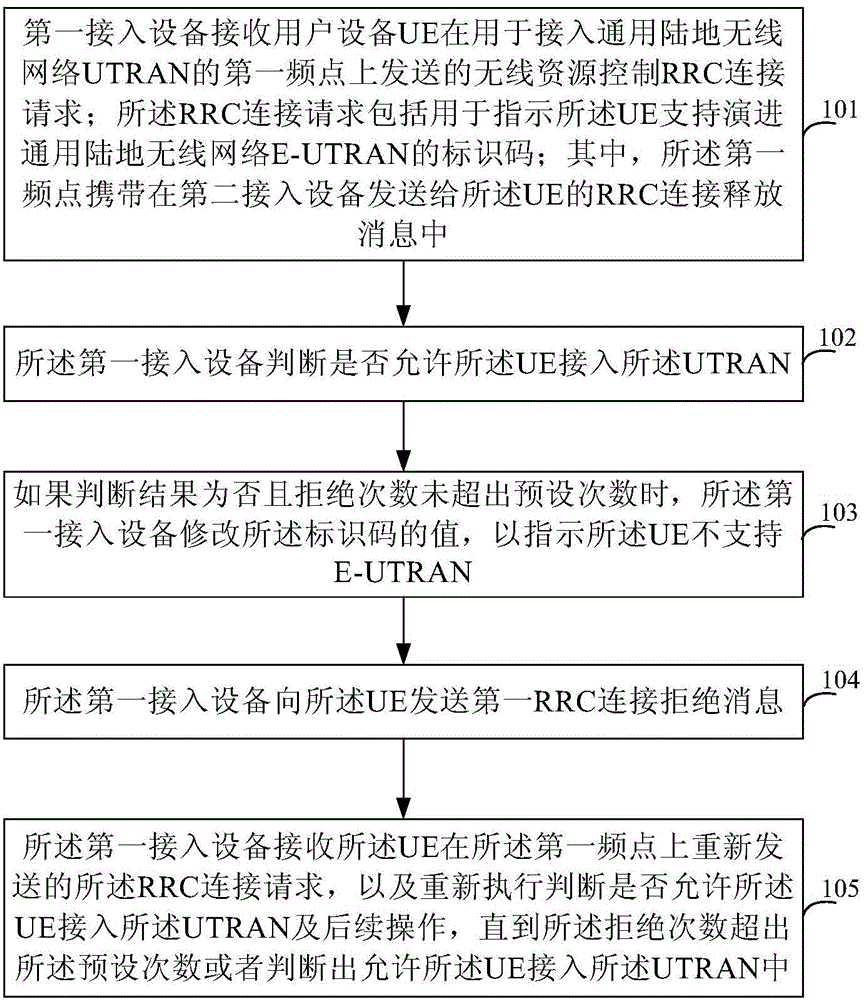

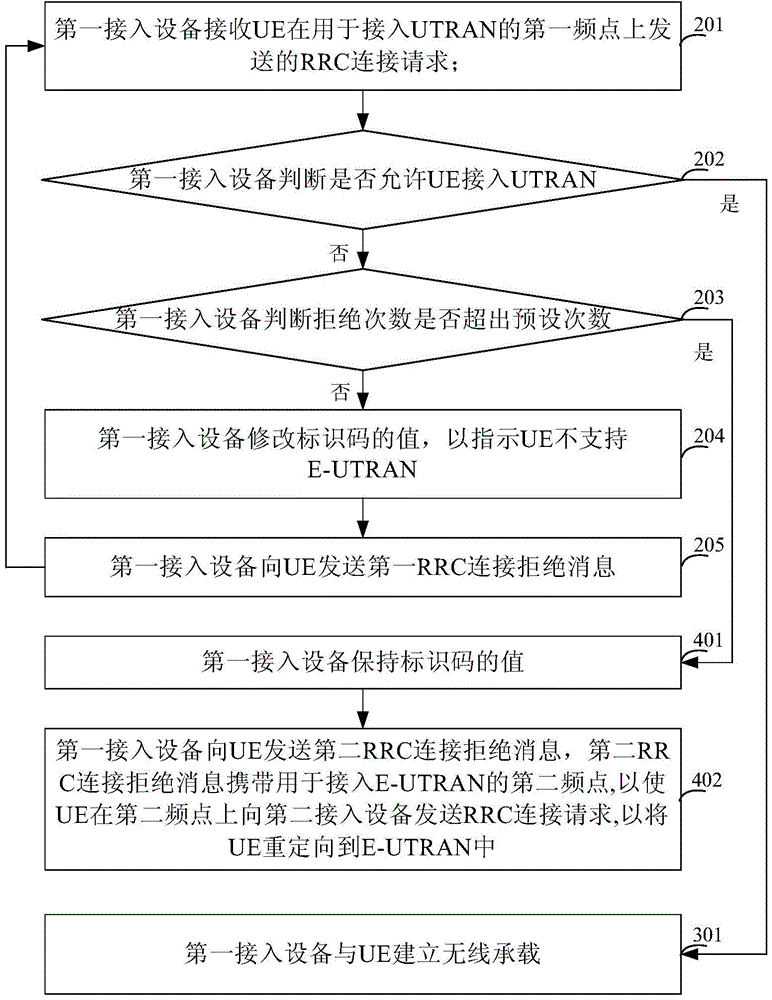

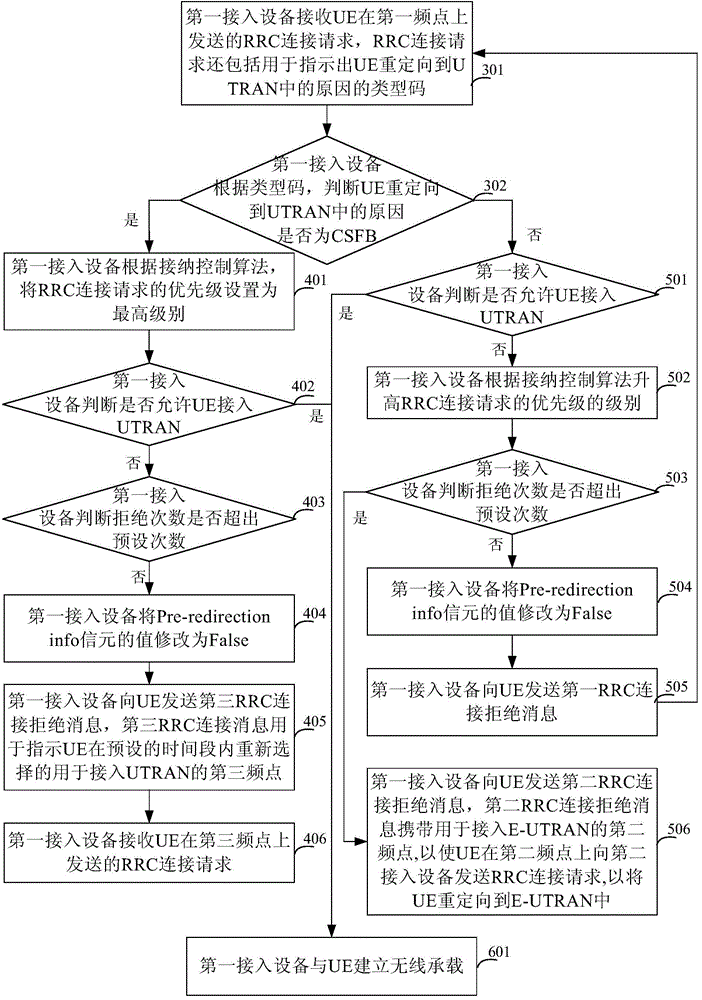

Network redirection method and device

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Method for producing biogas by virtue of anaerobic digestion of waste oil/fat

ActiveCN103966302AImprove fat degradation efficiencyPromote degradationMicroorganism based processesWaste based fuelMicroorganismAnaerobic bacteria

The invention discloses a method for producing biogas by virtue of anaerobic digestion of waste oil / fat. The method comprises the steps of preparing an anaerobic fermentation strain, adding an inorganic medium and carrying out an anaerobic digestion, and comprises the following specific steps: adding anaerobically digested sludge and fat-degradable bacteria to a base culture medium as an anaerobic fermentation strain, wherein the mass ratio of the anaerobically digested sludge, fat-degradable bacteria and base culture medium is (100-300):(1-2):1000; adding an inorganic medium into the anaerobic fermentation strain at a mass ratio of (1-12):100; sequentially adding the anaerobic fermentation strain, waste oil / fat and additives at a mass percentage of 100:(1-2):(0.1-0. 15) into an anaerobic fermentation device, evenly mixing and carrying out an anaerobic fermentation to produce biogas. The activity of fat-degradation in the reaction system is increased by adding microorganisms and acclimating to form an anaerobic bacteria strain, the adhesion and contact area between the microorganism and oil / fat is increased by adding the inorganic medium, and thus the waste oil / fat is converted into biogas.

Owner:BIOGAS SCI RES INST MIN OF AGRI

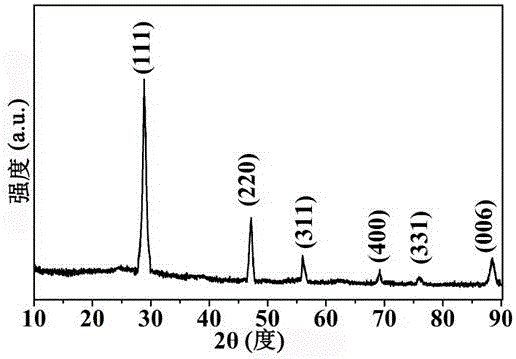

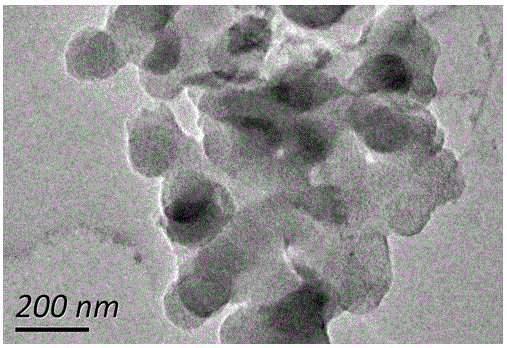

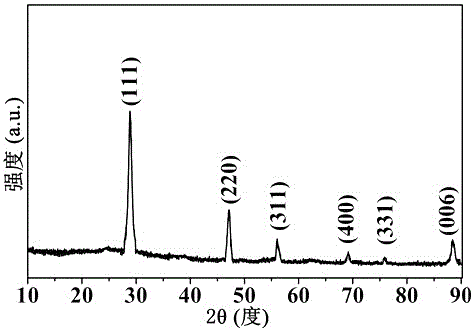

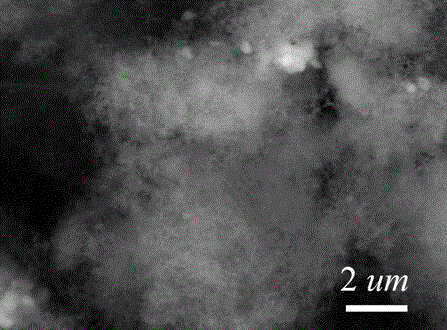

Low-temperature preparation method of rice-hull-based porous silicon material

InactiveCN106430213ASimple processLow priceMaterial nanotechnologyCell electrodesPorous siliconMaterials science

The invention discloses a low-temperature preparation method of a rice-hull-based porous silicon material and belongs to the technical field of nanoelectrode material preparation. The method comprises the steps that first, washed and dried rice hulls are heated and oxidized in air to obtain rice hull ash, then the rich hull ash is soaked with diluted hydrochloric acid, washed with distilled water and dried, and the dried rich hull ash is obtained; the dried rich hull ash, aluminum powder or a mixture of aluminum powder and magnesium powder and a chloride mixture are mixed and then subjected to a sealed heating reaction, the temperature is kept till the reaction is over, then the mixture is cooled to room temperature, the product obtained after the reaction is collected, soaked with diluted hydrochloric acid and washed with distilled water, and the rice-hull-based porous silicon material is obtained. The method has the advantages that the process is simple, the raw materials are low in price, the reaction process has a low requirement for temperature, and the yield is high; the prepared rice-hull-based porous silicon material has excellent electrochemical performance and can be used as a lithium ion battery cathode material, thereby providing a new way for high-value-added utilization of the rice hulls.

Owner:YANGZHOU UNIV

Ball milling preparation method of rice hull-based porous silicon nanomaterial

The present invention provides a ball milling preparation method of a rice hull-based porous silicon nanomaterial, belonging to the technical field of preparation of nano-electrode materials. The method comprises the steps of heating to oxidize or incompletely oxidize water-washed and dried rice hull in air, so as to obtain rice hull ash, then soaking by using dilute hydrochloric acid, washing with distilled water and then drying, and obtaining the dried rice hull ash; and mixing the dried rice hull ash with aluminum powder, or aluminum powder, magnesium powder and a corresponding chloride so as to obtain a mixed material, then putting the mixed material in a ball milling machine to grind and cool to room temperature, collecting the product, soaking with dilute hydrochloric acid, then washing with distilled water so as to obtain the rice hull-based porous silicon nanomaterial. The preparation method is simple, the cost of the raw material is low, the yield is high, solid phase reaction is good for industrial production, and the prepared rice hull-based porous silicon nanomaterial has excellent electrochemical performance.

Owner:YANGZHOU UNIV

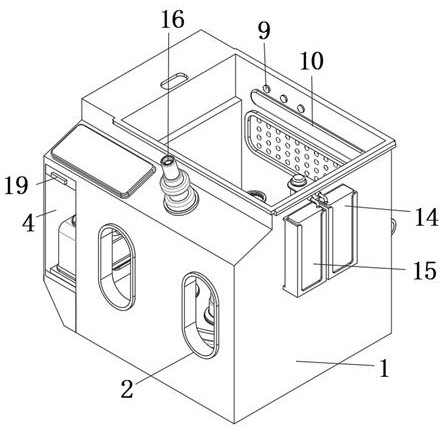

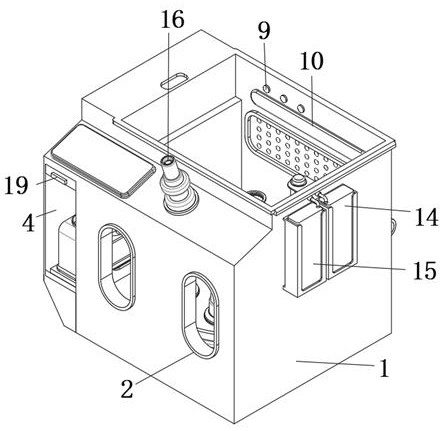

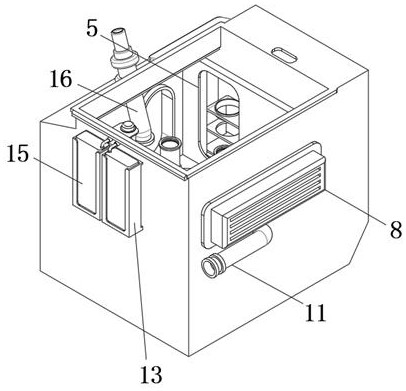

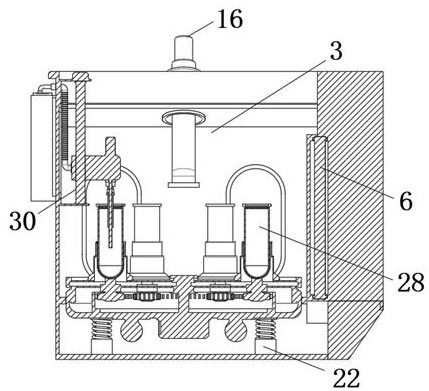

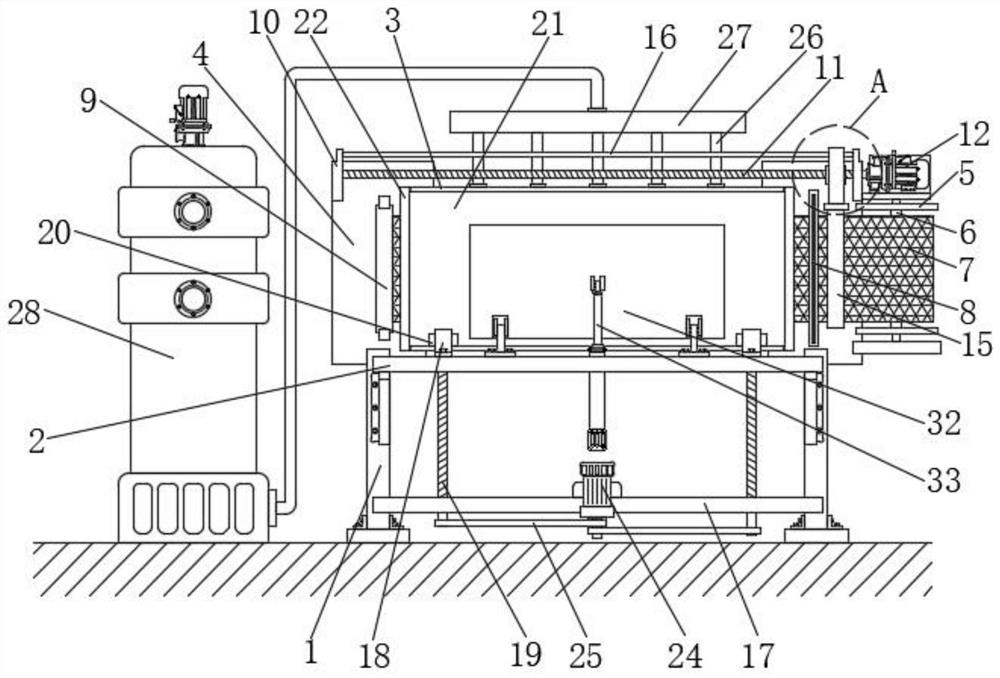

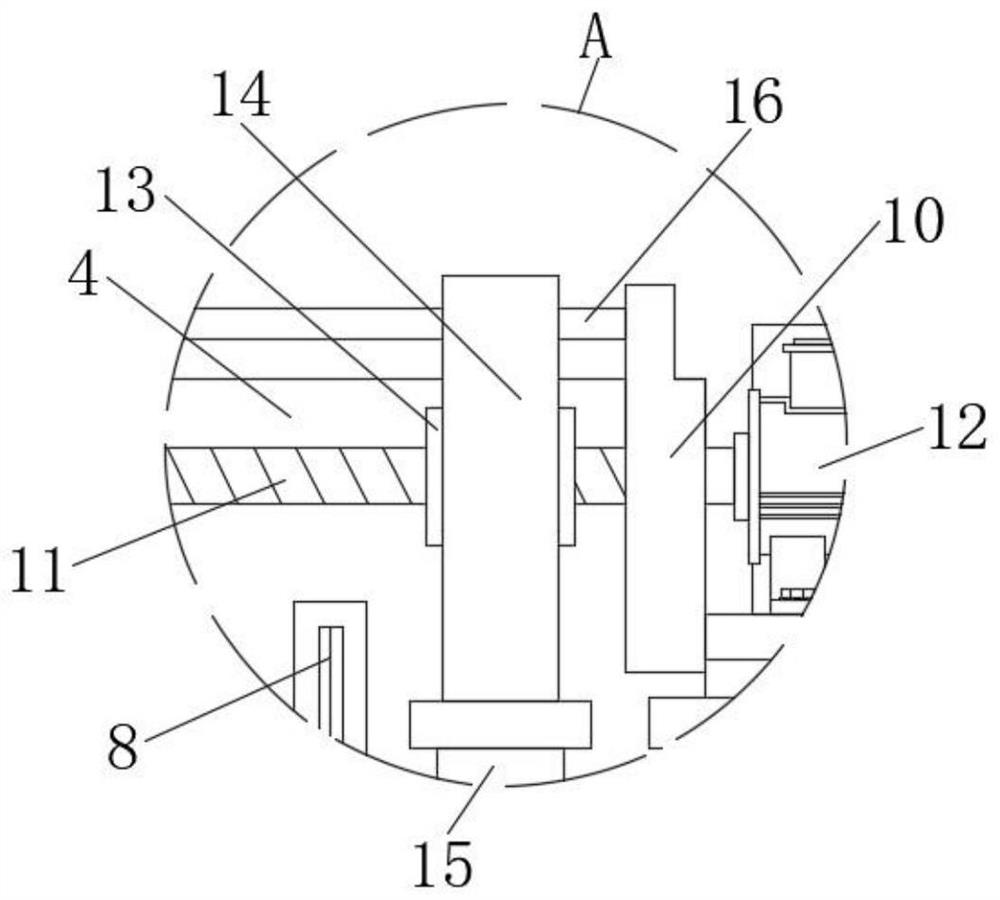

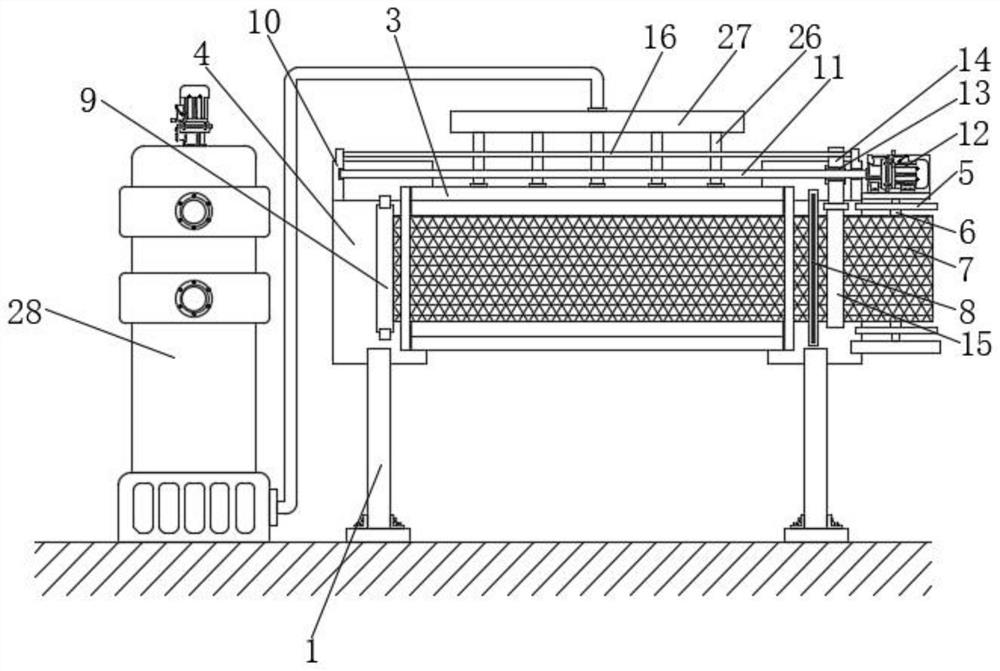

Medical cell culture equipment and cell culture method

ActiveCN111748473AIncrease mixing rateEnsure and maintain cell culture temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringBiotechnology

The invention discloses medical cell culture equipment and a cell culture method, which relate to the technical field of cell culture. The equipment comprises an incubator, a sealing cover is hinged to the top surface of the incubator; two operation holes are fixedly formed in the end surface of the incubator; rubber operation gloves are mounted on the surfaces of the two operation holes; the interior of the incubator is divided into a culture cavity and a transfer cavity through a partition plate; a transfer hole is formed in a communication part of the culture cavity and the transfer cavity;a sealing door mechanism is fixedly mounted on the inner wall of the culture cavity; one surface of the sealing door mechanism is slidably sealed with the transfer hole. Through the design of the transfer cavity, the sealing door mechanism and a positive-pressure air blowing assembly in the incubator, the probability that external impurity-containing and bacterium-containing air enters a culturedish can be effectively reduced in a cavity separation and positive-pressure air blowing mode during sampling of the equipment, and the normal environment during cell culture can be effectively guaranteed through reduction of the pollution probability.

Owner:湖南南华爱世普林生物技术有限公司

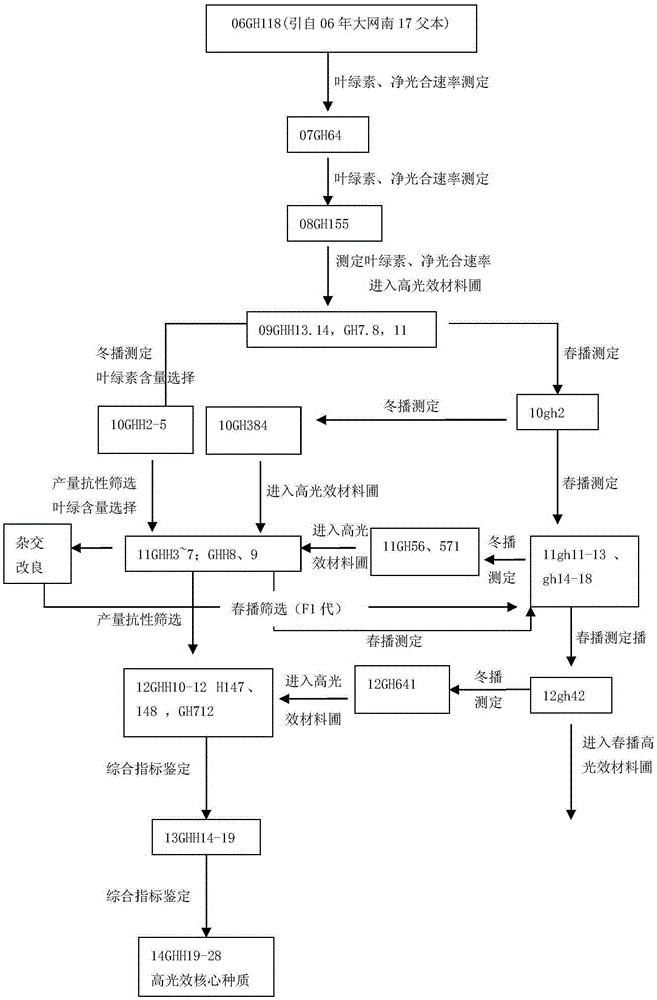

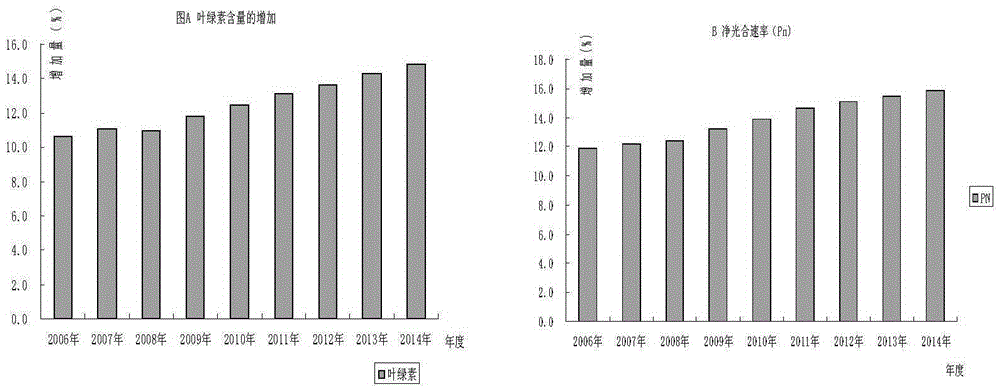

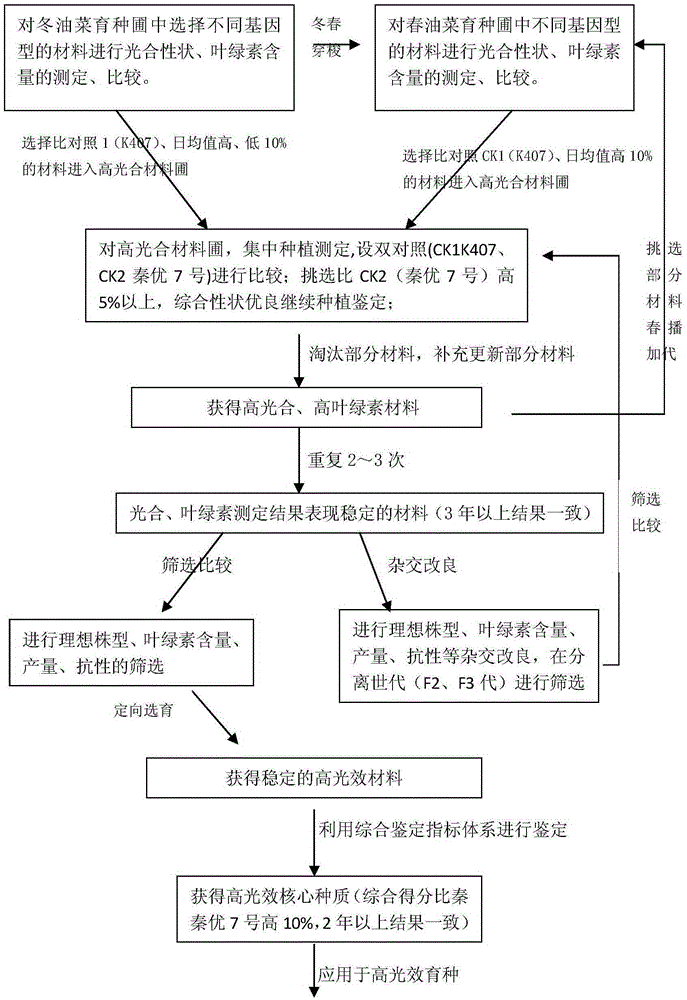

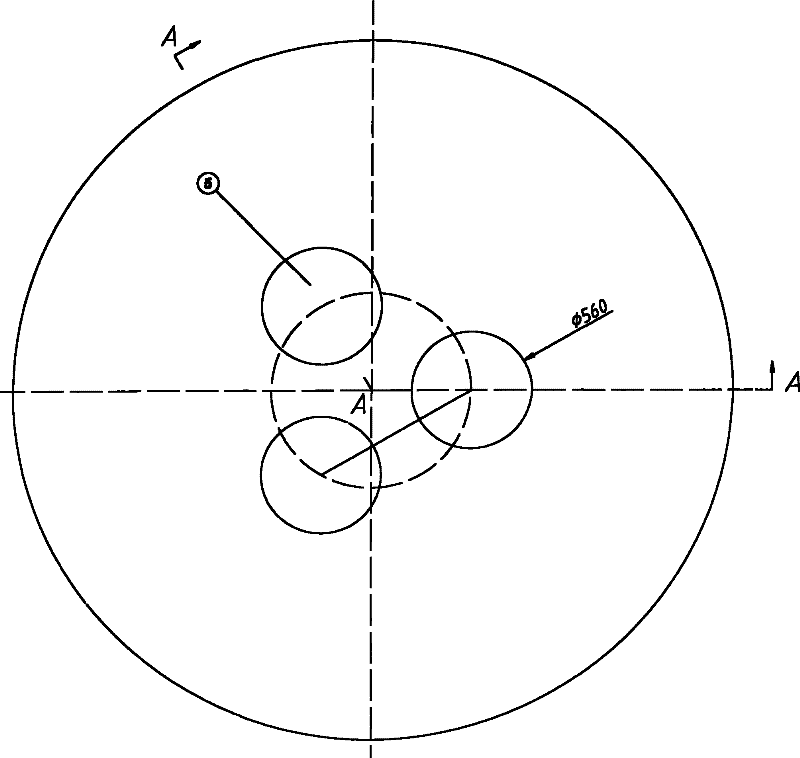

Breeding method of high-photosynthetic-efficiency core collections of rape

InactiveCN105248272AIncrease or decrease percentageAvoid differencesPlant genotype modificationGermplasmFishery

A breeding method of high-photosynthetic-efficiency core collections of rape comprises steps as follows: (1) screening of a high-photosynthetic-efficiency material of the rape; (2) screening of a high-photosynthetic-efficiency breeding nursery material; (3) rolling management of a high-photosynthetic-efficiency breeding nursery; (4) directional breeding of a high-photosynthetic-efficiency material; (5) hybrid improvement of the high-photosynthetic-efficiency material; (6) comprehensive identification of the high-photosynthetic-efficiency core collections. The breeding method has the characteristics that quantization and mechanical repetition can be realized, the non-transgenic technology is adopted and risks are avoided, increases the crop yield through improvement on the photosynthetic efficiency and has enormous yield increasing potential. With the adoption of the method, the requirement for screening the high-photosynthetic-efficiency collections of the rape can be met and the rape breeding method can be enriched and perfected; meanwhile, the method can provide beneficial reference for carrying out high-photosynthetic-efficiency breeding of other crops.

Owner:陕西省杂交油菜研究中心

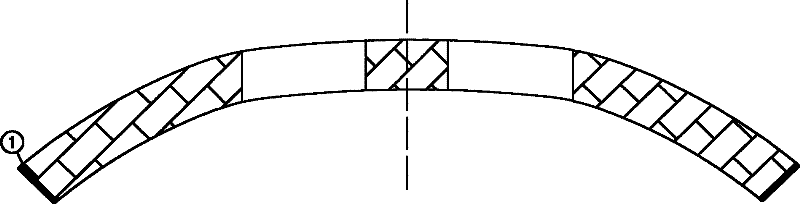

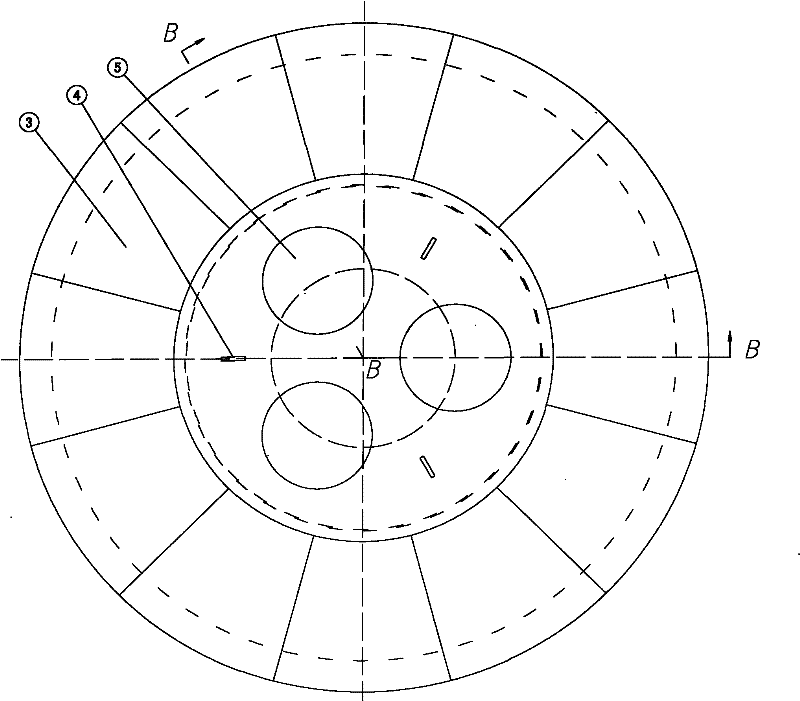

Combined arc furnace cover

InactiveCN102213545AEasy to manufactureSimple masonryLighting and heating apparatusElectric arc furnaceBrick

The invention discloses a combined arc furnace cover, which is assembled by two parts, namely a small furnace cover and a peripheral prefabricated part. Therefore, the small furnace cover on the top of the furnace, which is rapidly damaged, is convenient to replace directly on line. The traditional furnace cover is built by combining phosphate and high-alumina bricks. Compared with the traditional furnace cover, the arc furnace cover has the advantages of long comprehensive service life, convenience in building, simple replacement, simple production process and low production energy consumption.

Owner:张小旭

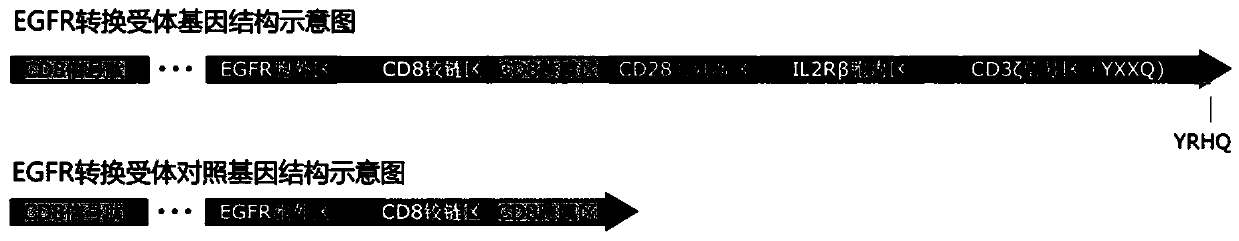

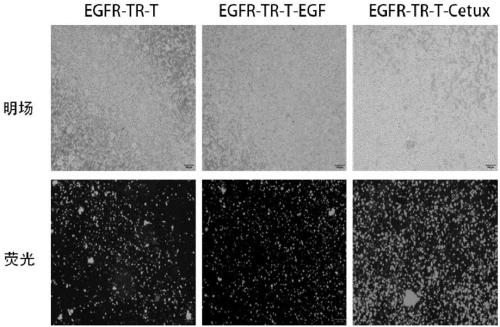

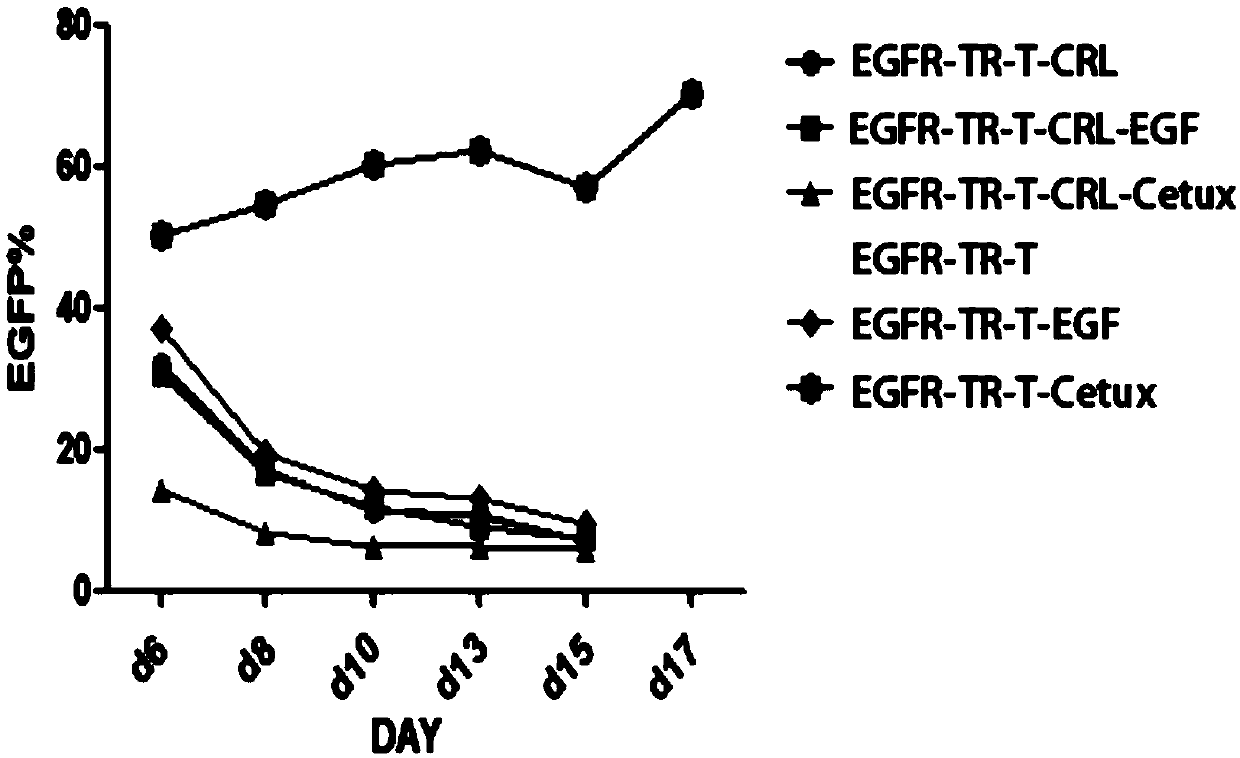

Immune effector cell conversion receptor

PendingCN111378046APromote proliferationPromote ongoingPolypeptide with localisation/targeting motifGenetically modified cellsEffector cellImmune effector

The invention provides an immune effector cell conversion receptor, coding nucleic acid of the immune effector cell conversion receptor, a nucleic acid construct containing the coding nucleic acid, animmune effector cell capable of expressing the immune effector cell conversion receptor, a pharmaceutical composition containing one or more selected from the group consisting of the immune effectorcell conversion receptor, the coding nucleic acid, the nucleic acid construct and the immune effector cell, a preparation method for the immune effector cell capable of expressing the immune effectorcell conversion receptor, and an application of one or more selected from the group consisting of the immune effector cell conversion receptor, the coding nucleic acid, the nucleic acid construct, theimmune effector cell and the pharmaceutical composition in preparation of anti-cancer drugs. According to the invention, through the interaction between the immune effector cell conversion receptor and a binding protein thereof, cells capable of expressing the immune effector cell conversion receptor can be effectively stimulated; specifically, immune effector cells activate signaling of a downstream intracellular CD3 zeta region and an STAT5 transcription factor signaling pathway mediated by a white hormone receptor chain mediated STAT3 transcription factor and a CD3 zeta region STAT5 binding motif; proliferation and continuation of the cells can be effectively promoted; and a novel method is provided for stimulating and amplifying the cells in vivo and / or in vitro.

Owner:SHANGHAI CELL THERAPY GRP CO LTD +1

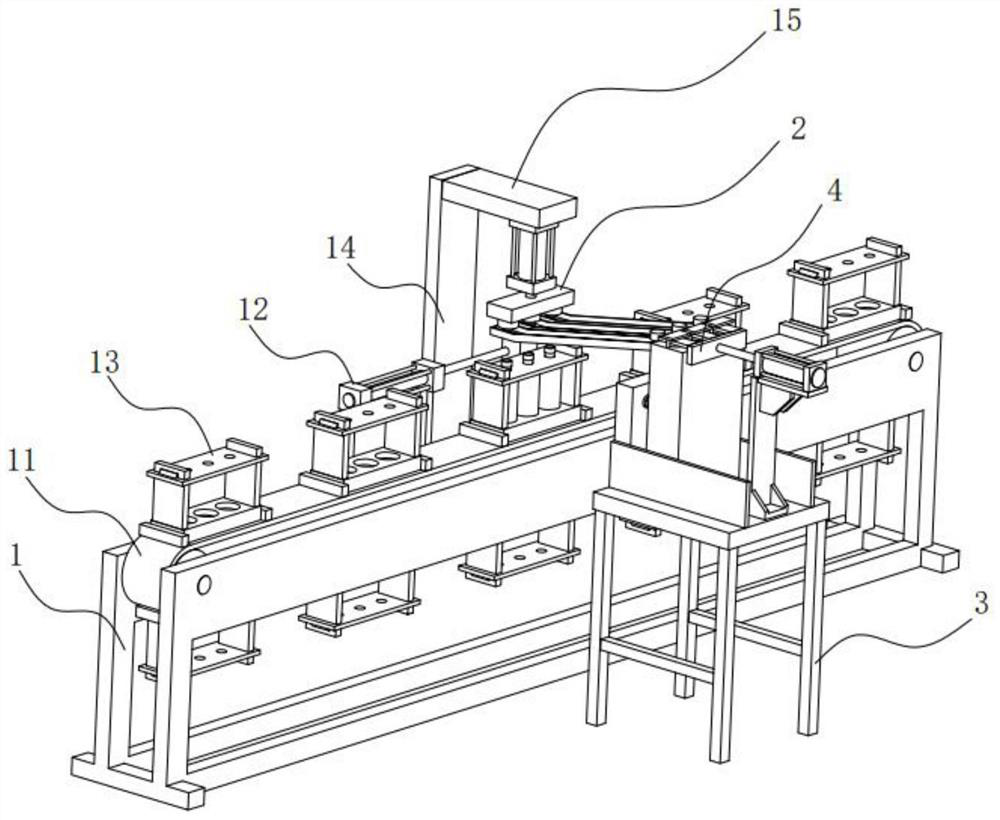

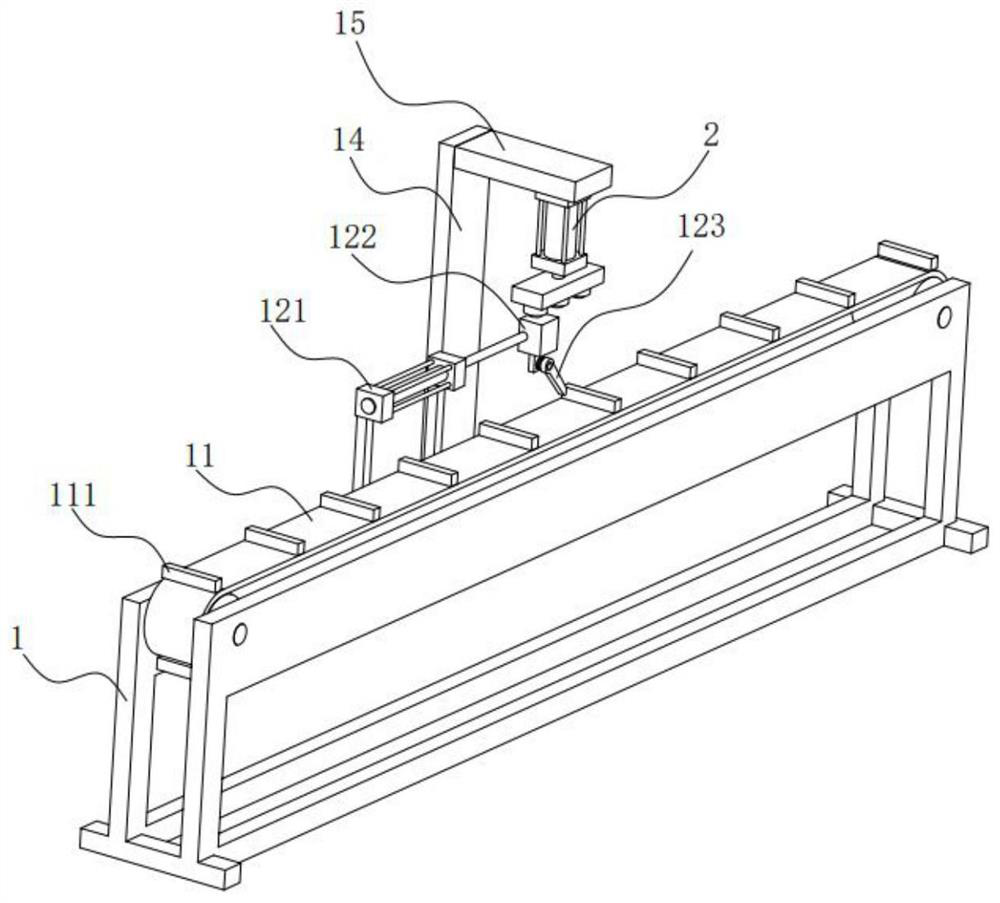

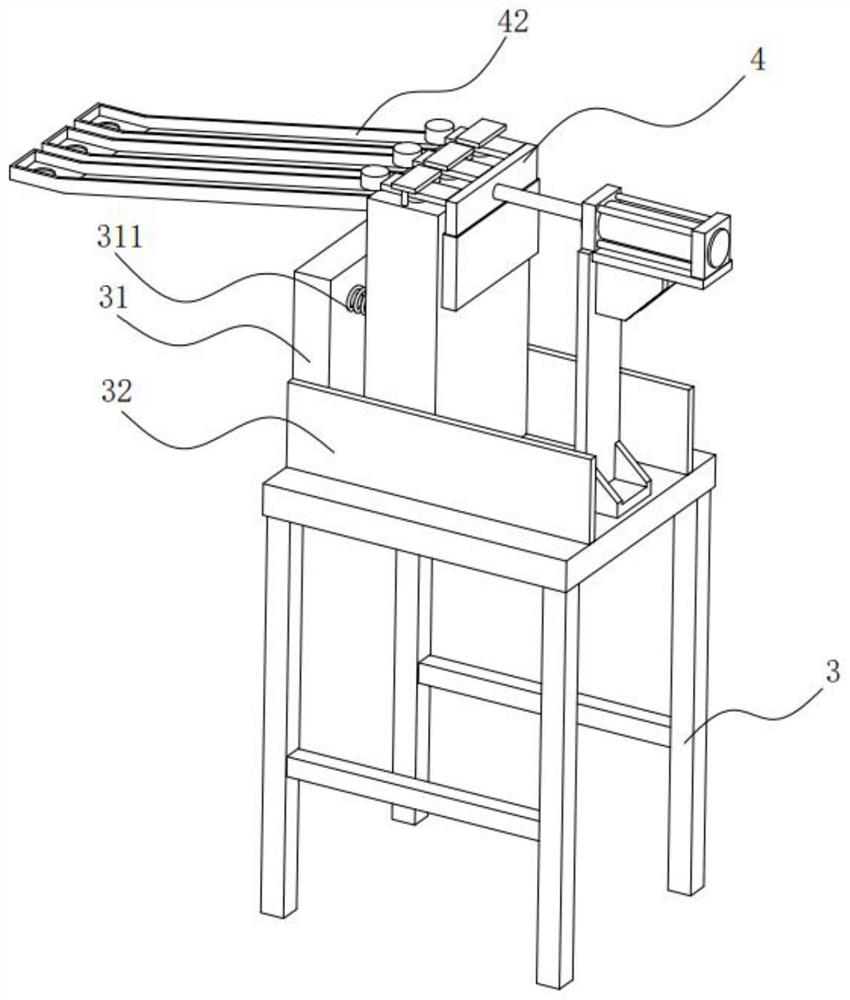

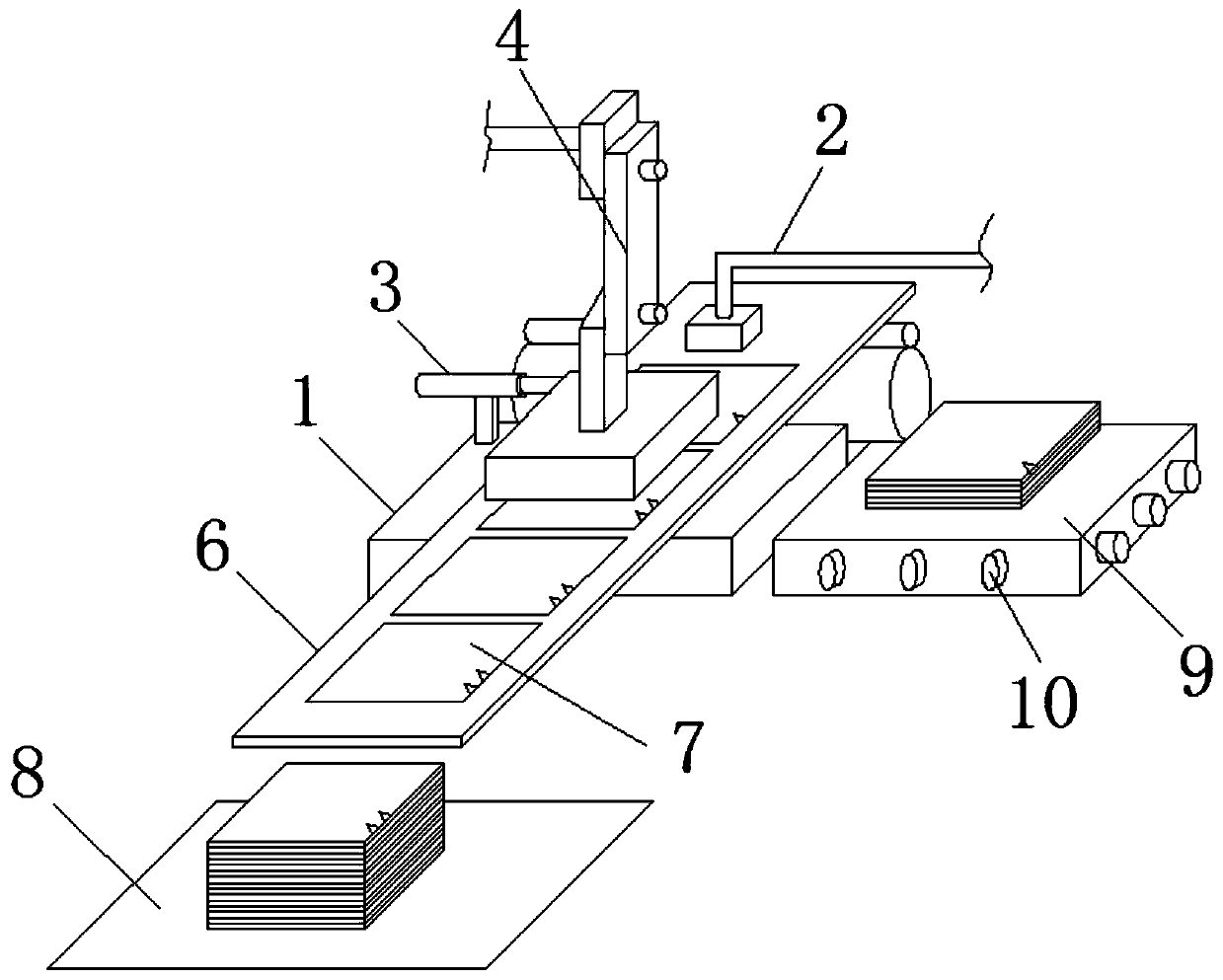

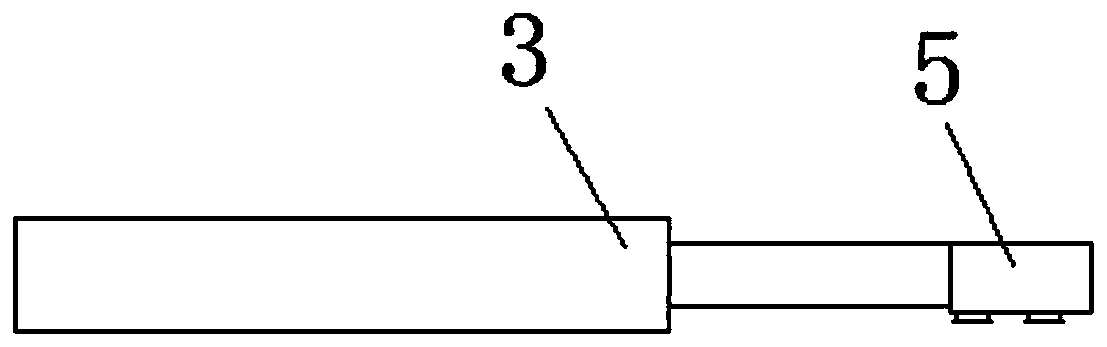

Full-automatic beer bottle capping device and using method thereof

The invention discloses a full-automatic beer bottle capping device which comprises a conveying frame. A conveying belt and a driving mechanism used for driving the conveying belt to run are arrangedon the conveying frame, a plurality of placement mechanisms used for placing beer bottles are arranged on the conveying belt, and a capping mechanism is arranged over the conveying belt. The capping mechanism comprises a pressing air cylinder and a cover suction assembly fixed to a piston rod of the pressing air cylinder. A supporting frame is arranged on one side of the conveying frame, and a bottle cap supply mechanism is arranged at the top of the supporting frame. The bottle cap supply mechanism comprises a bottle cap storage base, wherein bottle cap storage cavities are formed in the bottle cap storage base. Bottle cap conveying assemblies are arranged on the bottle cap storage base and arranged above the bottle cap storage cavities correspondingly. The invention further discloses a using method. According to the beer bottle capping device, manual capping operation is not needed, the labor intensity of workers is reduced, meanwhile, a plurality of beer bottles can be capped at a time, the working efficiency is improved, and therefore the beer bottle capping device has good market popularization prospects.

Owner:段洪永

Supercritical CO2 fluid cooperative biological in-situ leaching uranium mining method

The invention discloses a Supercritical CO2 fluid cooperative biological in-situ leaching uranium mining method. First, a uranium ore is pre-acid-leached by injecting organic weak acid citric acid into an ore layer, metal uranium is dissolved from mineral by using a method that a functional group of the citric acid forms a compound and chelate with metal uranium ions, then acclimated thiobacillusferrooxidans is injected into an acidified ore body as an oxidizing agent, Fe2+ in ore is oxidized to Fe3+, then Fe3+ is used to oxidize U4+ insoluble to acid soluble U6+, and finally a highly solubleuranyl carbonate complex is formed with an injected supercritical CO2 fluid. Therefore the concentration of the metal uranium in a leaching solution and the leaching efficiency of the metal uranium are improved, the leaching time is shortened, no side effect exerts on the environment, meanwhile, the use of citric acid can further reduce the precipitation of calcium, magnesium, iron and the like in the leaching solution, and the contact area between a leaching agent and the uranium ore in the subsequent leaching process is increased, so that continuous carrying out of a leaching reaction is facilitated.

Owner:NANHUA UNIV

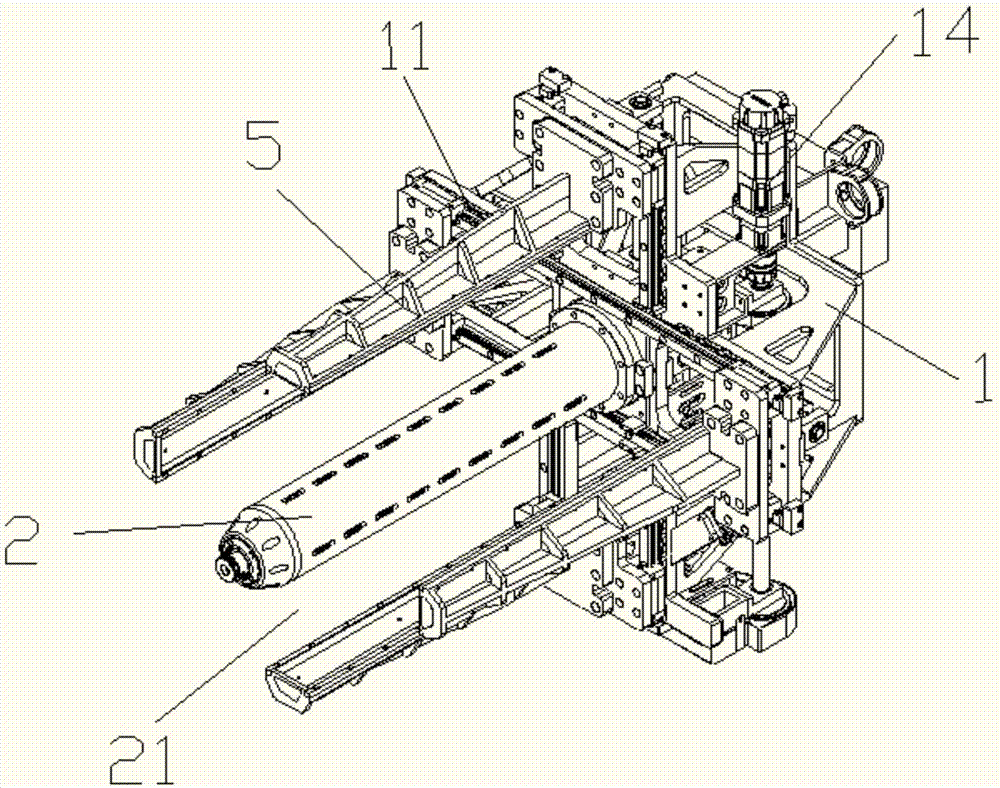

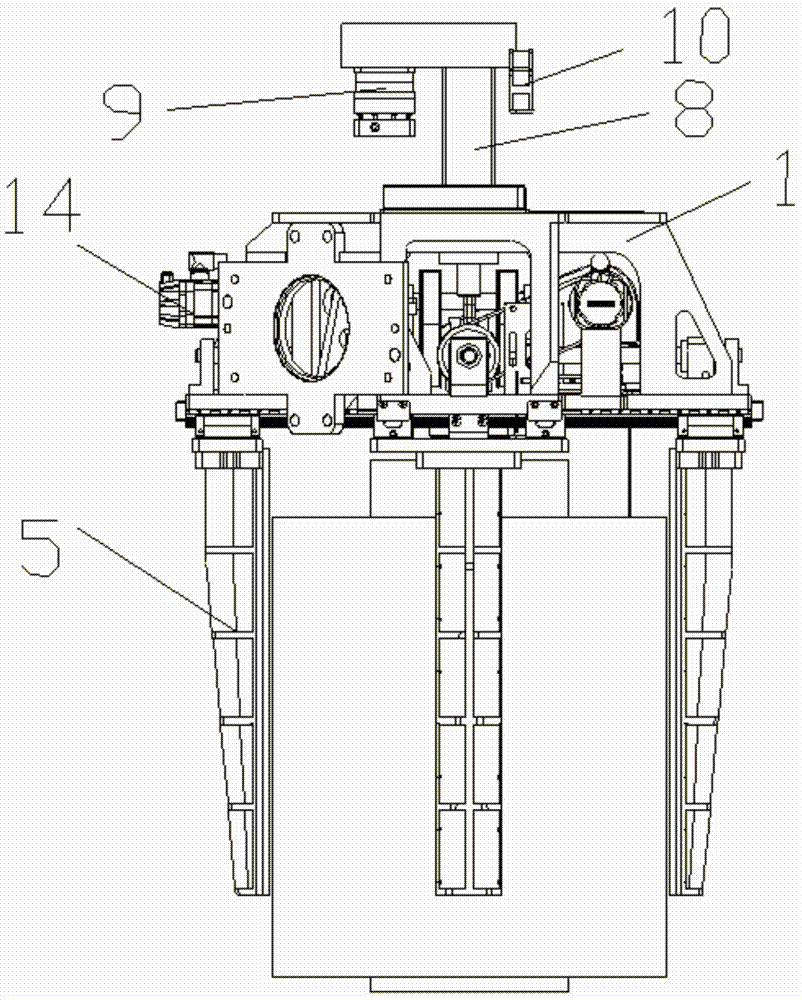

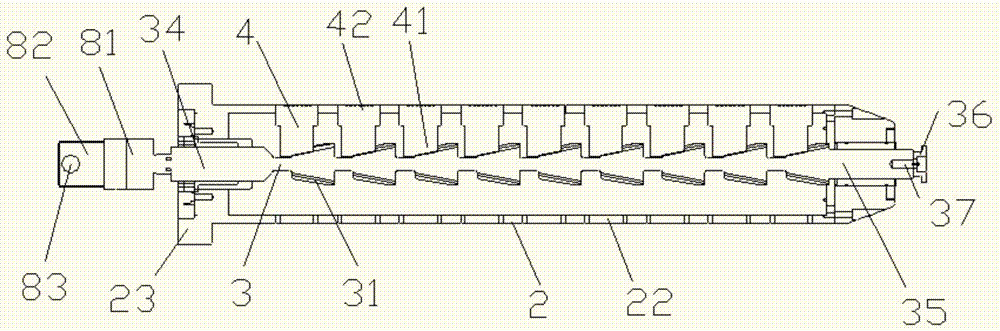

Taking mechanism of coiled material

PendingCN106956924AIncrease the stress-bearing area of the liftAvoid damageConveyor partsReciprocating motionEngineering

The invention discloses a taking mechanism of a coiled material applied in the field of production of coiled materials. The taking mechanism structurally comprises a mounting rack, a sleeve, and an inner pull rod which is arranged in the sleeve in a sleeving manner and axially moves along the sleeve, wherein a pressing block is arranged between the inner pull rod and the sleeve; a plurality of clamping plates which face the sleeve are arranged in the circumferential direction of the sleeve; an orbit and a driving motor used for driving the clamping plates to perform reciprocating motion along the orbit are arranged on the mounting rack; and the clamping plates move towards the sleeve along the orbit. When the taking mechanism is utilized to take a coiled material product, the pressing block presses a coiled material channel, the external clamping plates are utilized to clamp the outer surface of the coiled material product, and the sleeve and the clamping plates form an accommodating groove of the coiled material product, so that the lifting stress area of the coiled material product is effectively increased; and besides, the pressing block and the clamping plates are matched, the situations that the coiled material product is damaged by the device during the taking process and the coiled material product falls off are avoided, and quality maintenance of the coiled material product during the taking process is guaranteed, and taking efficiency is effectively improved.

Owner:苏州和丰工业设备有限公司

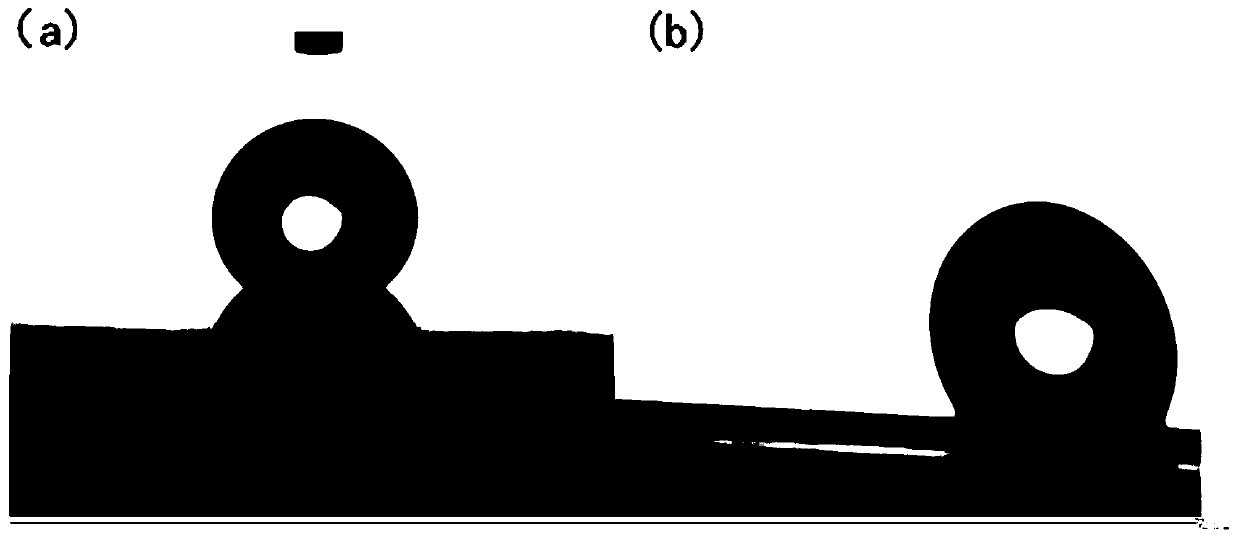

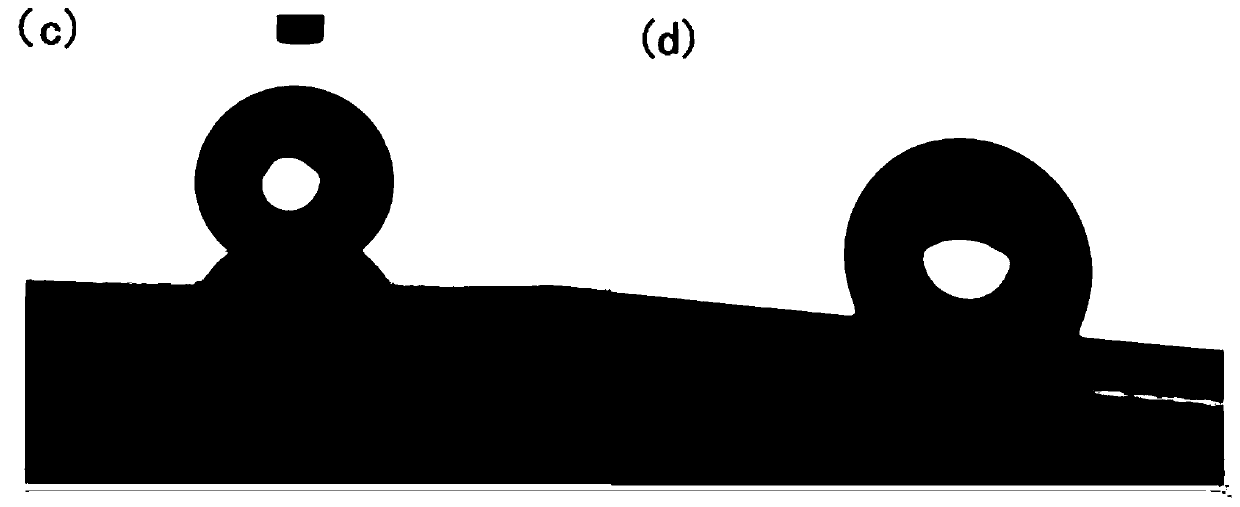

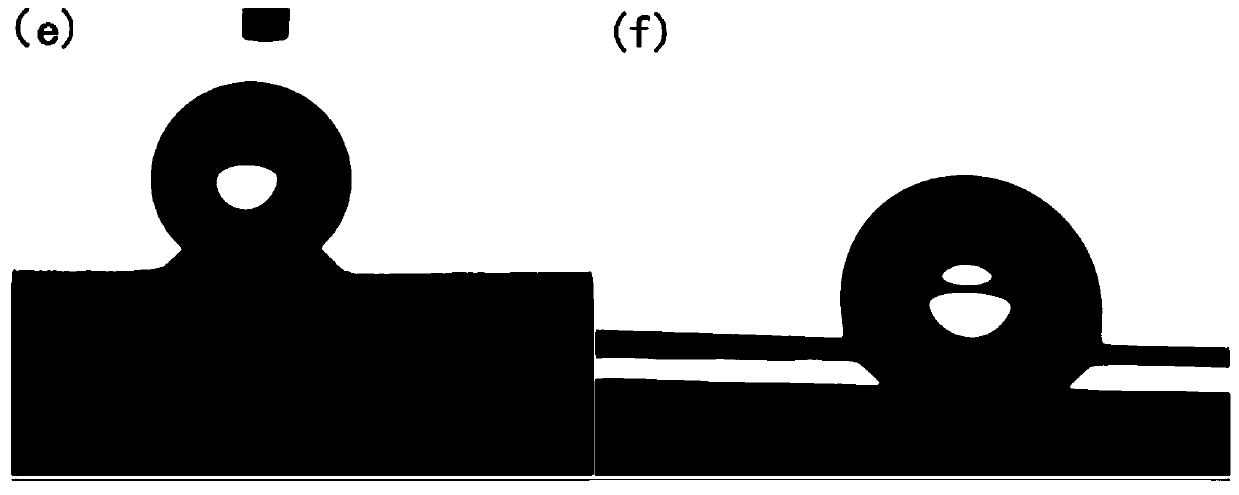

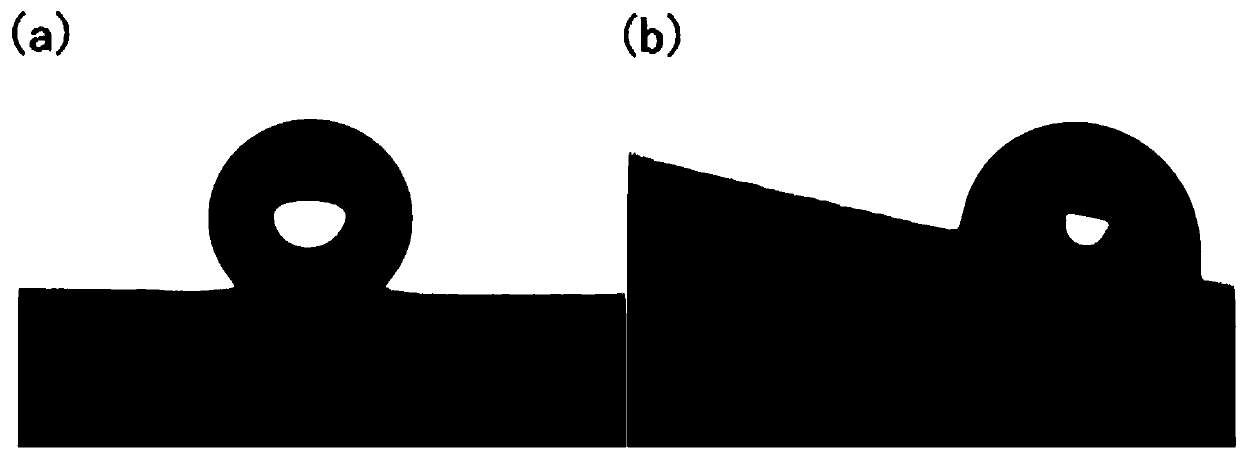

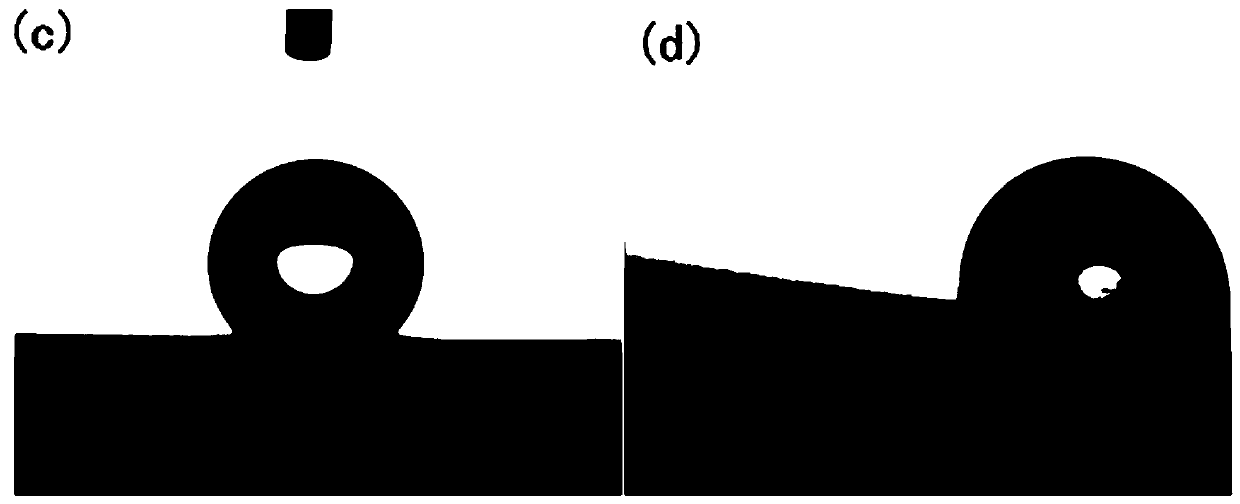

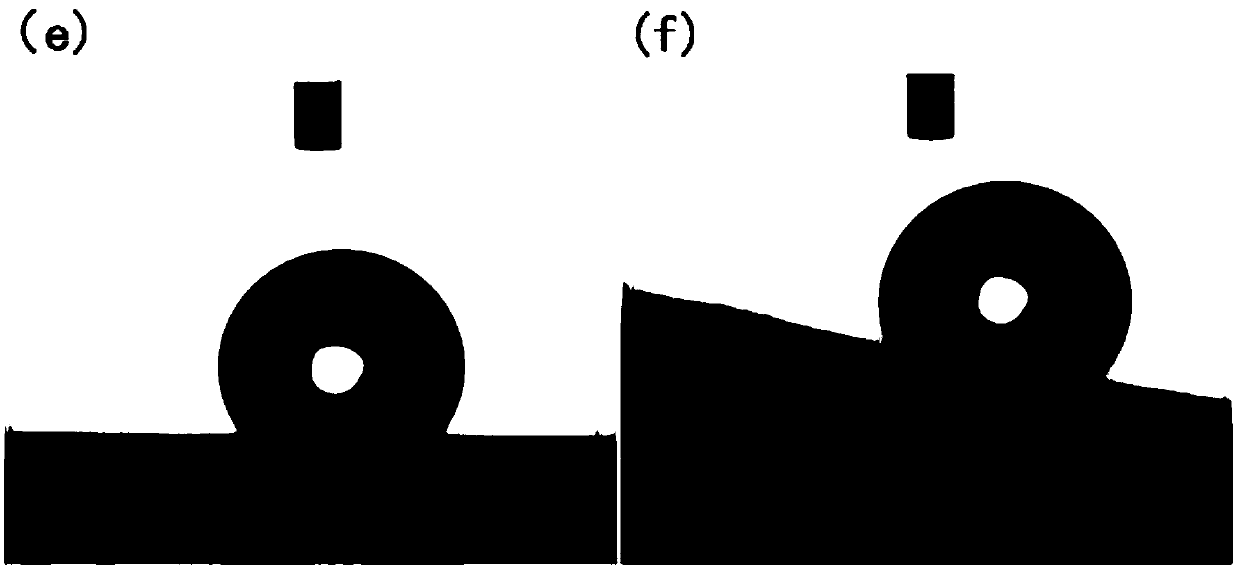

Modified brass surface and preparation method and application thereof

InactiveCN109732196ANo chemical modificationSimple processLaser beam welding apparatusCondensation processLaser processing

The invention provides a modified brass surface and a preparation method and application of the modified brass surface. The method comprises the steps that 1, a brass surface to be treated is polishedfor pretreatment, cleaned and dried to obtain a clean surface-polished brass sample; 2, laser scanning treatment is carried out on the surface of the brass sample through a pulse laser device, multiple micro-nano structures are machined on the surface of the sample, the brass surface is placed into an electric heating vacuum drying box to be baked, and the brass super-hydrophobic surface is obtained; 3, a wedged or triangular parallel-connected super-hydrophilic surface is obtained on the obtained brass super-hydrophobic condensed surface through laser processing treatment, and the super-hydrophobic super-hydrophilic wedged or triangular interphase surface is obtained. Chemical modification is avoided, the process is simple, operation is convenient, the cost is low, the prepared super-hydrophobic super-hydrophilic wedged or triangular interphase surface is quite beneficial to realization and continuous conducting of the droplet condensation process and has the excellent condensation performance, the brass heat exchange efficiency is improved, and condensation efficiency of a condensation pipe is improved.

Owner:HUBEI UNIV OF TECH

Modified aluminum substrate surface and preparation method and application thereof

InactiveCN109590691ANo chemical modificationSimple processHeat transfer modificationMicro nanoCondensation process

The invention provides a modified aluminum substrate surface and a preparation method and application thereof. The method comprises the following steps that (1) polishing pretreatment is carried out on the aluminum surface to be treated, and a clean aluminum sample with the polished surface is obtained after washing and drying are carried out; (2) a pulsed laser is adopted for conducting laser scanning treatment on the surface of the obtained aluminum sample, a plurality of micro-nano structures are machined on the surface of the sample, the micro-nano structures are placed in an electric vacuum drying oven to be baked, and an aluminum superhydrophobic surface is obtained; and (3) the wedge-shaped or triangular parallel connection superhydrophilic surface is obtained on the obtained aluminum superhydrophobic surface through laser processing treatment, and the superhydrophobic-superhydrophilic wedge-shaped or triangular phase alternative surface is obtained. The method has no chemical modification and is simple in process, convenient to operate and low in cost, and the prepared aluminum substrate surface is the superhydrophobic-superhydrophilic wedge-shaped or triangular phase alternative surface, realization and continuous operation of the droplet condensation process are facilitated, the excellent condensation performance is achieved, the aluminum heat exchange rate is greatlyincreased, and the condensation efficiency of a condenser pipe is improved.

Owner:HUBEI UNIV OF TECH

A kind of medical cell culture equipment and cell culture method

ActiveCN111748473BReduce entryGuarantee the environmentBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyPetri dish

Owner:湖南南华生物技术有限公司

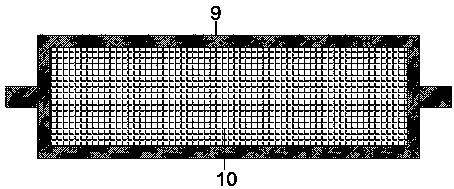

Industrial dust screening and collecting device with scrap iron recycling function

InactiveCN108636774APromote ongoingImprove screening efficiencySievingScreeningElectric machineryEngineering

The invention relates to the technical field of industrial dust treatment equipment, in particular to an industrial dust screening and collecting device with a scrap iron recycling function. The industrial dust screening and collecting device with the scrap iron recycling function comprises a feeding hopper, a scrap iron recycling barrel, a motor, a sleeve, magnet pieces, a rectangular framework a, a rectangular framework b, a rectangular framework c, rectangular installing frames, screen nets, an oscillating motor, shock absorbing springs, a bottom plate and rolling wheels; the upper portionof the scrap iron recycling barrel is connected with the magnet pieces in a sliding manner; the rectangular framework a, the rectangular framework b and the rectangular framework c are sequentially arranged at the bottom of the scrap iron recycling barrel from top to bottom; the shock absorbing springs and the oscillating motor are arranged between the bottom of the rectangular framework c and theupper portion of the bottom plate; and the rolling wheels are arranged at the bottom of the bottom plate. According to the industrial dust screening and collecting device with the scrap iron recycling function, scrap iron in industrial dust can be recycled, and dust in different particle sizes can also be screened and collected; and the oscillating motor and the shock absorbing springs are used in cooperation, the possibility that the screen nets are blocked can be reduced, continuous performing of dust screening is facilitated, and the dust screening and collecting efficiency is improved.

Owner:NANJING ZHUONAI HEAVY MACHINERY MFG CO LTD

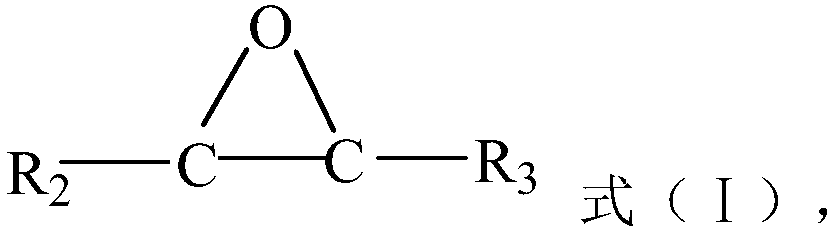

Catalyst carrier for olefin polymerization, preparation method and application thereof

Relating to the field of polymers, the invention discloses a catalyst carrier for olefin polymerization, a preparation method and application thereof. The preparation method includes: 1) subjecting amagnesium compound, a first alcohol compound and an ethylene oxide compound to reaction optionally in the presence of an inert liquid medium to obtain a solid substance; 2) dissolving the solid substance in a second alcohol compound for emulsification to obtain a fluid mixture; and 3) solidifying the fluid mixture by spraying to obtain the catalyst carrier for olefin polymerization. The preparation method provided by the invention can avoid the blockage of a spraying machine, facilitates the continuous proceeding of the preparation process, and the prepared catalyst carrier for olefin polymerization has the characteristics of difficult adhesion and good morphology, the catalyst for olefin polymerization prepared from the catalyst carrier has high catalytic activity, and a high bulk densityolefin polymer can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

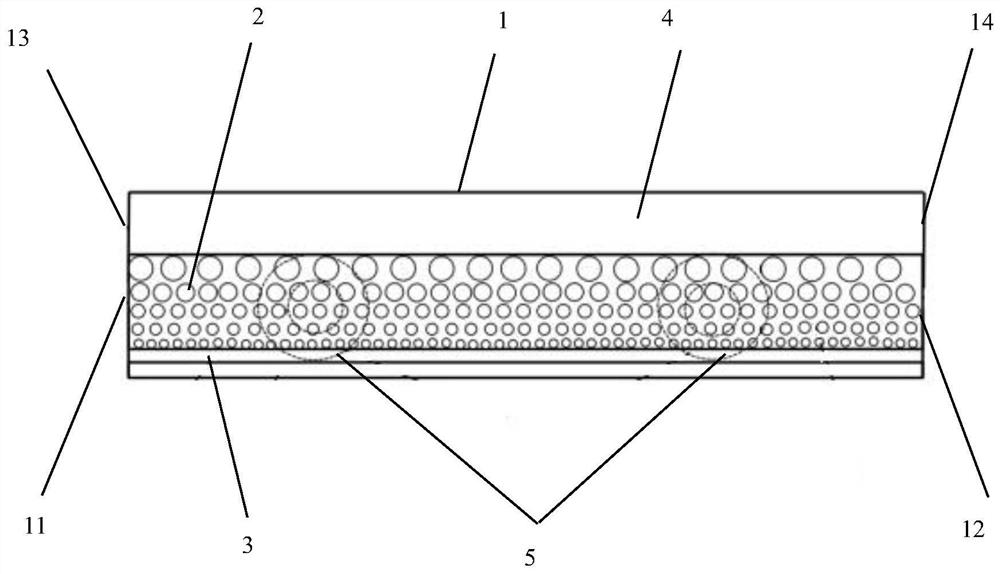

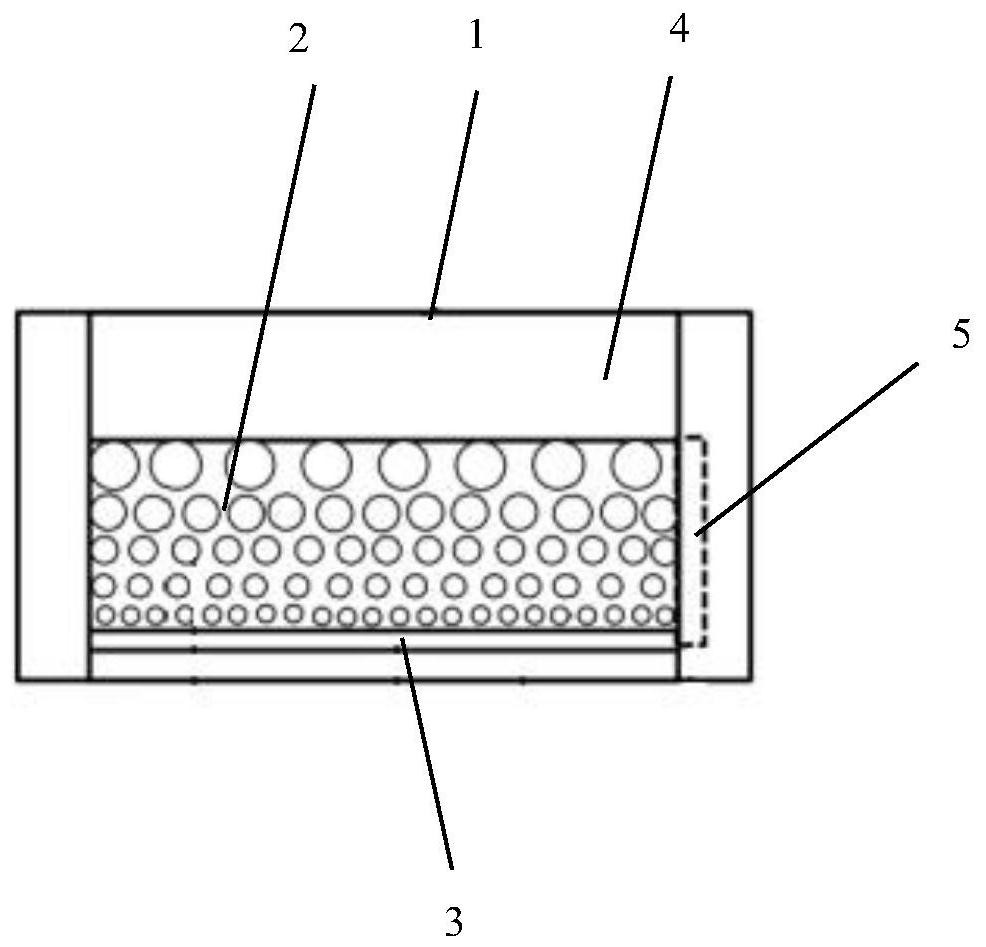

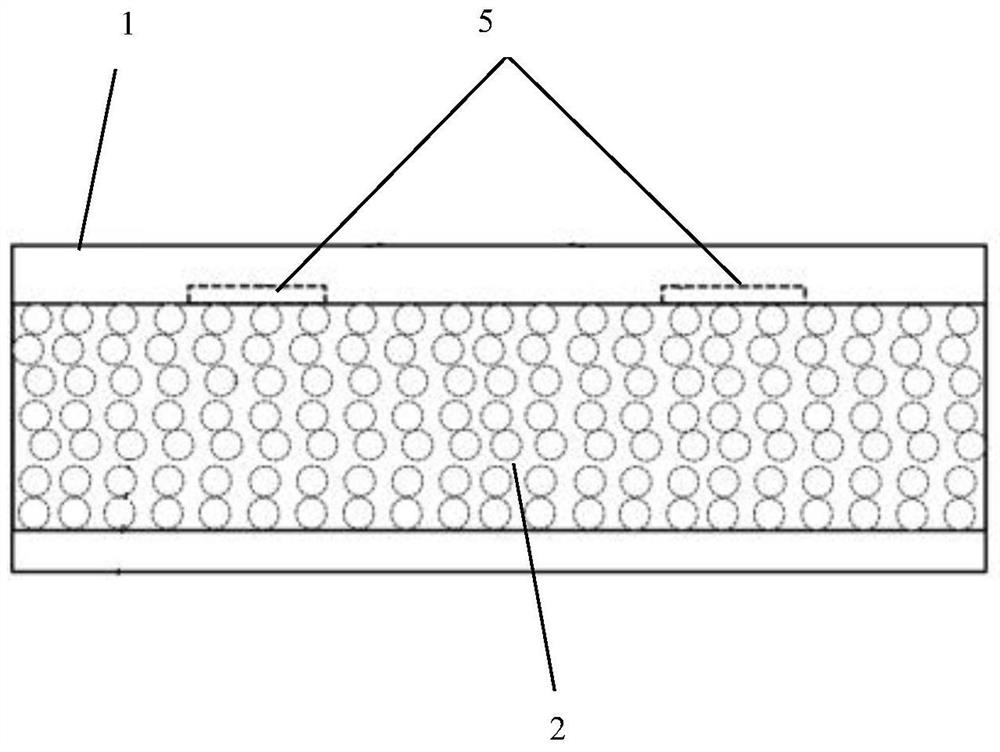

Porous medium liquid film small-channel cooling device

ActiveCN112203476AImprove permeabilityIncrease the areaModifications using liquid coolingModifications using gaseous coolantsThermodynamicsPorous medium

The invention discloses a porous medium liquid film small-channel cooling device, and relates to the technical field of electronic equipment cooling. The porous medium liquid film small-channel cooling device comprises a channel cooling main body, wherein a porous structure is arranged in the channel cooling main body, a flowing liquid film layer is arranged between the lower surface of the porousstructure and the inner bottom of the channel cooling main body, an air evaporation channel is formed between the upper surface of the porous structure and the top in the channel cooling main body, an ultrasonic wave generator is embedded in the inner side wall of the channel cooling main body and located on one side of the porous structure, and the porosity of the porous structure is linearly orstepwise increased from bottom to top. According to the invention, by using a variable-pore porous structure, the permeability and the specific surface area of a flowing liquid film in the porous structure are improved in the heat production direction, so that the relation and conflict between flowing performance and heat transfer performance are effectively decoupled, the cooling performance ofthe cooling device is improved, the cooling time is shortened; micro-convection of liquid in pores of the porous structure is promoted under the action of cavitation and acoustic streaming of ultrasonic waves, and fluid disturbance is enhanced.

Owner:SHANGHAI MARITIME UNIVERSITY

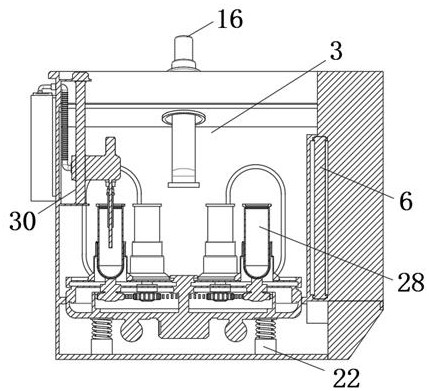

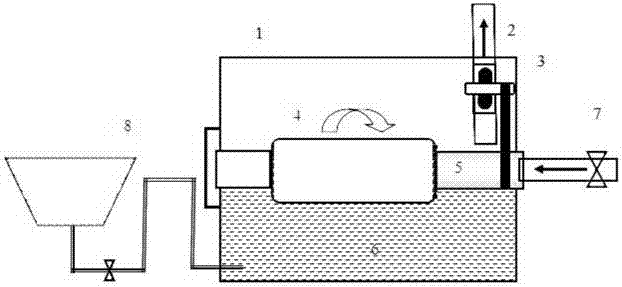

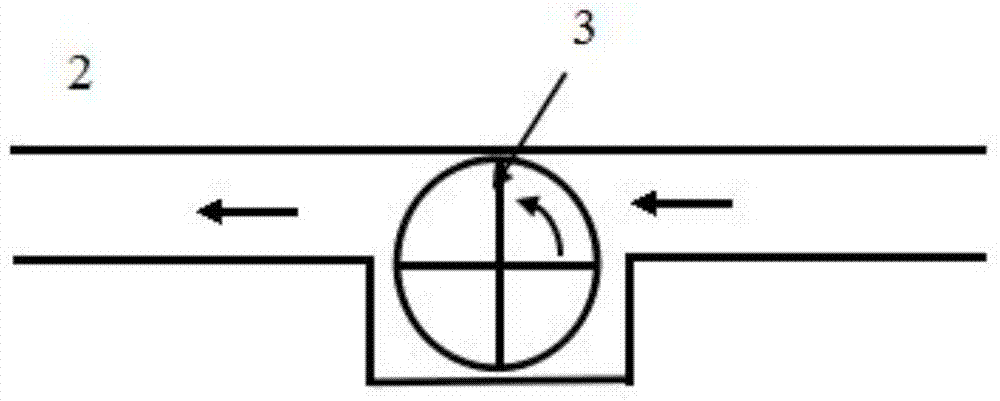

Hydrogen production device with self-stirring cage

InactiveCN104192797ASimple structurePromote ongoingHydrogen productionChemical/physical processesEngineeringMechanical engineering

The invention relates to a hydrogen production device with a self-stirring cage. The device comprises a sealed reaction cavity, a hydrogen outlet pipeline, pneumatic rotating vanes, a stirring cage, a stirring cage shaft, a fuel storage bin, a feeding system and a vacuum system, wherein the sealed reaction cavity comprises a reacting liquid bin; the hydrogen outlet pipeline has a square section, and the pneumatic rotating vanes are arranged on the path of the pipeline; the rotating shaft of the pneumatic rotating vanes is connected to the stirring cage shaft in a transmission manner, and is capable of driving the stirring cage shaft to rotate; at least part of the stirring cage is immersed below the liquid surface of the reacting liquid bin; the shaft of at least one end of the stirring cage is hollow, and is communicated with the stirring cage and the fuel feeding port of the sealed reaction cavity; the fuel storage bin is of a sealable structure; the feeding system comprises a liquid-phase feeding system and a fuel feeding system; and the vacuum system is used for vacuumizing the sealed cavity.

Owner:丁专生

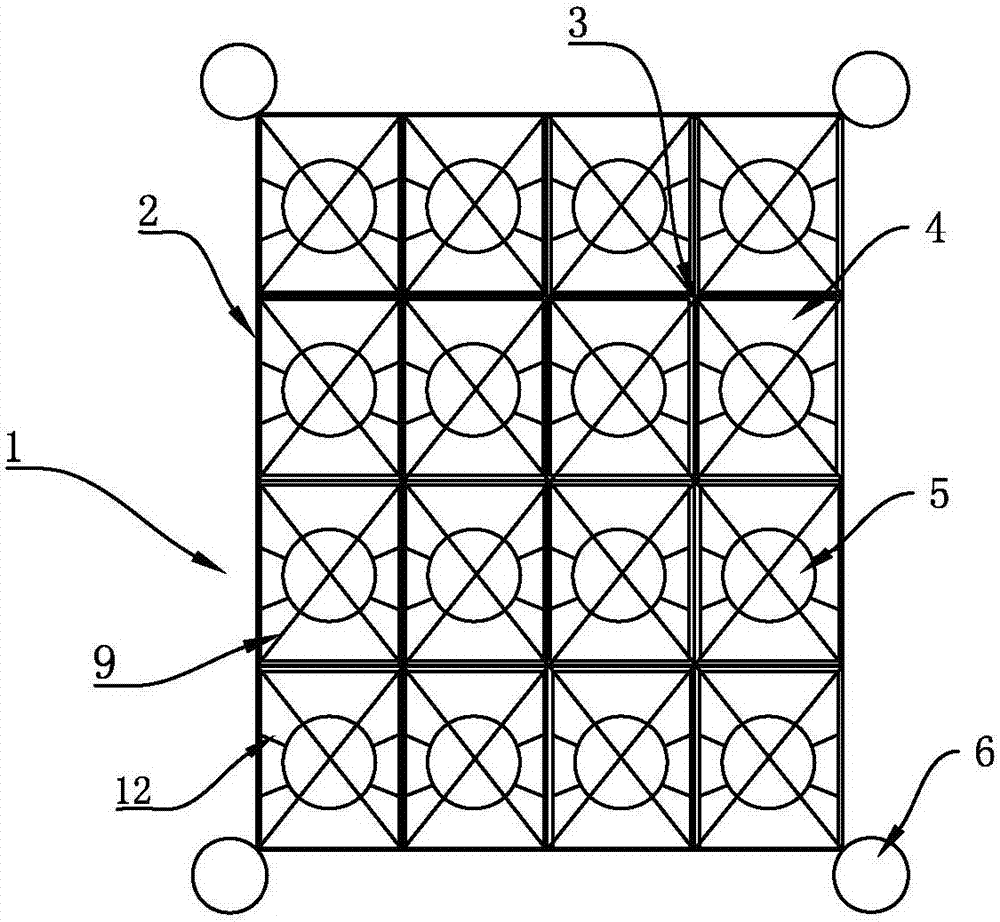

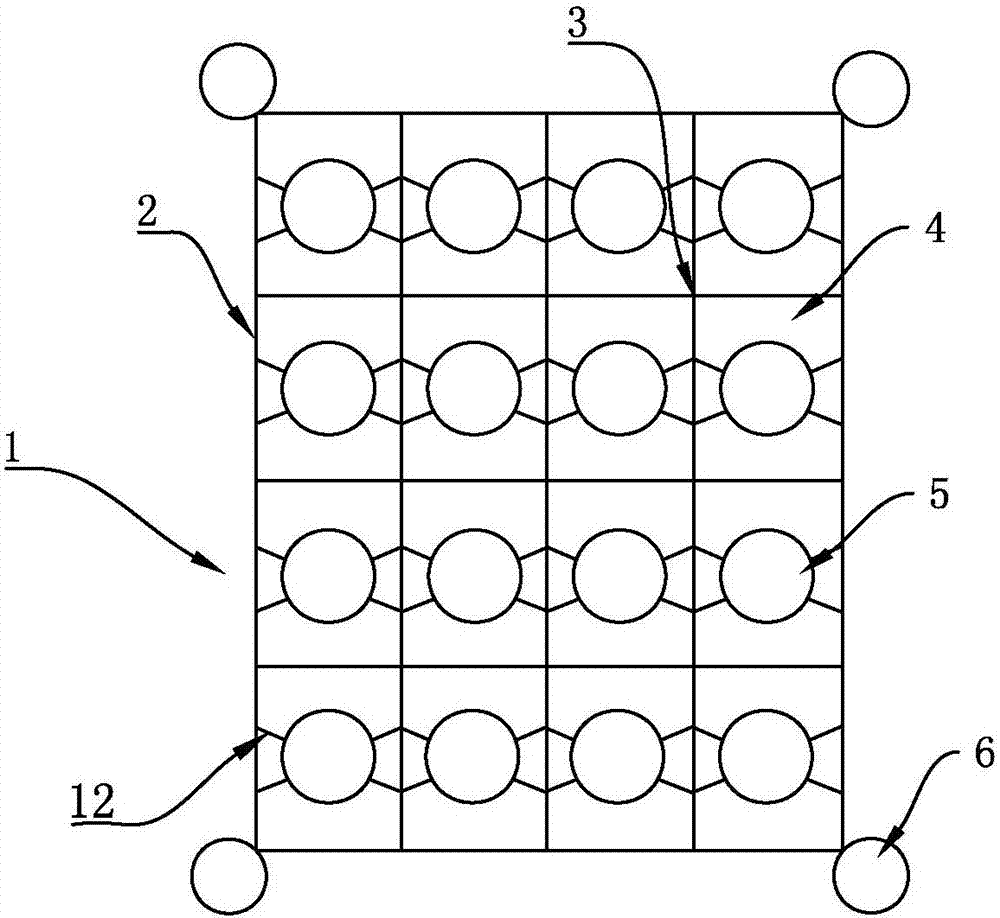

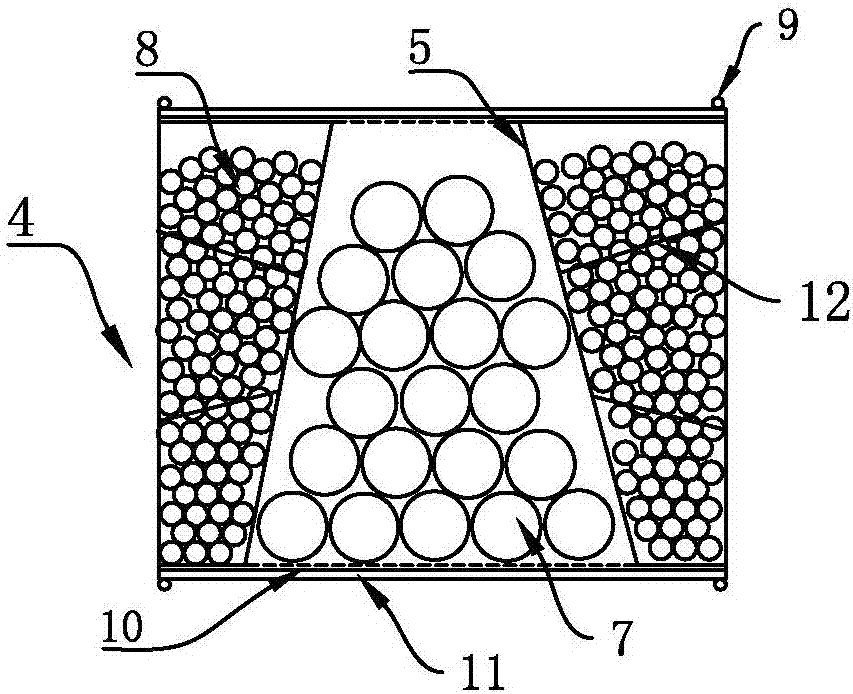

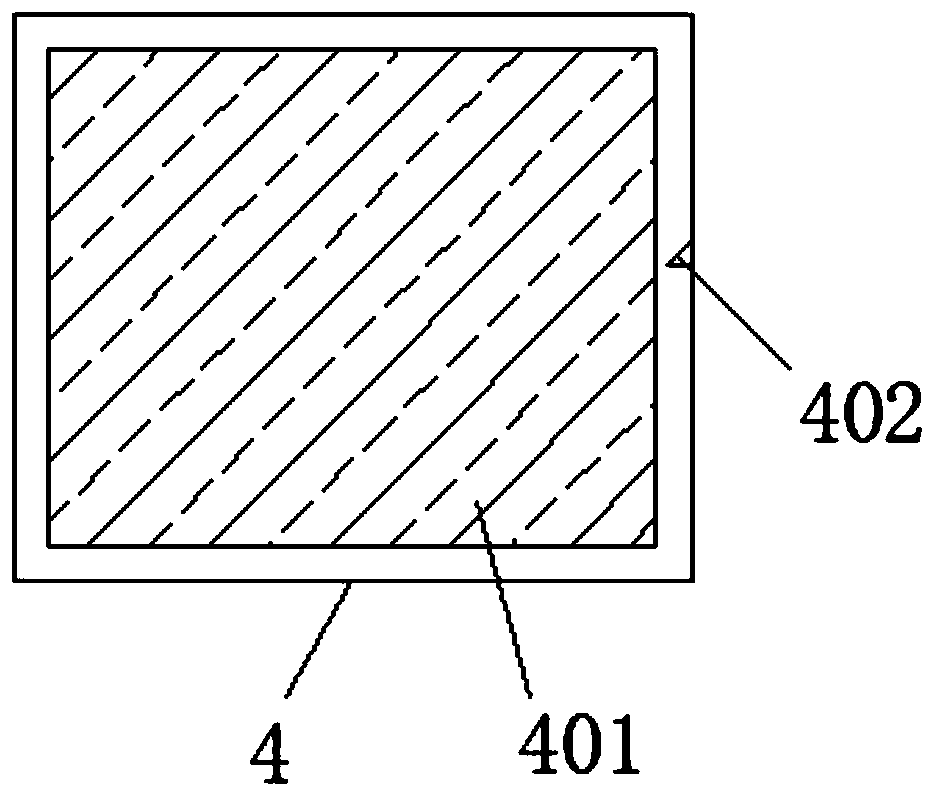

Filter screen for increasing oxygen and anions

ActiveCN107115729AGood stabilityIncrease the concentration of negative ionsMechanical apparatusDispersed particle filtrationWoven fabricEngineering

The invention discloses a filter screen for increasing oxygen and anions. The filter screen comprises an outer frame and a filter screen main body frame which is arranged in the outer frame and is formed by a latticed grid, wherein an air inlet tube is arranged inside each cell of the grid, and is filled with an oxygen-generating carbon-fixing ball; the space between the air inlet tube and the inner wall of each cell is filled with an anion ball; blocking nets are respectively arranged on front and rear sides of the grid, an non-woven fabrics are arranged outside the blocking nets, and the blocking nets and the non-woven fabrics are compressed on front and rear sides of the filter screen main body frame through depression bars or reticular glands; or a filter unit is arranged inside each cell of the grid, and is provided with an air inlet tube; each air inlet tube is filled with an oxygen-generating carbon-fixing ball, and the space between the air inlet tube and the peripheral wall of the filter unit is filled with an anion ball. The filter screen can solve the problems of single function and insufficient reaction of a traditional activated carbon filter screen by means of the design, can be used for increasing oxygen and anions, prolonging oxygen release duration and solving the problem that an oxygen-generating material cannot be sufficiently utilized, and the service life of the filter screen can be prolonged since a filter material can be replaced.

Owner:SHANDONG LEKANG ELECTRICAL TECH

Cigarette mark printing procedure color marking method and cigarette mark printing procedure color marking equipment

InactiveCN110816097AReduce wasteEasy to return for inspectionDuplicating/marking methodsPattern printingEngineeringWorkbench

The invention discloses a cigarette mark printing procedure color marking method and cigarette mark printing procedure color marking equipment. The cigarette mark printing procedure color marking equipment comprises a workbench, a color mark sensor and a plate type conveying belt; the color mark sensor, an electric telescopic rod and a lifting type printing assembly are fixedly mounted at the topof the workbench; an electric sucking disc is fixedly mounted at the bottom of the output end of the electric telescopic rod; the plate type conveying belt is fixed to the top of the workbench and islocated below the color mark sensor, the electric telescopic rod and the lifting type printing assembly; a first carrying plate is mounted at the end of the plate type conveying belt; a second carrying plate is mounted below the side of the plate type conveying belt; warning tools are fixedly mounted at the outer edge of the second carrying plate; and dyeing marks are arranged at the edge of printing paper. According to the cigarette mark printing procedure color marking method and the cigarette mark printing procedure color marking equipment, it is guaranteed that each procedure is accomplished, the finished product rate is ensured, the printing efficiency is improved, and the purposes that the material cost is reduced, and the waste of resources is reduced are achieved.

Owner:云南华红科技股份有限公司

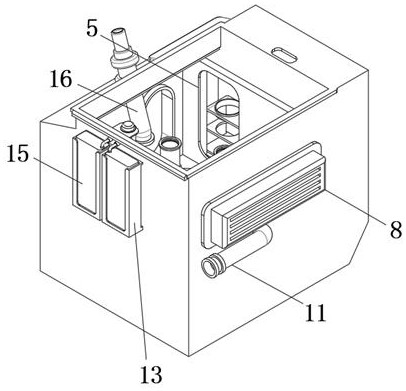

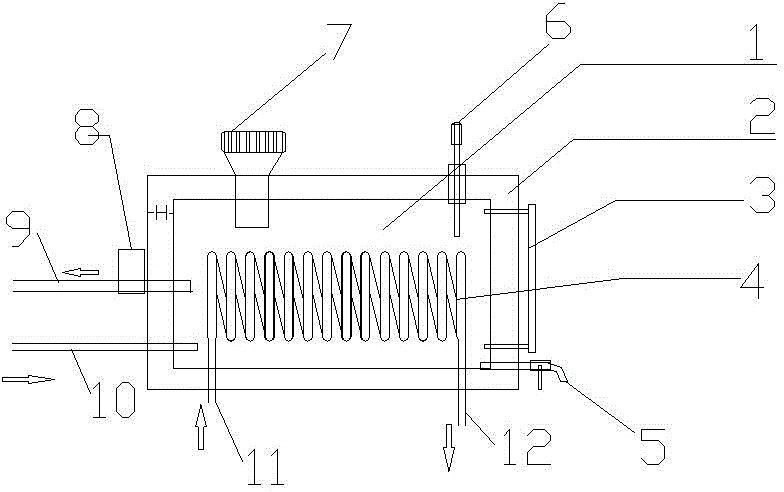

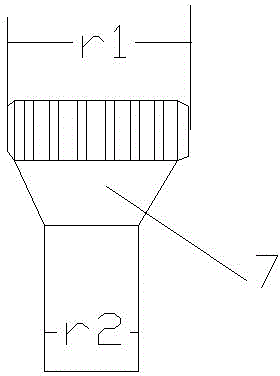

Water cooling tank for vacuum oil purifier

InactiveCN105465858AReduce wastePromote ongoingDomestic stoves or rangesLighting and heating apparatusWater levelWater pipe

The invention relates to a water cooling tank for a vacuum oil purifier. The water cooling tank comprises a water cooling tank body, an anti-backflow filter, a water filling nozzle, a temperature sensor, a heat preservation layer, a water level gauge, a condenser, a blow-down valve, a water outlet pipe and a water inlet pipe. The heat preservation layer is arranged on the periphery of the water cooling tank body. The water filling nozzle is located on the left side of the upper portion of the water cooling tank body. The temperature sensor is located on the right side of the upper portion of the water cooling tank body. The water level gauge is fixed to the right side of the water cooling tank body. The blow-down valve is located on the lower portion of the right side of the water cooling tank body. The condenser is sleeved with the water cooling tank body. Both an inlet and an outlet of the condenser are located in the lower portion of the water cooling tank body. The water inlet pipe is located on the lower portion of the left side of the water cooling tank body. The water outlet pipe is located on the upper portion of the left side of the water cooling tank body. The water outlet pipe is sleeved with the filter. Through the installation of the anti-backflow filter, various factors which can cause the backflow phenomenon are eliminated; in addition, fault removal and restarting can be conducted automatically, and intelligence is achieved.

Owner:镇江市长江机电设备厂有限公司

Purging method and structure, deposition process and gas inlet system

PendingCN111863589AAdjust UniformityResponse continuesSemiconductor/solid-state device manufacturingPhysical chemistryDeposition process

The invention provides a purging method and structure, a deposition process and a gas inlet system. The purging method is used in the chemical vapor deposition process. A substrate is borne on a chuck, and purging gas and process gas are conveyed to the edge of the substrate in the process of carrying out the chemical vapor deposition process. Due to the fact that the purging gas and the process gas are introduced into the edge of the substrate, the process gas reacts with process gas introduced into a cavity, continuous proceeding of the reaction on the edge of the substrate is promoted, products on the edge of the substrate are supplemented, and thus the uniformity of the edge of the substrate is adjusted.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

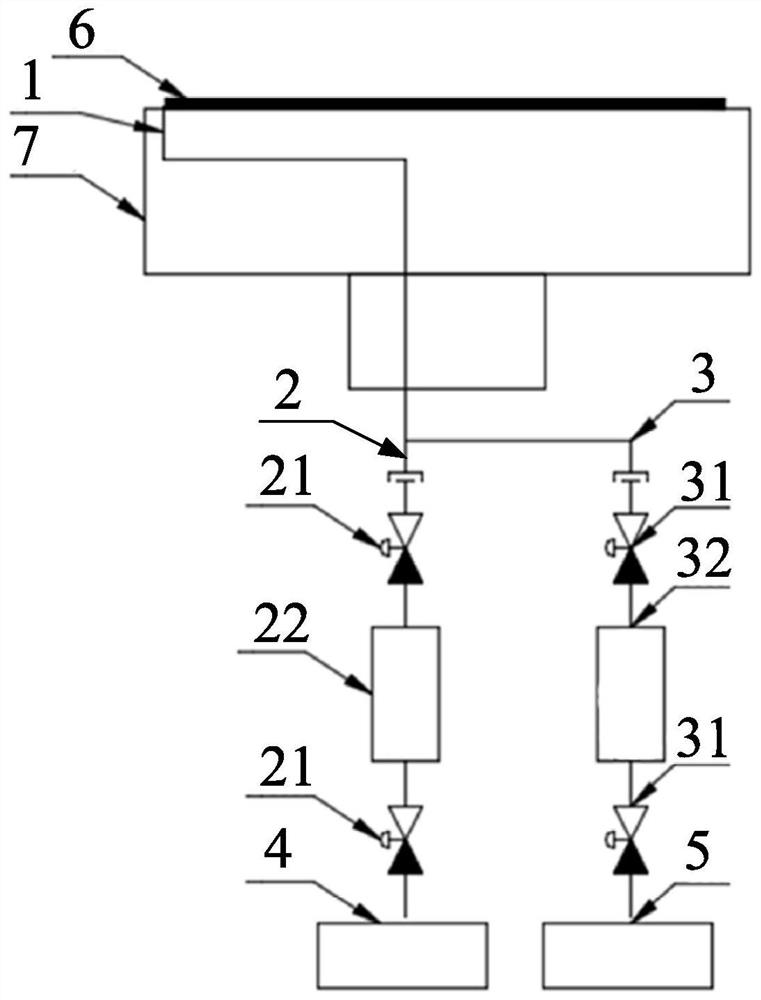

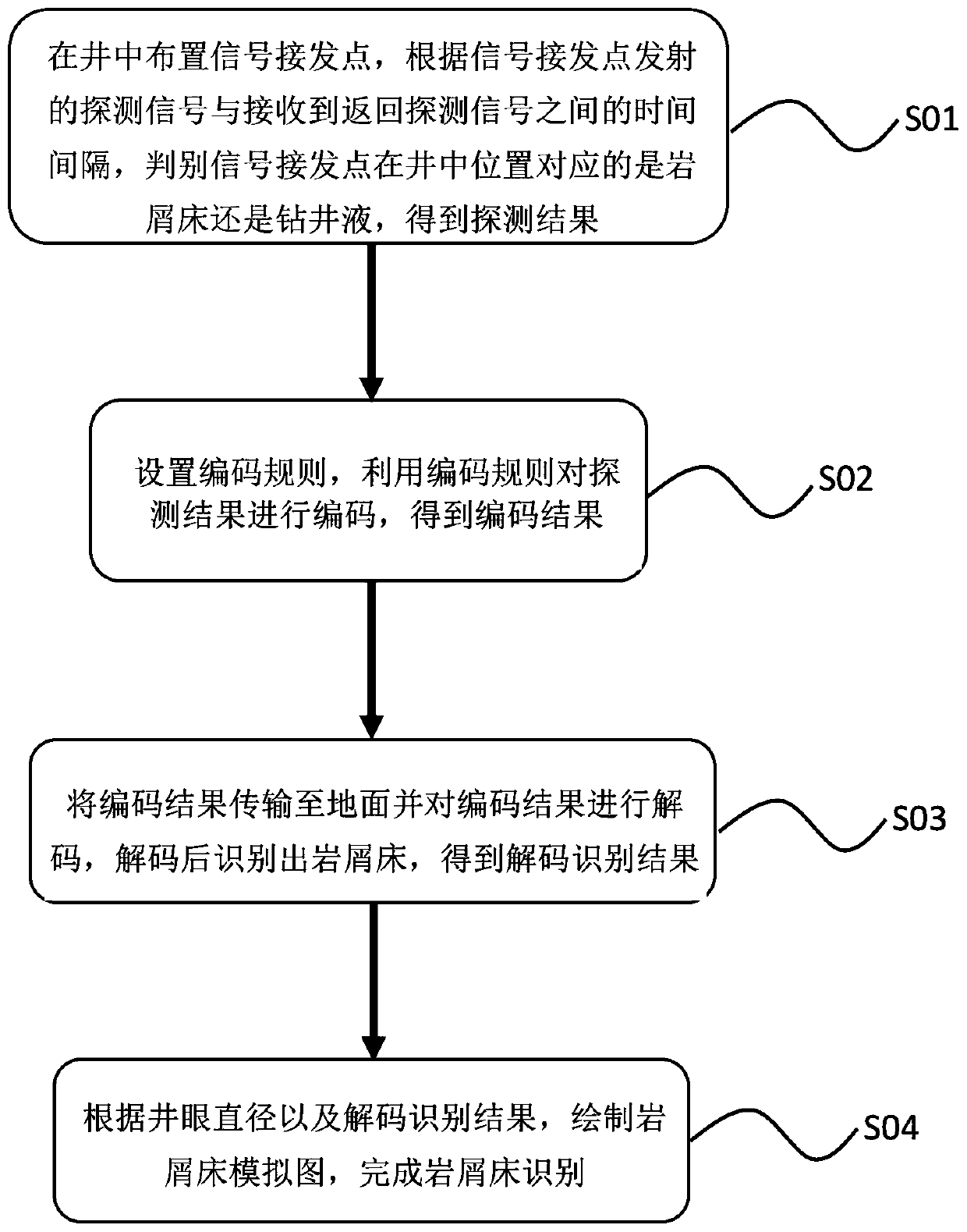

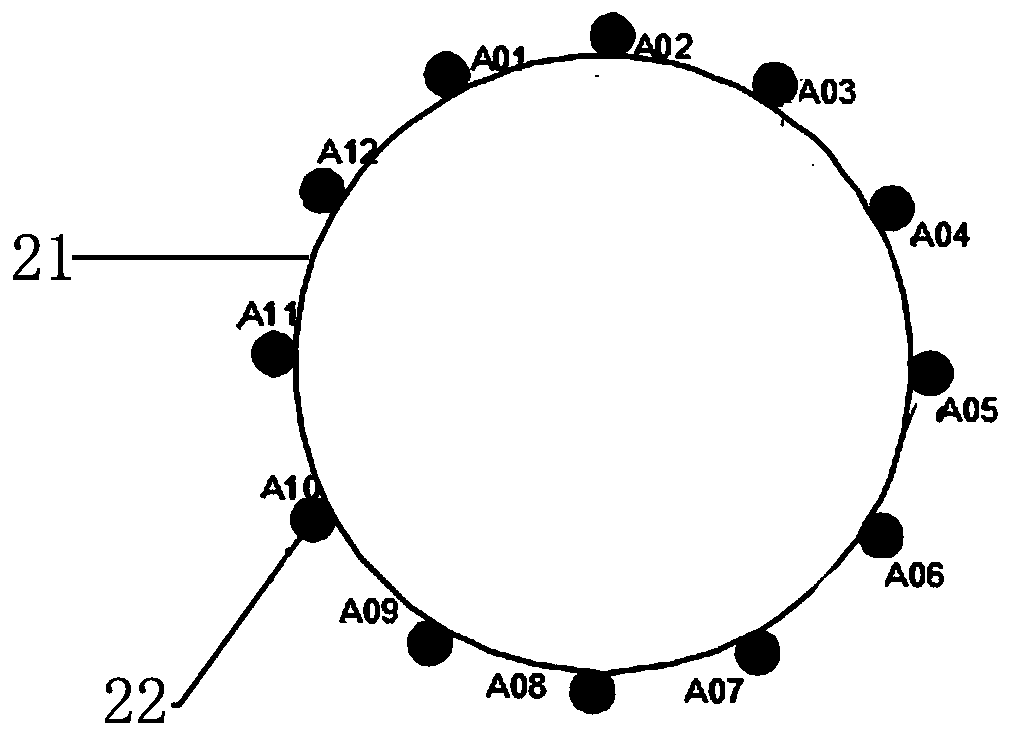

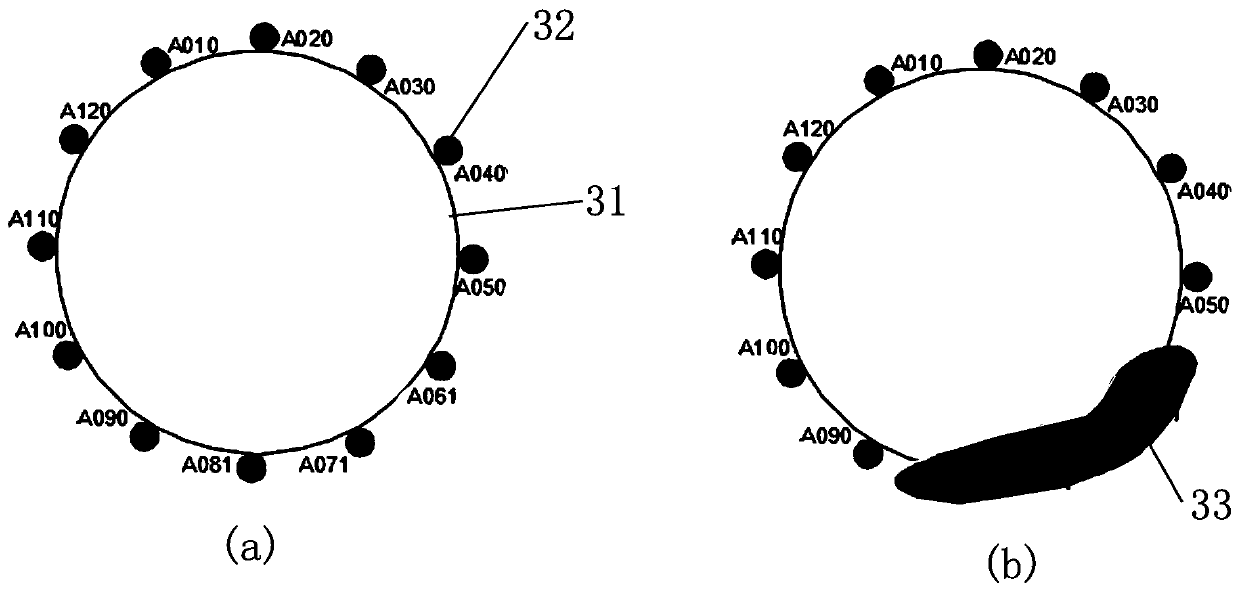

Cuttings bed identification method and position determination method

ActiveCN110454149APromote ongoingOptimizing Drilling MeasuresSurveyMaterial analysis using wave/particle radiationEngineeringWellbore

The invention provides a cuttings bed identification method and a position determination method. The identification method comprises the steps of: arranging a plurality of signal receiving points in awell, determining whether the position of each signal receiving point in the well corresponds to the cuttings bed or drilling liquid according to the time interval between a transmitted detection signal and a received return detection signal, and obtaining a detection result; setting a coding rule, coding the detection result by using the coding rule, and obtaining a coding result; transmitting the coding result to the ground and decoding the coding result, identifying the cuttings bed after decoding, and obtaining a decoding identification result; drawing a cuttings bed simulated diagram according to the diameter of a wellbore and the decoding identification result, and completing the cuttings bed identification. The position determination method comprises determining the position of thecuttings bed in the well according to the position of the signal receiving points. The invention can identify and monitor the condition of the underground cuttings bed in real time, and can optimizedrilling measures according to the obtained cuttings bed simulated diagram, so as to perform the continuous drilling work conveniently.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

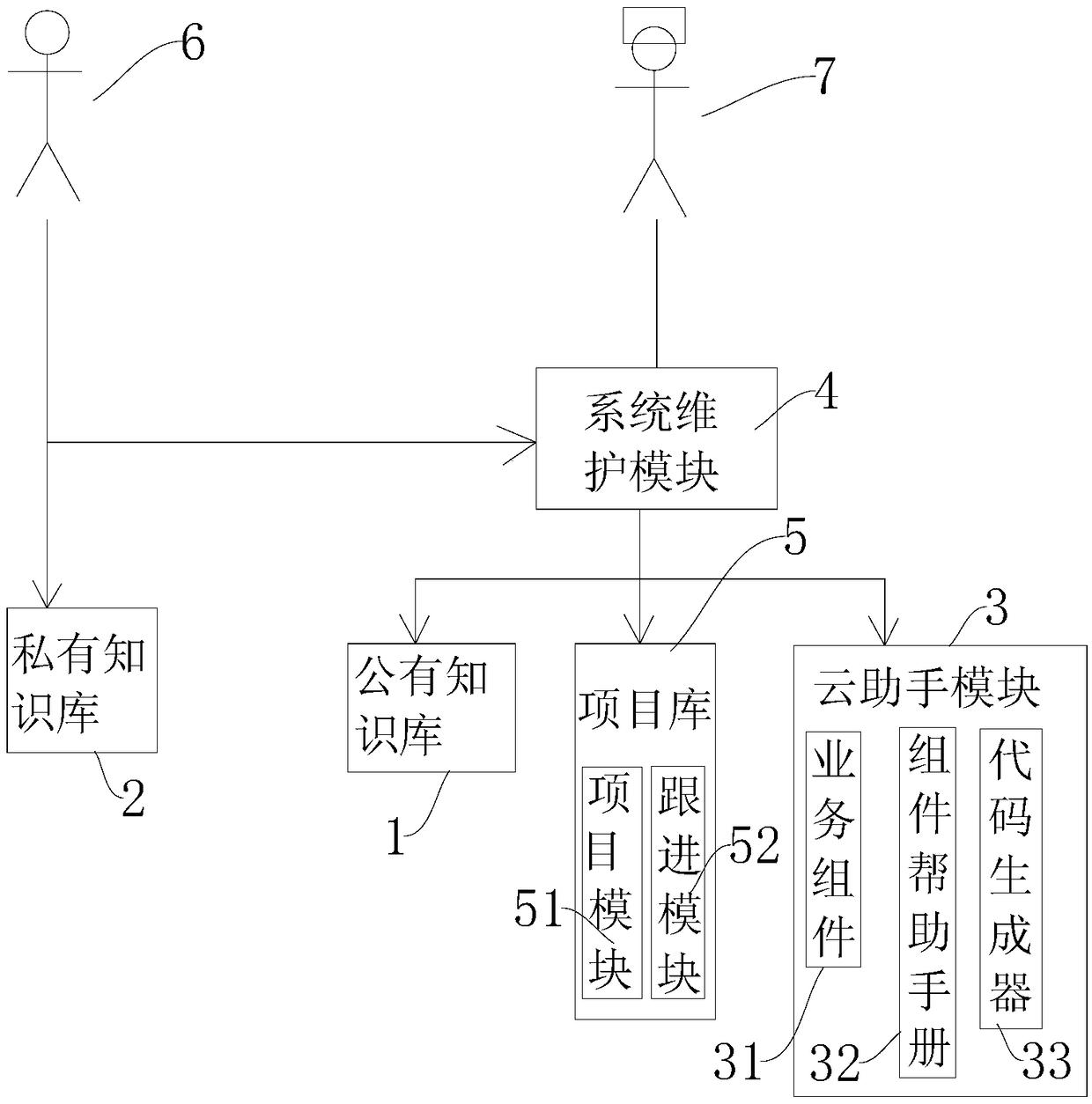

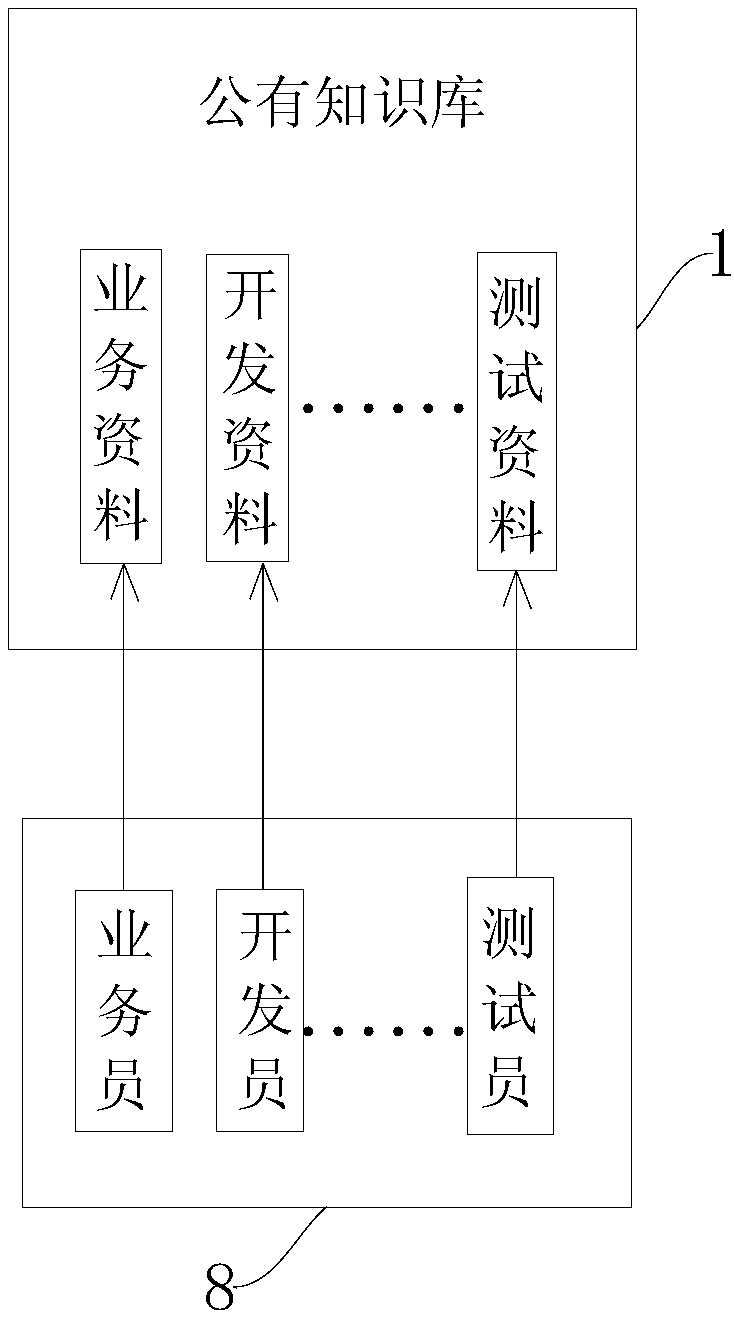

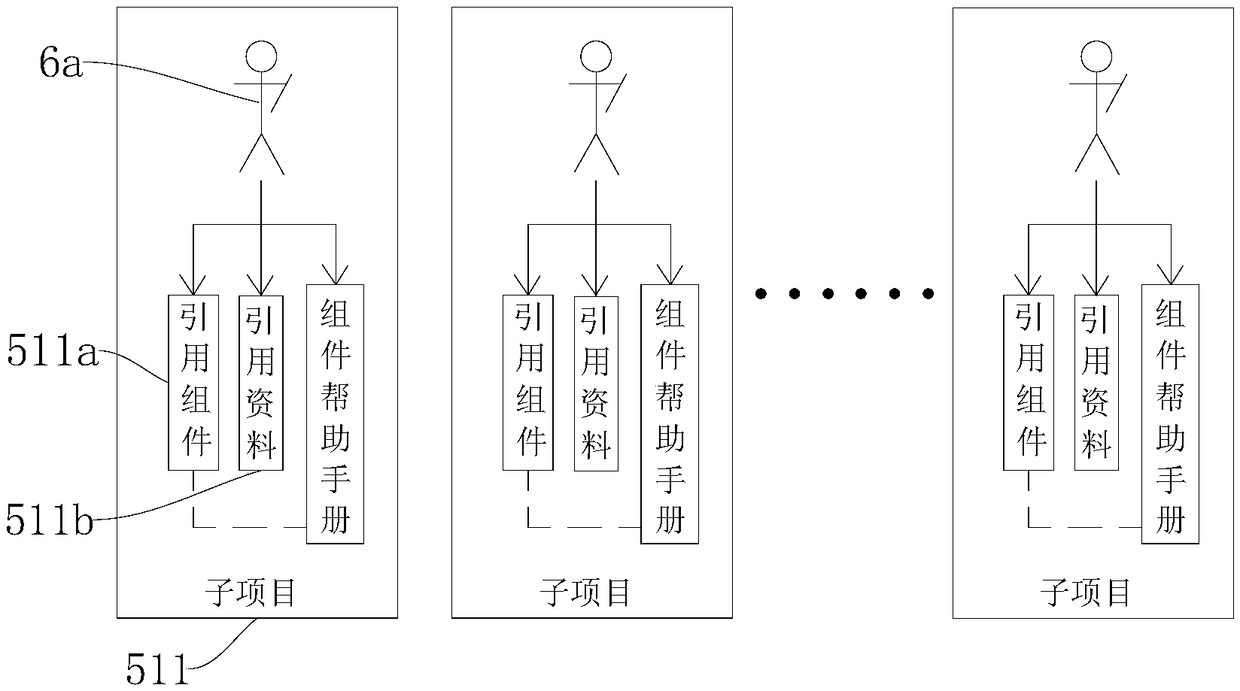

Software development management system

InactiveCN108921489AAvoid understandingReduce the Risk of ConfidentialityOffice automationResourcesUser needsSystem maintenance

Owner:广州电加软件有限责任公司

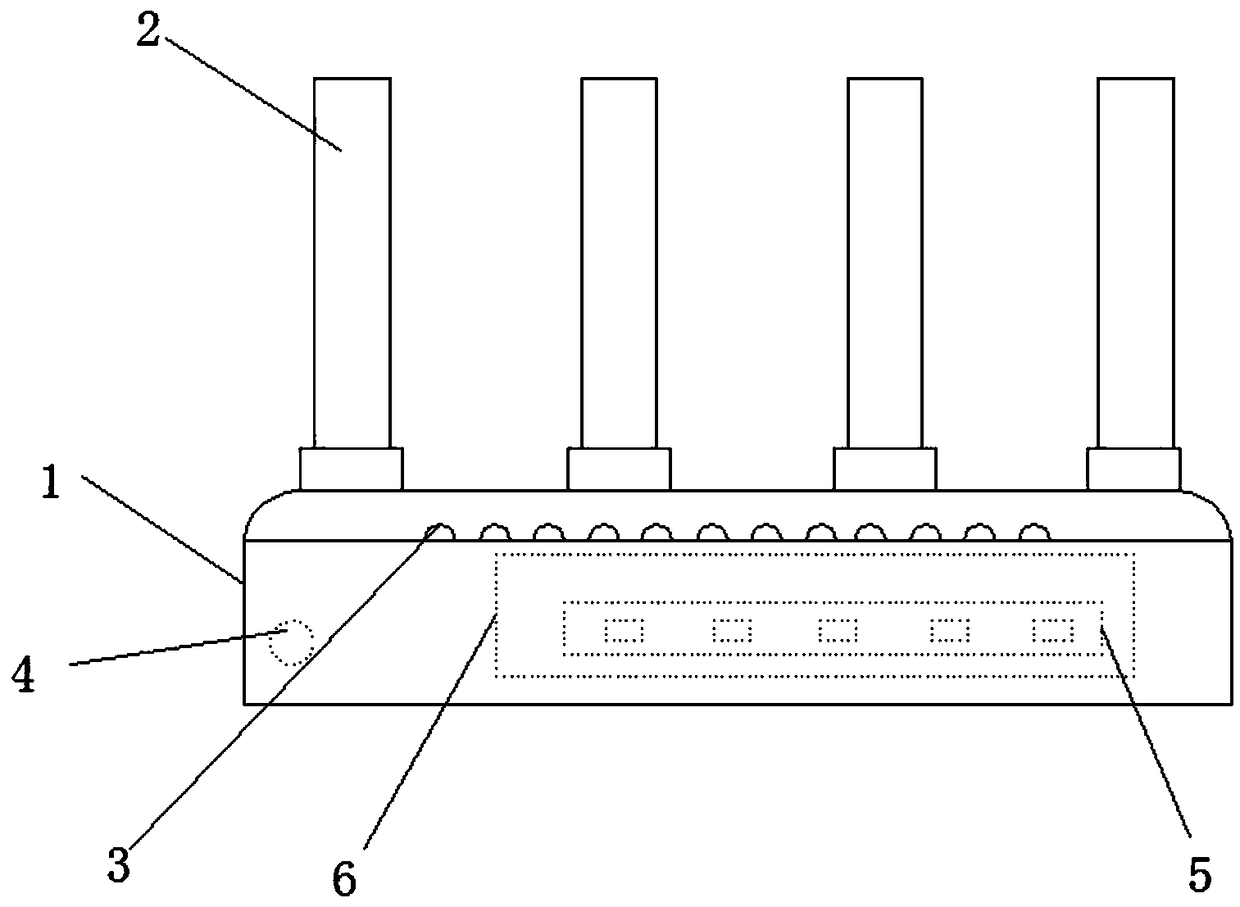

A network cable clamping device for router

InactiveCN109066214APrevent network cable from falling offImprove stabilityCoupling device detailsNetwork connectorsNetworking cablesIndustrial engineering

A network cable clamping device for a router includes the router body, the top of the router body is provided with a plurality of antennas, the top of the router body is provided with a plurality of indicator lights, one side of the router body is provided with a power supply, A terminal board is arranged on the side of the router body close to the power supply, One side of the terminal board is provided with a clamping mechanism, wherein, the clamping mechanism comprises a support plate 1 and a support plate 2 located above the support plate 1; the bottom end of the support plate 2 is provided with a mother pipe 1; the inner part of the mother pipe 1 is inserted with the child pipe 1; the top end of the child pipe 1 is provided with a moving plate 1 located in the mother pipe 1; and the top end of the support plate 1 is provided with the mother pipe 2. The network cable clamping device has the advantages that the network cable connected with the terminal board is fixed, the network cable connected with the terminal board is effectively prevented from falling off, the stability of the work is greatly improved, the temporary interruption of the work is avoided, and the continuous work is facilitated.

Owner:ANHUI DOUZHUANXINGYI INFORMATION TECH CO LTD

Device and method for producing light fabricated siding walls from municipal sludge

ActiveCN111716492APouring evenlyAvoid hollowingCeramic shaping apparatusClay mixing apparatusSludgeProcess engineering

The invention relates to the technical field of production of light fabricated siding walls from municipal sludge, in particular to a device and method for producing the light fabricated siding wallsfrom the municipal sludge. The device comprises supporting legs, a first electric clamping jaw, a first servo motor, a second electric clamping jaw, a second servo motor, a belt wheel transmission mechanism, a raw material conveyor, a first electric telescopic rod and a second electric telescopic rod, a supporting platform is fixedly welded to the tops of the supporting legs, a rear mold plate isvertically fixed to one side of the back face of the top of the supporting platform, and fixing plates are symmetrically fixed to the left side and the right side of the back face of the rear mold plate. According to the device, feeding pipes are evenly distributed at the top of the rear mold plate, so that when the device is used, mixed raw materials can effectively enter the interior of the rearmold plate at multiple positions at the same time through flow dividing and guiding of the multiple sets of feeding pipes, the light siding walls are more uniform during pouring, hollowing in the light siding walls can be prevented, and the quality of the device can be improved conveniently.

Owner:武汉绿发环能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com