Modified aluminum substrate surface and preparation method and application thereof

A technology of aluminum substrate and aluminum surface, applied in the field of modified aluminum substrate surface and its preparation, can solve the problems of complex processing technology, low processing efficiency, low condensation efficiency, etc., and achieves simple process, convenient operation, improved The effect of condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

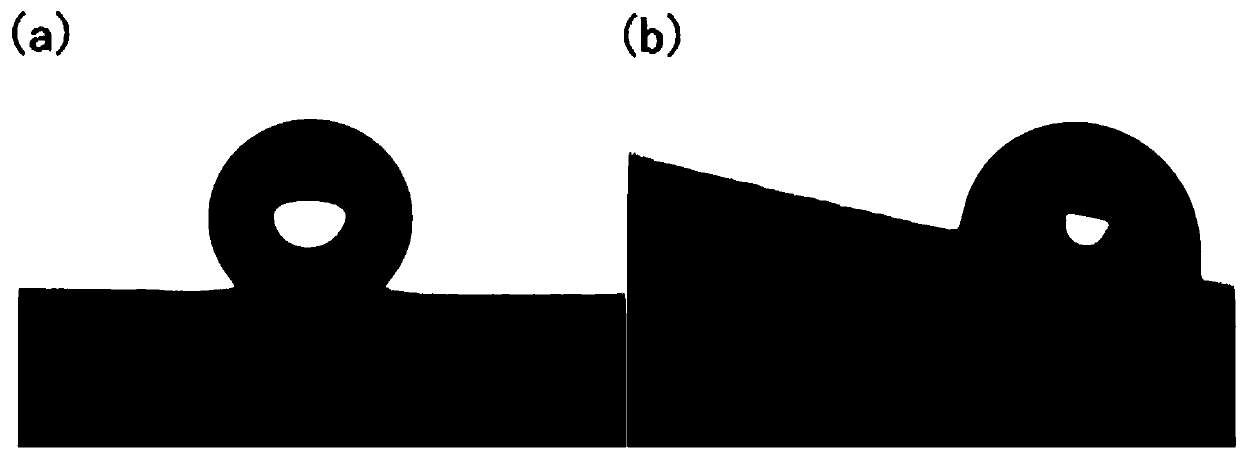

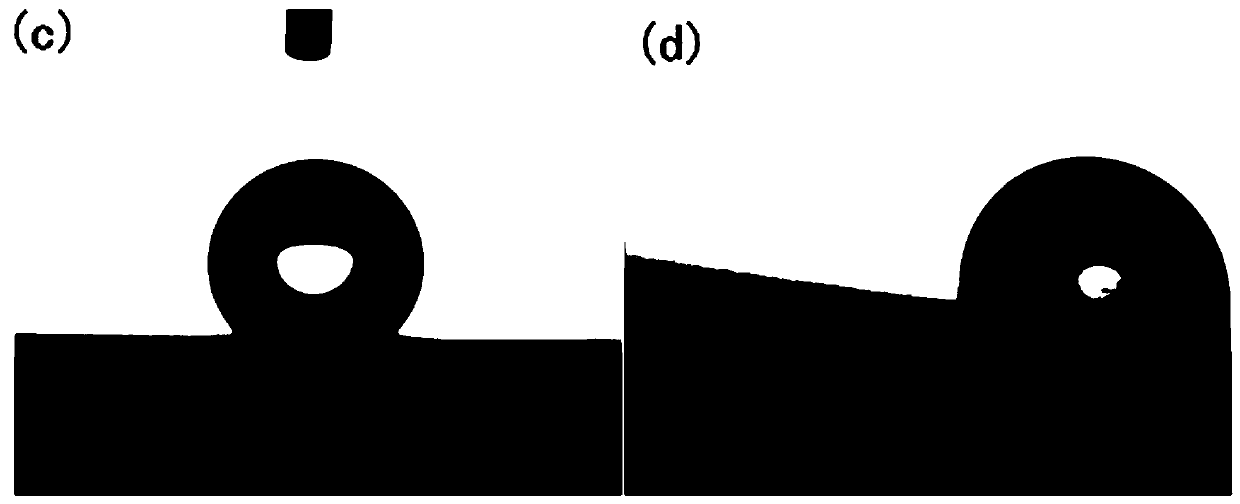

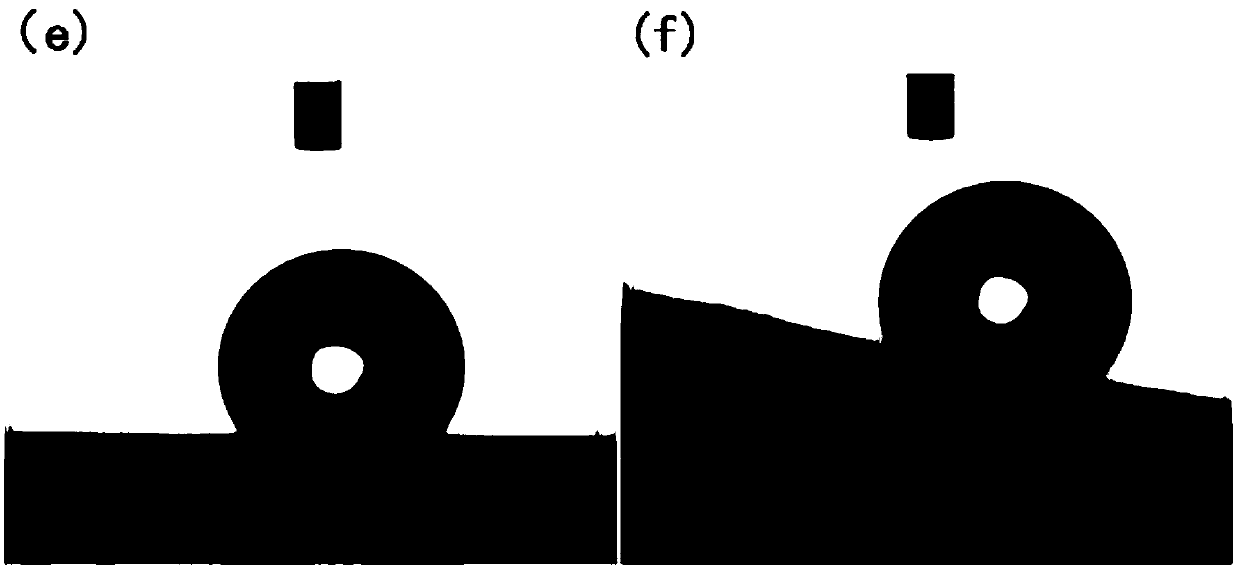

Image

Examples

Embodiment 1

[0037] An embodiment of the present invention provides a modified aluminum substrate surface and a preparation method thereof, the method comprising the following steps:

[0038] Step 1. Polish 1050 aluminum, select a metallographic sample pre-grinding machine with a power of 370W, a grinding disc speed of 450 rpm, and a grinding disc diameter of 230mm. The polishing process requires auxiliary SiC water sandpaper with a diameter of 200mm and 1200 mesh in the The aluminum surface is polished, and the polishing range is 100cm 2 , the polishing time is 10 minutes, and the aluminum sample after surface polishing is obtained;

[0039] The aluminum sample after described surface polishing is cleaned with ultrasonic cleaner, and the ultrasonic frequency of ultrasonic cleaner is 40kHz, submerges sample surface with the deionized water of resistivity 18.25 megohms at room temperature, cleans continuously for 30 minutes, and then with ethanol Cleaning, after cleaning, take out the samp...

Embodiment 2

[0044] In the method for preparing the surface of the modified aluminum substrate in this embodiment, the pulse width of the laser described in step 2 and step 3 is 240 ns, the single pulse energy is 0.12 mJ, and the repetition frequency is 450 kHz, and the laser scan uses an X-Y scanning galvanometer , making the laser beam ablate the surface of the aluminum product row by row at a scanning speed of 5575mm / s; the rest are the same as in Example 1.

Embodiment 3

[0046] The method for preparing the surface of the modified aluminum substrate in this embodiment, except that the pulse width of the laser described in step 2 and step 3 is 240ns, the single pulse energy is 0.375mJ, and the repetition frequency is 160kHz, and the laser scanning uses an X-Y scanning galvanometer , making the laser beam ablate the surface of the aluminum product row by row at a scanning speed of 1666.7mm / s; the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com