Ball milling preparation method of rice hull-based porous silicon nanomaterial

A technology of silicon nanometer and porous silicon is applied in the field of preparation of rice husk-based porous silicon nanometer materials, which can solve the problems of high raw material price and unfavorable preparation process, and achieve the effects of lowering reaction temperature, simple operation and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

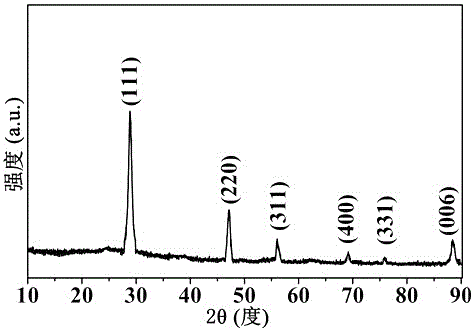

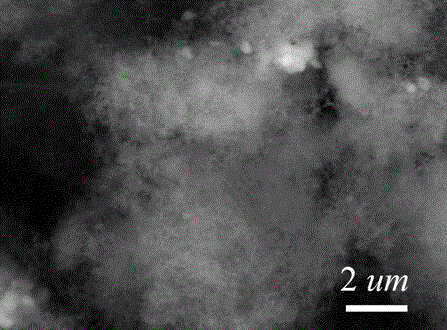

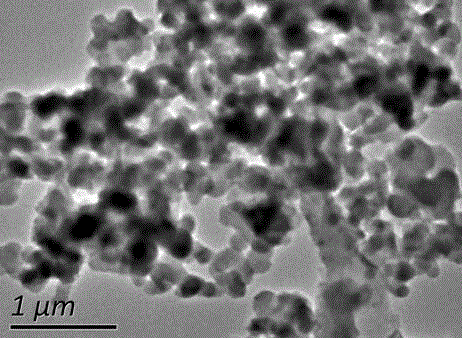

Image

Examples

Embodiment 1

[0031] Step 1: Take the washed and dried rice husk as raw material, heat and oxidize the rice husk with a microwave device at 1000 W for 30 minutes in an air atmosphere to obtain rice husk ash, then soak it in dilute hydrochloric acid, and finally wash it repeatedly with distilled water and dry it to obtain the dried of rice husk ash.

[0032] Step 2: Combine the dried rice husk ash with aluminum powder and AlCl 3 Mix at a mass ratio of 1:1:10 to obtain a mixture.

[0033] Step 3: Put the mixture in an agate jar filled with inert gas, and use a planetary ball mill for ball milling with a mass ratio of ball to material of 5:1, a rotational speed of 400 rpm, and a milling time of 20 h.

[0034] Step 4: After the ball milling, cool naturally to the greenhouse to collect the product, soak it with 0.1 M dilute hydrochloric acid, wash it repeatedly with distilled water, and finally remove the residual silicon oxide with a hydrofluoric acid solution with a mass percentage of 3% to o...

Embodiment 2

[0042] Step 1: Take the washed and dried rice husk as raw material, heat and oxidize the rice husk with a microwave device at 1000 W for 30 minutes in an air atmosphere to obtain rice husk ash, then soak it in dilute hydrochloric acid, and finally wash it repeatedly with distilled water and dry it to obtain the dried of rice husk ash.

[0043] Step 2: Combine the dried rice husk ash with aluminum powder, magnesium powder, AlCl 3 Mix at a mass ratio of 1:1:1:9 to obtain a mixture.

[0044] Step 3: Put the above mixture in an agate jar filled with inert gas, and use a planetary ball mill for ball milling with a mass ratio of ball to material of 5:1, a rotational speed of 800 rpm, and a ball milling time of 16 h.

[0045] Step 4: After ball milling, cool naturally to the greenhouse to collect the product, soak it in 0.1M dilute hydrochloric acid, wash it repeatedly with distilled water, and finally remove the residual silicon oxide with 3% hydrofluoric acid solution to obtain th...

Embodiment 3

[0050] Step 1: Take the washed and dried rice husk as raw material, heat and oxidize it with a microwave device at 800 W for 15 minutes in an air atmosphere to obtain rice husk ash, then soak it in dilute hydrochloric acid, and finally wash it repeatedly with distilled water and dry it to obtain the dried of rice husk ash.

[0051] Step 2: Combine the dried rice husk ash with aluminum powder, magnesium powder, AlCl 3 Mix at a mass ratio of 1:0.5:0.5:12 to obtain a mixture.

[0052] Step 3: Put the above mixture in an agate jar filled with an inert gas, and use a planetary ball mill for ball milling with a ball-to-material mass ratio of 4:1, a rotational speed of 600 rpm, and a ball milling time of 16 h.

[0053] Step 4: After the ball milling, cool naturally to the greenhouse to collect the product, soak it in 0.1M dilute hydrochloric acid, wash it repeatedly with distilled water, and finally remove the residual silicon oxide with 2M NaOH solution at 70°C to obtain rice husk-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com