Low-temperature preparation method of rice-hull-based porous silicon material

A technology of silicon materials and rice husks, which is applied in the field of preparation of rice husk-based porous silicon nanomaterials to achieve high yield, simple process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Use the washed and dried rice husk as raw material, heat it with microwave radiation in the air, and oxidize it with a power of 900 W for 50 minutes to obtain rice husk ash, then soak it in 0.1 M dilute hydrochloric acid, and wash it repeatedly with distilled water After drying, the rice husk ash after drying is obtained;

[0029] Step 2: Combine the dried rice husk ash with aluminum powder and AlCl 3Mixing, the mass ratio of these three mixtures is 1:1:10, and the mixture is loaded into a stainless steel airtight container, heated to 190 ° C and incubated for 10 hours;

[0030] Step 3: After the reaction time is up, cool the sealed stainless steel container to the greenhouse naturally, collect the reaction product, soak it with 3% dilute hydrochloric acid, and wash it repeatedly with distilled water; finally remove it with 3% hydrofluoric acid The residual silicon oxide is the rice husk-based porous silicon material.

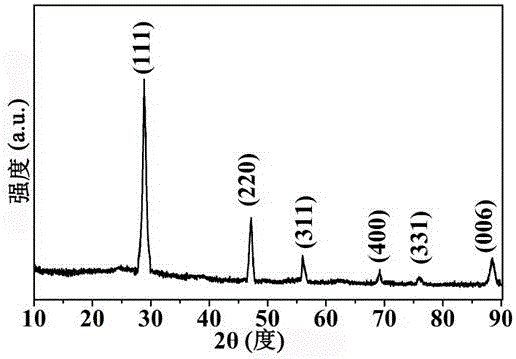

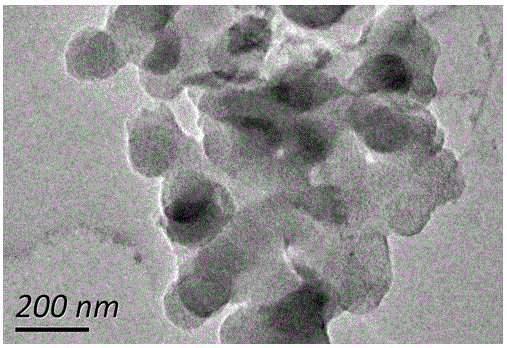

[0031] Product and performance testing: ...

Embodiment 2

[0038] Step 1: Use washed and dried rice husks as raw materials, heat them with microwave radiation in the air with a microwave device at a power of 800W, and oxidize them for 25 minutes to obtain rice husk ash, then soak them in 0.1 M dilute hydrochloric acid, and wash them repeatedly with distilled water After drying, the rice husk ash after drying is obtained;

[0039] Step 2: Combine the dried rice husk ash with aluminum powder, magnesium powder, AlCl 3 Mixing, wherein the mixing mass ratio of the four raw materials is 1:0.5:0.5:10. Then the mixture is loaded into a stainless steel airtight container, heated to 200°C and incubated for 5 hours;

[0040] Step 3: After the reaction time is up, cool the sealed stainless steel container to the greenhouse naturally, collect the reaction product, soak it with 3% dilute hydrochloric acid, and wash it repeatedly with distilled water; finally remove it with 3% hydrofluoric acid Residual silicon oxide, that is, a carbon-doped rice ...

Embodiment 3

[0045] Step 1: Use washed and dried rice husks as raw materials, heat them with microwave radiation in the air with a microwave device, and oxidize them for 30 minutes at a power of 1000W to obtain rice husk ash, then soak them in 0.1M dilute hydrochloric acid, and wash them repeatedly with distilled water After drying, the rice husk ash after drying is obtained;

[0046] Step 2: First mix aluminum powder and magnesium powder with a mass ratio of 1:1, and then mix them with dried rice husk ash, AlCl 3 Mix again with a mass ratio of 2:1:8, then load the mixture into a stainless steel airtight container, heat to 180°C and keep it warm for 18 hours;

[0047] Step 3: After the reaction time is up, cool the stainless steel airtight container to the greenhouse naturally, collect the reaction product, soak it in 3% dilute hydrochloric acid, wash it repeatedly with distilled water, and finally remove the residual silicon oxide with 70°C, 2M NaOH solution material, that is, the rice h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com