Method for preparing interface optical catalyst

A photocatalyst, photocatalysis technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of zero photocatalytic activity and loss of application value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

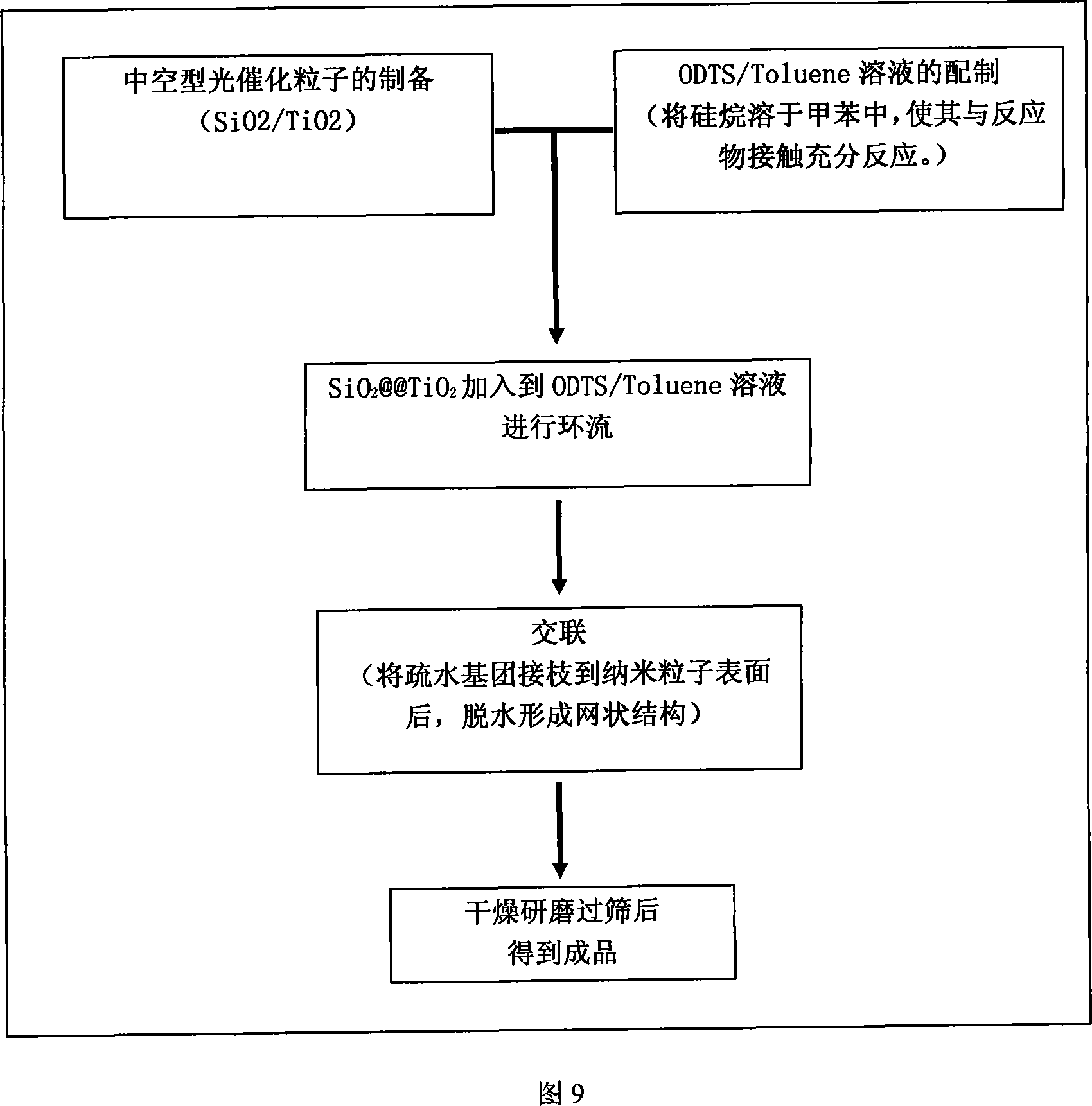

[0045] Embodiment 1, please refer to Figure 9,

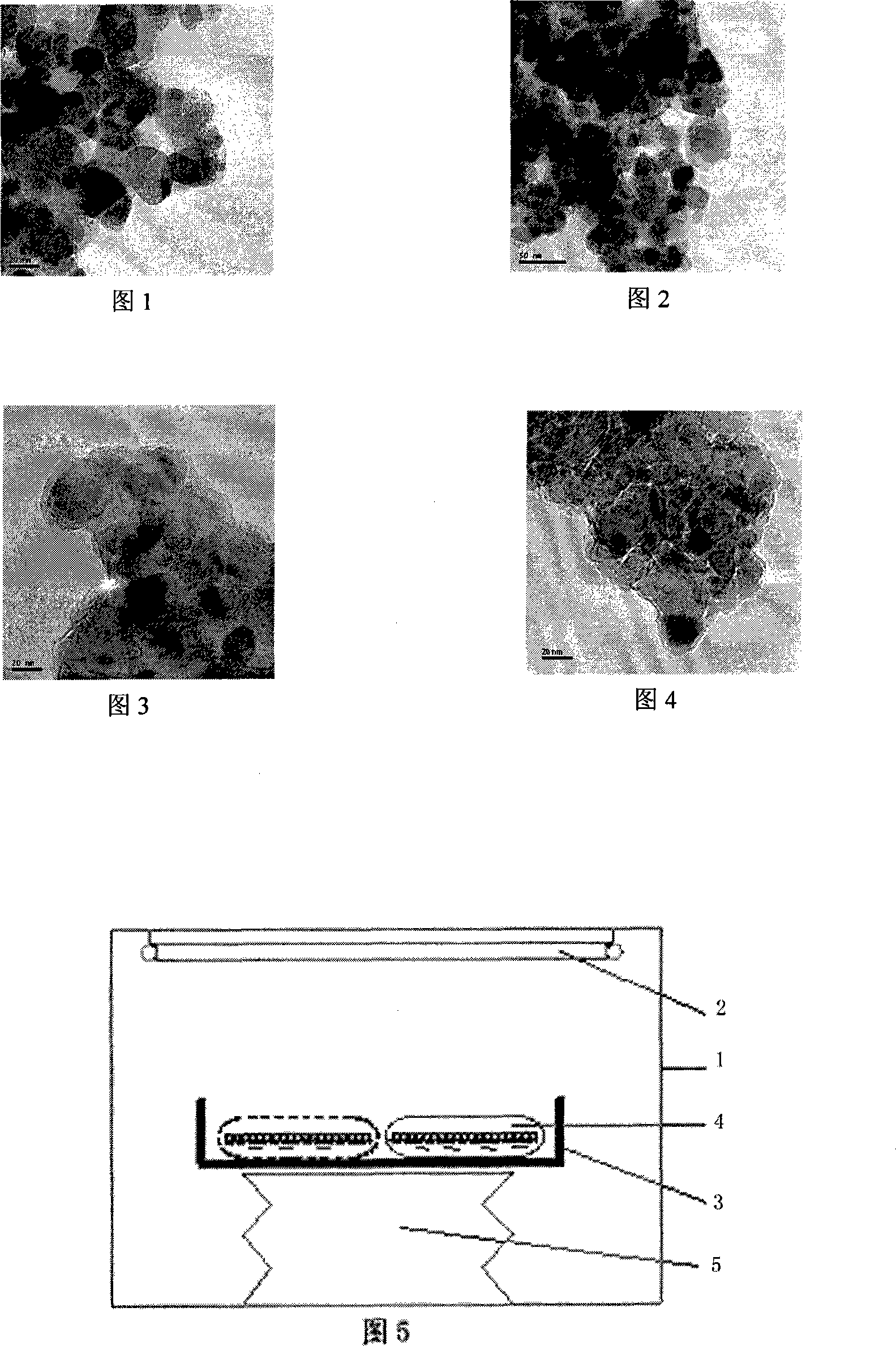

[0046] (1) Firstly, the hollow photocatalytic particle SiO with a silica shell-hollow layer-titania nano-core structure is produced 2 @@TiO 2 , (see 200610154415.X for the accompanying drawings).

[0047] (a) Pretreatment of titania nanoparticles with TiO 2 To represent,

[0048] Add 100 mg of titanium dioxide nanoparticles into a NaOH solution with a concentration of 0.5 mol / L, and magnetically stir at a speed of 500 rpm for 7 hours, then wash with water three times and centrifuge until the pH is 7 for use.

[0049] (b) The process of wrapping carbon on the surface of nanoparticles, using C@TiO 2 To represent,

[0050] Add 100 mg of nanoparticles prepared in step (a) into polyvinyl alcohol resin (PVA) in an aqueous solution of carbon-containing organic matter soluble in water at a concentration of 0.7 mol / L. After thorough mixing, the mixed solution was introduced into a hydrothermal reaction kettle, and heat-treated at 1...

Embodiment 2

[0064] Embodiment 2, please refer to Figure 9,

[0065] (1) Firstly, the hollow photocatalytic particle SiO with a silica shell-hollow layer-titania nano-core structure is produced 2 @@TiO 2 , (see 200610154415.X for the accompanying drawings).

[0066] (a) Pretreatment of titania nanoparticles with TiO 2 To represent,

[0067] Add 500 mg of titanium dioxide nanoparticles into HCl solution with a concentration of 1.2 mol / L, and magnetically stir at 1000 rpm for 14 hours, then wash with water five times and centrifuge until the pH is 7 for use.

[0068] (b) The process of wrapping carbon on the surface of nanoparticles, using C@TiO 2 To represent,

[0069] Add 450 mg of nanoparticles prepared in step (a) into polyethylene glycol (PEG) in an aqueous solution of carbon-containing organic matter soluble in water at a concentration of 2.2 mol / L. After thorough mixing, the mixed solution was introduced into a hydrothermal reaction kettle, and heat-treated at 200° C. for 8 hour...

Embodiment 3

[0083] Embodiment 3, please refer to Fig. 9,

[0084] (1) Firstly, the hollow photocatalytic particle SiO with a silica shell-hollow layer-titania nano-core structure is produced 2 @@TiO 2 , (see 200610154415.X for the accompanying drawings).

[0085] (a) Pretreatment of titania nanoparticles with TiO 2 To represent,

[0086] Add 300 mg of titanium dioxide nanoparticles into NaOH solution with a concentration of 0.8 mol / L, and magnetically stir at 750 rpm for 10 hours, then wash with water four times and centrifuge until the pH is 7 for use.

[0087] (b) The process of wrapping carbon on the surface of nanoparticles, using C@TiO 2 To represent,

[0088] 275 mg of nanoparticles prepared in step (a) was added into an aqueous solution of carbon-containing organic matter soluble in water sucrose (Sucrose) with a concentration of 1.4 mol / L. After thorough mixing, the mixed solution was introduced into a hydrothermal reaction kettle, and heat-treated at 175° C. for 5 hours. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com