Patents

Literature

91results about How to "Adjust Uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

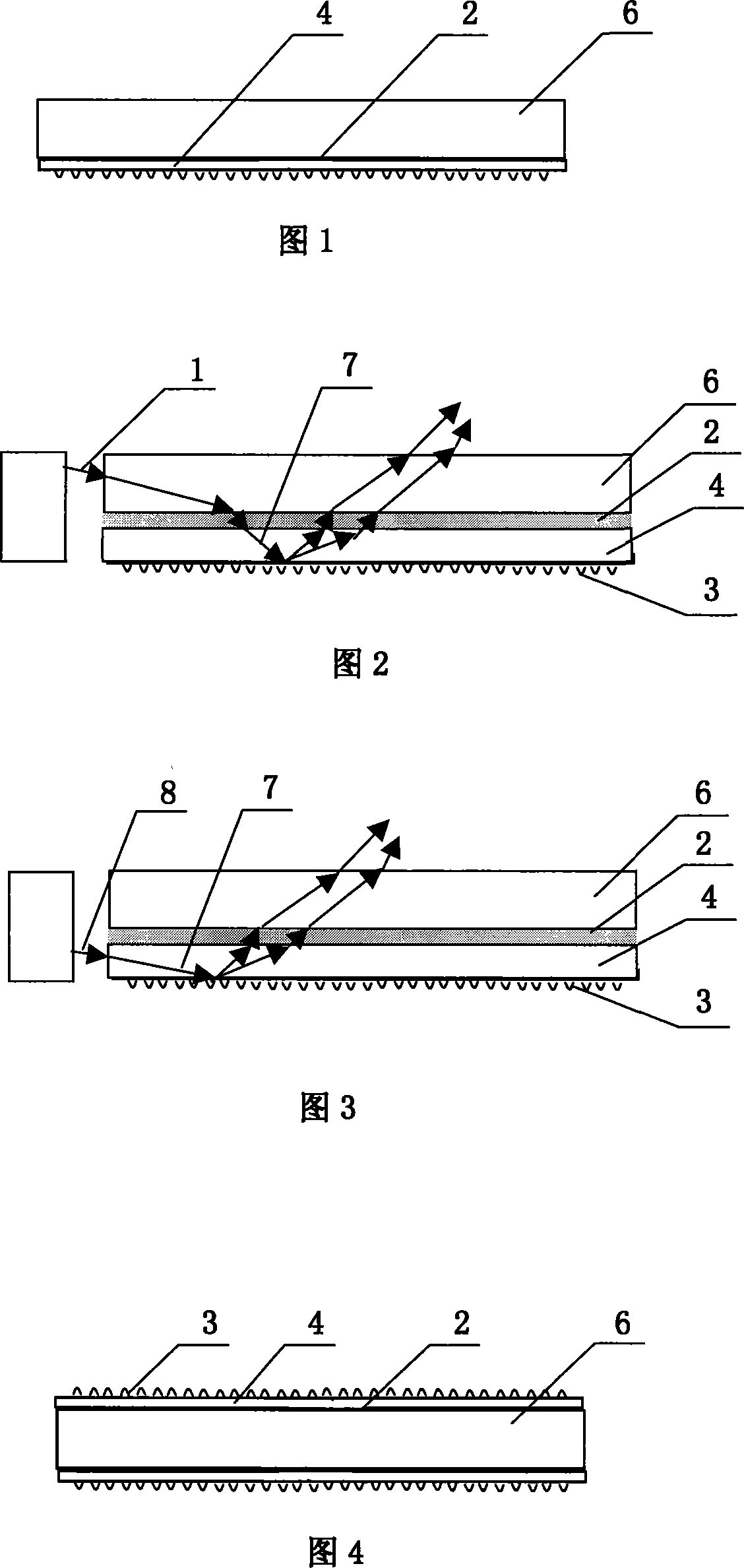

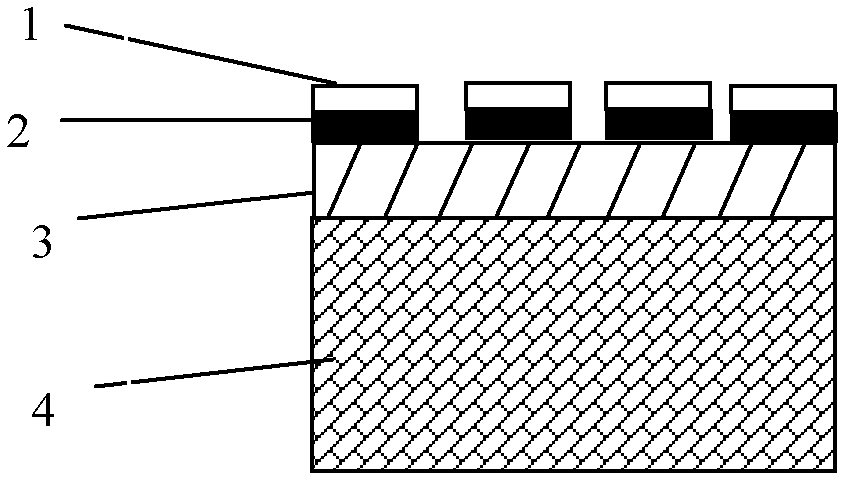

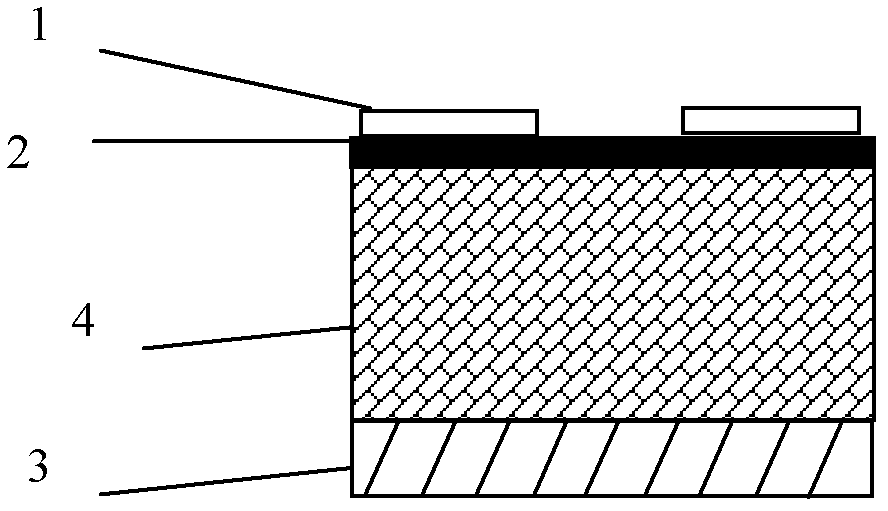

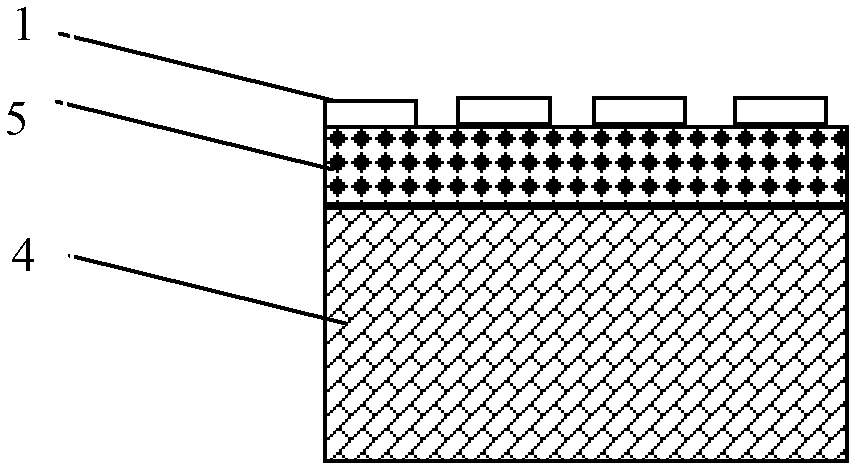

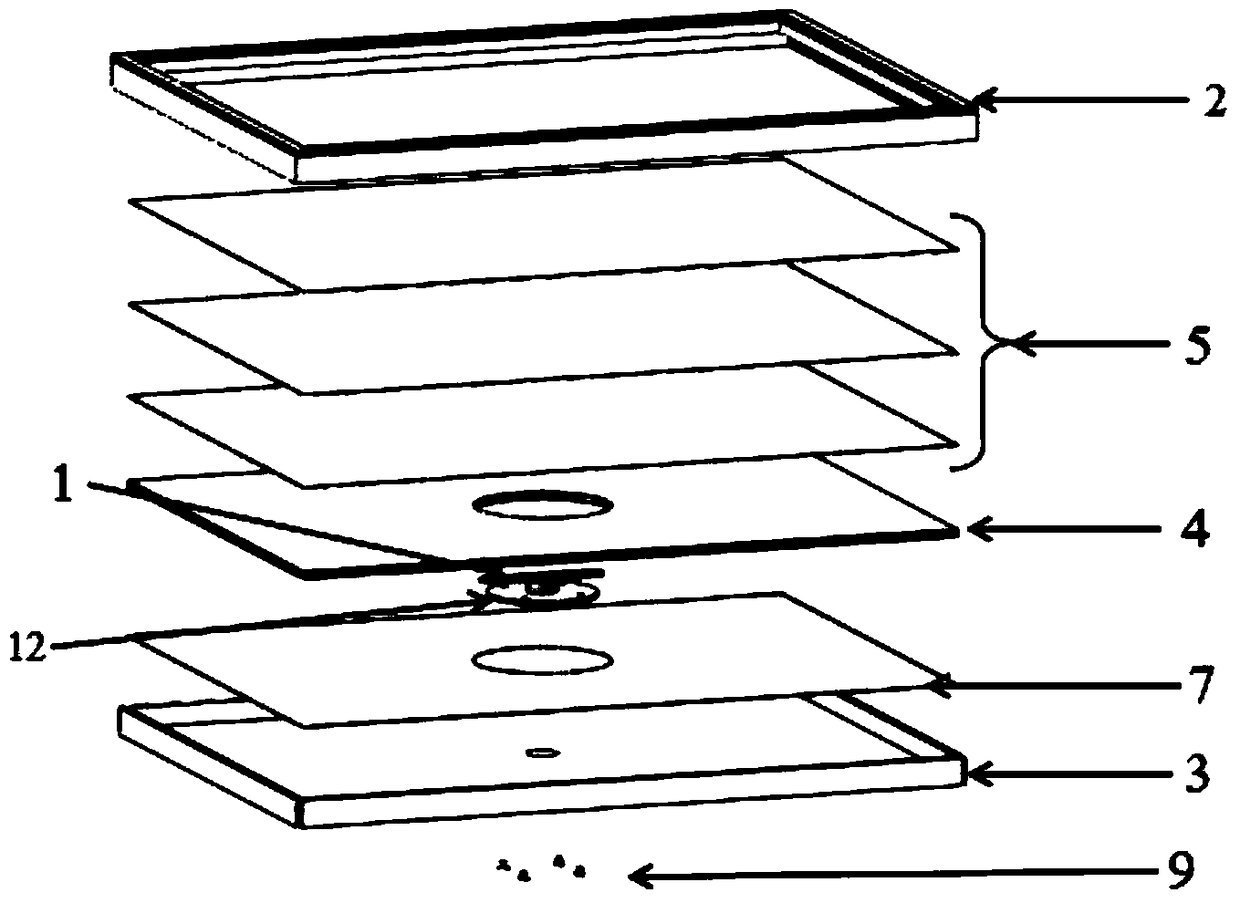

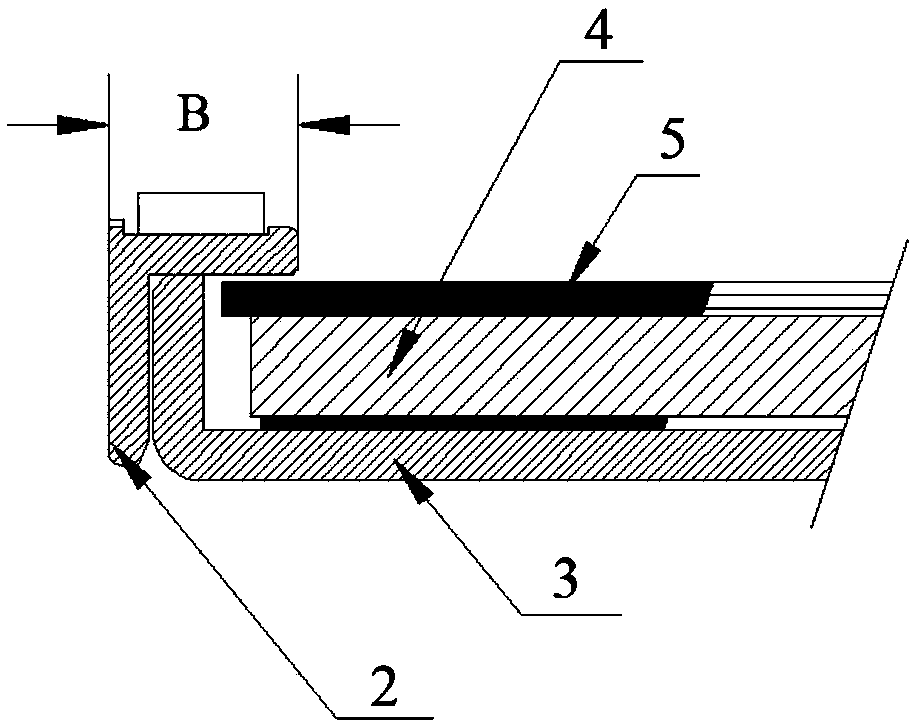

Combined light guide board and preparation method

InactiveCN101216573AImprove processing efficiencyImprove yieldLaminationLamination apparatusScreen printingMicro nano

The invention discloses a composite light guide plate structure and a high-efficiency production method for fabricating the light guide plate structure. The production method is characterized in that a flexible light guide thin film is compounded with a substrate layer, the composite light guide plate includes a double-layer or three-layer structure, and light guide grid dots are distributed on the lower surface or on the upper and the lower surfaces of the composite structure, wherein the flexible light guide thin film is produced by advanced reel-to-reel micro-nano imprint and is compounded with the substrate layer through a transparent viscous substance. The invention can greatly improve the production efficiency, and the grid dots manufactured by reel-to-reel micro-nano imprint have the advantage of high consistency, thus ensuring the performance stability of the light guide plate. The invention is particularly applicable for large-size backlight module and has the advantage of low cost. Meanwhile, the invention belongs to environment-friendly manufacture method due to no organic solve discharge in the screen printing process.

Owner:陈林森

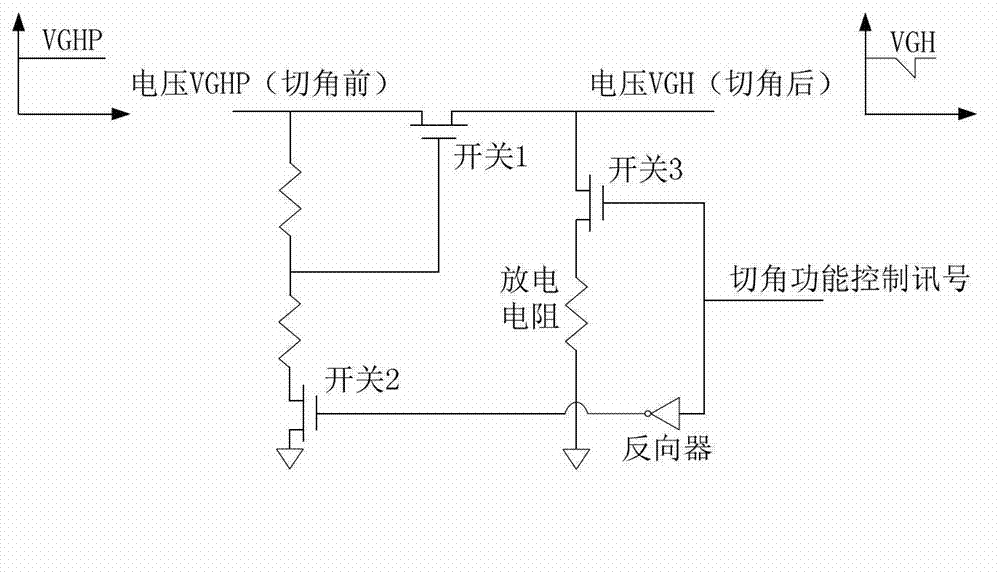

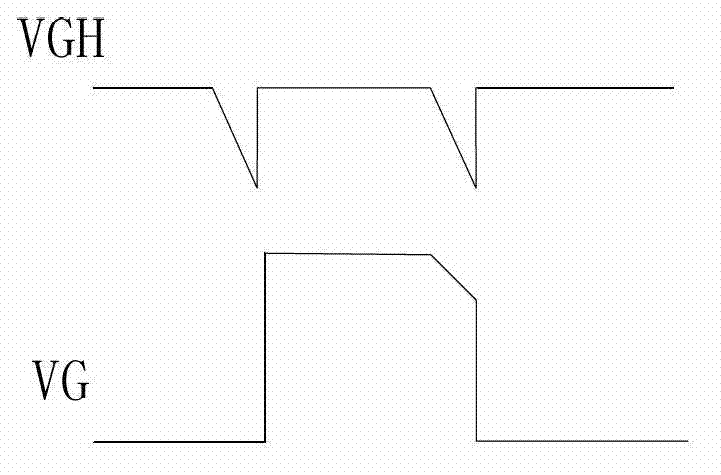

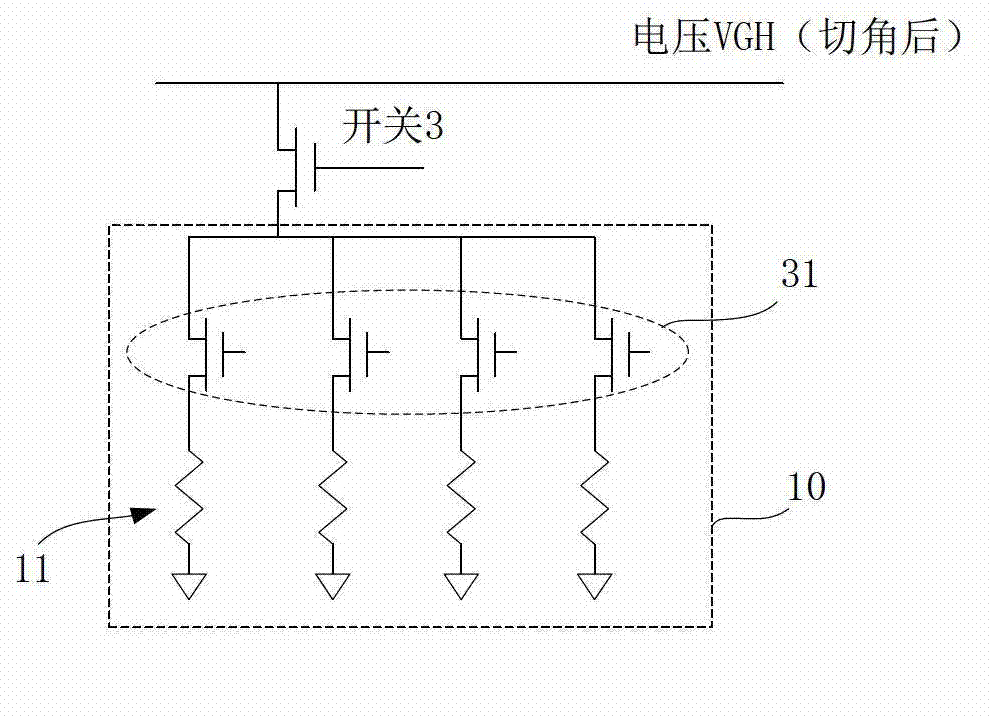

Corner cutting circuit in liquid crystal panel driving system and levelness adjusting system and method

InactiveCN102956216AAdjust UniformityChange uniformityStatic indicating devicesElectrical resistance and conductanceLiquid-crystal display

The invention discloses a corner cutting circuit in a liquid crystal panel driving system, and a levelness adjusting system and method; the corner cutting circuit comprises a discharge resistor; and the discharge resistor is an adjustable resistor with adjustable resistance. According to the corner cutting circuit in the liquid crystal panel driving system, the levelness adjusting system and method, because the discharge resistor of the corner cutting circuit in the liquid crystal panel driving system is changed into the adjustable resistor with the adjustable resistance, the discharge slope can be changed by adjusting the resistance of the discharge resistor, so that the levelness of a liquid crystal panel is changed; and in such manner, the discharge resistance can be adjusted without changing the discharge resistor, so that the levelness of each liquid crystal panel can be regulated, and the production quality of the liquid crystal panel is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

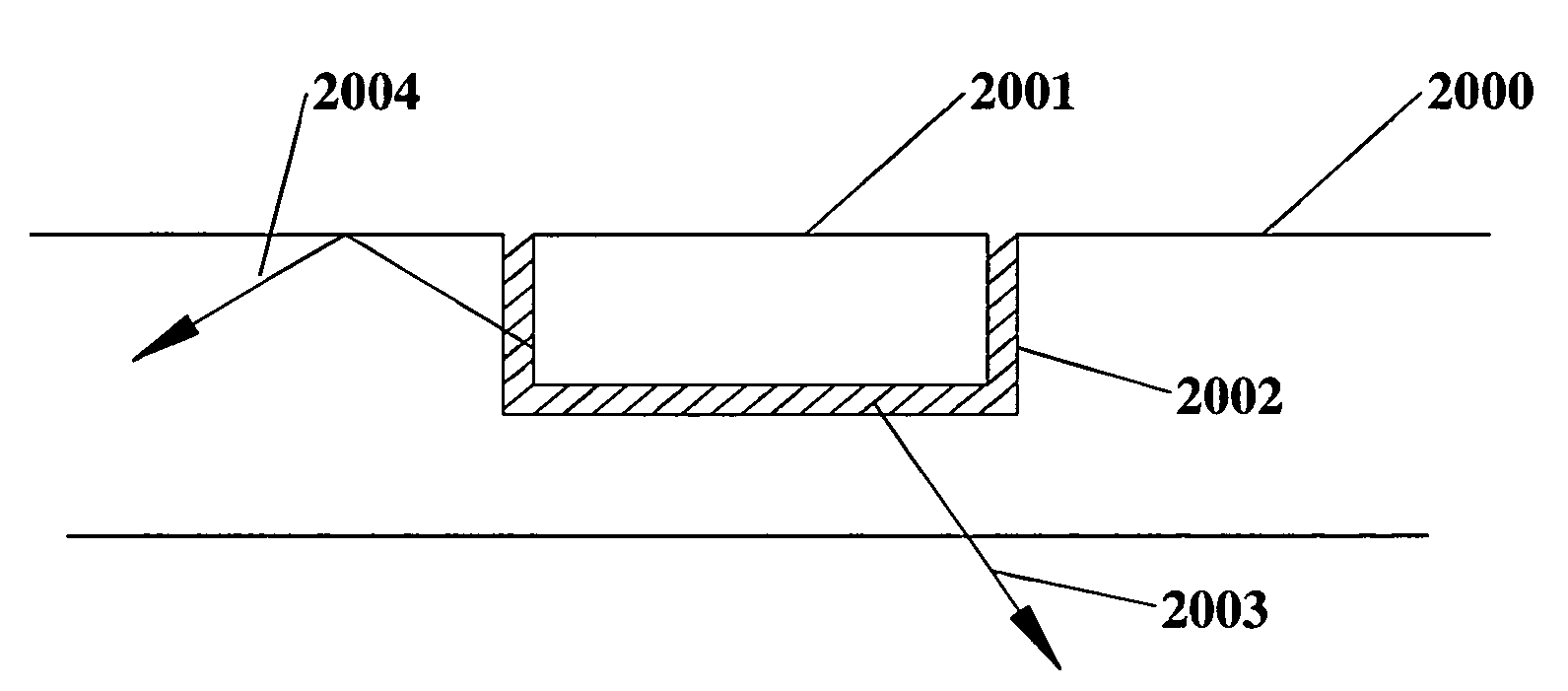

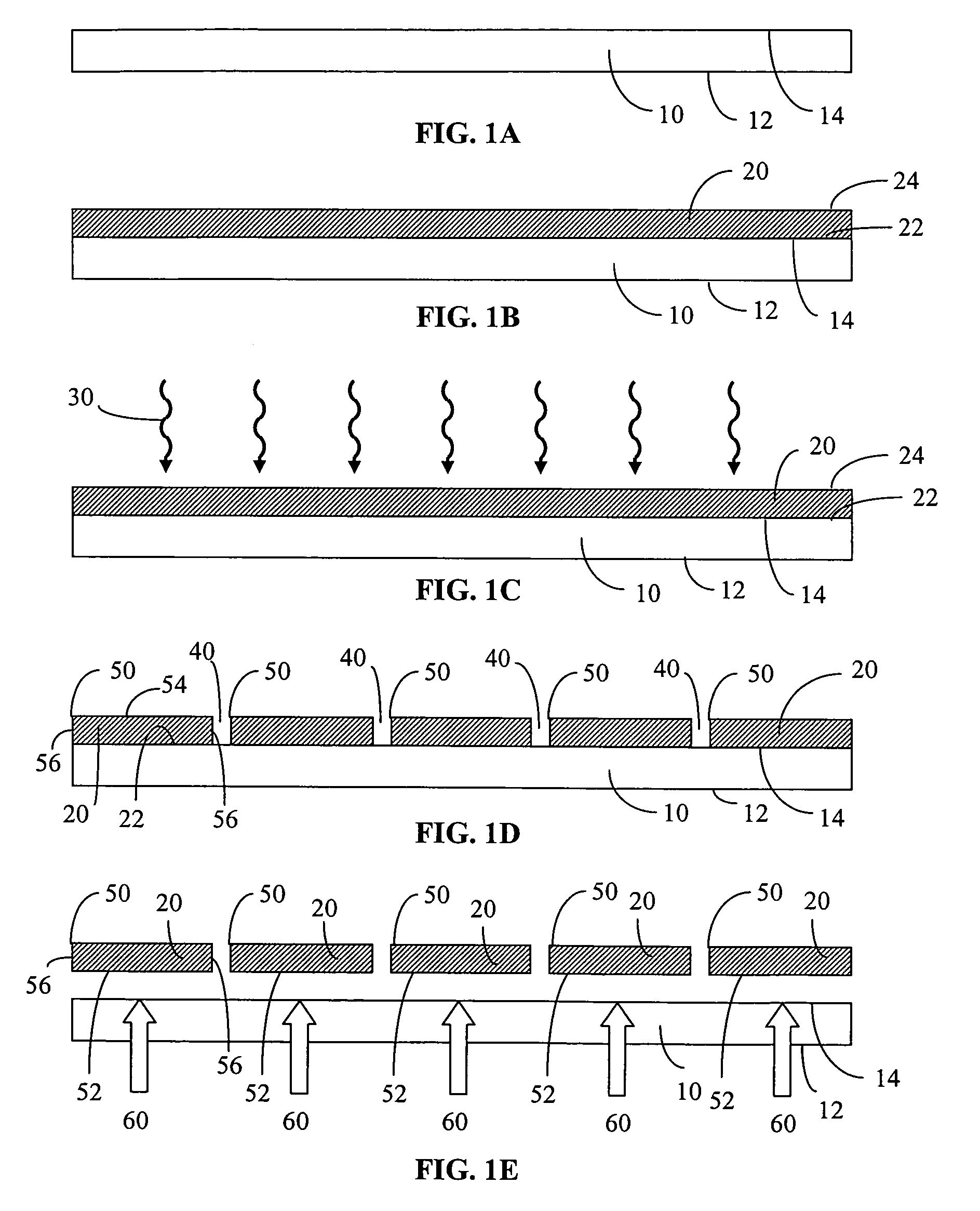

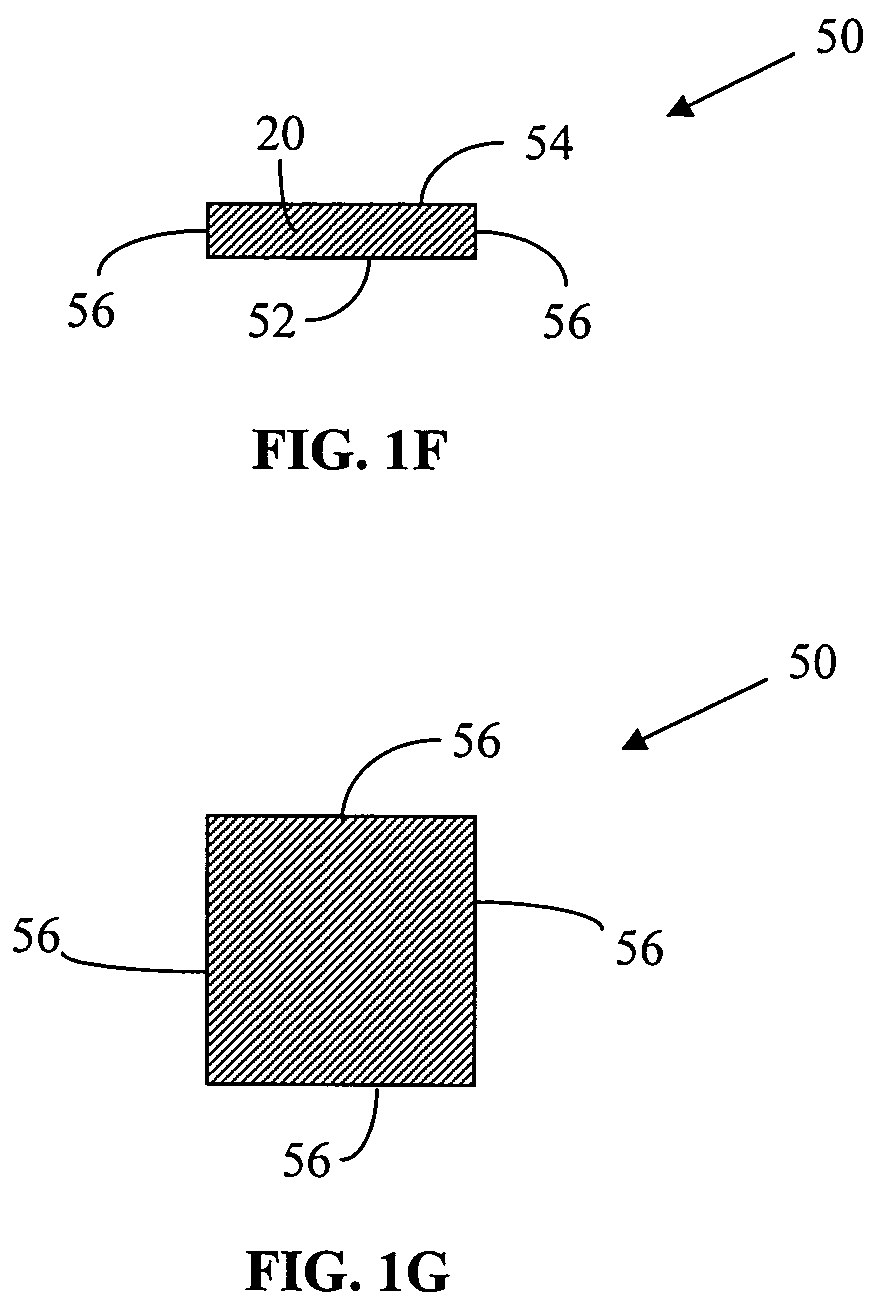

LED light source with thermally conductive luminescent matrix

ActiveUS8481977B2Reduce impactLower levelDischarge tube luminescnet screensElectroluminescent light sourcesOptical coatingElectrical connection

A wavelength conversion chip is formed by depositing a wavelength conversion material on a substrate to form a layer, removing the resulting wavelength conversion layer from the substrate and then segmenting the wavelength conversion layer into a plurality of wavelength conversion chips. The wavelength conversion material can be annealed by thermal annealing or radiation annealing to increase the wavelength conversion efficiency of the chips or to sinter the wavelength conversion material to form a ceramic material. Optical coatings, vias, light extraction elements, electrical connections or electrical bond pads can be fabricated on the wavelength conversion chips.

Owner:GOLDENEYE

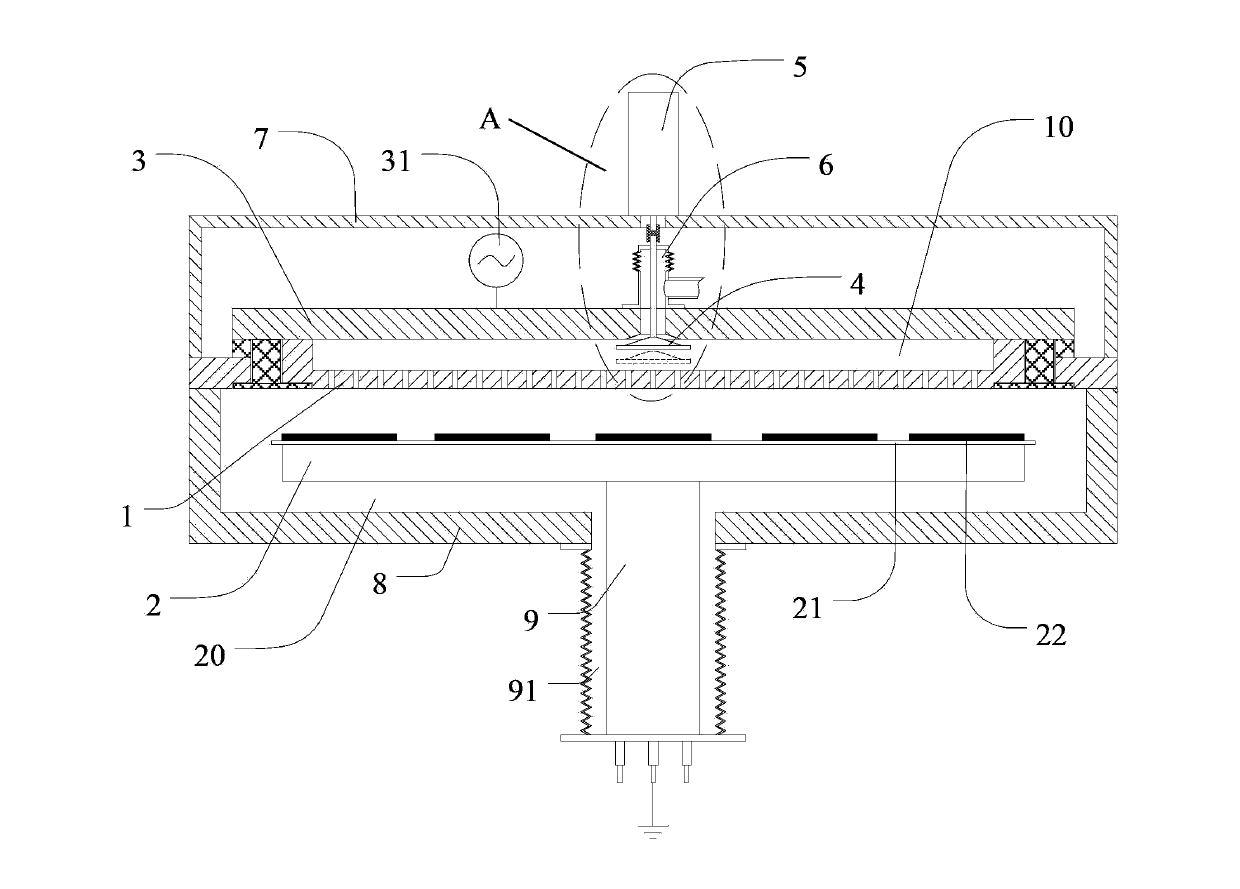

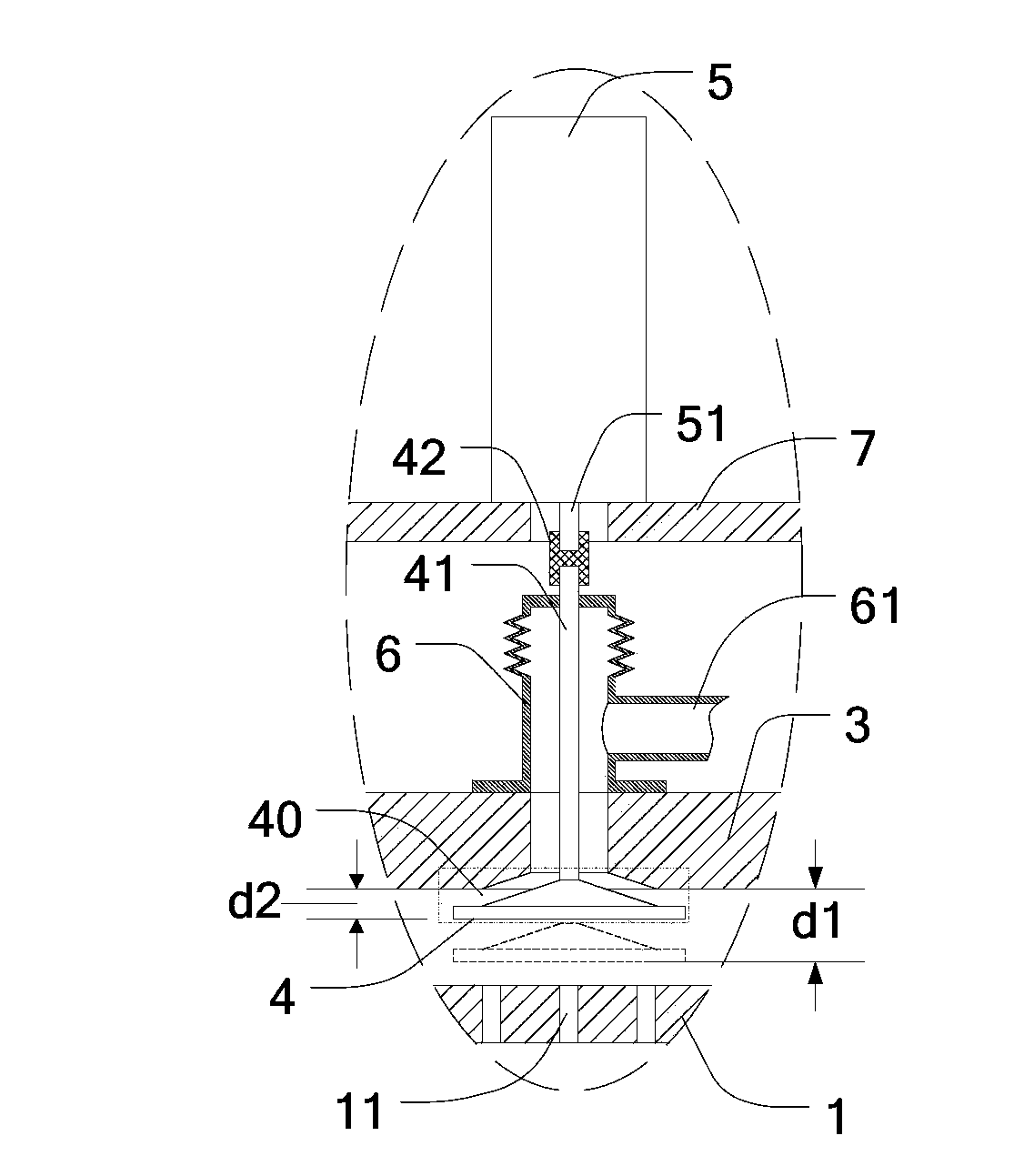

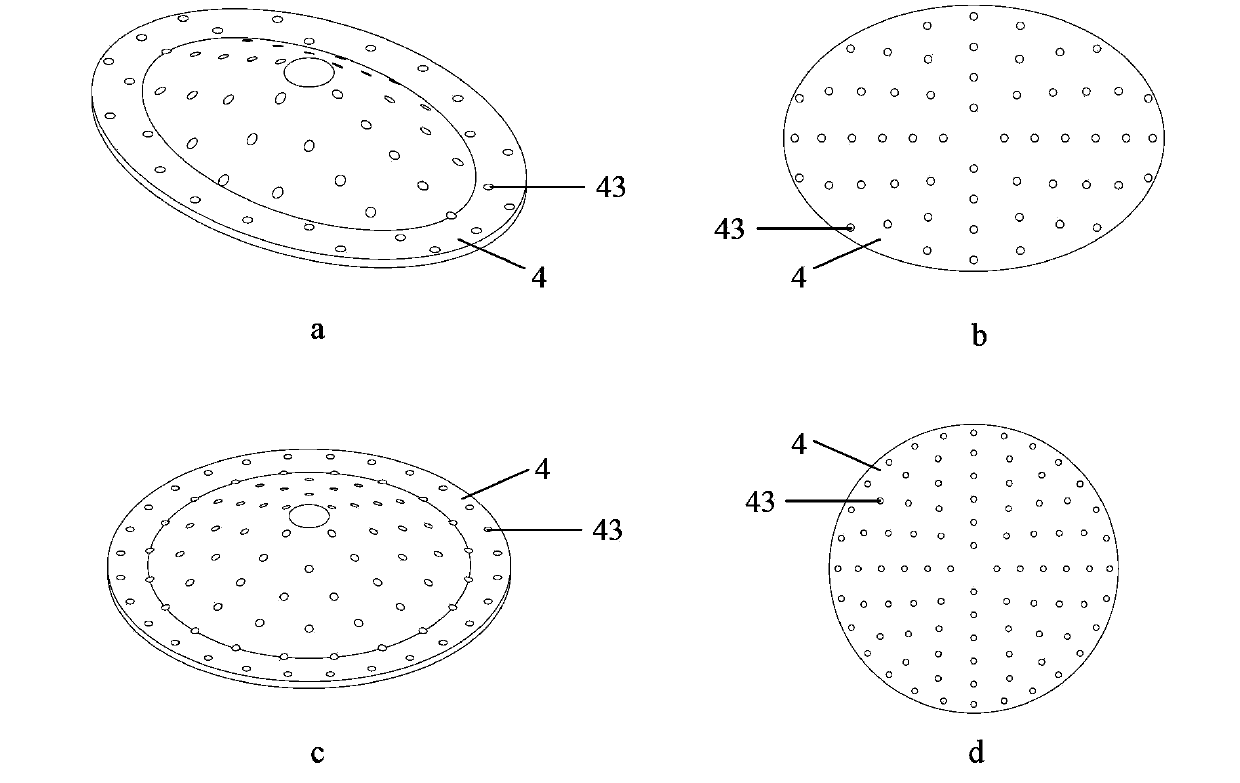

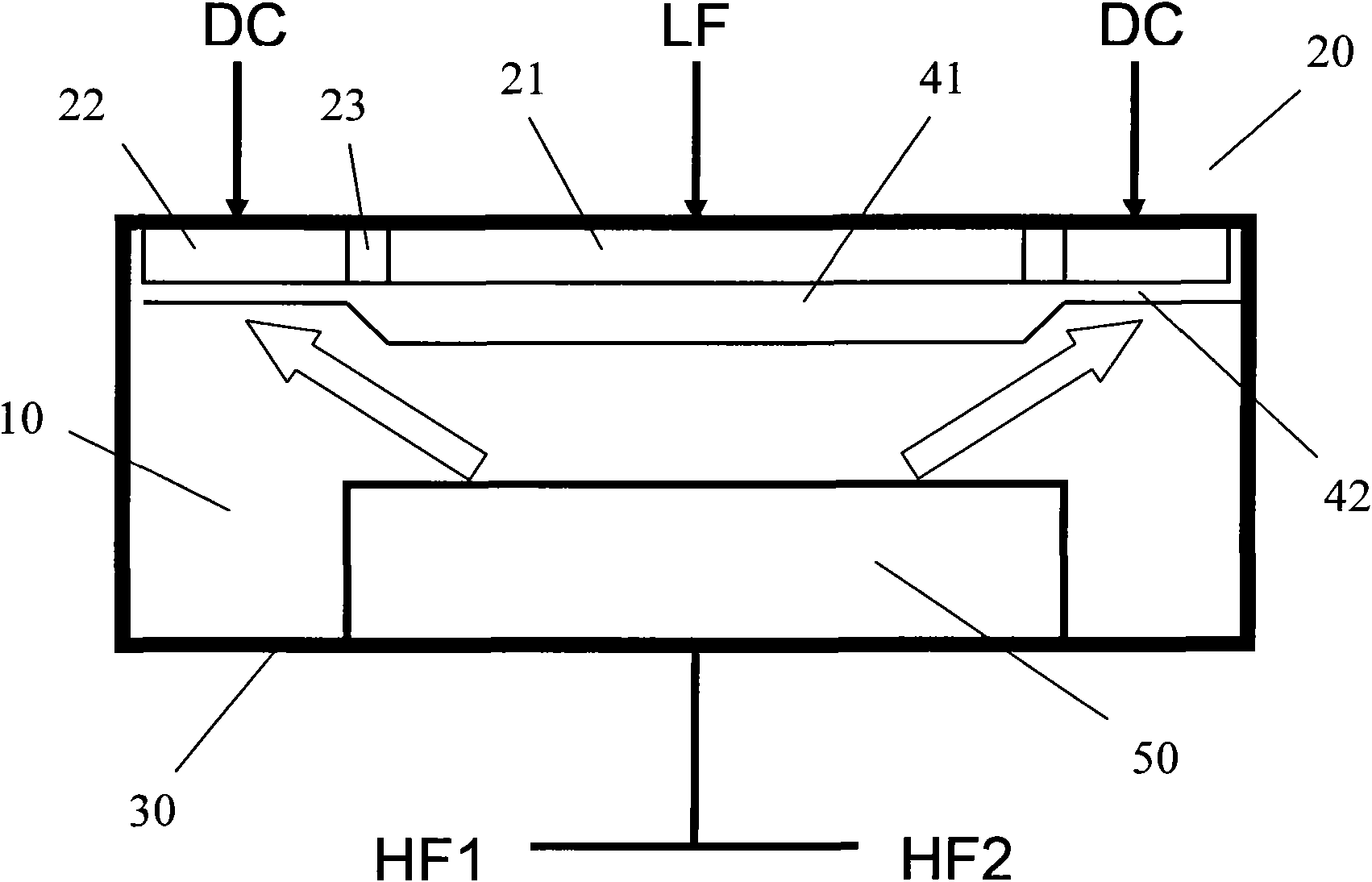

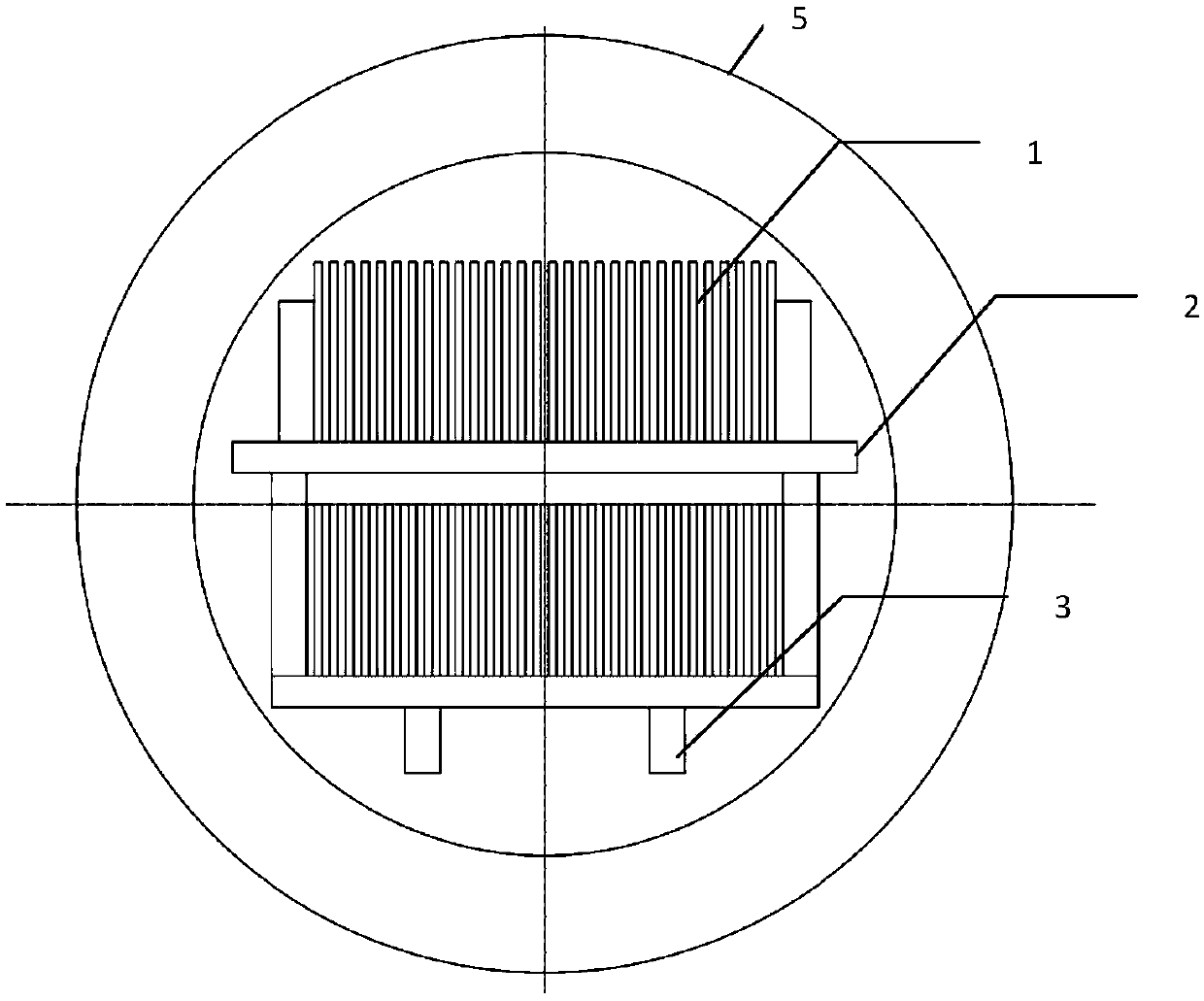

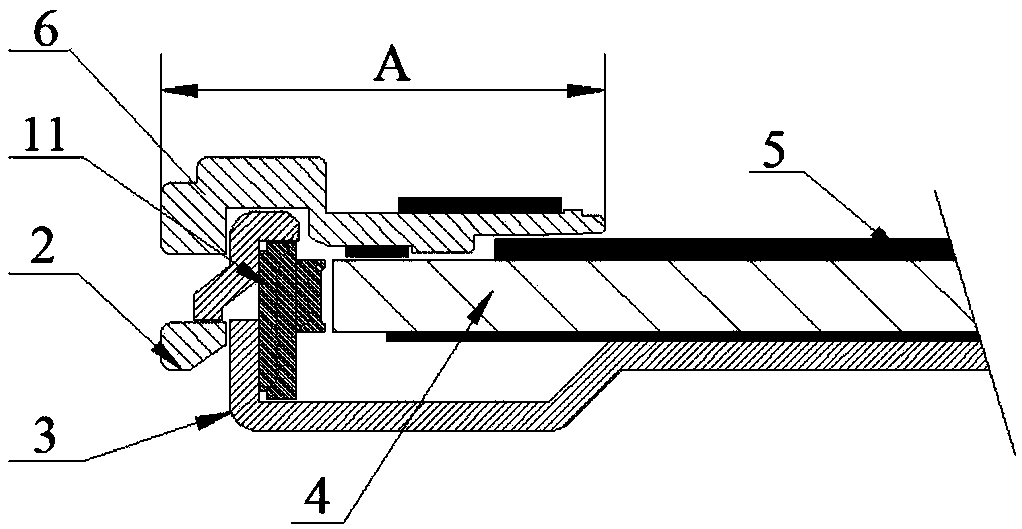

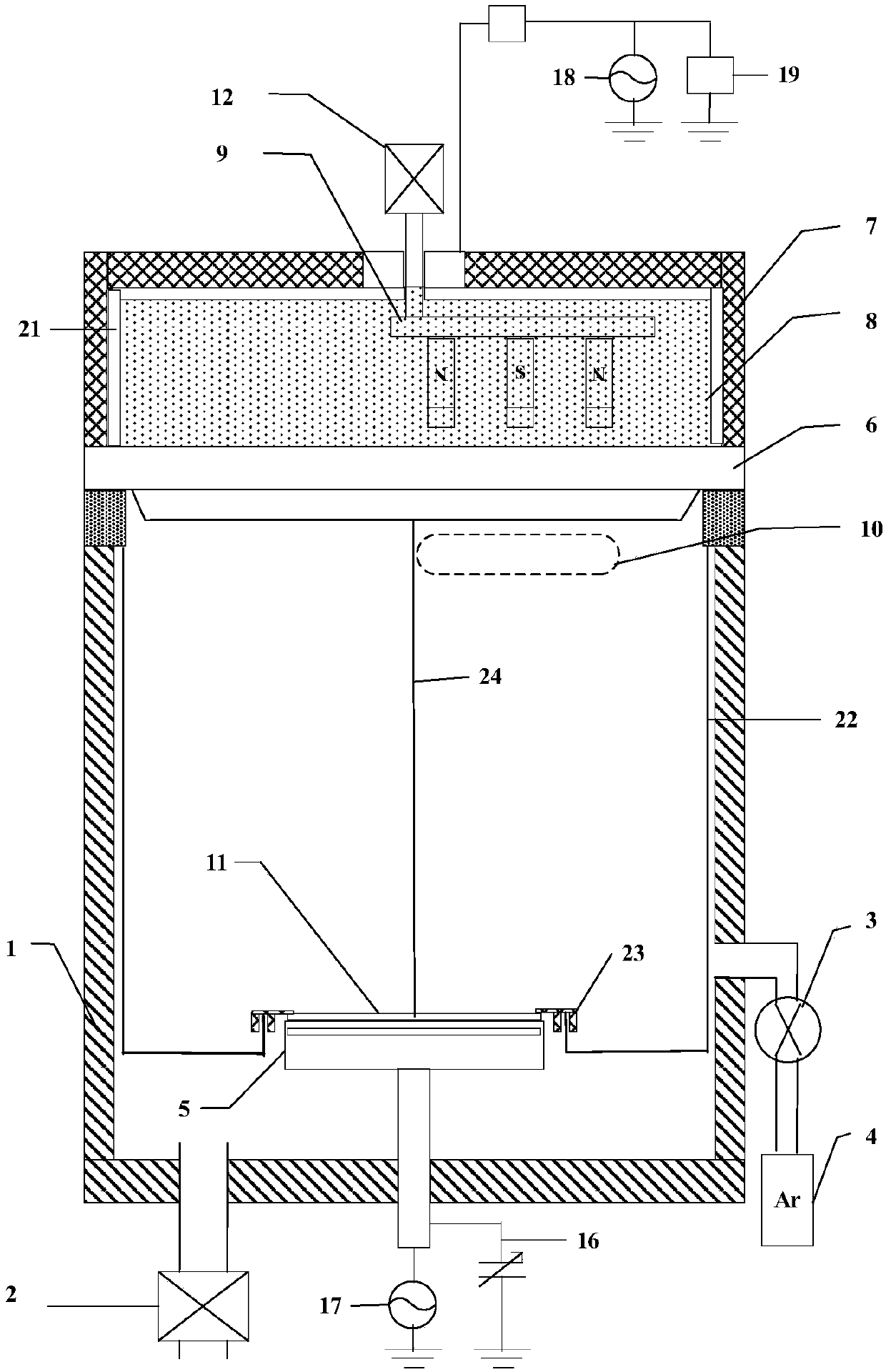

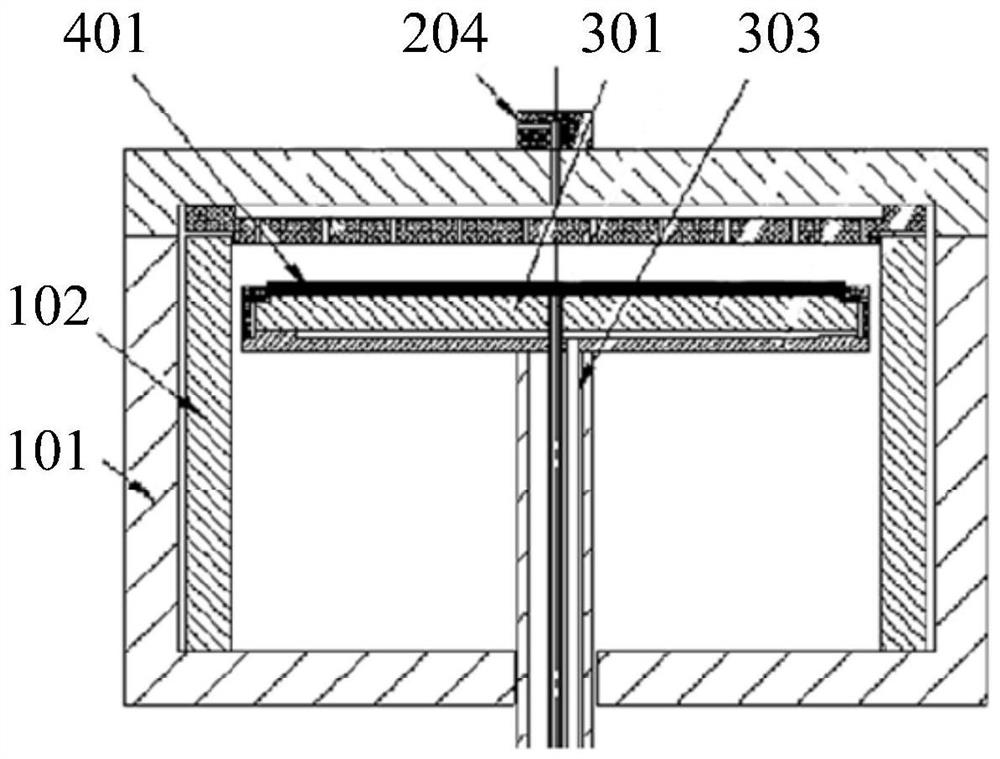

Plasma enhanced chemical vapor deposition equipment

ActiveCN103866281AAdjust UniformityUniformity adjustableChemical vapor deposition coatingEngineeringRadio frequency

The invention discloses plasma enhanced chemical vapor deposition (PECVD) equipment, and belongs to the technical field of vapor deposition. The equipment can guarantee the gas uniformity when the flow and pressure of process gas change greatly under a condition that the flow modulating mechanism is not modified. The equipment comprises an upper electrode plate, a lower electrode plate, a radio-frequency cover, and a diffusion plate; the upper electrode plate is communicated with the radio-frequency power supply through the radio-frequency cover, and the lower electrode plate is grounded; the radio-frequency plate is provided with a gas inlet pipe and forms a flow modulating cavity with the upper electrode plate; the upper electrode plate is provided with a plurality of through holes, a reaction cavity is arranged under the upper electrode plate, and the lower electrode plate is arranged in the reaction cavity; the PEVCD equipment also comprises a driving device; the diffusion plate is arranged under the gas inlet pipe and is connected to the driving device, and the driving device drives the diffusion plate to move up and down relative to the radio-frequency cover. The PECVD equipment can be applied to fields of photovoltage, thin-film transistor, and the like.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

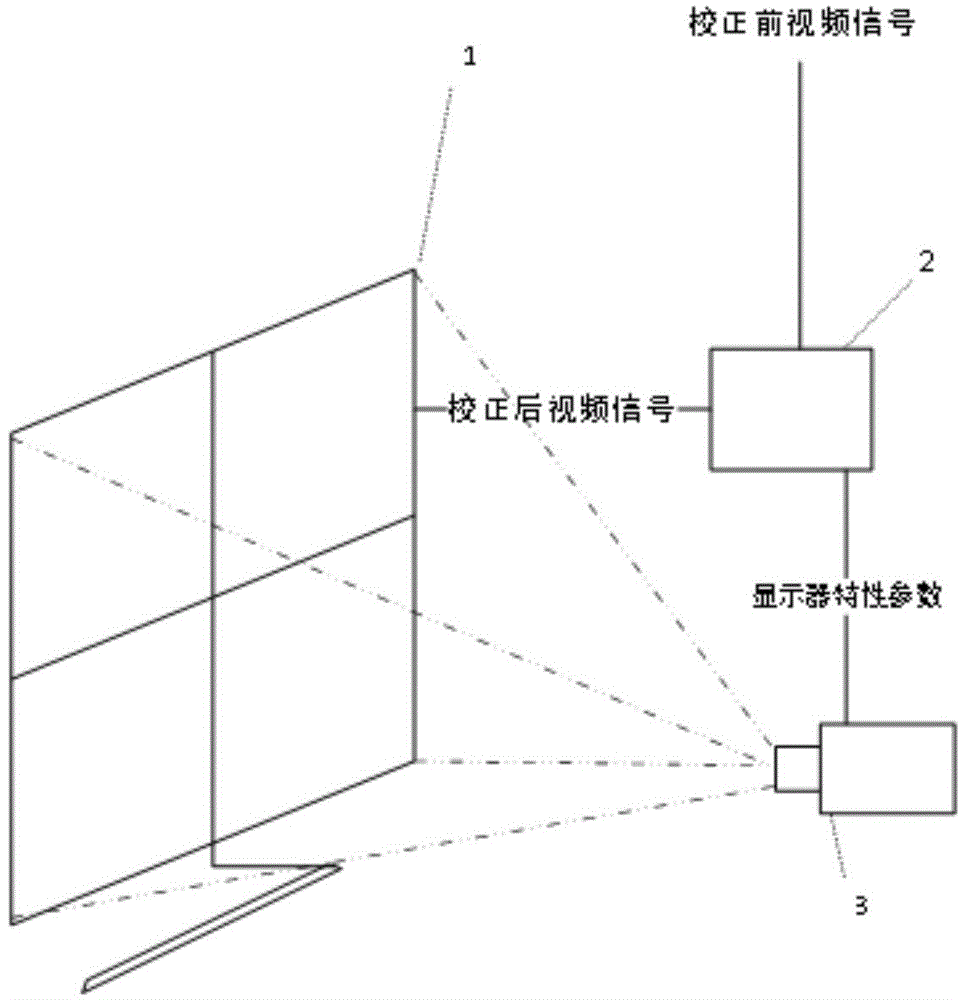

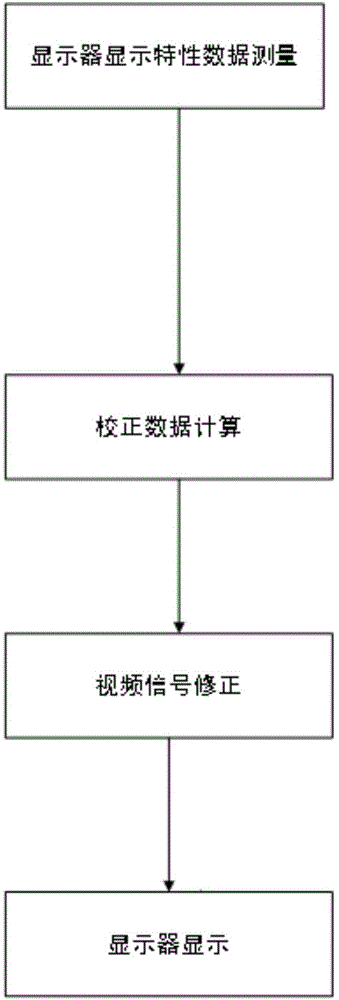

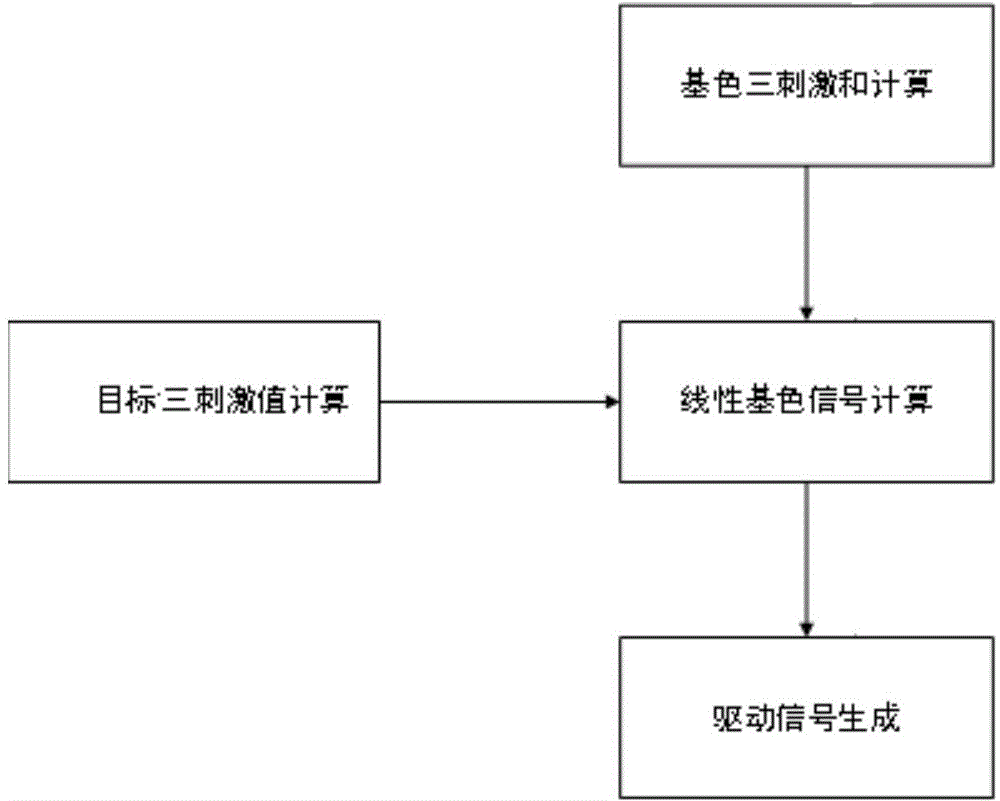

Display calibrating method

ActiveCN104361879AImplement fixesTo achieve the display effectCathode-ray tube indicatorsDisplay deviceComputer science

The invention discloses a display calibrating method and device. A measuring device comprising a photo sensor measures screen performance parameters including primary color coordinates, tristimulus values obtained when displaying is the maximum brightness white, tristimulus values obtained when displaying is the minimum brightness black, and photoelectricity tuning curves of primary colors. The measured parameters are transmitted to a signal processing device, and the signal processing device generates calibration data according to obtained data and the specific calibration algorithm and stores the calibration data in a nonvolatile storage. After that, external video signals are calibrated in real time based on calibration data. The display calibrating method can be used for calibrating uniformity, colors and brightness of single screens or spliced screens in the production process or the using process.

Owner:NANJING PANDA ELECTRONICS MFG

Plasma processing device and processing method thereof

ActiveCN101789362AHigh densitySteady adjustment of uniformitySemiconductor/solid-state device manufacturingPlasma densityRadio frequency

The invention relates to a plasma processing device, which comprises a vacuum processing cavity, an upper electrode and a lower electrode, a first radio frequency power source and an AC power source, wherein the vacuum processing cavity induces reaction gas; the upper electrode and the lower electrode are oppositely arranged at the inner side of the processing cavity; the lower electrode is provided with a base plate to be processed; the first radio frequency power source is connected with the lower electrode, is provided with a first frequency, and is used for forming the plasma of the reaction gas between the upper electrode and the lower electrode; the upper electrode comprises a plurality of subareas which are mutually and electrically insulated from each other; the AC power source is connected with at least one of the subareas on the upper electrode and is provided with a second frequency, wherein the second frequency is smaller than the first frequency. As the upper electrode is provided with a plurality of electrically-insulated subareas, the AC power source with changeable powder is applied onto some subareas, and a sheath layer, the depth of which is in proportion to the power, is formed under the upper electrode, the plasma processing device leads the more plasma to flow into the position of the thinner plasma sheath layer and increases the plasma density at the position, thereby being capable of stably adjusting the homogenization of the plasma in the processing cavity.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

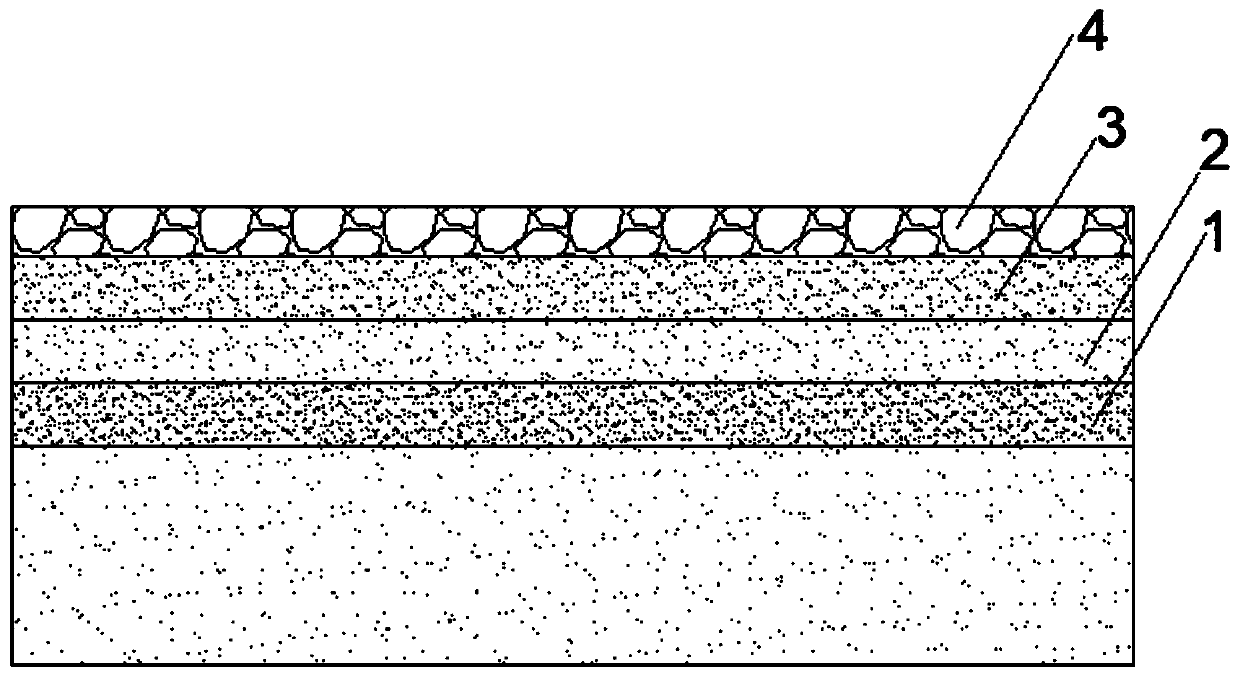

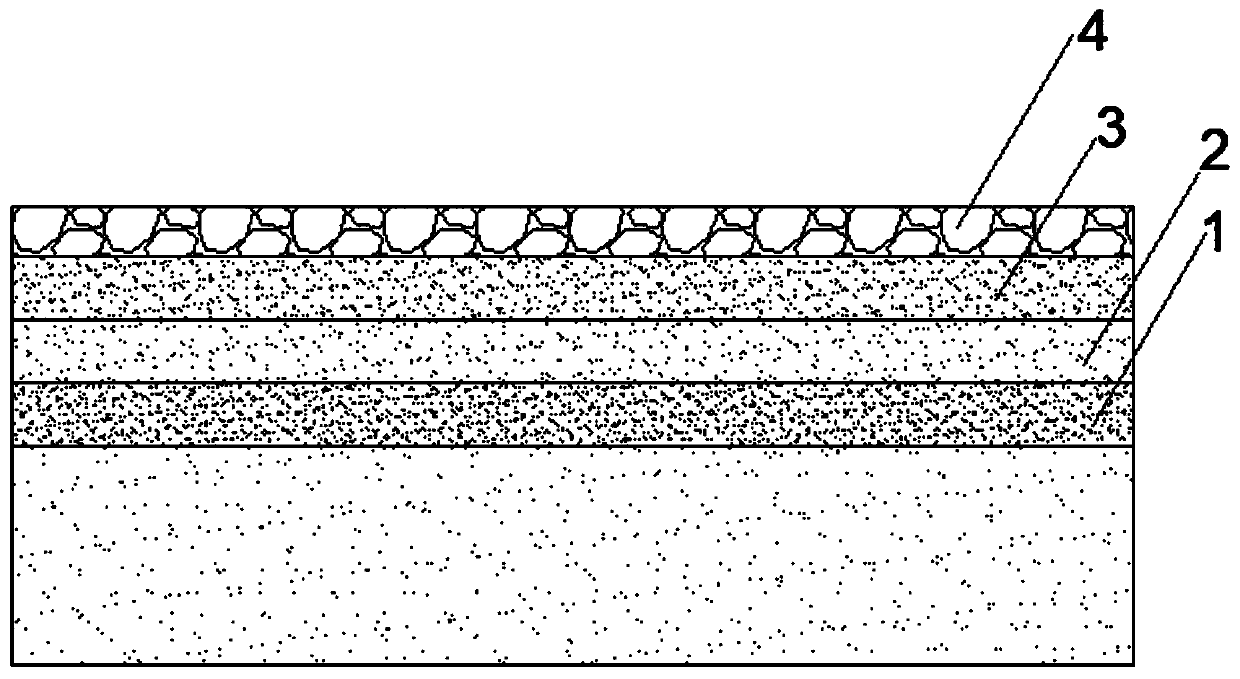

Self-luminous road pavement structure and construction method thereof

PendingCN110004796ANot easy to accumulate waterImprove close bondingIn situ pavingsSidewalk pavingsSurface layerChipseal

The invention discloses a self-luminous road pavement structure and a construction method thereof. The self-luminous road pavement structure comprises a water sealing layer, a water guiding layer, a permeable layer and a self-luminous surface layer, the water sealing layer, the water guiding layer, the permeable layer and the self-luminous surface layer are arranged from the bottom up in a layer-by-layer mode, the self-luminous surface layer is filled with artificial luminescent stone particles, road water removing can be accelerated through the structure, and the phenomena of instability of clearance and gravel embedded into a soil matrix are eliminated; and the construction method comprises the following steps that (1) the water sealing layer is poured; (2) the water guiding layer is paved; (3) the permeable layer is poured; and (4) the self-luminous surface layer is poured. According to the self-luminous road pavement structure and the construction method thereof, construction is convenient, universality of the technology is high, and cost engineering is saved.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

High-power high-brightness light-emitting diode (LED) light source packaging structure and packaging method thereof

ActiveCN102593317AImprove cooling effectIncrease output powerPoint-like light sourceLighting heating/cooling arrangementsElectricityThermal expansion

The invention discloses a high-power high-brightness light-emitting diode (LED) light source packaging structure and a packaging method thereof. The packaging structure provided by the invention comprises a radiation board, a circuit board and an LED module, wherein the LED module is manufactured by performing contact-type radiation treatment, thermal stress reduction treatment and insulation treatment on an LED chip; the LED module is welded on the radiation board; and the circuit board is welded or adhered to the radiation board, so that the circuit board is distributed on the periphery of the LED module and is electrically connected with the LED chip. According to the invention, through the optimal design of the LED light source packaging structure, the problems of low radiation efficiency and poor stability of the LED packaging structure in the prior art can be solved, the problem that the LED chip is mismatched with a heat sink thermal expansion coefficient is solved, and the packaging structure has the advantages of high stability, long storage life, low cost and the like.

Owner:FOCUSLIGHT TECH

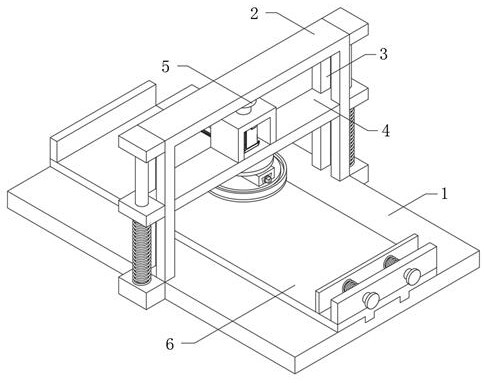

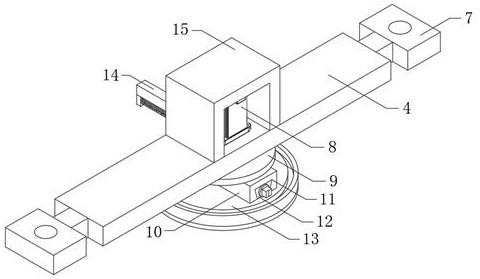

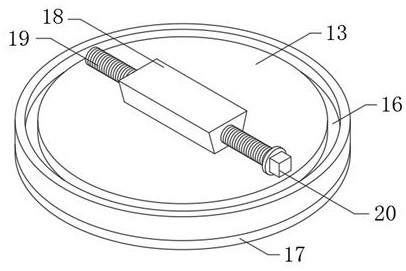

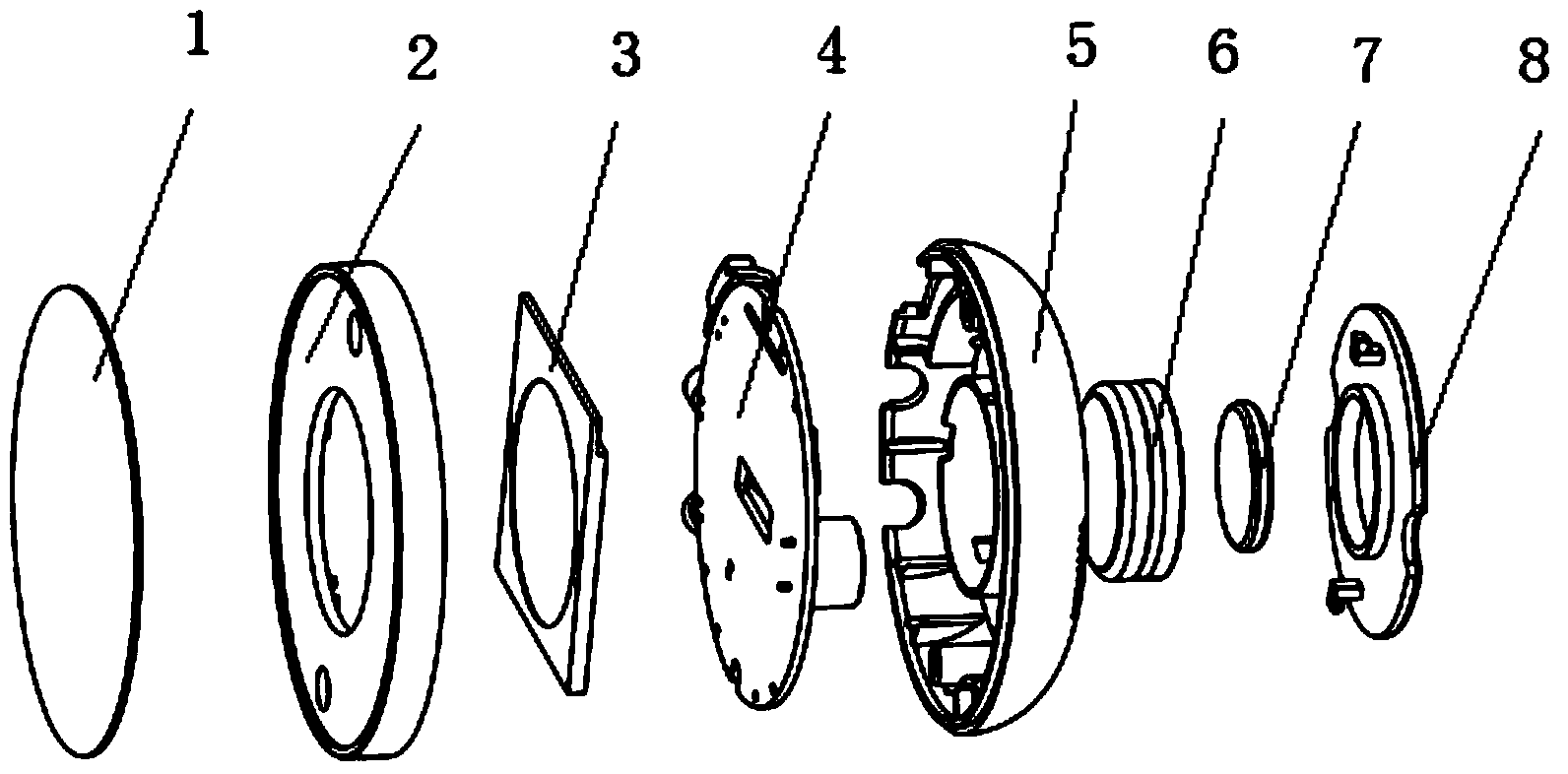

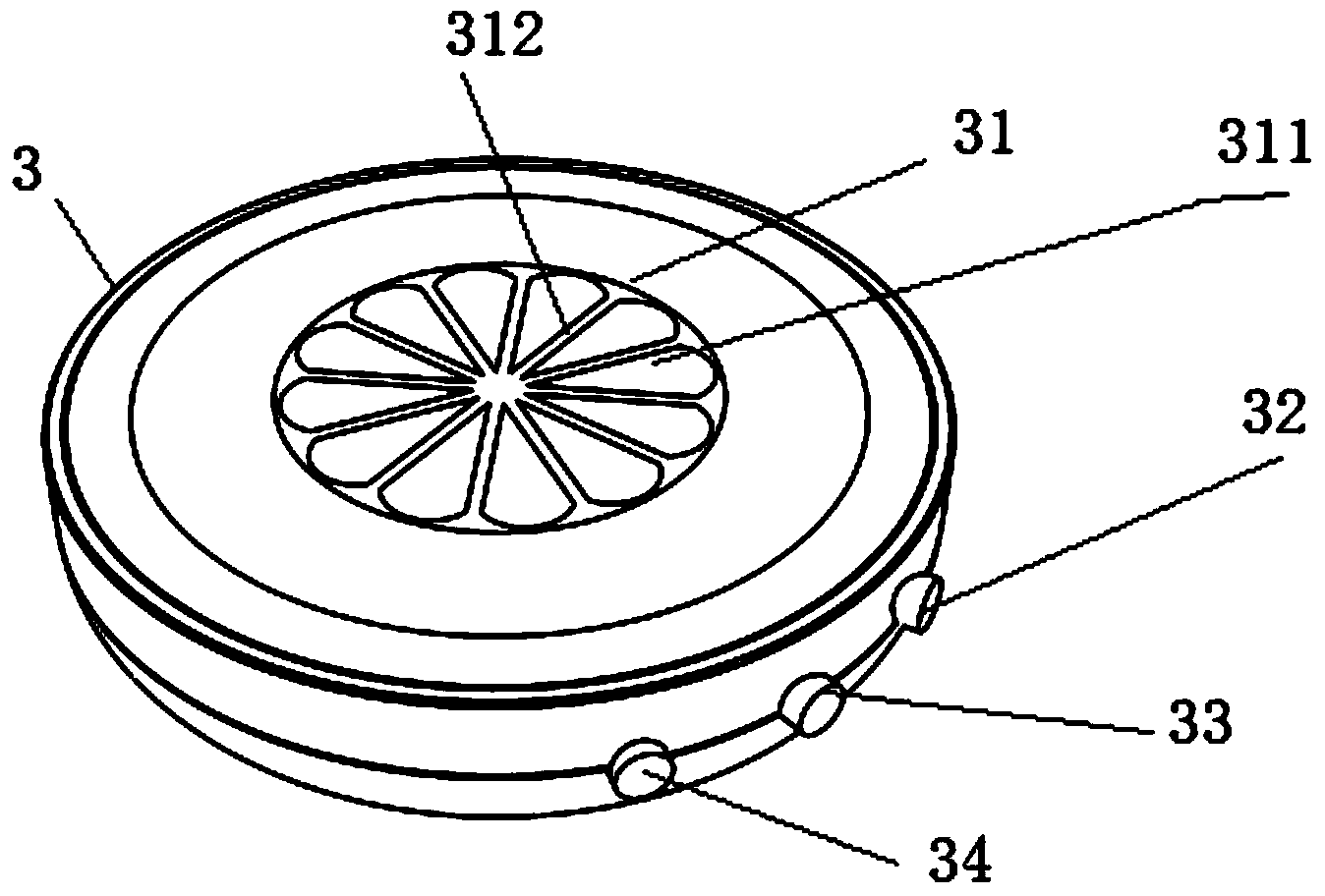

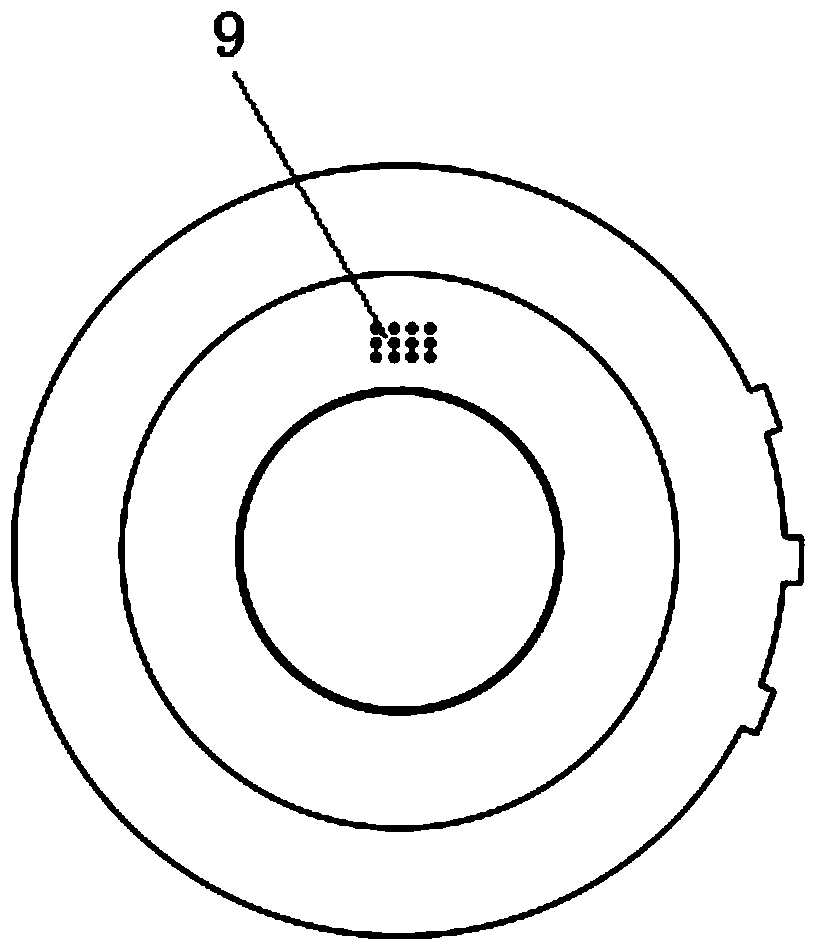

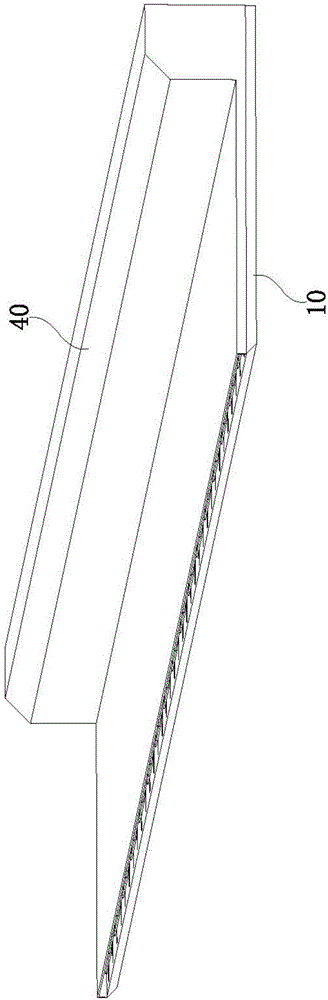

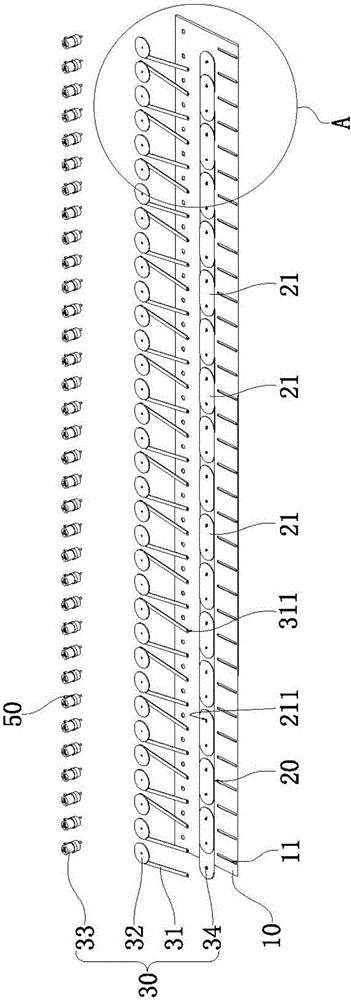

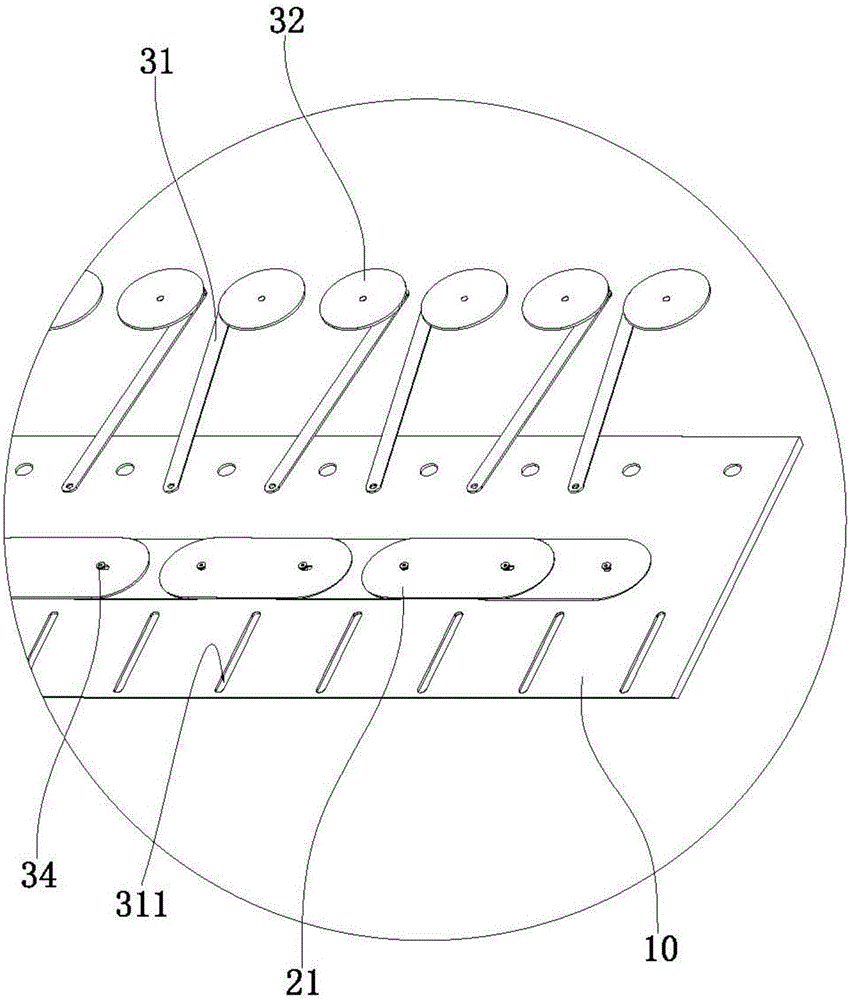

Aluminum profile machining surface polishing device capable of adjusting polishing uniformity

ActiveCN113103133AAdjust UniformityEasy to polishGrinding carriagesPolishing machinesPolishingScrew thread

The invention discloses an aluminum profile machining surface polishing device capable of adjusting the polishing uniformity, which comprises a base, a positioning frame is fixedly arranged in the middle of the top of the base, through grooves are arranged at the middles of the two sides of the inner wall of the positioning frame, sliding blocks are arranged in the two through grooves in a sliding mode, a fixed plate is fixedly arranged at one end of the two sliding blocks, and one end of each of the two sliding blocks is fixedly connected with the middle position of the two sides of the fixed plate correspondingly. A positioning handle is rotated, so that a moving block arranged on the outer wall of a lead screw in a threaded mode drives a second rotating disc at the bottom end to move, the second rotating disc slides along a first sliding groove on the inner wall of a positioning seat fixed to the bottom end of a first rotating disc through a moving block fixed to the top end, the second rotating disc can be adjusted to different rotating polishing areas, and therefore the surface polishing and grinding uniformity of an aluminum profile is adjusted, and aluminum profiles with different specification requirements can be ground conveniently, and the practicability of the aluminum profile surface machining, polishing and grinding device is improved.

Owner:江苏万和铝业有限公司

Imaging OLED timer

ActiveCN103513570ASimple structureVariety of colorsElectronic time-piece structural detailsVisual indicationsGraphicsElectricity

The invention discloses an imaging OLED timer which comprises an OLED screen body and a driving circuit board electrically connected with the OLED screen body. A timing display image formed by a plurality of time indicating zones is formed on the OLED screen body. The time indicating zones are independently arranged and are electrically connected with the driving circuit board respectively. The driving circuit board is used for controlling image displaying of the time indicating zones. The imaging OLED timer is simple in structure, light, easy to carry and even in color development, the imaging OLED timer can display any color in the visible light range by adjusting light-emitting color of a light-emitting layer in the OLED screen body, color is abundant, in addition, and the OLED screen body is a self-light-emitting device and is similar to a Lambertian source, so that the imaging OLED timer has the advantages of being wide in body view angle and is not affected by checking angles.

Owner:GUAN YEOLIGHT TECH CO LTD

Method for preparing large-size silicon carbide ceramic plate through reactive sintering

The invention relates to a method for preparing a large-size silicon carbide ceramic plate through reactive sintering. The method comprises the following steps: weighing 60-85 parts by mass of siliconcarbide, 5-10 parts by mass of graphite powder, 2-5 parts by mass of carbon black and 2-4 parts by mass of an auxiliary agent, carrying out uniform mixing under stirring, adding 5-15 parts by mass ofwater, continuing stirring for uniform mixing, and performing aging to obtain a mud material; subjecting the mud material to pugging and then to extrusion molding through an extruder so as to obtaina biscuit; and conducting drying and sintering to obtain the silicon carbide ceramic plate. According to the invention, a standing charging mode is adopted, so a large number of cracks can be effectively reduced, and cracks caused by shrinkage during drying in the prior art are overcome. According to the method, the large-size silicon carbide ceramic plate can be prepared on a large scale, and theproblems occurring in forming, drying, sintering and other processes in the prior art are solved under the condition that flatness is guaranteed.

Owner:SHAANXI UDC MATERIALS TECH CO LTD

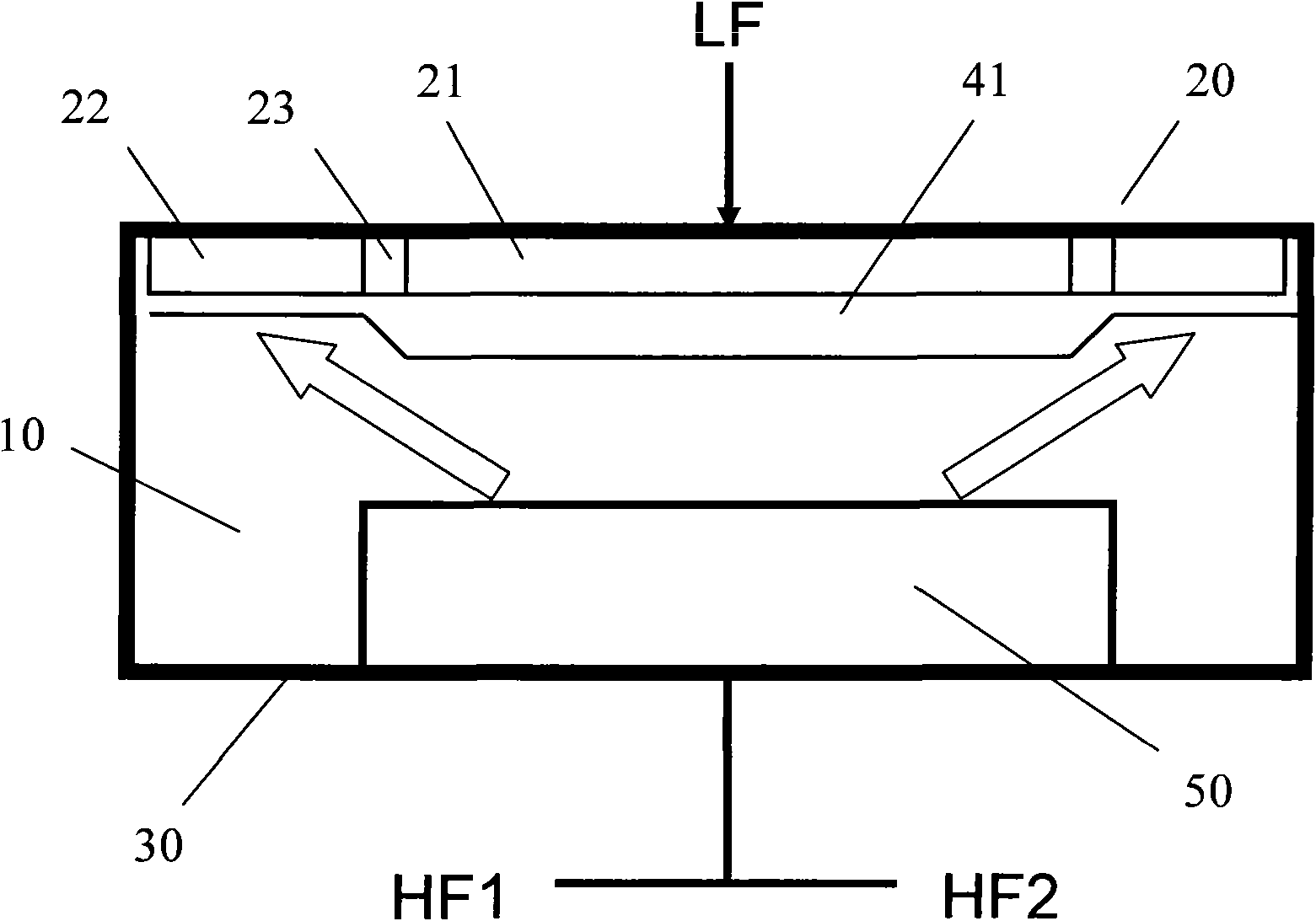

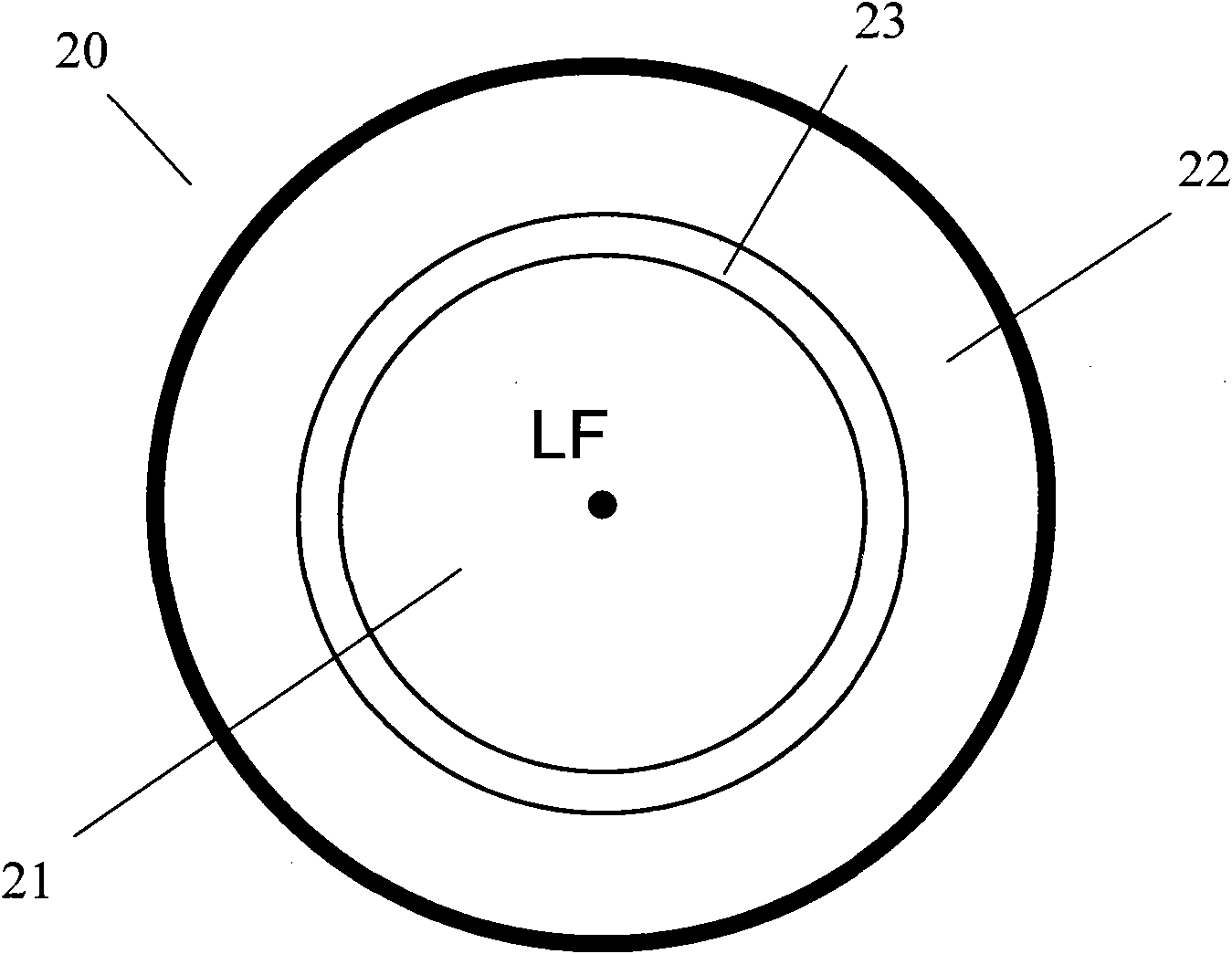

Backlight module and display device

InactiveCN108897171AAdjust UniformityImprove uniformityOptical light guidesNon-linear opticsLight guideDisplay device

The invention relates to the technical field of display, and provides a backlight module. The backlight module comprises a light guide plate, a diffusion assembly and a light source assembly. A lightguide plate is provide with a hole; The diffusion assembly is arranged on the light guide plate; A light source assembly include a light emitting portion dispose in that hole, the light emitting portion including a COB light source having a light emitting surface toward the diffusion assembly and an LED light source have a light emitting surface toward the hole wall; The transmittance of the diffuser relative to the COB light source is smaller than the transmittance of the rest of the diffuser. The light emitting part is arranged in the hole of the light guide plate, and the backlight module does not exist on the light entrance side, and the periphery of the backlight module can be arranged as a narrow frame. The light uniformity of the whole backlight module can be adjusted by the different transmittance of the diffusion module. The COB light source emits uniformly and has no light spots, which further improves the uniformity of the light emitted from the whole backlight module.

Owner:BOE TECH GRP CO LTD +1

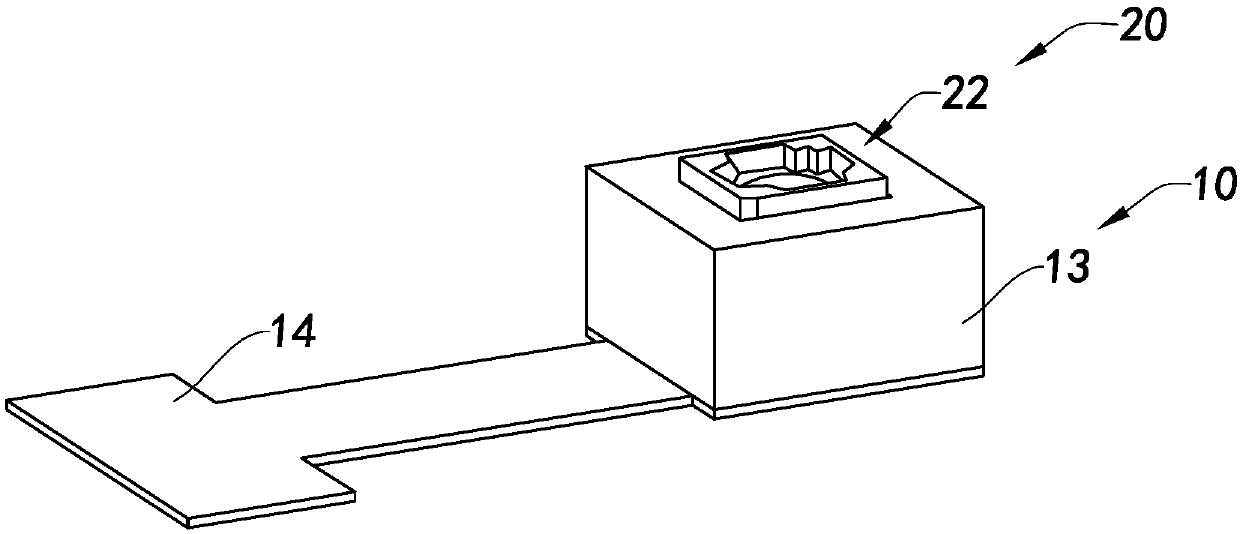

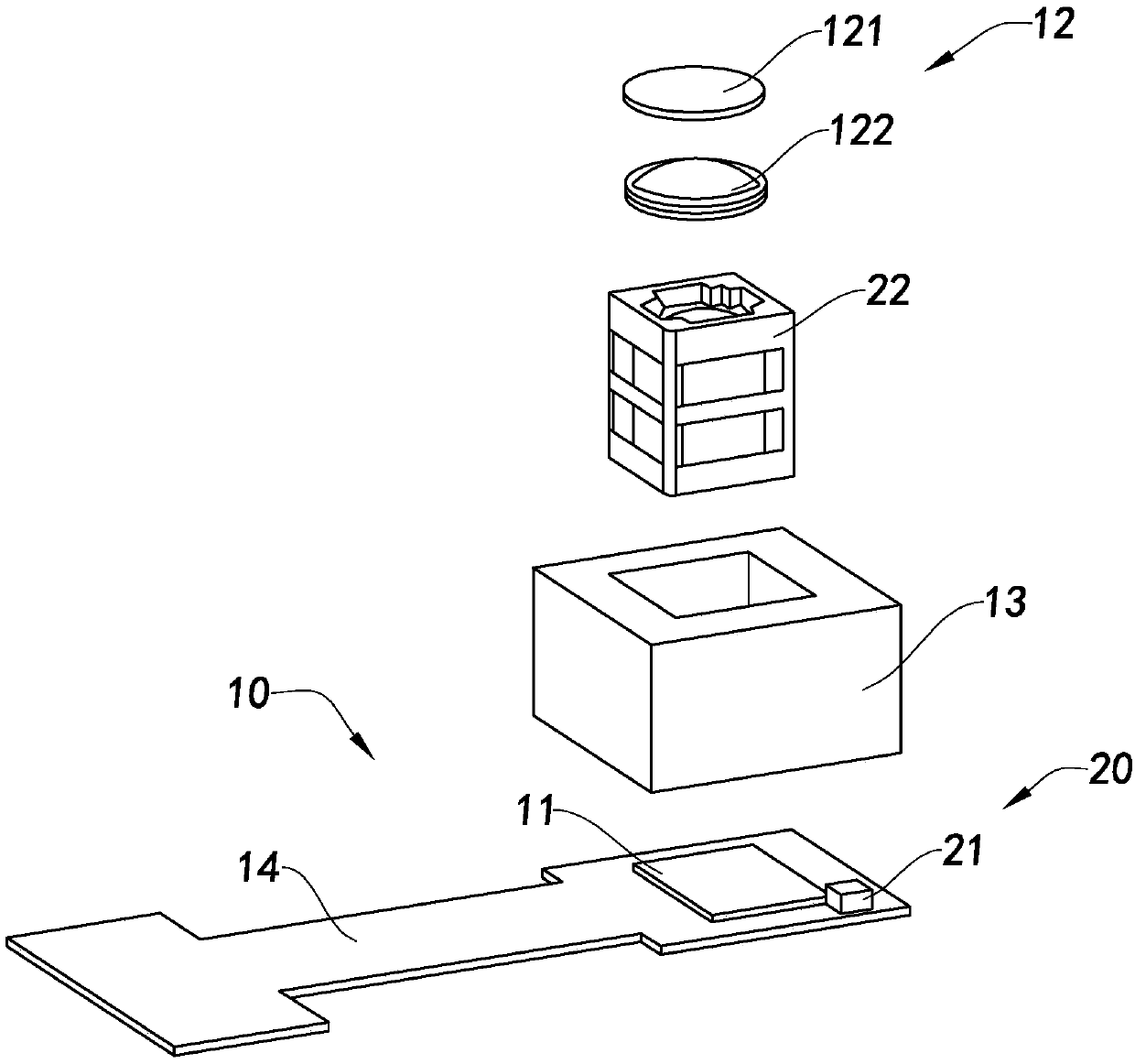

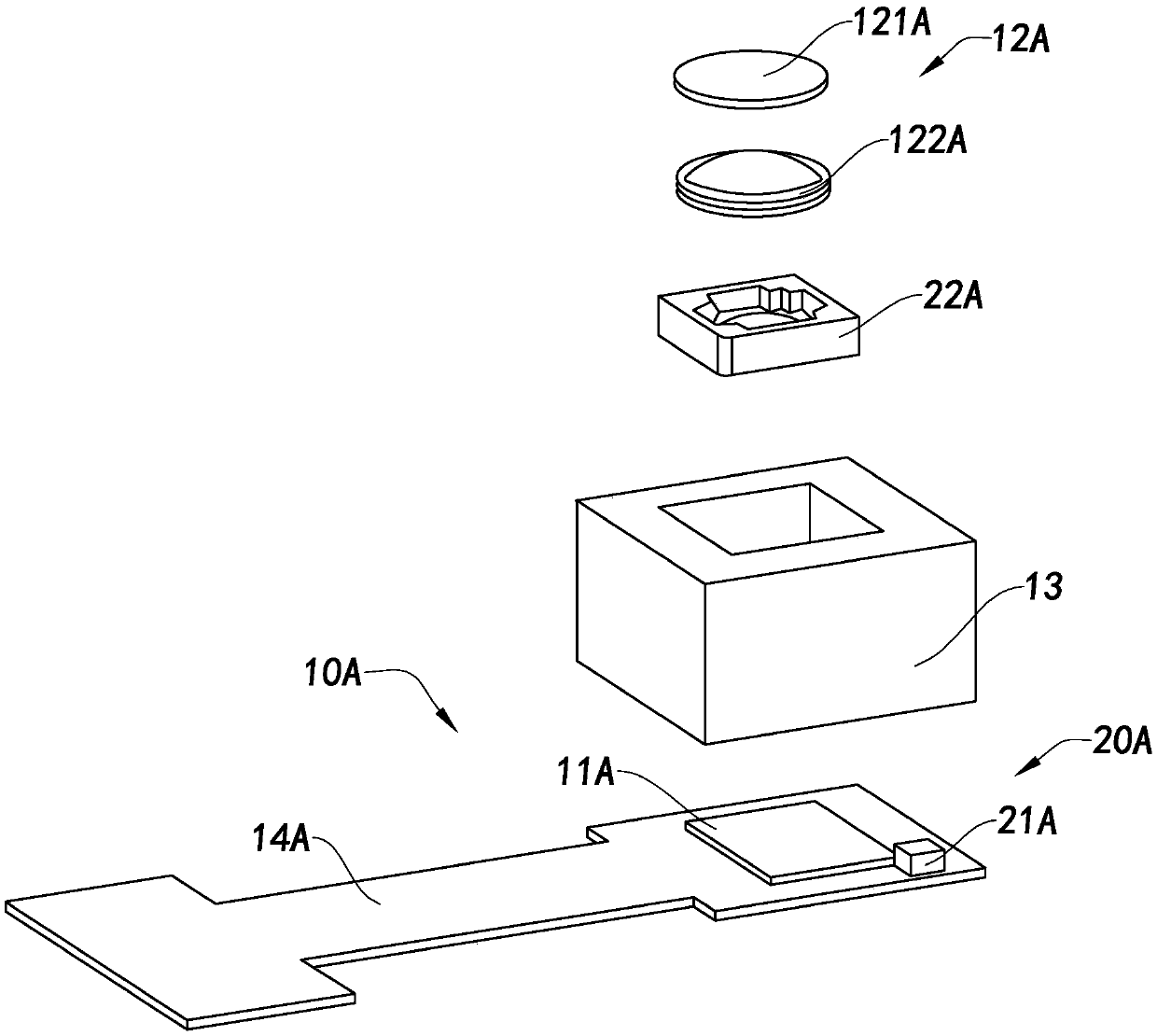

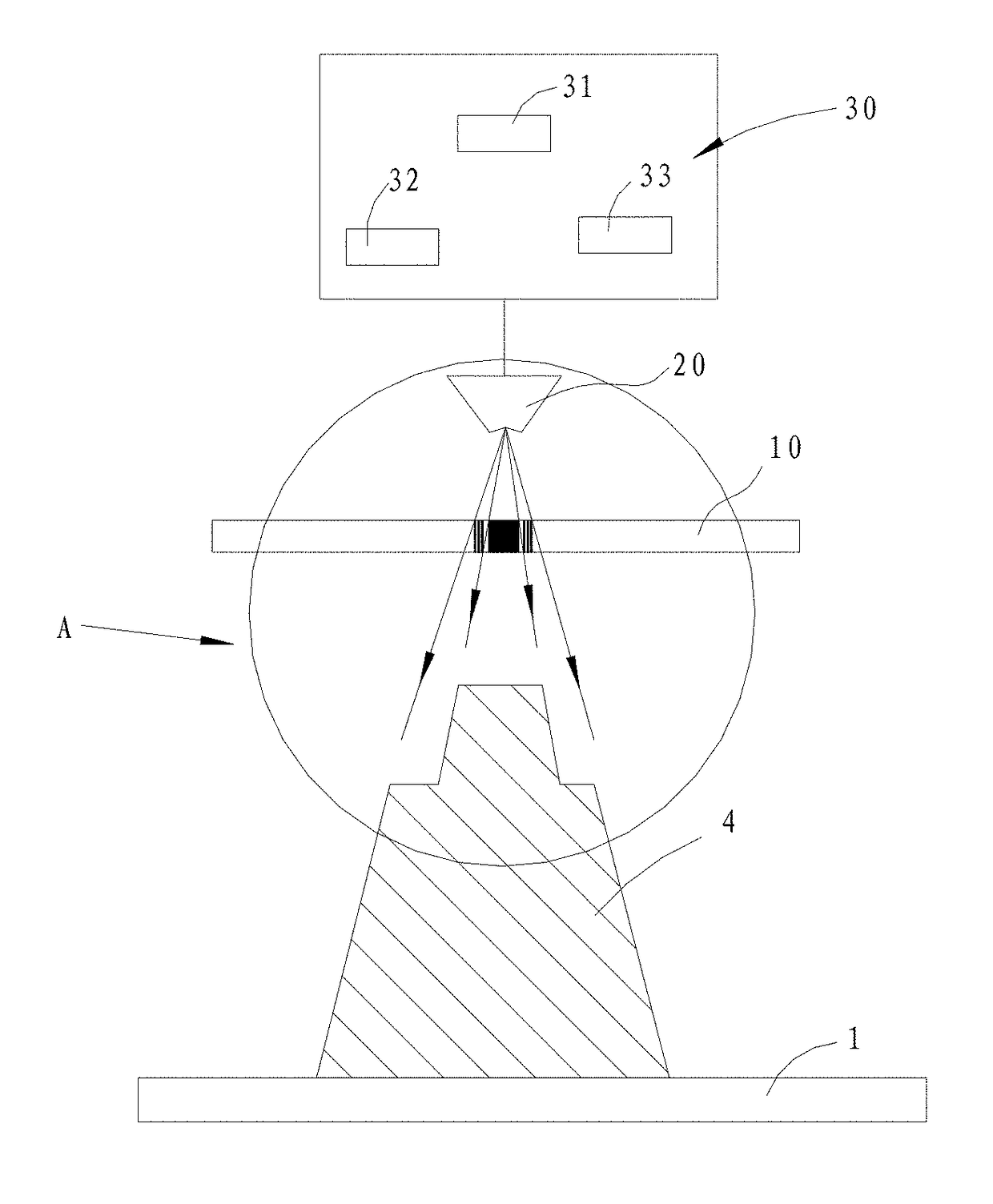

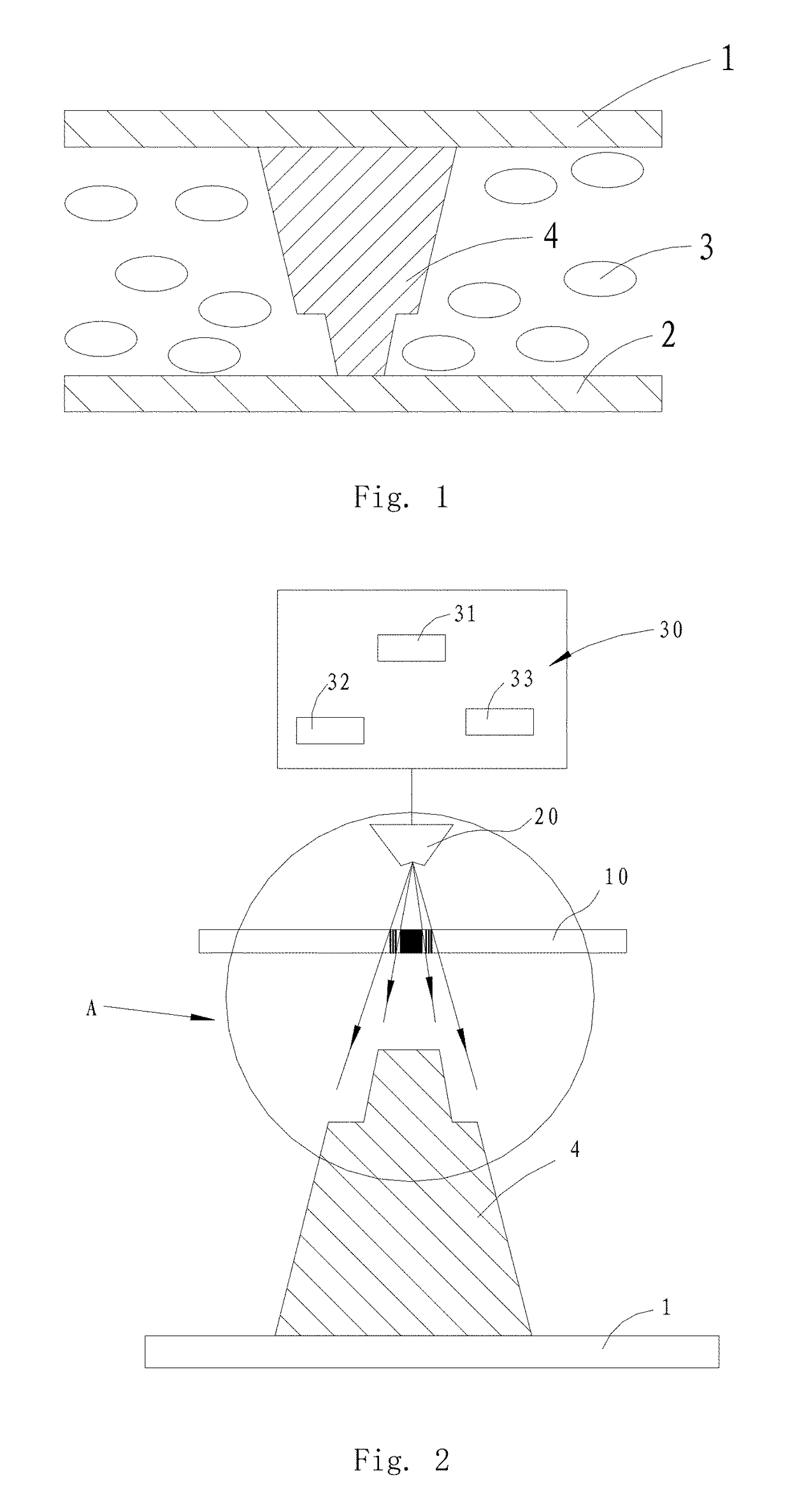

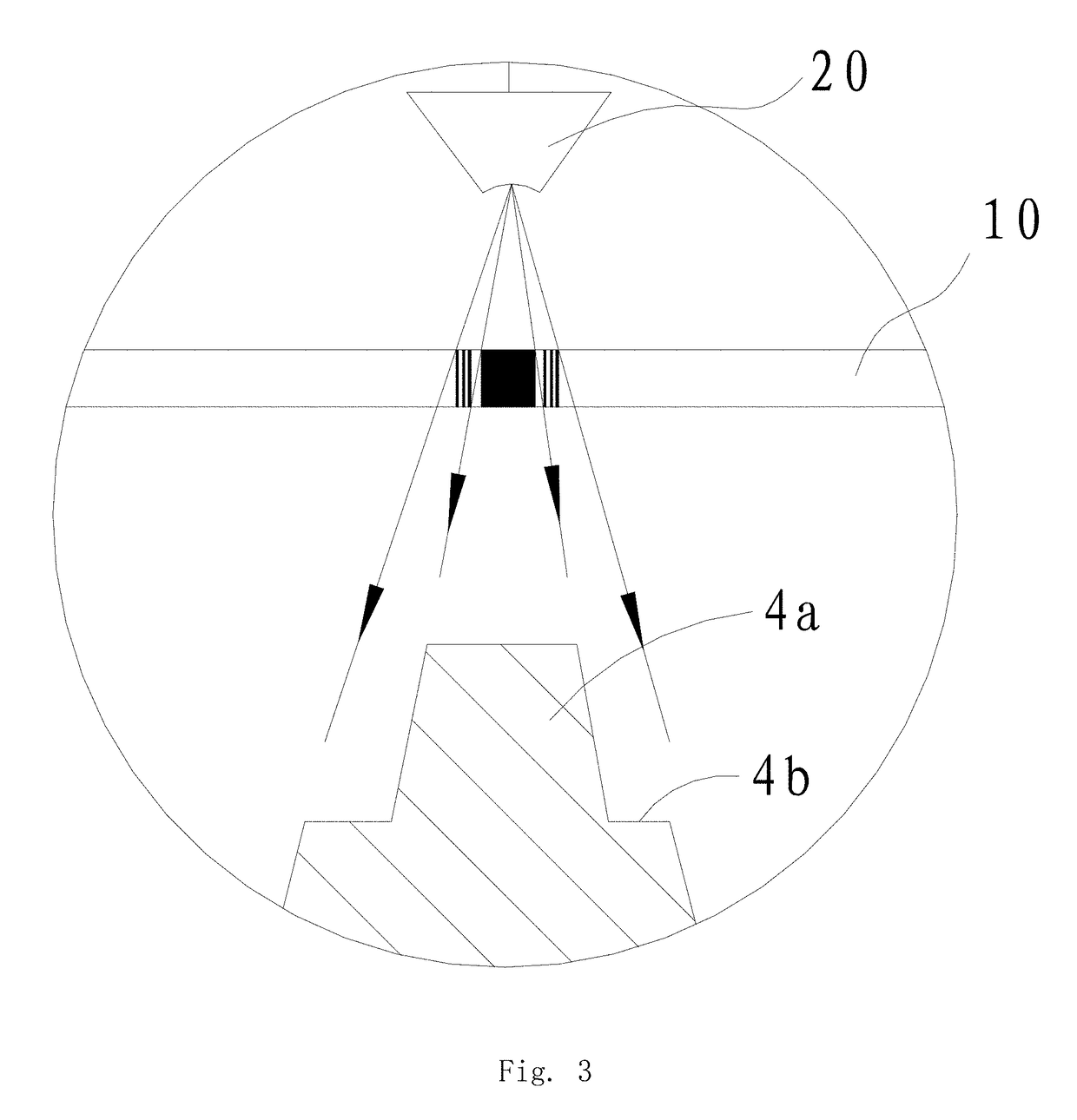

Structured light projection device having automatic focusing device and method thereof

InactiveCN110095882ALight spot uniformityUniformityOptical elementsLaser transmitterMotor controller

The invention relates to a structured light projection device having an automatic focusing device and a method thereof. The device comprises a structured light projector and an automatic focusing device. The structured light projection device includes a laser emitter for emitting light and an optical system for converting the light emitted by the emitter into light having a particular pattern. Theautomatic focusing device includes a motor and a motor controller. When motor controller drives the motor to move, the motor can drive the optical system to move so as to adjust the relative positionbetween the laser emitter and the optical system, thereby improving the uniformity of the projected pattern.

Owner:SUNNY OPTICAL ZHEJIANG RES INST CO LTD

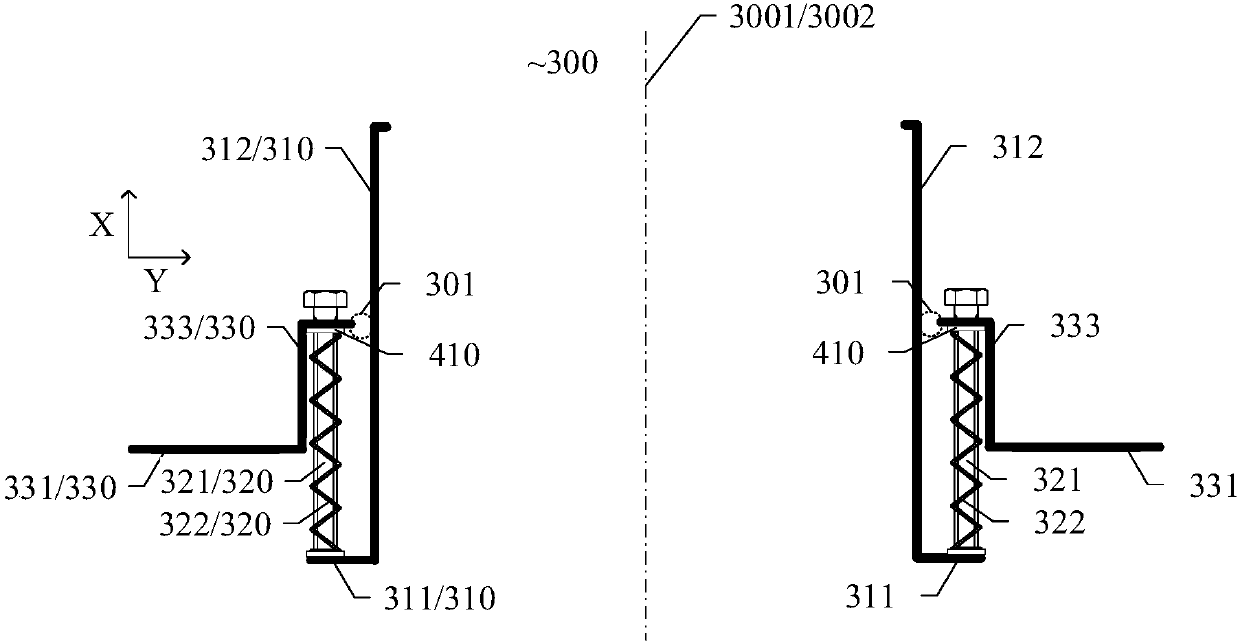

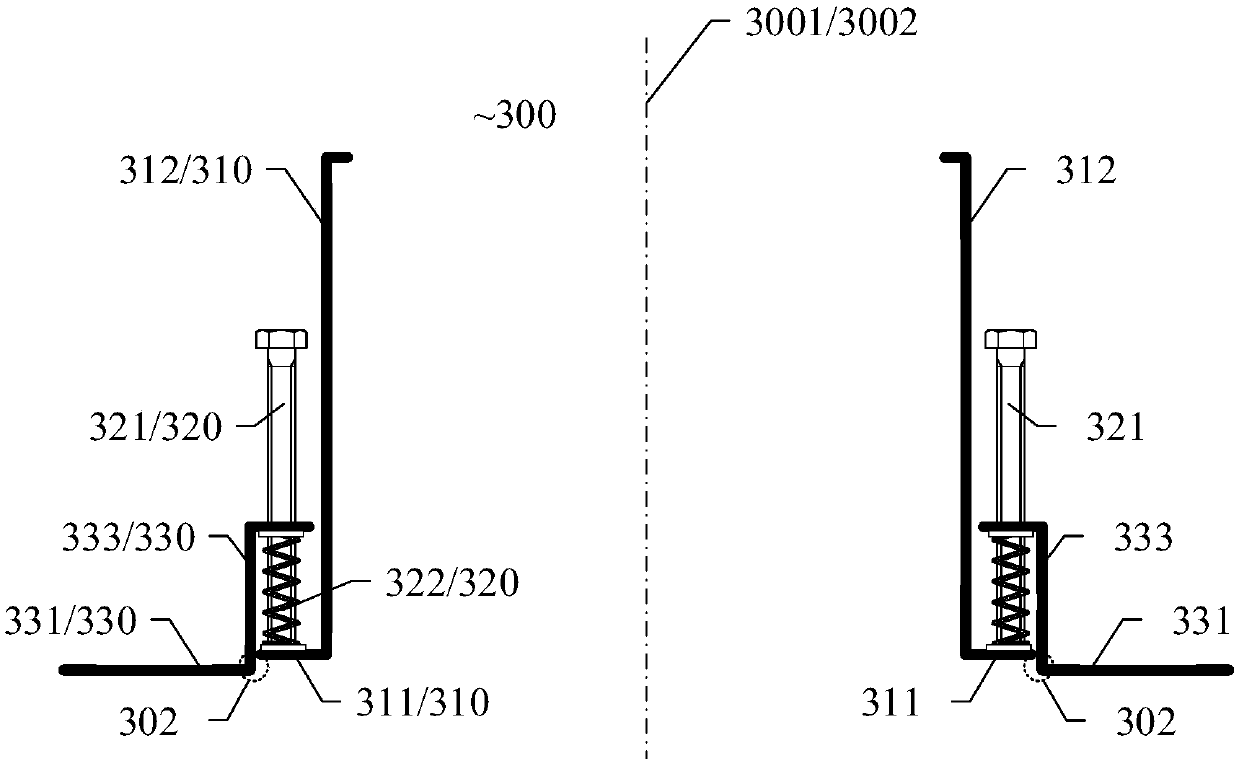

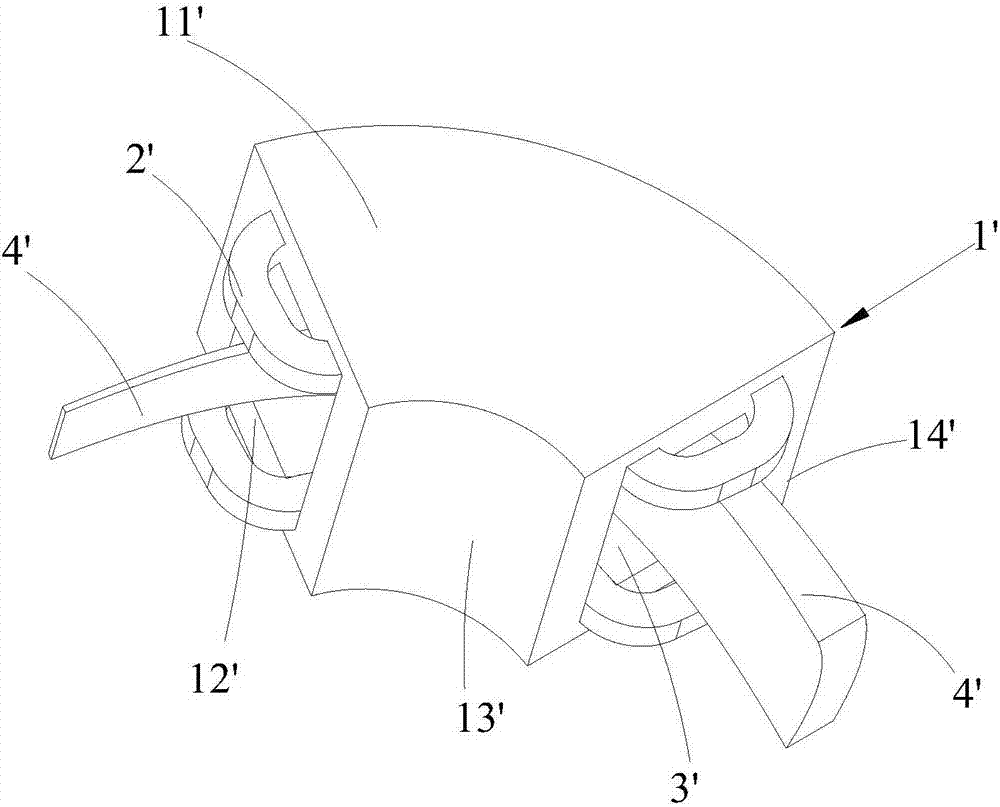

Grounding ring, chamber, and physical vapor deposition apparatus

ActiveCN110396664AReliable electrical connectionLarge adjustment rangeVacuum evaporation coatingSputtering coatingEngineeringPhysical vapor deposition

The present disclosure provides a grounding ring, a chamber, and a physical vapor deposition apparatus. The grounding ring includes a first conductive ring, a second conductive ring, and a plurality of elastic devices electrically connecting the first conductive ring and the second conductive ring, wherein a first central axis of the first conductive ring is parallel to or coincident with a secondcentral axis of the second conductive ring, and the plurality of elastic devices are configured such that the first conductive ring and the second conductive ring can move relative to each other in adirection of the first central axis. The elastic devices in the grounding ring may expand the adjustment range between the first conductive ring and the second conductive ring.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Electric adjustable coating baffle device and coating equipment

ActiveCN106399964ASolve technical problems with limited adjustment rangeControl UniformityVacuum evaporation coatingSputtering coatingBiochemical engineeringLarge range

The invention relates to the technical field of automatic equipment, and particularly relates to an electric adjustable coating baffle device and coating equipment. The electric adjustable coating baffle device disclosed by the invention is applied to the coating equipment. The coating equipment comprises a target material and a substrate which are arranged in a spaced manner; the electric adjustable coating baffle device comprises a base plate, a baffle component and an adjusting mechanism, wherein the baffle component is arranged above the base plate; and the adjusting mechanism is arranged above the base plate, is connected with the baffle component and is used for controlling the baffle component to move so that the baffle component can extend out of the base plate and reach a place between the target material and the substrate. In a vacuum coating process, when a non-uniform region is detected in a membrane layer on the substrate, the adjusting mechanism is used for controlling the baffle component to extend out of the base plate and reach the place between the target material and the substrate, so that the baffle component can obstruct the substrate in a region in which the membrane layer is relatively thick, and thus the uniformity of the membrane layer in the region can be controlled. The electric adjustable coating baffle device disclosed by the invention can be used for implementing large-range adjustment of the uniformity of the membrane layer on the substrate in a vacuum state, so time and cost are effectively saved.

Owner:XINYI GLASS (TIANJIN) CO LTD

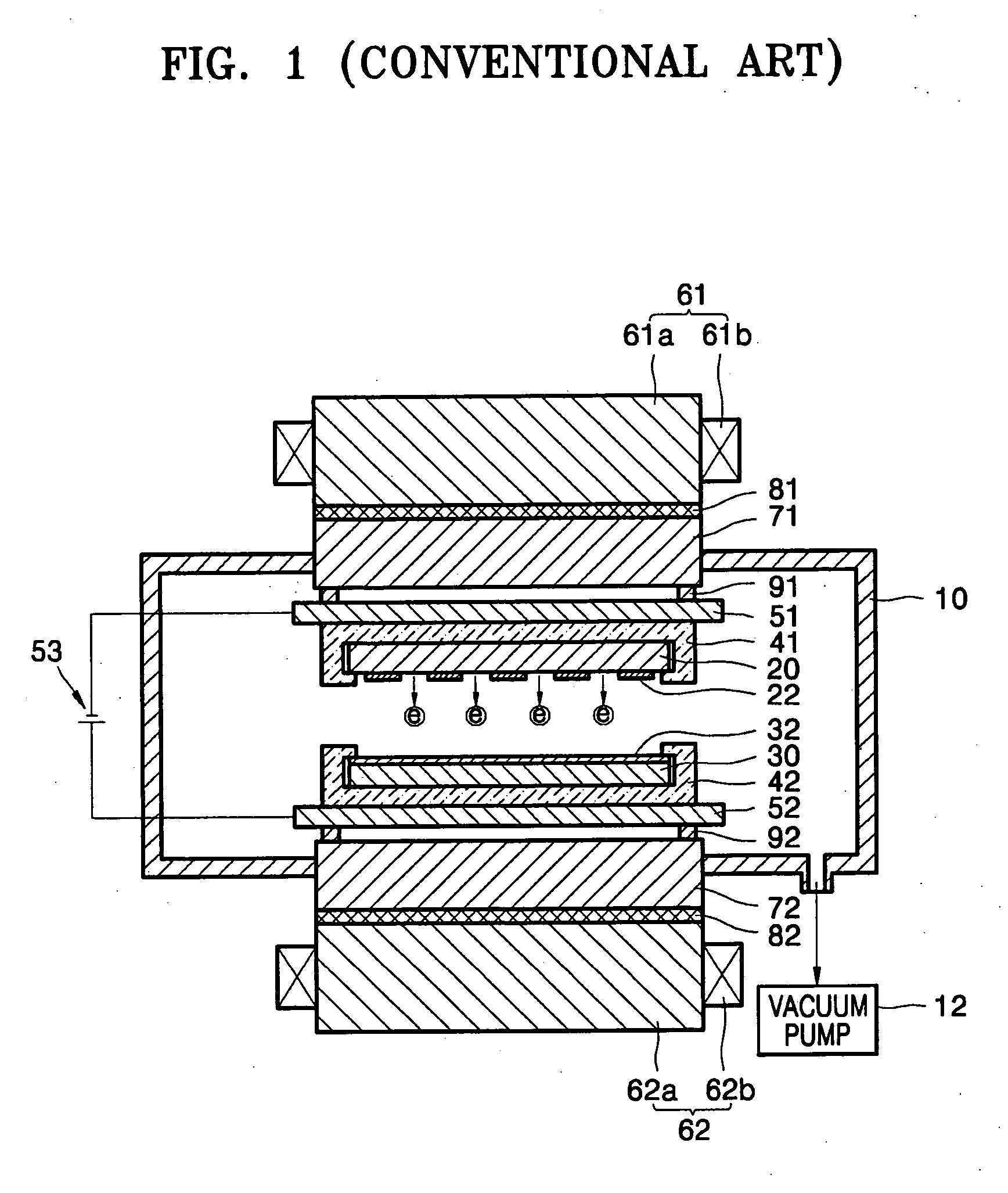

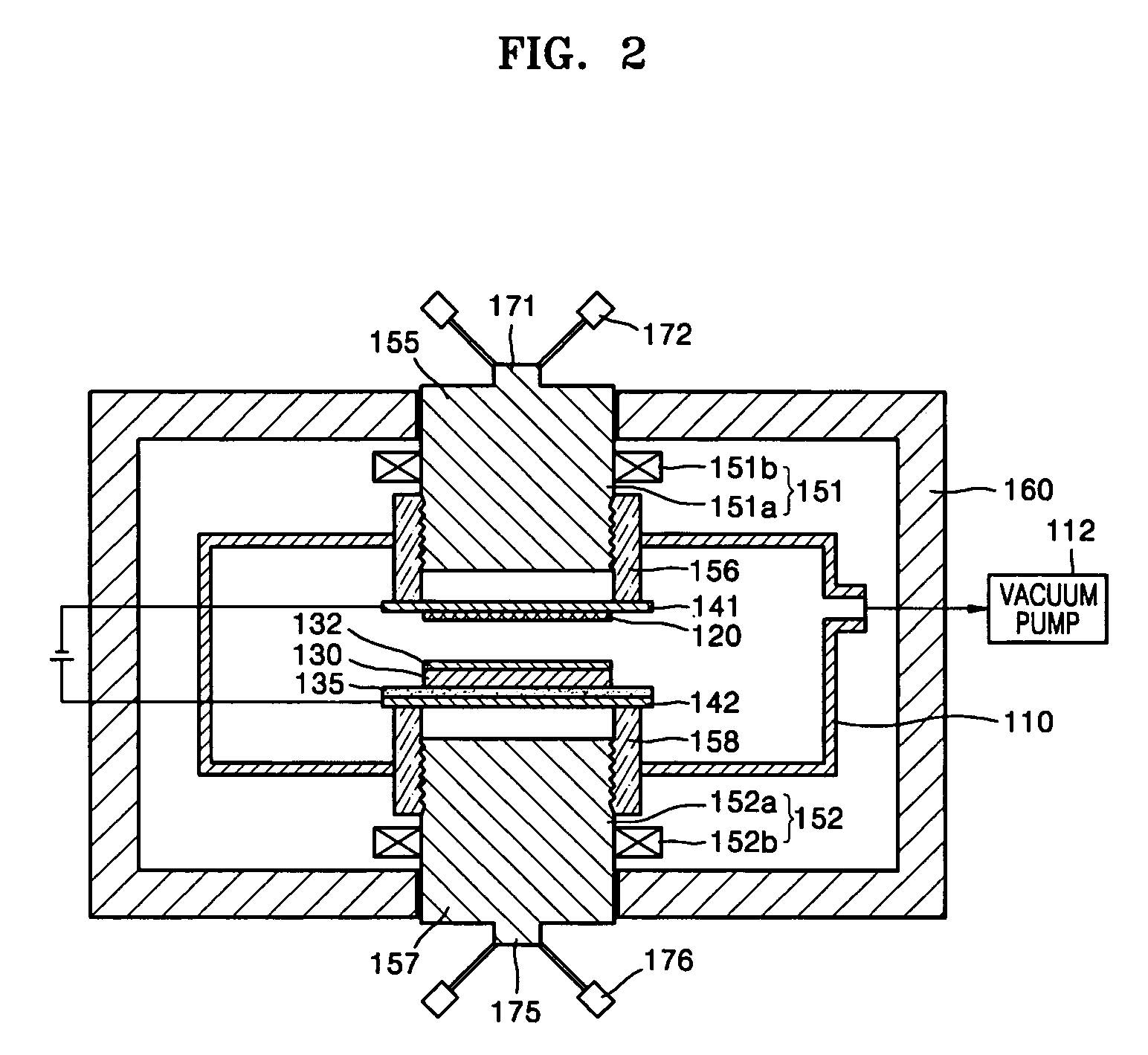

Focusing apparatus and lithography system using the same

InactiveUS20060151712A1Adjust UniformityReduce spacingMaterial analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsLithographic artistElectromagnetic field

A focusing apparatus and a lithography system using the same capable of adjusting a uniformity of an electromagnetic field by moving a portion of a magnetic field generator. The focusing apparatus may control a path of an electron beam generated from an electron-beam emitter of the lithography system. In the focusing apparatus, a uniformity of the magnetic field in the vacuum chamber may be adjusted through movement of the portion of the magnetic field generator with respect to the vacuum chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

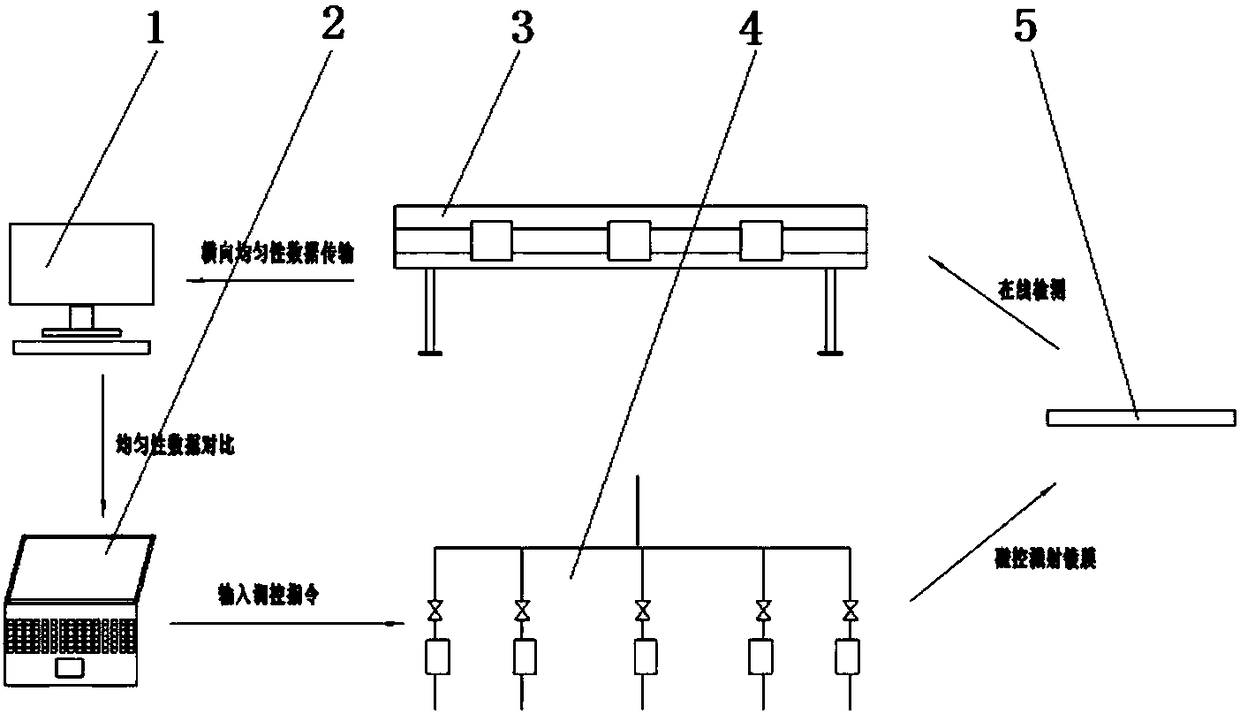

Intelligent online uniformity adjusting system

PendingCN108342704AAdjust UniformityControl UniformityVacuum evaporation coatingSputtering coatingEngineeringCoating

The invention discloses an intelligent online uniformity adjusting system. The intelligent online uniformity adjusting system comprises a WinCC monitoring computer, a uniformity comparison computer, an online detection mechanism and a reaction gas control mechanism. The reaction gas control mechanism is used for controlling the intake speed and intake amount of a reaction gas. The WinCC monitoringcomputer, the uniformity comparison computer, the online detection mechanism and the reaction gas control mechanism are wirelessly connected. According to the intelligent online uniformity adjustingsystem, it is ensured that the vacuum magnetron sputtering gas distribution amount is precisely adjusted and controlled in time, and automatic online adjustment is realized completely according to thebackground data; the uniformity of coating of the surface of coating glass can be controlled effectively, the manual operation amount can be lowered as well, the labor investment is saved while the high-quality coating is ensured, the speed of glass coating is increased, and the production is increased. The intelligent online uniformity adjusting system is wildly applicable to the automatic production and processing industry.

Owner:HEBEI WUHUATIANBAO COATING S & T CO LTD

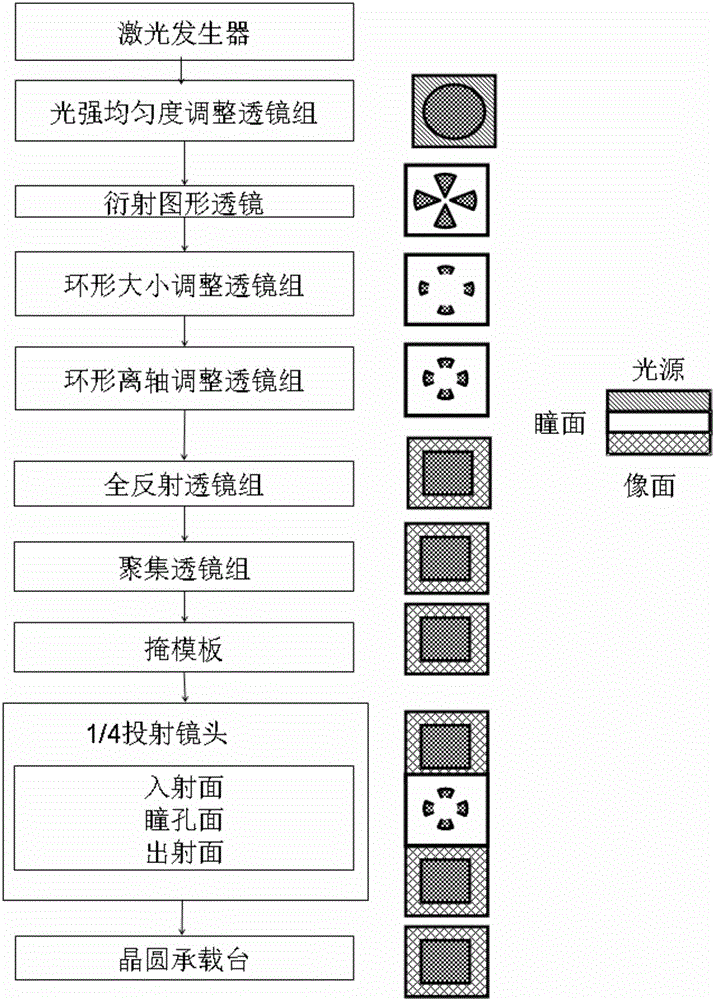

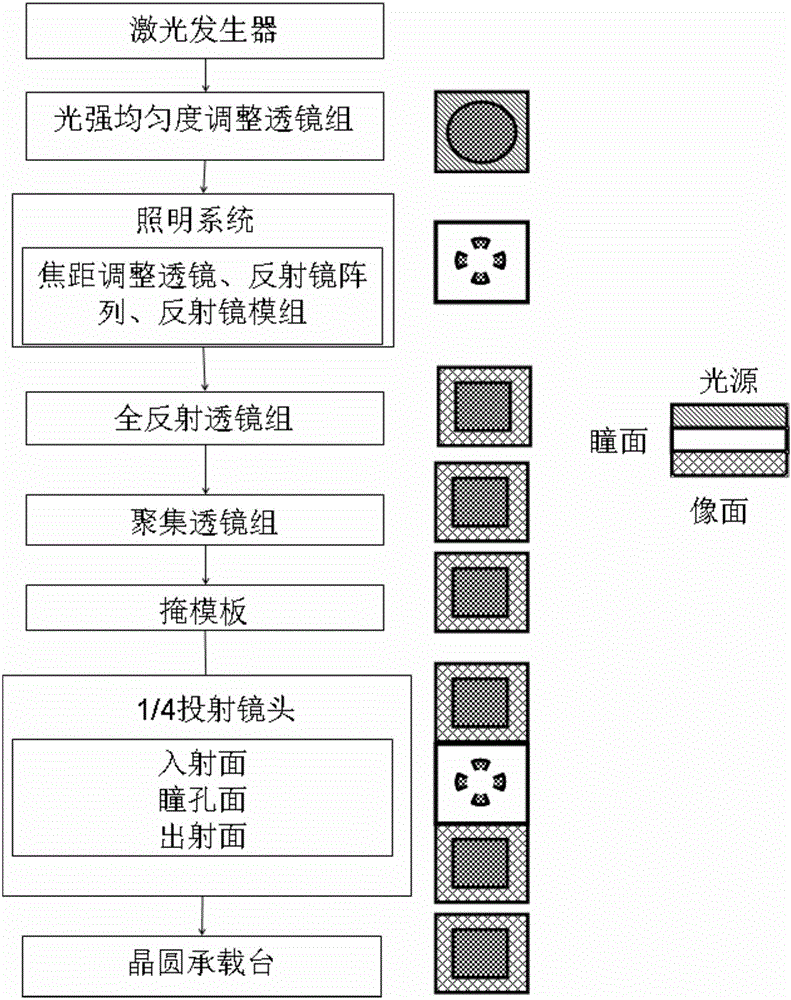

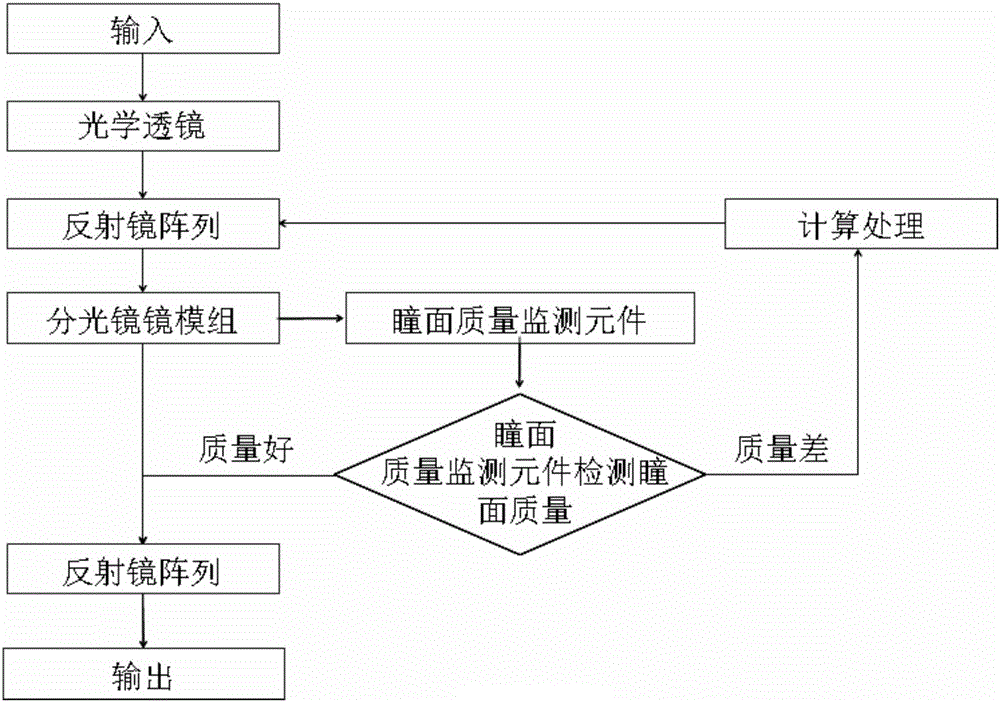

Photoetching machine lighting system and method with pupil plane quality monitoring and calibrating functions

InactiveCN105137724AAdjust UniformityMonitor qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusEffect lightPupil

The invention provides a photoetching machine lighting system and a photoetching machine lighting method with pupil plane quality monitoring and calibrating functions. The method comprises the following steps: emitting laser generated by a laser generator onto a first reflecting mirror so as to reflect the laser to a miniature reflecting mirror array; operating the reflecting mirror array, and adjusting a specific inclination angle of each miniature reflecting mirror unit to enable incident laser to pass through the reflecting mirror array to form a pupil plane shape; projecting a first part of the laser onto a pupil plane quality monitoring element through a light splitting component, acquiring complete pupil plane information through a light intensity value, and judging whether the reflecting mirror array needs to be adjusted; if it is determined that the reflecting mirror array does not need to be adjusted, reflecting a second part of the laser by a second reflecting mirror to enable the laser to enter a subsequent light path for subsequent adjustment; if it is determined that the reflecting mirror array needs to be adjusted, computing pupil plane quality information to obtain a needed adjustment angle of each miniature reflecting mirror unit in the reflecting mirror array, then feeding back to the reflecting mirror array, and performing angle adjustment by the reflecting mirror array according to the needed adjustment angle to calibrate a pupil plane.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

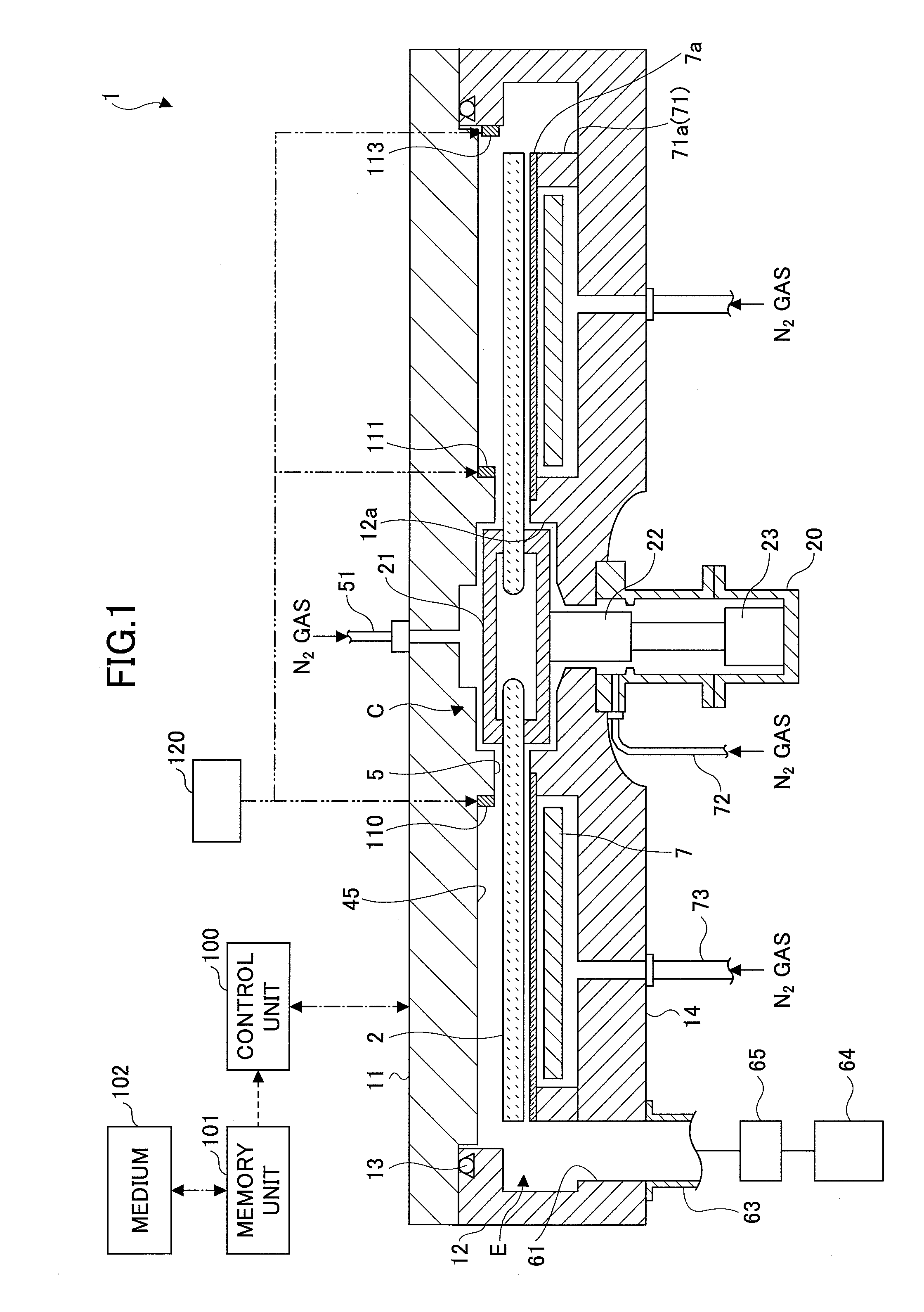

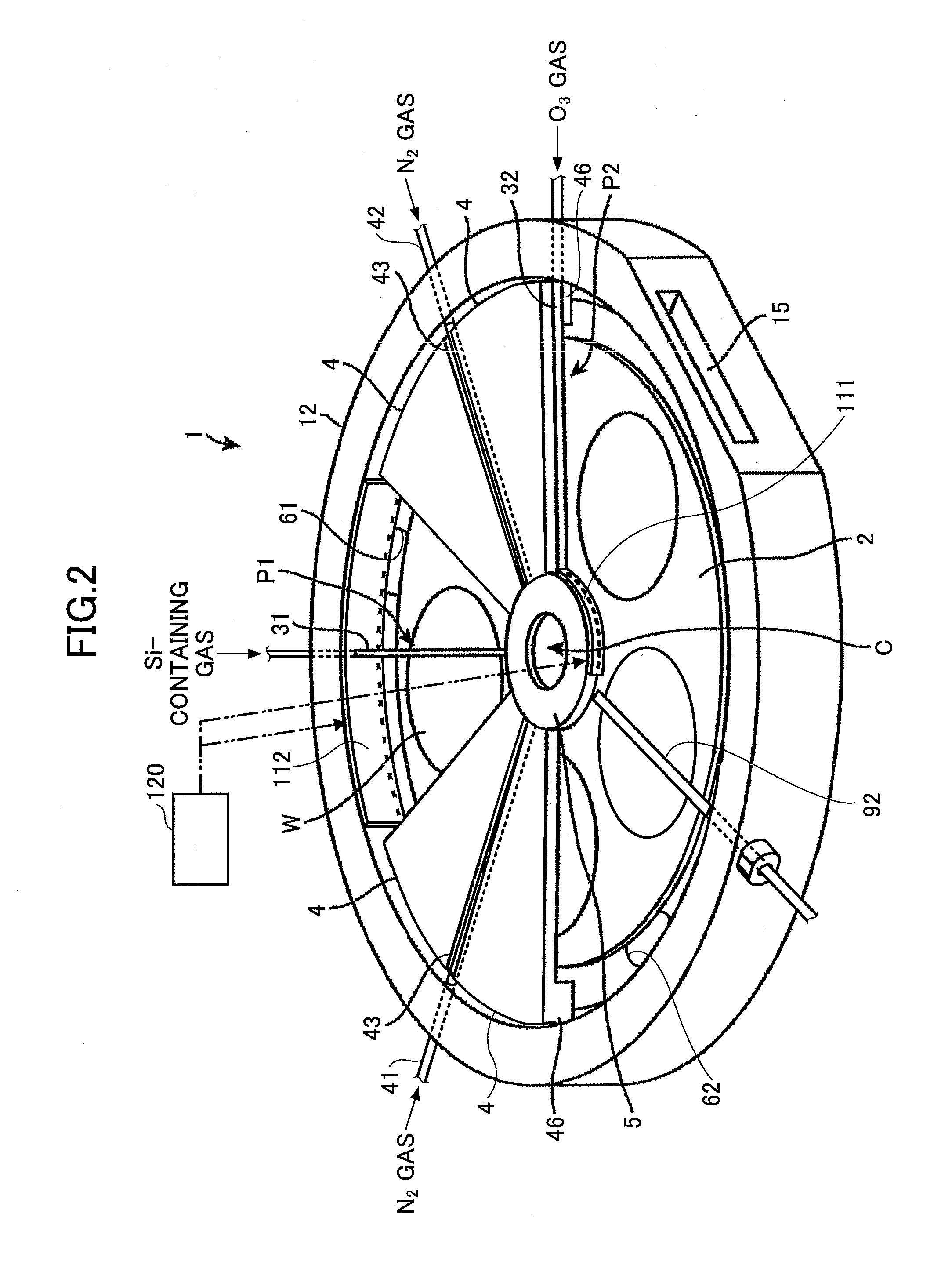

Film deposition apparatus

A film deposition apparatus includes a process chamber having a substantially cylindrical shape, and a turntable to receive a substrate thereon provided in the process chamber. At least one gas nozzle extends toward a central axis of the turntable from an inner side wall of the process chamber above the turntable along a radial direction of the turntable. At least one side wall heater is provided to cover at least part of the inner side wall of the process chamber and / or at least part of a surrounding area of the central axis of the turntable in a wall-shaped manner.

Owner:TOKYO ELECTRON LTD

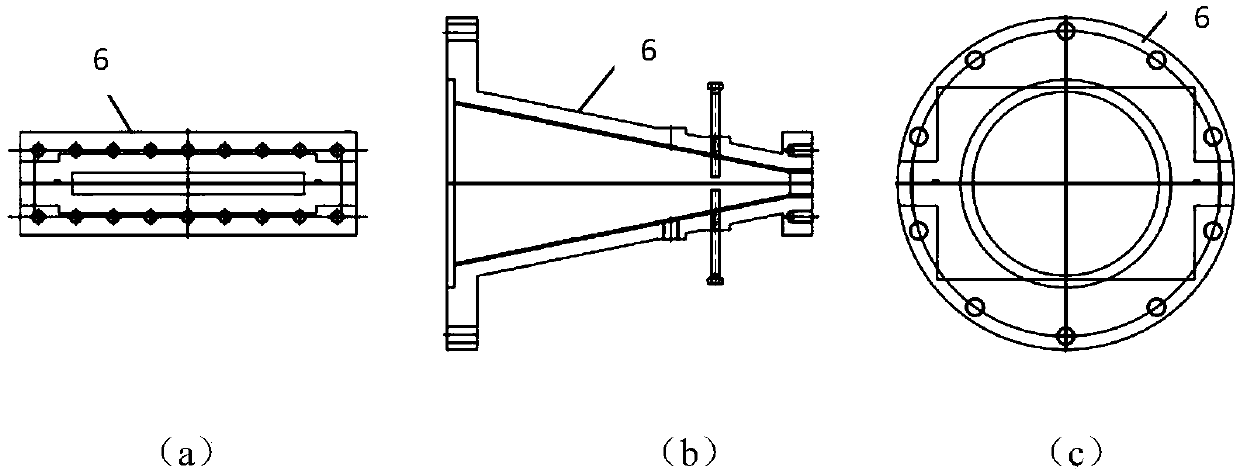

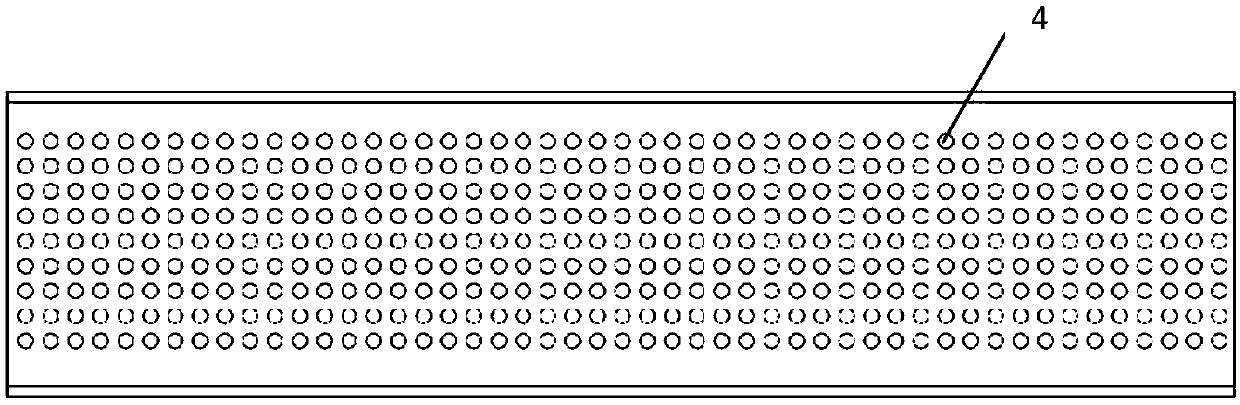

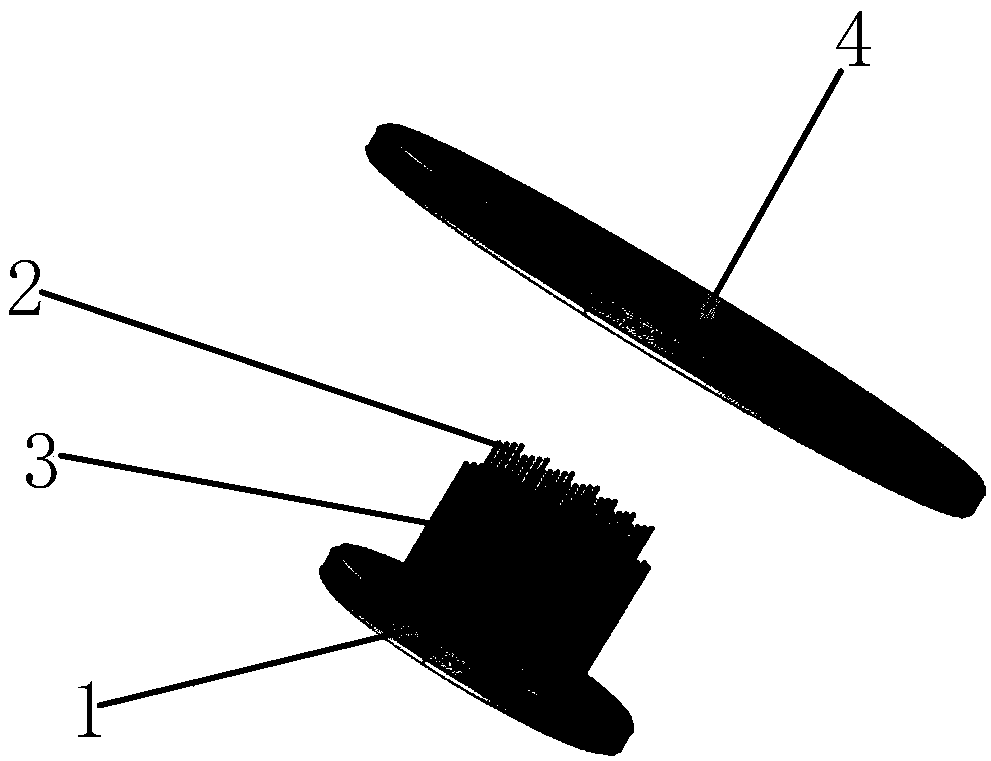

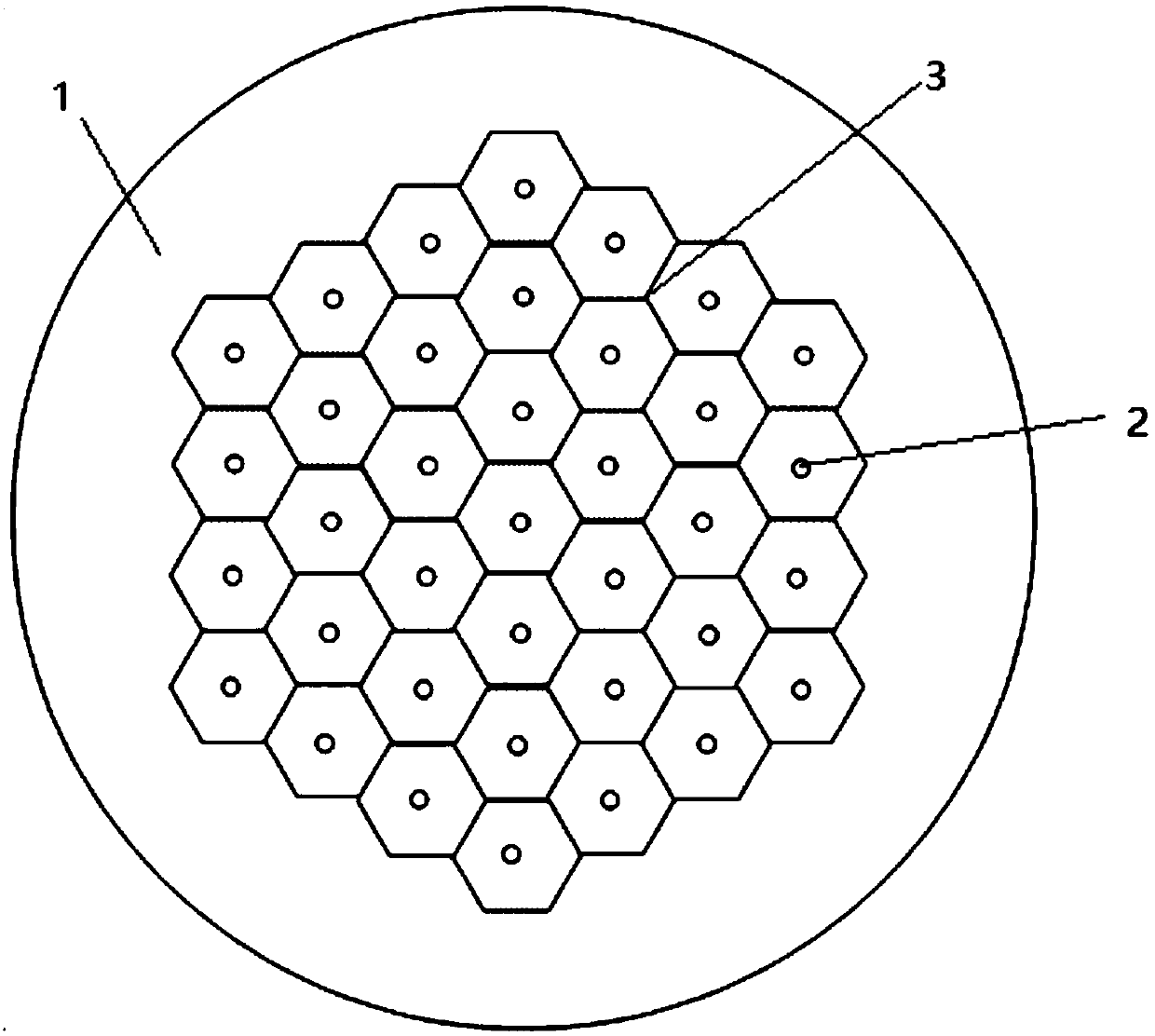

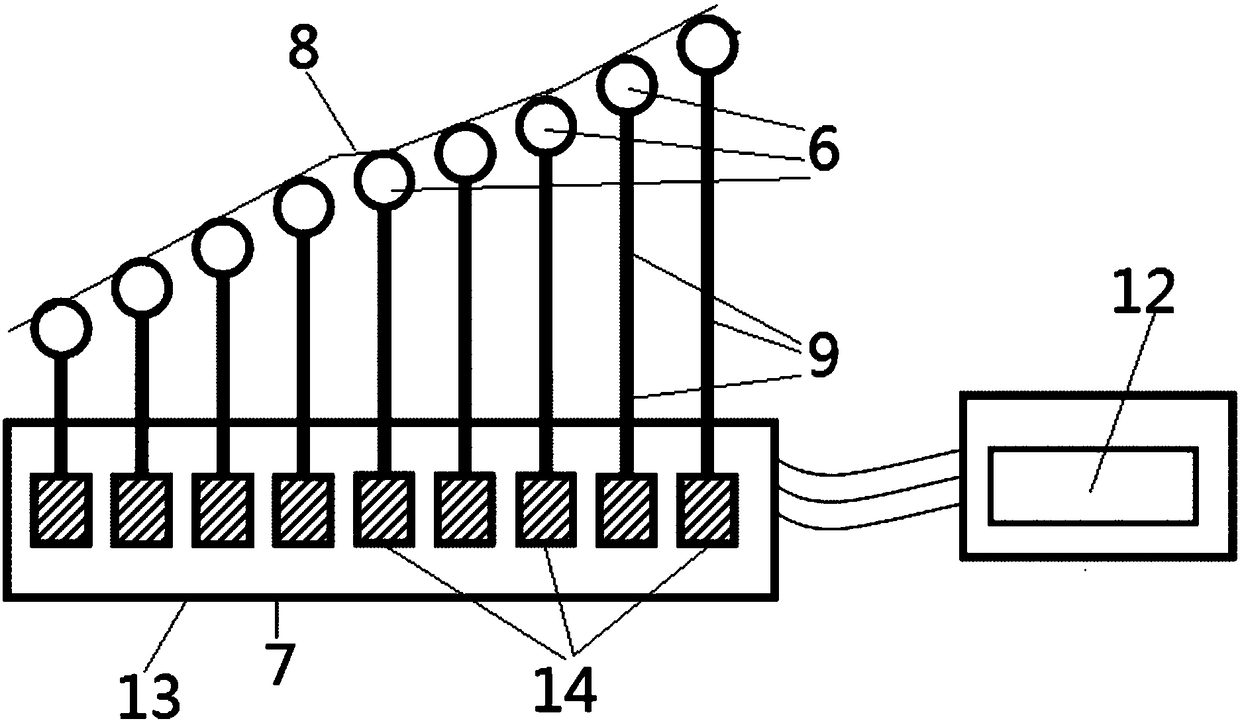

Large-volume honeycomb corona plasma 3D uniformity adjusting device

The invention discloses a large-volume honeycomb corona plasma 3D uniformity adjusting device, and the device comprises a first panel structure, wherein an end face of the first panel structure is provided with a honeycomb-shaped multi-pin electrode composed of electrode pins. The electrode pins are perpendicular to the first panel structure, and the connection lines between the electrode pins andthe contact point of the first panel structure form a regular hexagon, wherein the center of the regular hexagon is provided with an adjustment pin with the adjustable length. The adjustment pin is perpendicular to the first panel structure, and the first panel structure, the honeycomb-shaped multi-pin electrode and the adjustment pin form a discharge combined electrode. The device provided by the invention can generate a large-volume corona plasma under a lower voltage, can adjust the size and shape of the corona plasma in a three-dimensional range, enables the corona plasma to better applyto the industrial production and scientific research.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST

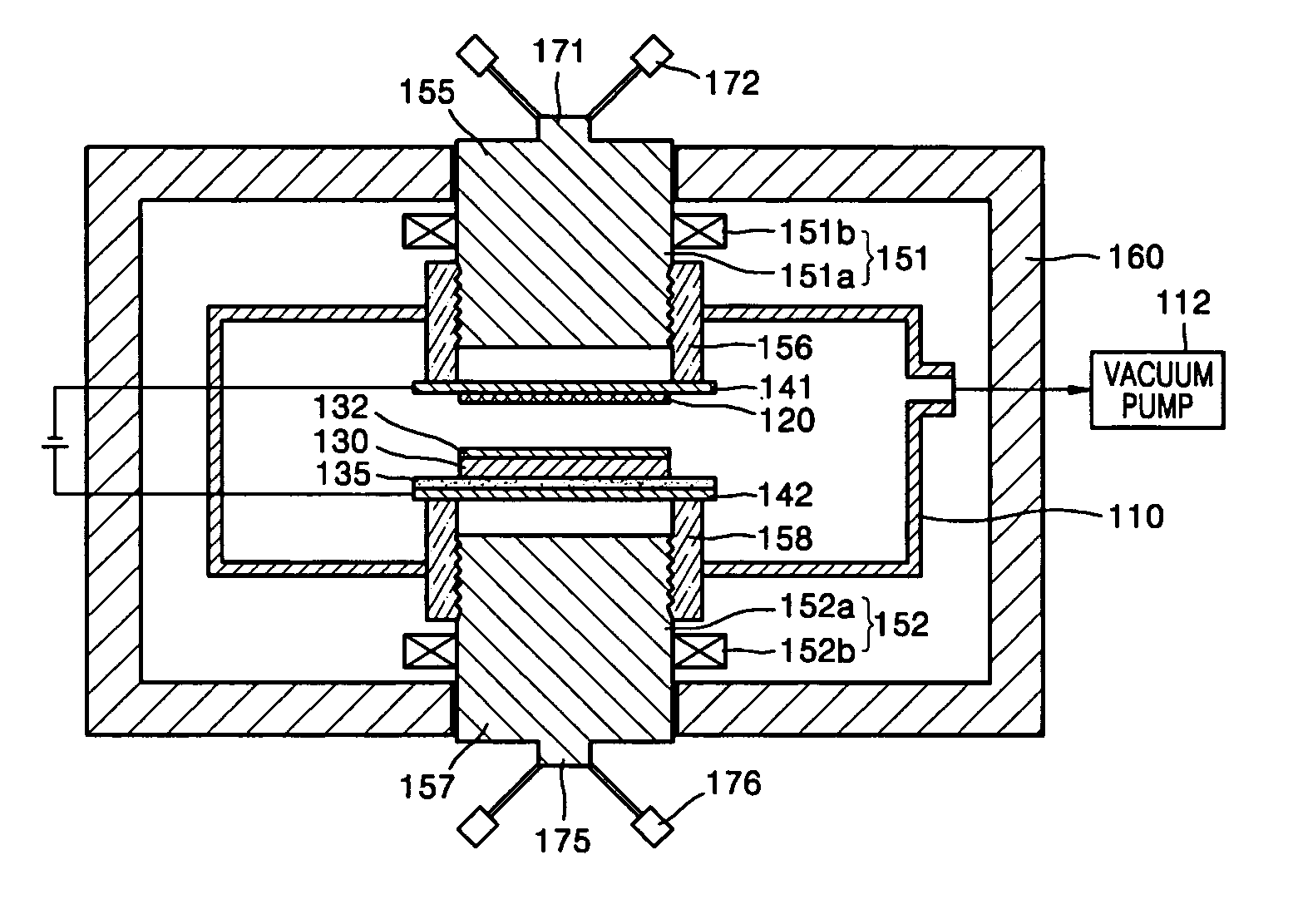

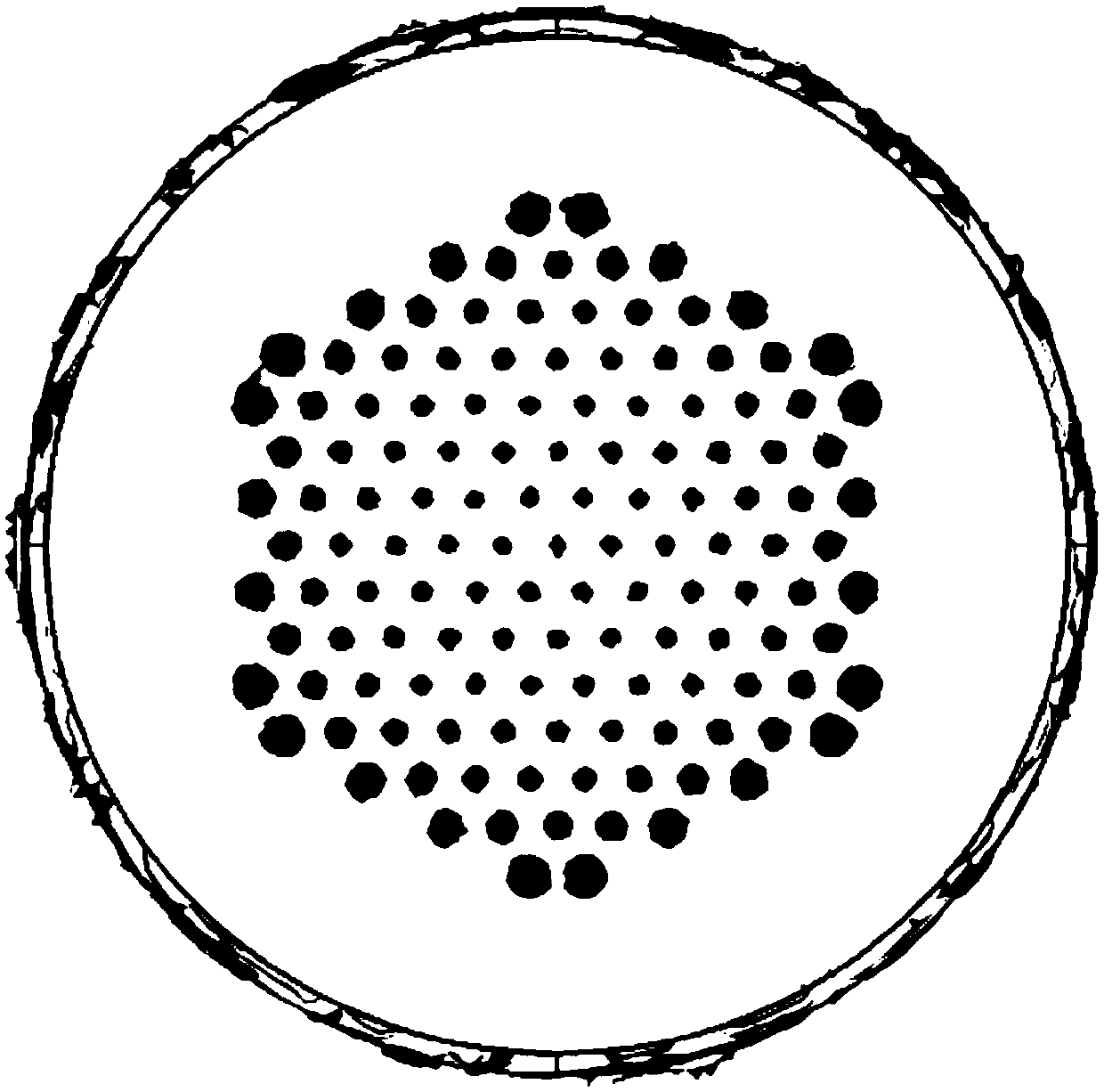

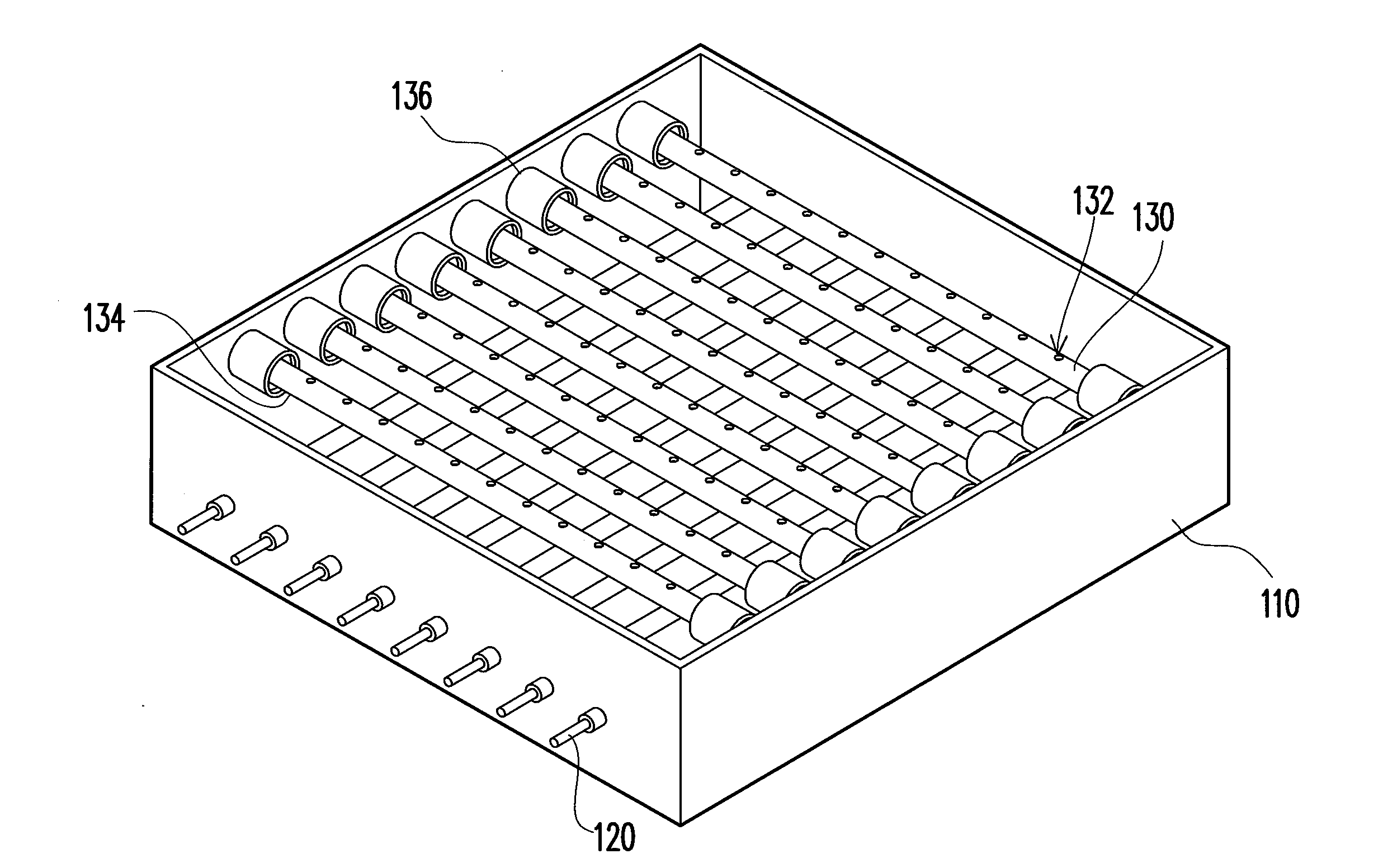

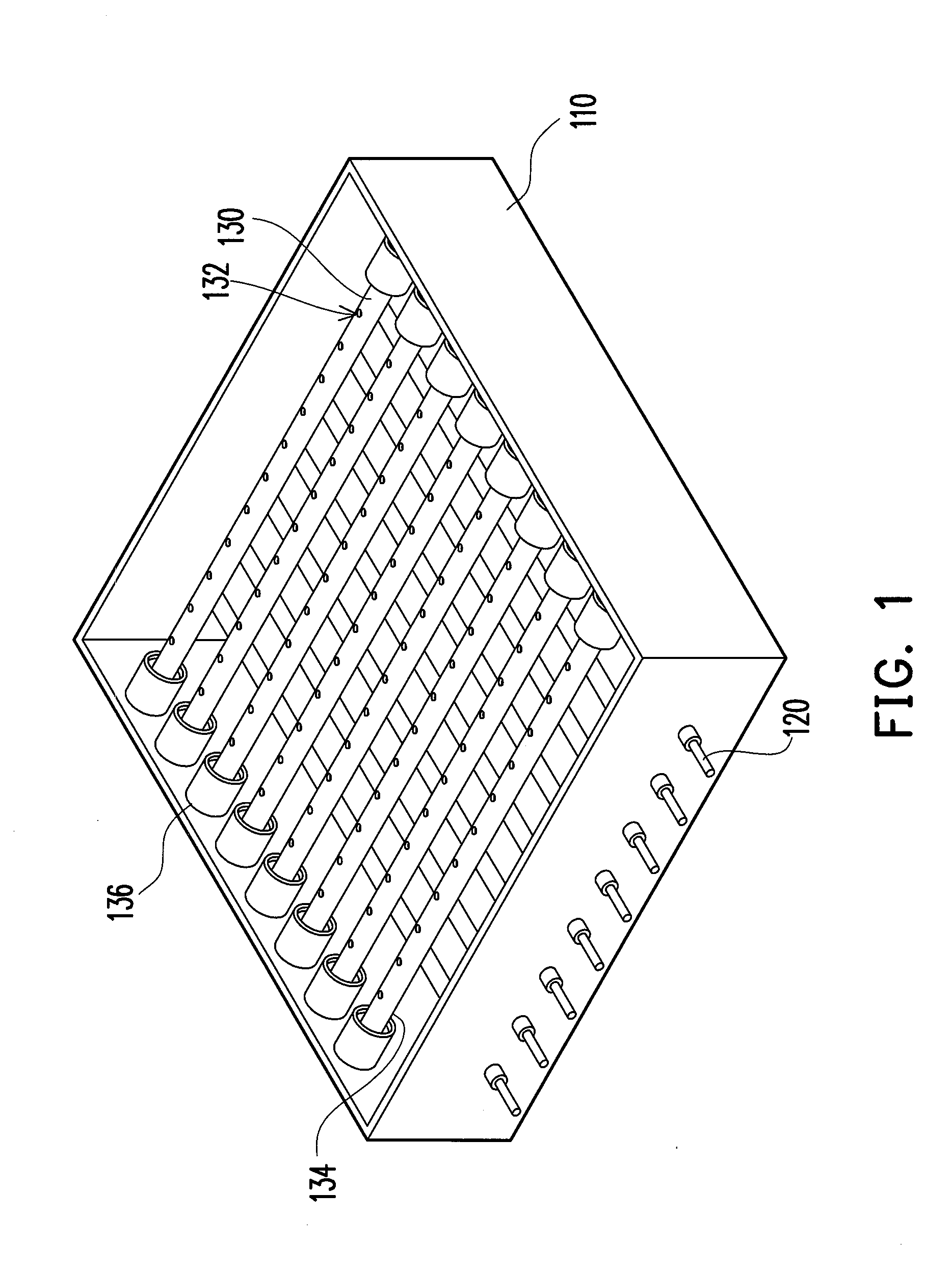

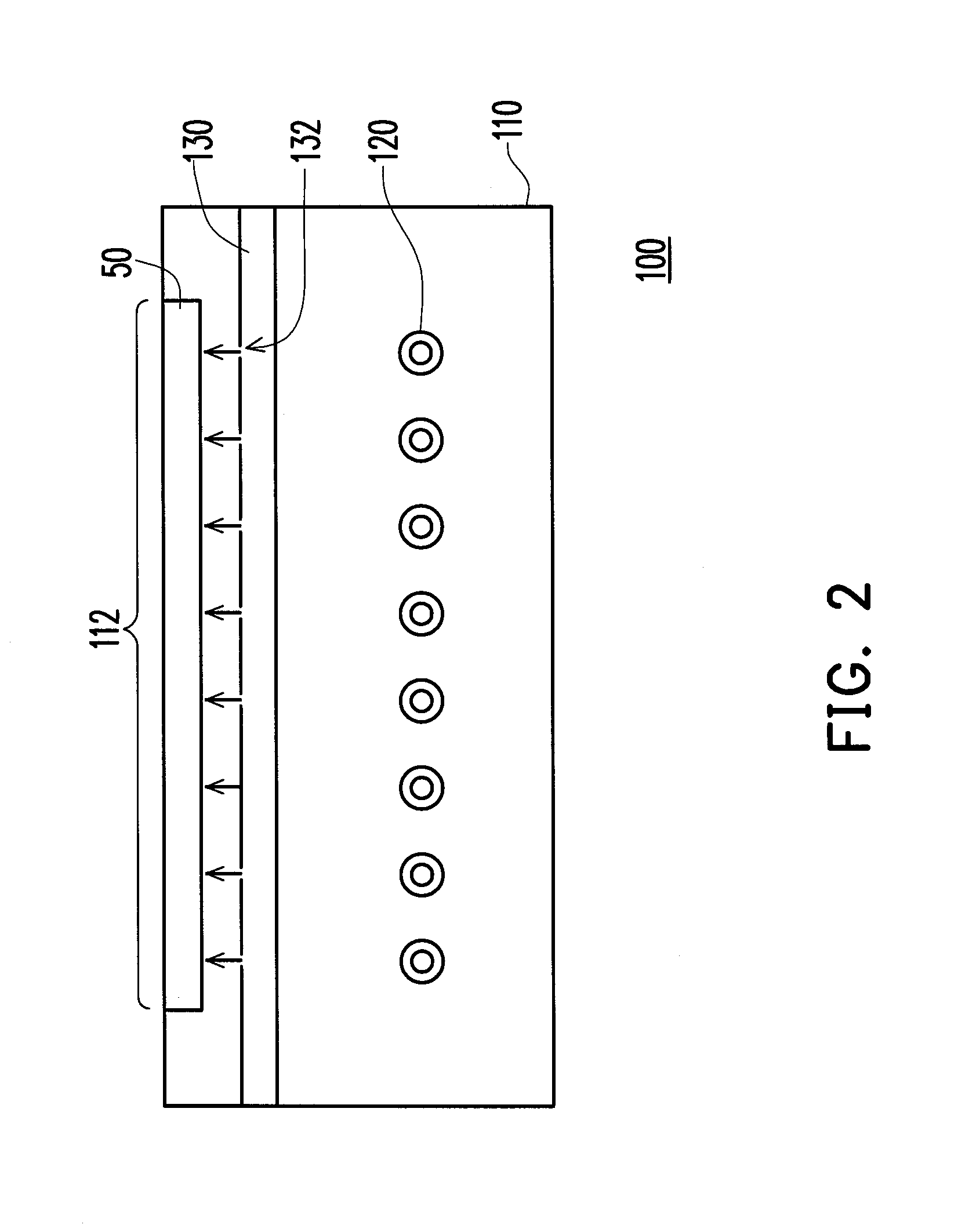

Plasma apparatus

InactiveUS20120145325A1High fabrication yieldImprove yieldElectric discharge tubesSemiconductor/solid-state device manufacturingTubing setEngineering

A plasma apparatus including a chamber, an electrode set and a gas supplying tube set is provided. The chamber has a supporting table for supporting a substrate. The gas supplying tube set is disposed in the chamber and has a plurality of gas apertures. The gas supplying tube set is located between the supporting table and the electrode set.

Owner:IND TECH RES INST

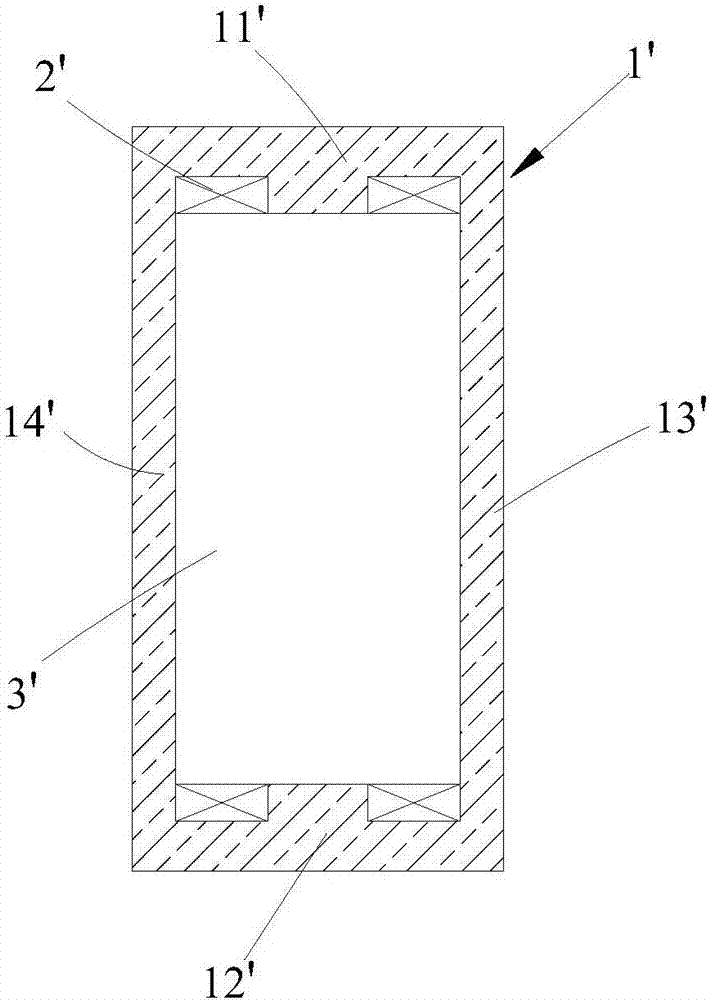

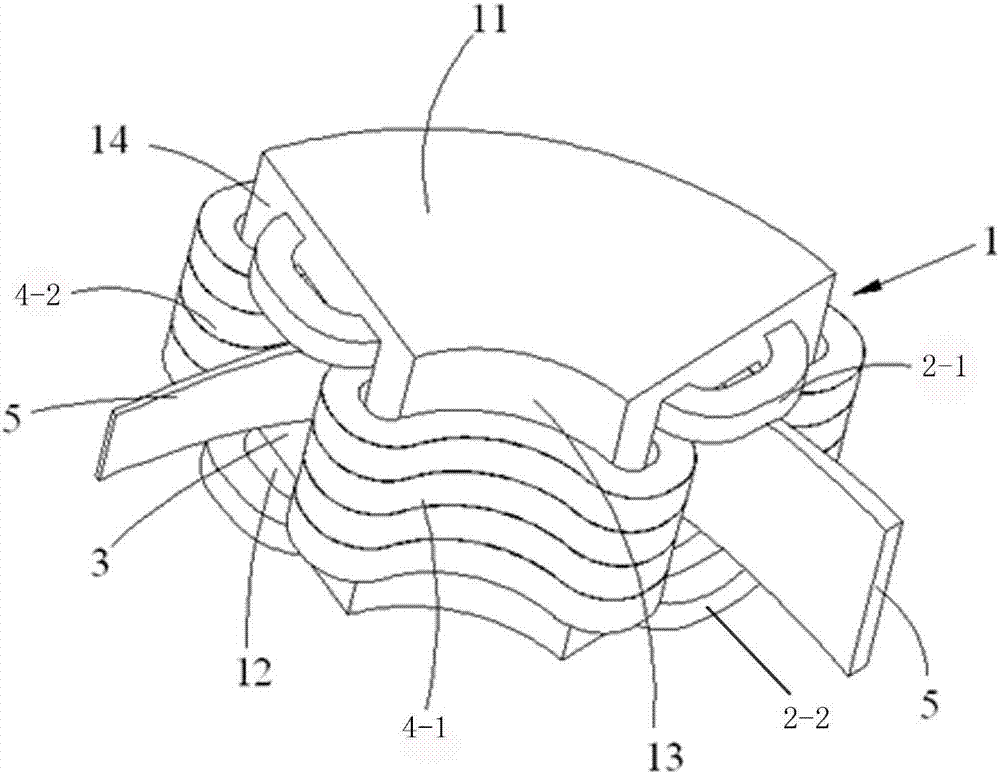

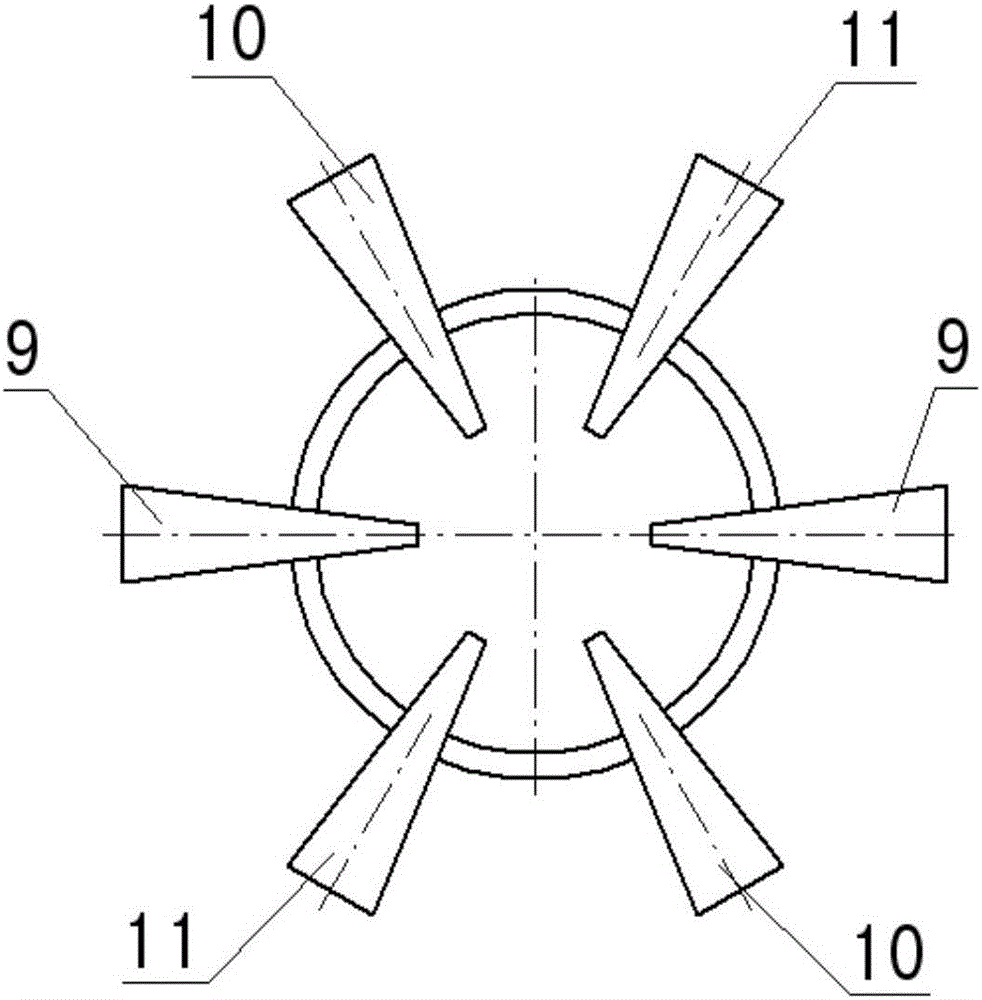

Ion beam adjusting device

ActiveCN107221485AAdjust UniformitySatisfy Beam TransportElectric discharge tubesShaped beamIon beam

The invention mainly belongs to the technical field of ion beam adjusting device, and specifically relates to an ion beam adjusting device. The ion beam adjusting device comprises an iron core, pole heads, a first coil and a second coil, wherein the iron core comprises an upper iron core block, a lower iron core block, a front iron core block and a rear iron core block; the front ends and the rear ends of the upper iron core block and the lower iron core block are connected with the front iron core block and the rear iron core block respectively; and the inner side faces of the upper iron core block, the lower iron core block, the front iron core block and the rear iron core block are defined together to form a through hole. The ion beam adjusting device also comprises third coils stacked on the front iron core block in sequence in a sleeving manner and fourth coils stacked on the rear iron core block in sequence in the sleeving manner. According to the ion beam adjusting device disclosed by the invention, the cross section shape of a strip-shaped beam can be maintained to be the shape of a straight line when the beam passes through the device, and the uniformity of the beam in the height direction can be adjusted, so that the requirements of beam transmission and injection are met.

Owner:东莞嘉拓日晟智能科技有限公司

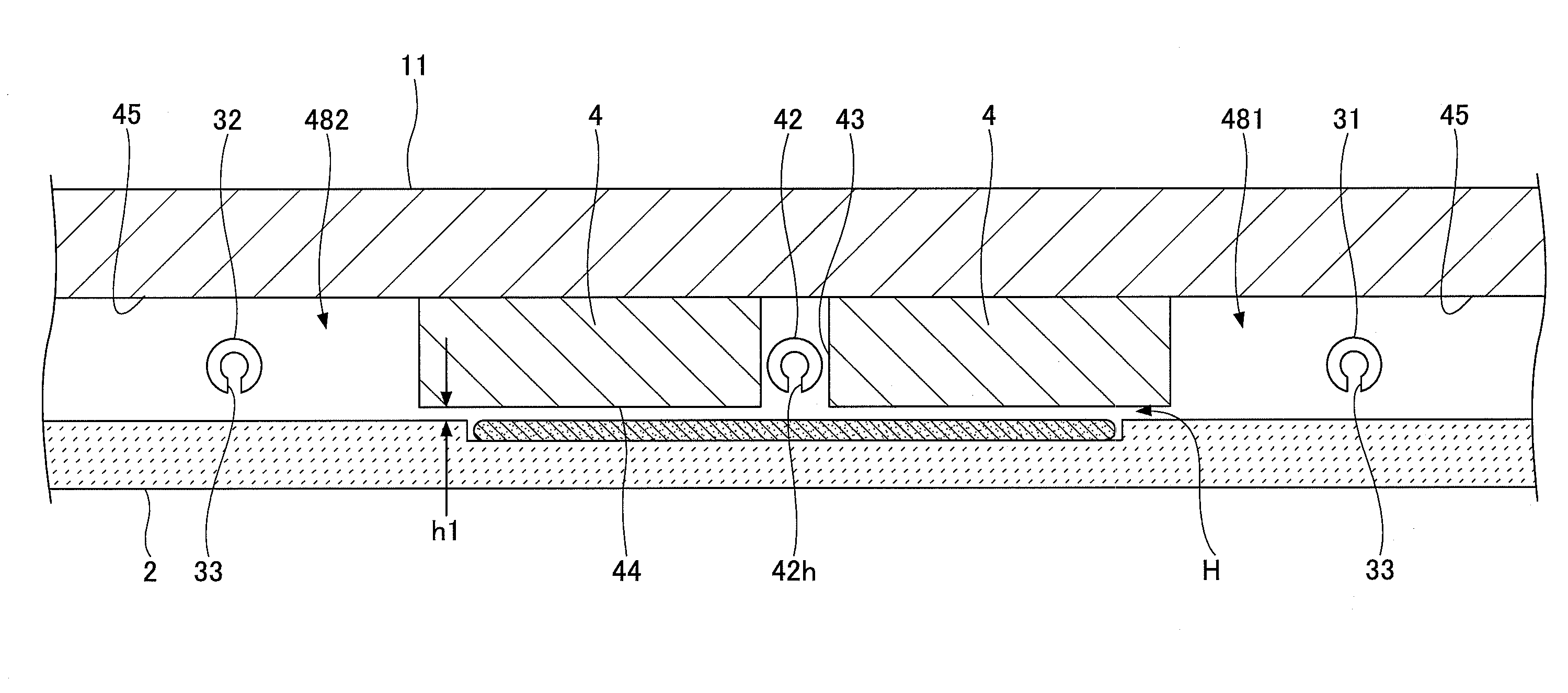

Spacer and manufacturing device for the same

ActiveUS9946154B2Improve pixel aperture ratioEasy to makePhotomechanical exposure apparatusMicrolithography exposure apparatusPhotoresistPhotomask

A spacer manufacturing device is disclosed. The device includes a photo mask having a central light-transmitting region and a peripheral light-transmitting region disposed at a periphery of the central light-transmitting region; and an exposure device right opposite to the photo mask. Wherein, light emitted from the exposure device is irradiated to a negative photoresist material after passing through the photo mask, the light intensity passing through the peripheral light-transmitting region is less than the light intensity passing through the central light-transmitting region. A spacer is also disclosed. Only one exposure process is required to realize the spacer having a convex-shaped cross section. The process is simple and the manufacturing cost is low. At the same time, a flatness of the convex shoulder of the spacer having a convex-shaped cross section is adjustable, which can satisfy the requirement for manufacturing spacers having different specifications.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Gas baking method and device for aluminium electrolysis cell

The invention discloses a gas baking method and device for an aluminium electrolysis cell. The method comprises the following steps of: heating a cell cavity to 900 DEG C, and directly pouring electrolyte into the cell cavity for starting; in the heating process of the cell cavity, dividing the cell cavity of the electrolysis cell into a plurality of areas, respectively arranging controlled burners at multiple spots of each area, wherein the controlled burners are uniformly distributed and are arranged under the bottom palm of the positive pole of the big surface of the aluminium electrolysis cell in a staggering mode, and controlled draught flues are respectively arranged in the central joint of the cell cavity and at multiple spots of the side surface of the cell cavity so as to reduce the temperature difference between all the areas; and in the baking process, controlling the ratio of the gas to the air to be less than 1:3, and preventing carbon blocks from oxidizing in a controlled oxygen deprivation combustion mode. The device comprises the plurality of controlled special-shaped burners and the controlled draught flues, wherein the controlled special-shaped burners are uniformly distributed and are arranged under the bottom palm of the positive pole of the big surface of the electrolysis cell in a staggering mode, and the controlled draught flues are arranged in the central joint of the cell cavity and at the multiple spots of the side surface of the cell cavity. The invention is beneficial to the uniform heating of the cell cavity, reducing of the temperature difference between all areas and the oxidation of the carbon blocks in the baking process.

Owner:ZHENGZHOU ZHONGSHI CELL TECH

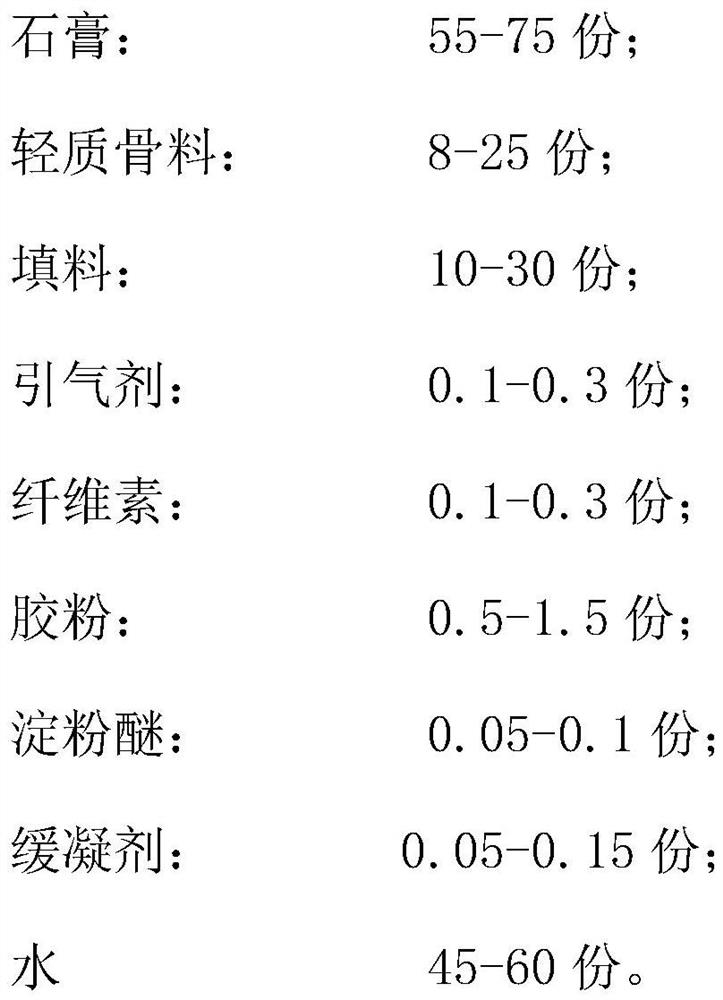

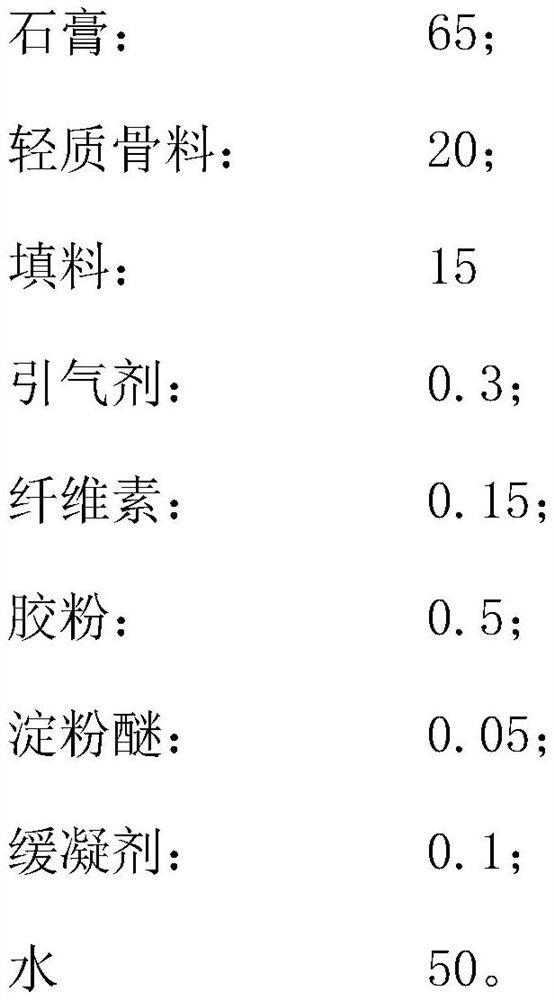

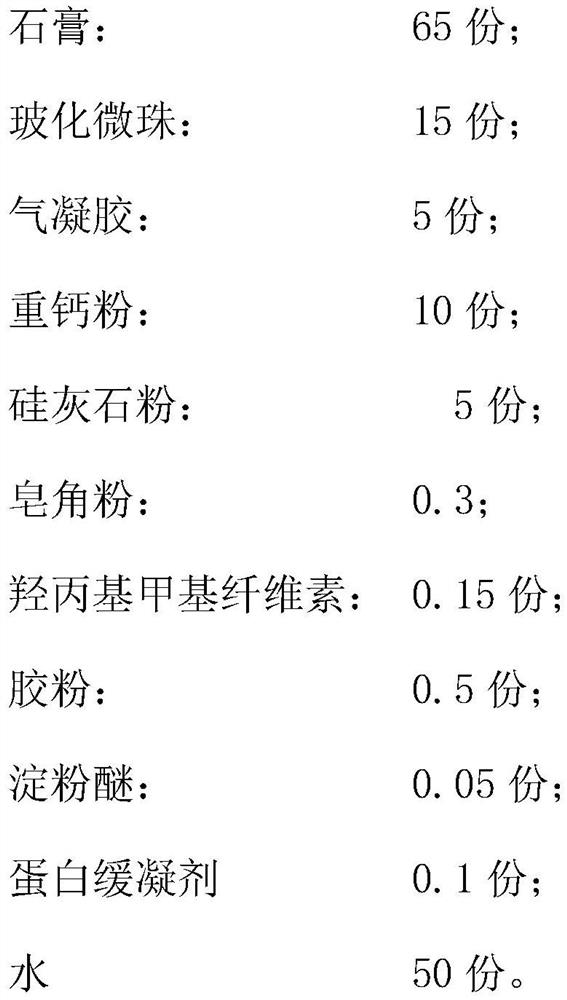

Heat-preservation and heat-insulation plaster for interior wall

The invention discloses an interior wall thermal insulation plaster, which comprises the following components by mass: 55 to 75 parts of gypsum; 8 to 25 parts of lightweight aggregate; 10 to 30 parts of filler; 0.1 to 0.3 part of an air entraining agent; 0.1 to 0.3 part of cellulose; 0.5 to 1.5 parts of rubber powder; 0.05 to 0.1 part of starch ether; and 0.05 to 0.15 part of a retarder. The internal wall heat insulation plastering method is convenient and simple in manufacturing, the material has the advantages of being high in strength, low in heat conductivity coefficient, good in heat insulation effect and the like, construction operation is easy and convenient, and good market prospects are achieved.

Owner:漆仙姑新材料技术重庆有限公司

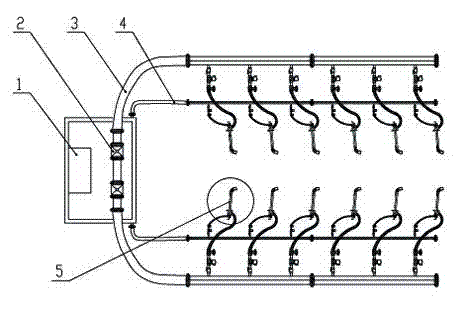

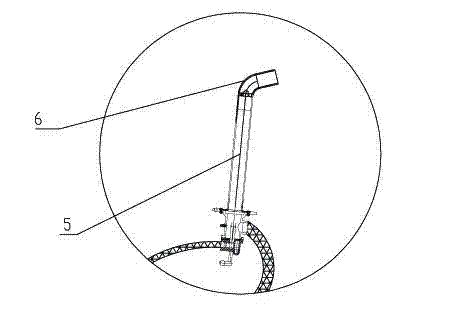

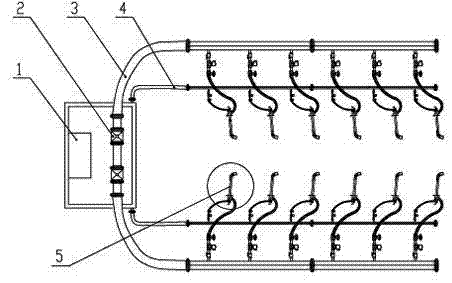

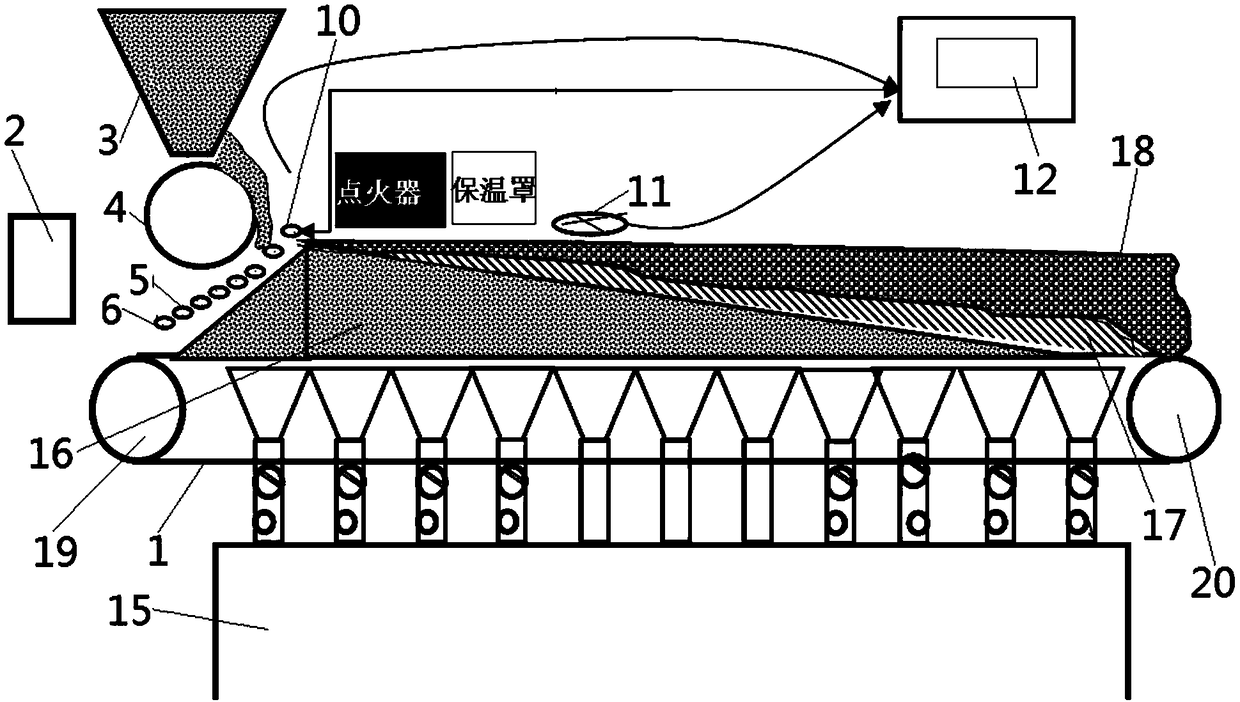

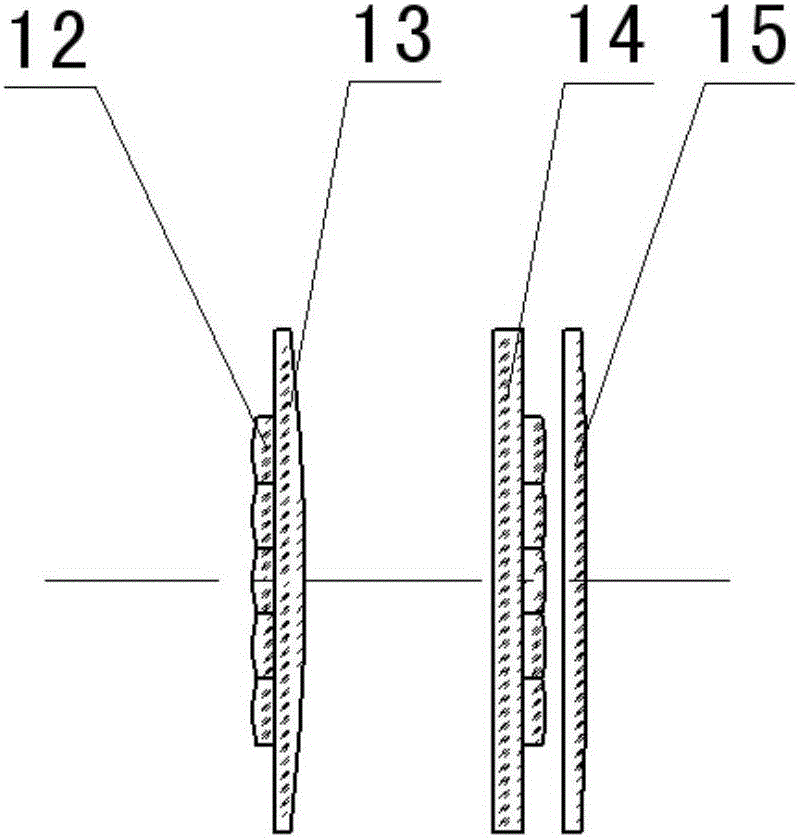

Distributor for sintering machine and method for distributing material using the distributor for sintering machine

ActiveCN106959012BSimple structurePromote sinteringCharge treatment typeFurnace typesDistributorMixing tank

The invention provides a sintering machine distributing device applied to the technical field of iron and steel smelting equipment parts, and further relates to a distributing method using the sintering machine distributing device. A sintering mixing tank (3) is arranged on the upper portion of one side of a sintering machine body (1) of a sintering machine. A round roller feeder (4) is arranged under the sintering mixing tank (3). A distributing device body (5) is arranged under the round roller feeder (4) and composed of a plurality of distributing rollers (6). A distributing face (8) is formed by the upper surfaces of the multiple distributing rollers (6). The bottom of each distributing roller (6) is connected with an adjusting part (7) through a connecting base (9). According to the distributing device and the distributing method, particle segregation and sinter bed particle uniformity of a sinter mixture are achieved advantageously, the bed breathability is improved, sintering solid fuel consumption is reduced advantageously, and the sintering production cost is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

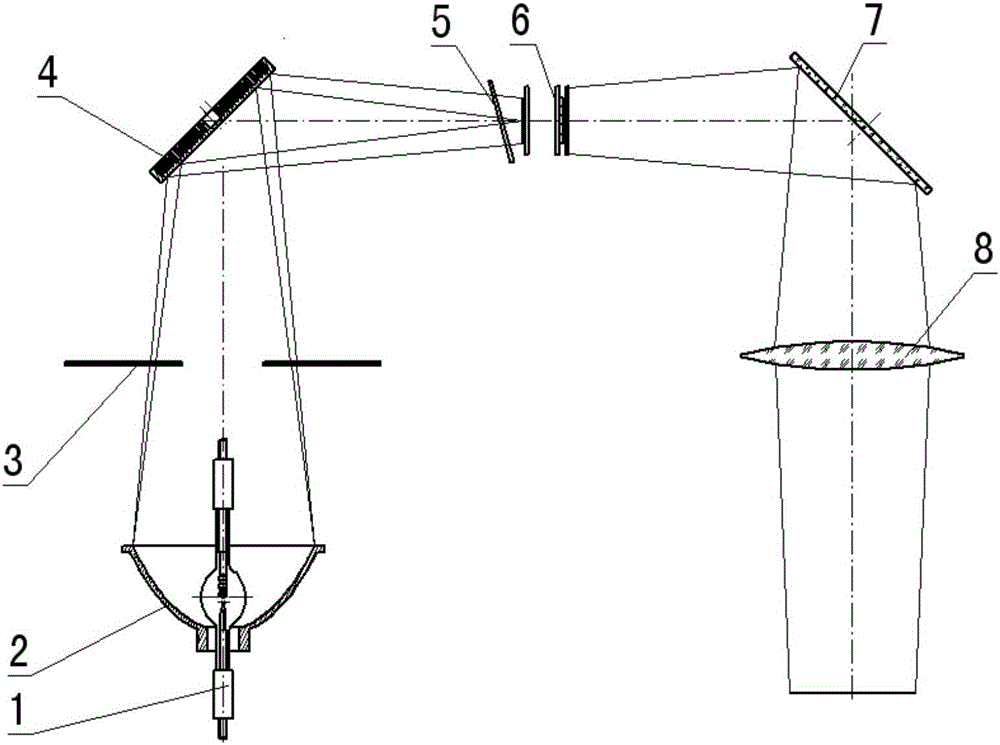

Solar simulator optical system for testing triple-junction gallium arsenide solar cell

InactiveCN106764680AImprove Spectral Matching AccuracyMeet the test requirementsSpectral modifiersRefractorsSolar lightIntegrator

The invention provides a solar simulator optical system for testing a triple-junction gallium arsenide solar cell, and relates to the technical field of light spectrum, aiming at solving the problems of an existing solar simulator optical system that difference is formed between a partial spectrum band and a solar light spectrum, so that measurement requirements cannot be met and the like. The solar simulator optical system comprises a xenon lamp, an ellipsoidal reflecting mirror, an optical filter array, a first plane reflecting mirror, an AM0 optical filter, an optical integrator, a second plane reflecting mirror and a collimator objective, and further comprises an optical filter array; the optical filter array comprises two first optical filters, two second optical filters and two third optical filters; the two first optical filters, the two second optical filters and the two third optical filters are uniformly distributed along the periphery at intervals; light emitted by the xenon lam is reflected by the ellipsoidal reflecting mirror, and then is filtered through the optical filter array; after the direction of a light beam is changed through the first plane reflecting mirror, the light is filtered through the AM0 optical filter again, and is converged on the optical integrator; then the light passes through the optical integrator, the second plane reflecting mirror and the collimator objective in sequence and then is projected onto an irradiation surface, so as to form the uniform irradiation surface.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Multi-functional thermal insulation material

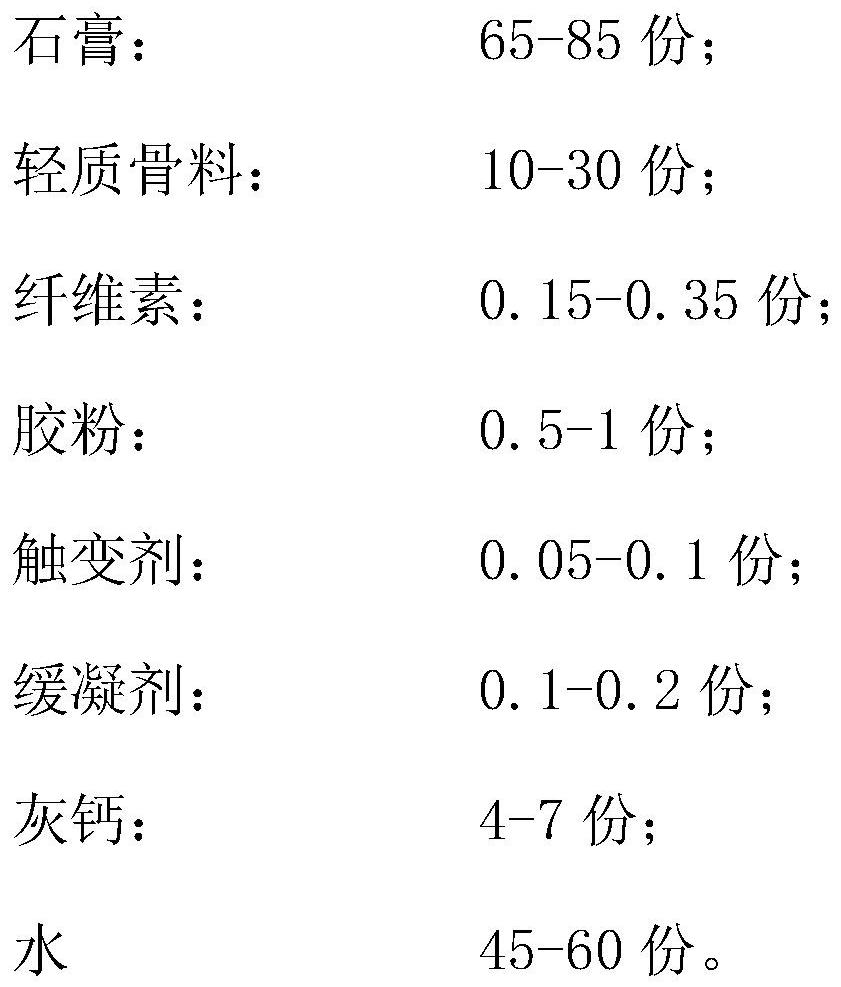

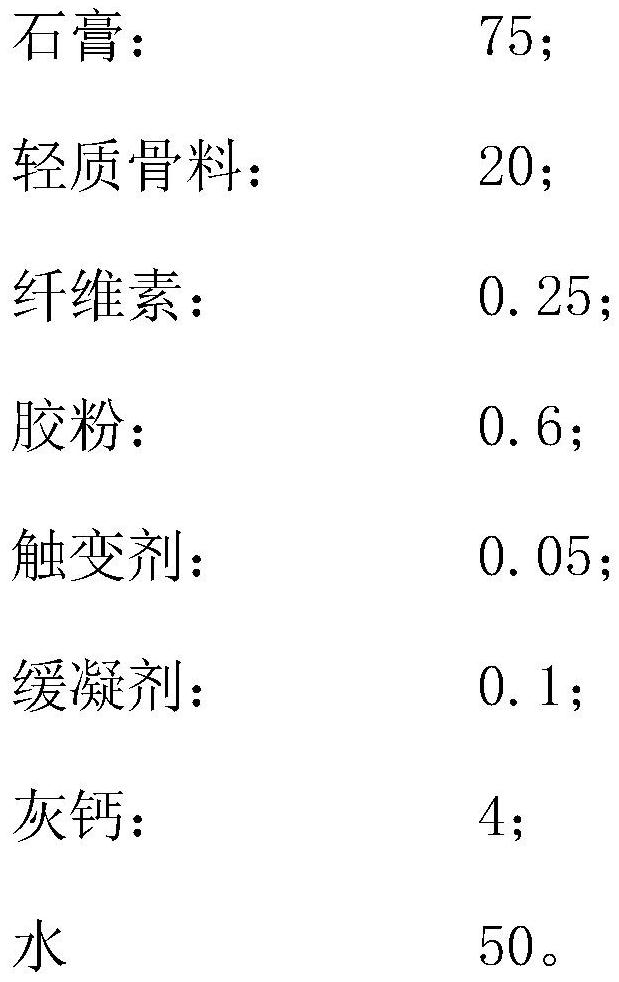

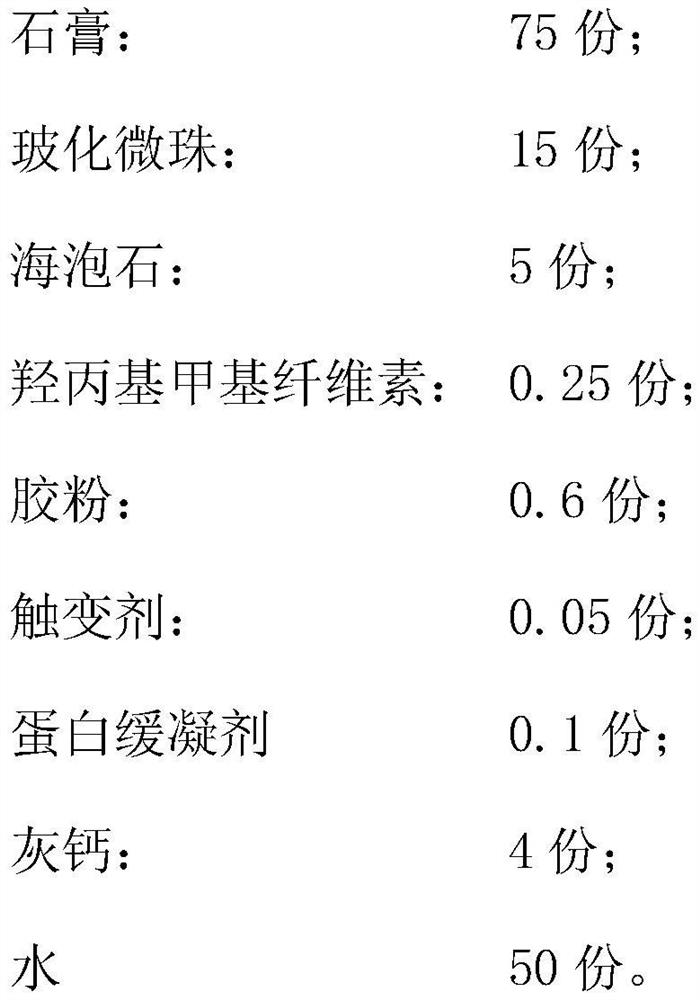

The invention discloses a multi-functional thermal insulation material which comprises the following components in parts by mass: 65-85 parts of gypsum; 10-30 parts of a lightweight aggregate; 0.15-0.35 parts of cellulose; 0.5-1 part of rubber powder; 0.05-0.1 parts of a thixotropic agent; 0.1-0.2 parts of a retarder; and 4-7 parts of ash calcium. The lightweight aggregate is one or more of vitrified microbeads, expanded perlite, polyphenyl granules, ceramic microbeads, sepiolite or closed-cell perlite. The cellulose is one or more of hydroxypropyl methyl cellulose, ethyl cellulose or carboxymethyl cellulose. The rubber powder is one or more of dispersible latex powder, VAE rubber powder or resin rubber powder. The thixotropic agent is one or two of fumed silica, organic bentonite, asbestos, magnesium aluminum silicate or kaolin. The material has the advantages that the method for preparing the multi-functional thermal insulation material is simple and easy to implement, the thermal insulation material has the characteristics of low density, high strength and low heat conductivity coefficient, subsequent construction operation is simple and convenient, and manpower can be greatly saved.

Owner:漆仙姑新材料技术重庆有限公司

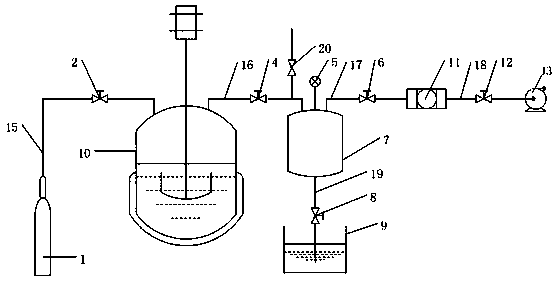

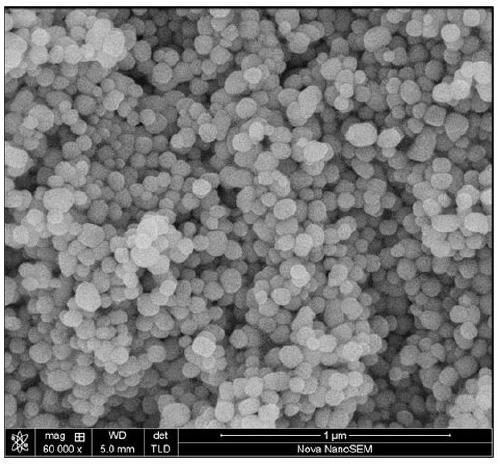

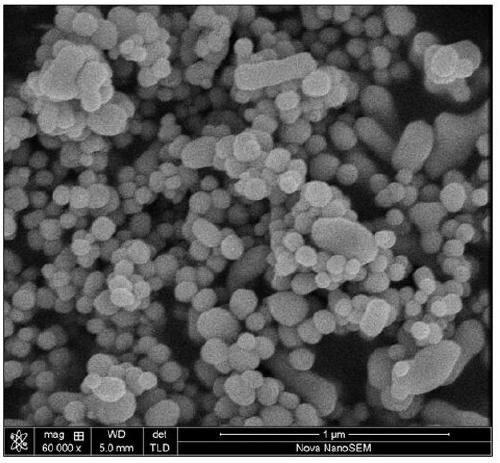

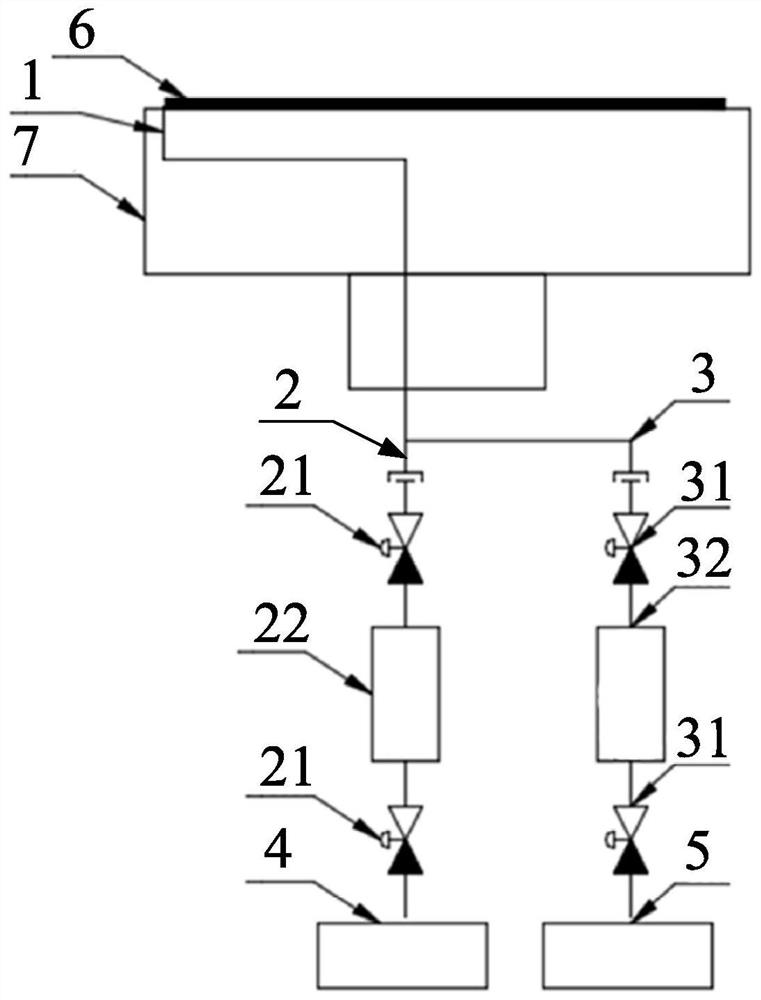

Apparatus and method for preparing high-purity barium titanate

PendingCN109721096ALow reaction temperatureLess energy consumption and less timeMaterial nanotechnologyChemical industryEngineeringBarium titanate

The invention relates to an apparatus and a method for preparing high-purity barium titanate. According to the apparatus, a storage tank (1) is connected to the inlet of a reaction kettle (10) througha first pipeline (15) and a first valve (2), the outlet of the reaction kettle (10) is connected to the inlet of a buffer tank (7) through a second pipeline (16) and a second valve (4), the outlet ofthe buffer tank (7) is connected to an air filter (11) through a third pipeline (17) and a third valve (6), the air filter (11) is connected to a vacuum pump (13) through a fourth pipeline (18) and afourth valve (12), the bottom outlet of the buffer tank (7) is connected to a waste liquid groove (9) through a fifth pipeline (19) and a fifth valve (8), the second pipeline (16) is connected to a sixth valve (20), and the buffer tank (7) is provided with a vacuum meter gauge (5). According to the present invention, the apparatus has advantages of simple equipment, low reaction temperature, environmental protection and energy saving, and the obtained barium titanate powder can meet the requirements of electronic components such as MLCC, PTC and the like.

Owner:安徽凯盛应用材料有限公司 +2

Purging method and structure, deposition process and gas inlet system

PendingCN111863589AAdjust UniformityResponse continuesSemiconductor/solid-state device manufacturingPhysical chemistryDeposition process

The invention provides a purging method and structure, a deposition process and a gas inlet system. The purging method is used in the chemical vapor deposition process. A substrate is borne on a chuck, and purging gas and process gas are conveyed to the edge of the substrate in the process of carrying out the chemical vapor deposition process. Due to the fact that the purging gas and the process gas are introduced into the edge of the substrate, the process gas reacts with process gas introduced into a cavity, continuous proceeding of the reaction on the edge of the substrate is promoted, products on the edge of the substrate are supplemented, and thus the uniformity of the edge of the substrate is adjusted.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com