Backlight module and display device

A backlight module, light source technology, applied in the direction of light guide, optics, optical components, etc., can solve problems such as the inability to achieve four-sided narrow borders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

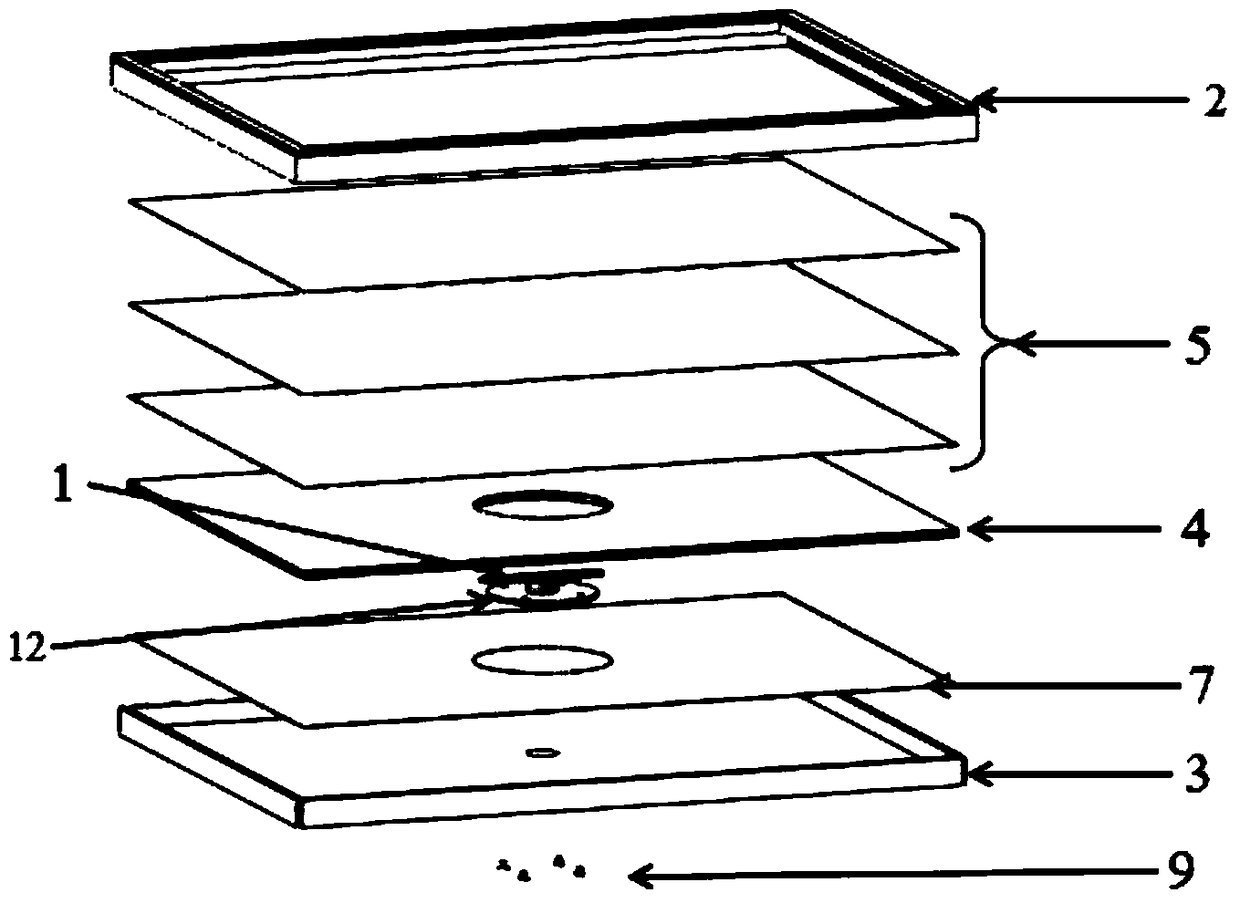

[0050] refer to Figure 4 The three-dimensional structure schematic diagram of the light source assembly is shown, the light source assembly may include a drive motor 8 with a drive shaft and a light emitting part 1 .

[0051] In this example implementation, refer to Figure 5 As shown in the structural schematic diagram of the light emitting part 1, the light emitting part may include a PCB board 15, which is arranged in a strip shape, and the two sides of the PCB board 15 are symmetrically fixed to the drive shaft of the drive motor 8, so that the drive motor 8 can drive the PCB board 15 Rotate to form a circular surface; the side of the PCB board 15 close to the diffusion assembly 5 is provided with a COB light source 13, that is, the entire upper surface of the PCB board 15 is provided with a COB light source 13; the two ends of the length direction of the PCB board 15 are close to the hole wall One side is provided with an LED light source 14 .

[0052] COB light source...

Embodiment approach 2

[0065] The main difference between this exemplary embodiment and the first exemplary embodiment is that: the light source assembly is different, and this exemplary embodiment directly adopts a surface light source; at the same time, there is no need to set a second through hole on the back plate 3, and it is not necessary to set a second through hole on the reflective plate. A through hole. The differences will be described in detail below.

[0066] In this exemplary embodiment, the holes on the light guide plate 4 may be blind holes, and the shape of the blind holes may be set as a rectangle. The blind hole is set at the center of the light guide plate 4 . Of course, those skilled in the art can understand that the holes on the light guide plate 4 can also be through holes, and in this case, the light emitting part 1 can be fixed on the reflective plate. The shape of the hole can also be circular, trapezoidal or elliptical or the like. The blind hole may not be arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com