Method for preparing large-size silicon carbide ceramic plate through reactive sintering

A sintered silicon carbide and large-size technology, which is applied in the field of preparation of large-size reactive silicon carbide ceramic plates, can solve the problems of press size limitation, large production investment, and silicon carbide ceramic plates that have not been mass-produced, so as to reduce cracking , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

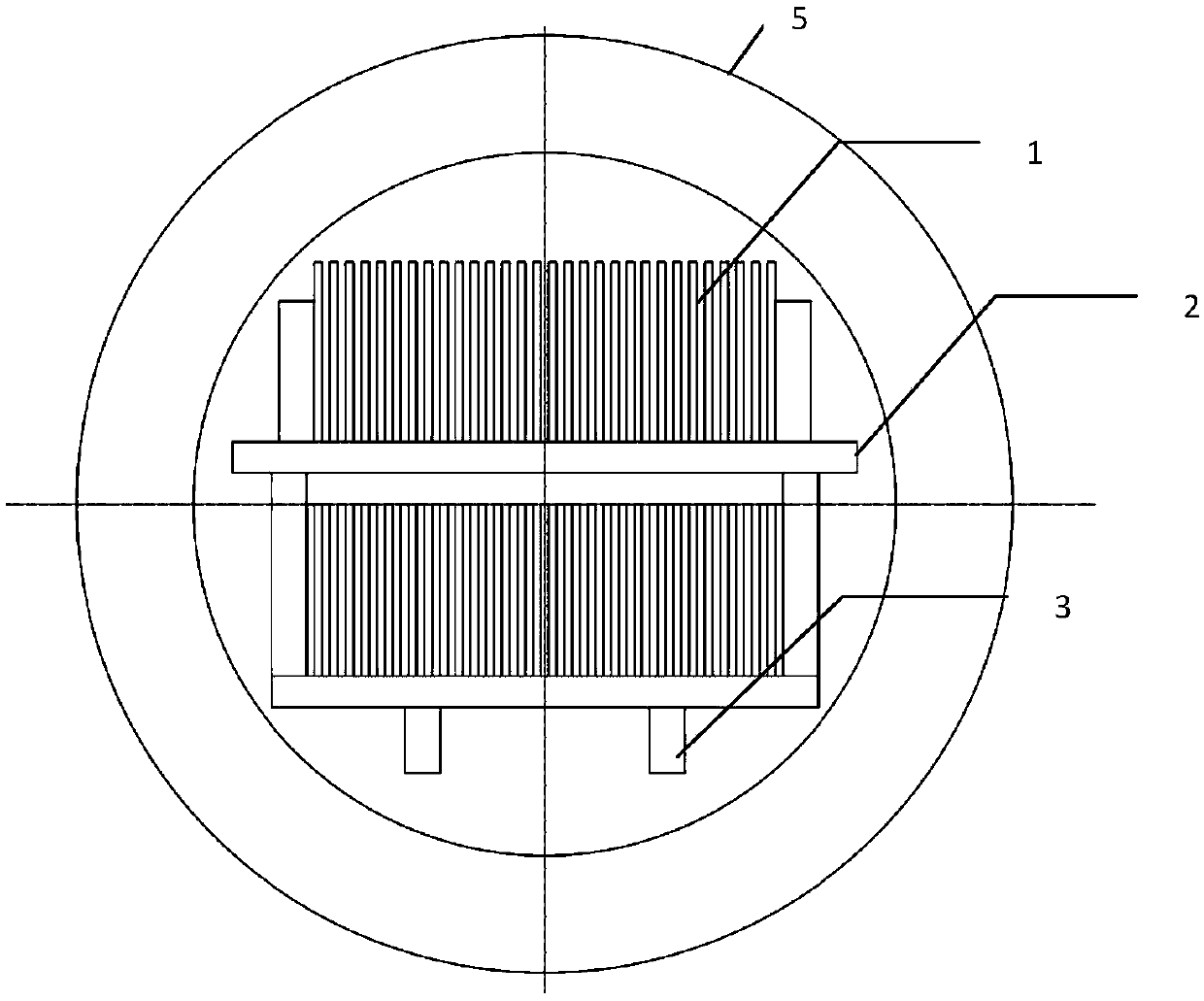

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The large size in the present invention is 3100*500*10mm in length×width×height.

[0030] 1) Ingredients, according to the ratio of parts by mass, weigh 60-85 parts of silicon carbide, 5-10 parts of graphite powder, 2-5 parts of carbon black and 2-4 parts of additives, stir well and add 5-15 parts Continue to stir for more than 4 hours with a portion of water, and then stale for 24-72 hours to obtain mud.

[0031] Wherein, the auxiliary agent is PAM (polyacrylamide), PVA (polyvinyl alcohol), PVP (polyvinylpyrrolidone) or CMC (carboxymethylcellulose).

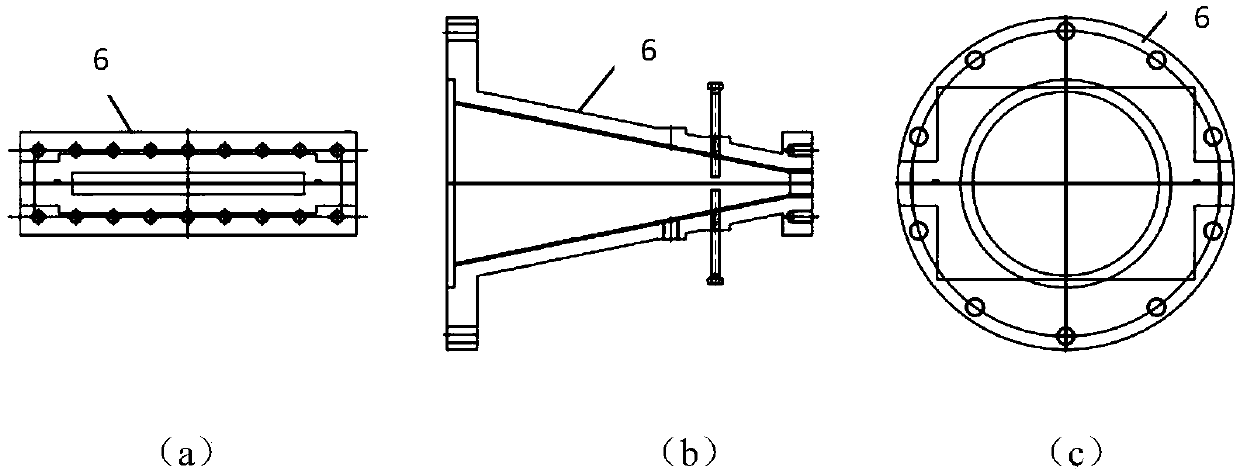

[0032] 2) Extrude the mud with an extruder after smelting, and set a duckbill die 6 at the outlet of the extruder, see figure 1 In Figures (a), (b) and (c), the duckbill die 6 includes a cylinder with two openings, one end of the cylinder is rectangular, and the other end is circular, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com