Gas baking method and device for aluminium electrolysis cell

A gas roasting and aluminum electrolytic cell technology, which is applied in the field of aluminum electrolysis technology, can solve the problems of complicated equipment and technology, confidentiality, unsuitable structure, etc., and achieve uniform temperature distribution in the tank chamber and avoid excessive temperature effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

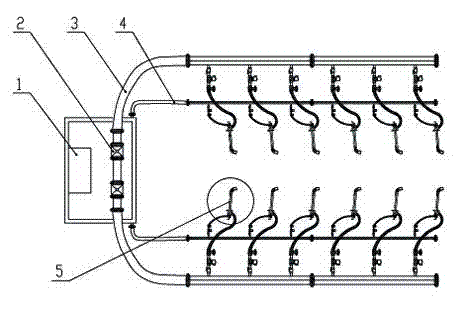

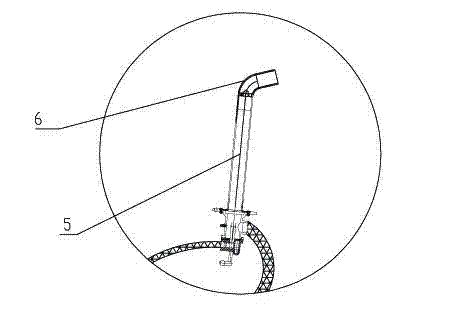

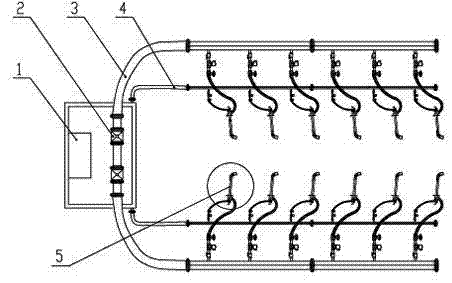

[0015] combine figure 1 and figure 2 As shown, the gas roasting device for an aluminum electrolytic cell of the present invention includes a PLC control unit 1, an air-gas proportional regulating valve 2, an air branch pipe 3, a gas branch pipe 4, and several controllable burners connected to the air branch pipe 3 and the gas branch pipe 4 5; Among them, the controllable burners are installed in multiple partitions and multiple points of the aluminum electrolytic cell hall, and are evenly distributed and staggered under the bottom palm of the large-faced anode of the electrolytic cell; the gas roasting device for the aluminum electrolytic cell also includes The controllable exhaust flue is provided at multiple points in the middle seam of the trough and the side of the trough; the controllable burner adopts a special-shaped burner, and the special-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com