High-power high-brightness light-emitting diode (LED) light source packaging structure and packaging method thereof

A technology of LED light source and packaging method, applied in the field of LED light source, can solve the problems of poor stability, thermal expansion coefficient mismatch between LED chip and heat sink, low heat dissipation efficiency of LED packaging structure, etc., achieve stable performance, simple structure, and enhanced heat dissipation capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in further detail below in conjunction with accompanying drawing:

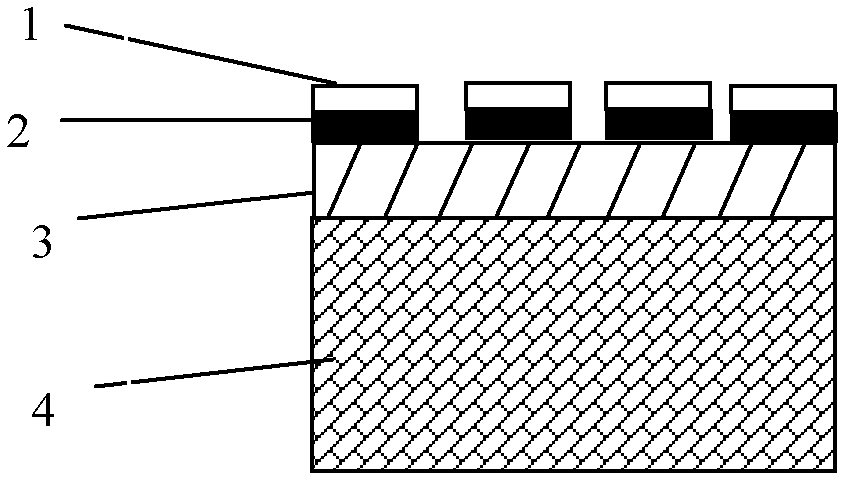

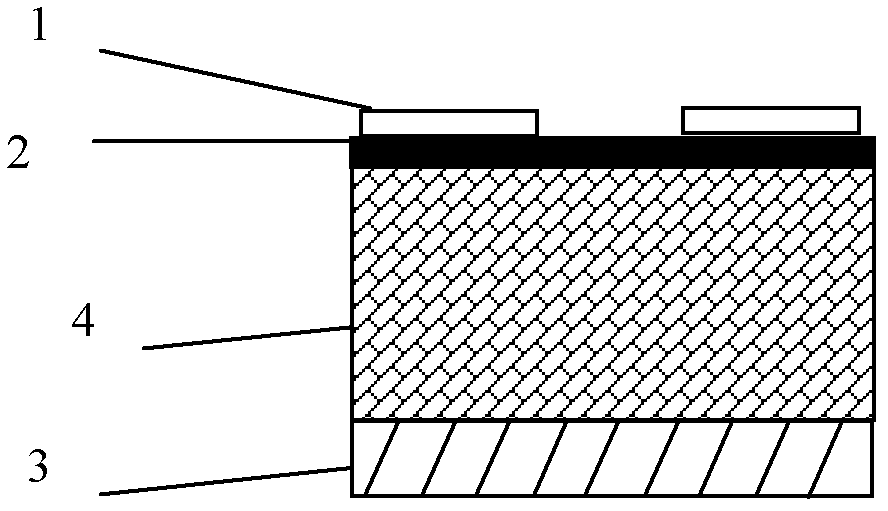

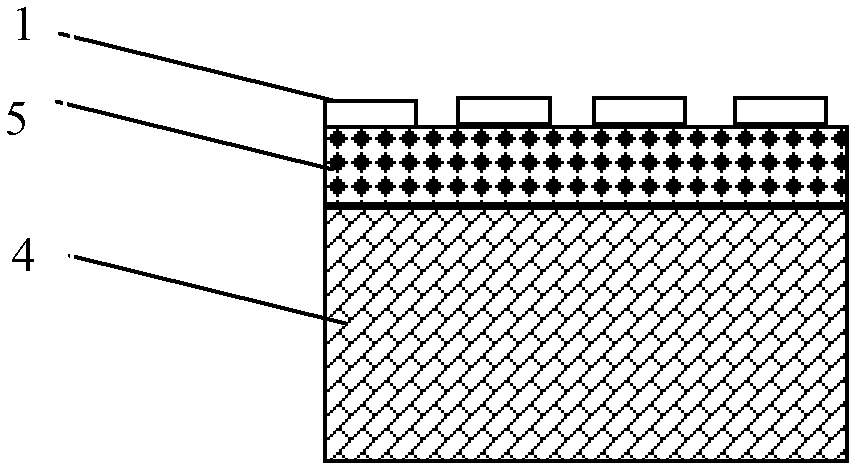

[0054] figure 1 It is the structural diagram of the first LED module of the present invention. A stress relief layer is set on the bottom surface of the LED chip (non-luminous surface) to reduce the thermal stress of the LED chip. figure 1 For the material of the stress-releasing layer in contact with the bottom surface (non-luminous surface) of the 4 LED chips, the difference between the thermal expansion coefficient and the LED chip is less than 40%, and 0.05mm thick aluminum nitride ceramics can be selected as the stress-releasing layer. Solder, such as gold-tin solder, is welded with the LED chip, and then an insulating layer is provided. The material of the insulating layer can be ceramic or diamond, and then the heat dissipation base is used to conduct contact heat dissipation treatment on the chip. The material of the heat dissipation base can be selected with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com