Ion beam adjusting device

A current regulation and ion beam technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of uneven magnetic field in the height direction, adverse effects of sample uniformity, unfavorable post-beam transmission and control, etc., to achieve cost Low, simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

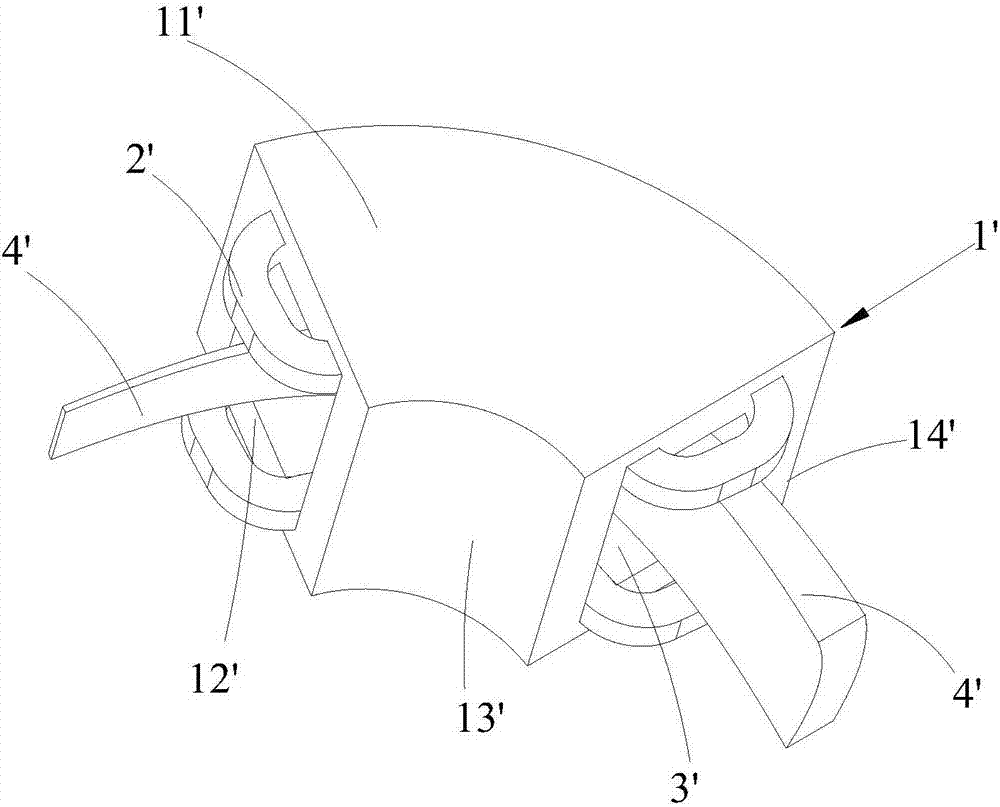

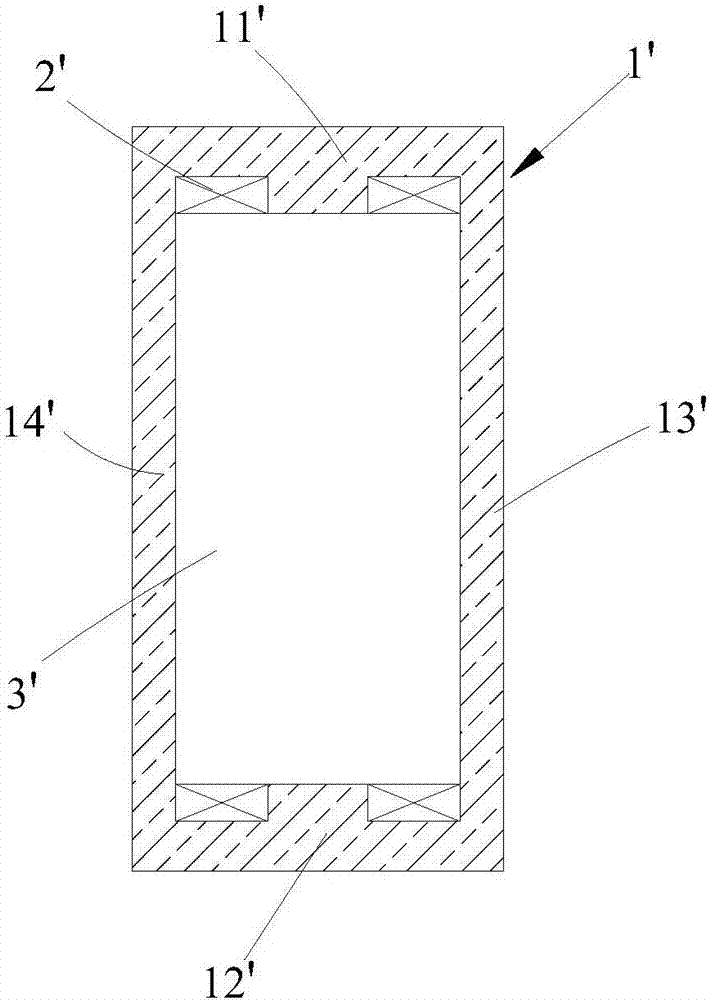

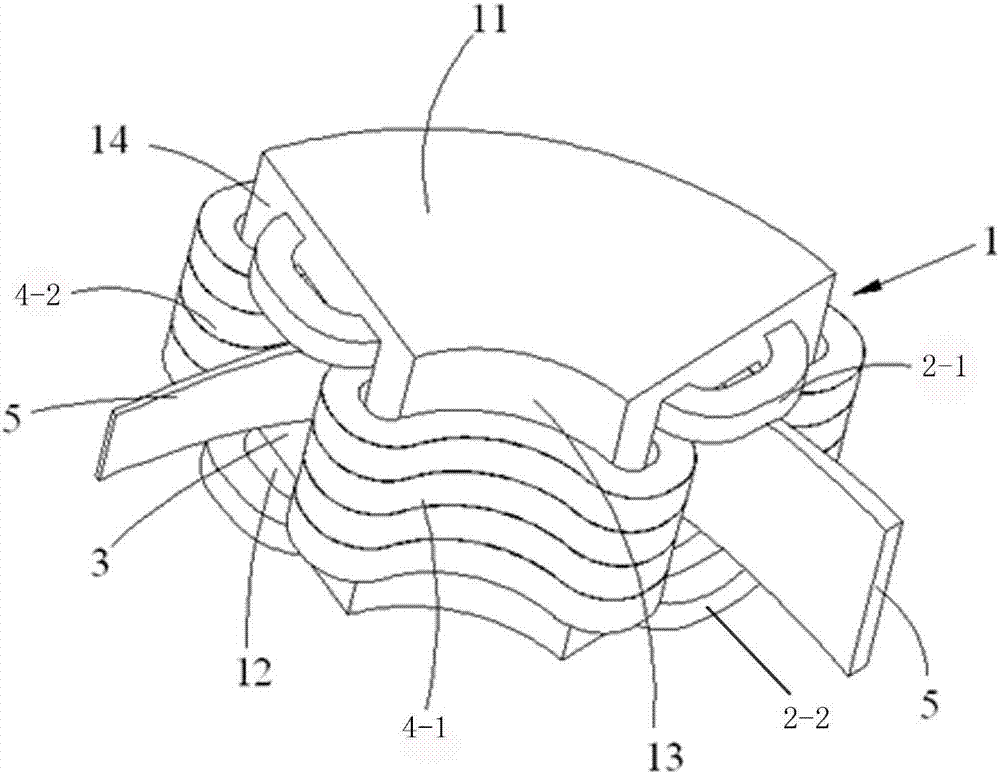

[0032] Such as image 3 and 4 As shown, the present invention provides an ion beam adjustment device, which can keep the cross-sectional shape of the ribbon beam in a straight line when the beam passes through by adjusting the current magnitude and direction of the coil, and can adjust The uniformity of the beam flow in the height direction.

[0033] The ion beam current regulating device comprises an iron core 1, a pole head, a first coil 2-1 and a second coil 2-2, and the iron core 1 comprises an upper iron core block 11, a lower iron core block 12, a front iron core Block 13 and rear core block 14, the pole head includes an upper pole head 6-1 and a lower pole head 6-2, the front and rear ends of the upper core block 11 and the lower core block 12 respectively pass through the front The iron core block 13 is connected to the rear iron core block 14, and the upper pole head 6-1 and the lower pole head 6-2 are attached to the upper iron core block 11 and the lower iron core...

Embodiment 2

[0048] This embodiment is substantially the same as Embodiment 1, except that the third coil 4-1 sleeved on the front core block 13 and the fourth coil sleeved on the rear core block 14 are The quantity is 2; the radians of the front core block and the rear core block are both 3π / 4.

Embodiment 3

[0050] This embodiment is substantially the same as Embodiment 1, except that the third coil 4-1 sleeved on the front core block 13 and the fourth coil sleeved on the rear core block 14 are The quantity is 50; the radians of the front core block and the rear core block are both π / 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com