Combined light guide board and preparation method

A manufacturing method and technology for a light guide plate, which are applied in chemical instruments and methods, light guides, optics, etc., can solve the problems of production efficiency limitation, product price increase, and difficulty in mold manufacturing, and achieve precise structure, stable quality, and stable quality. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

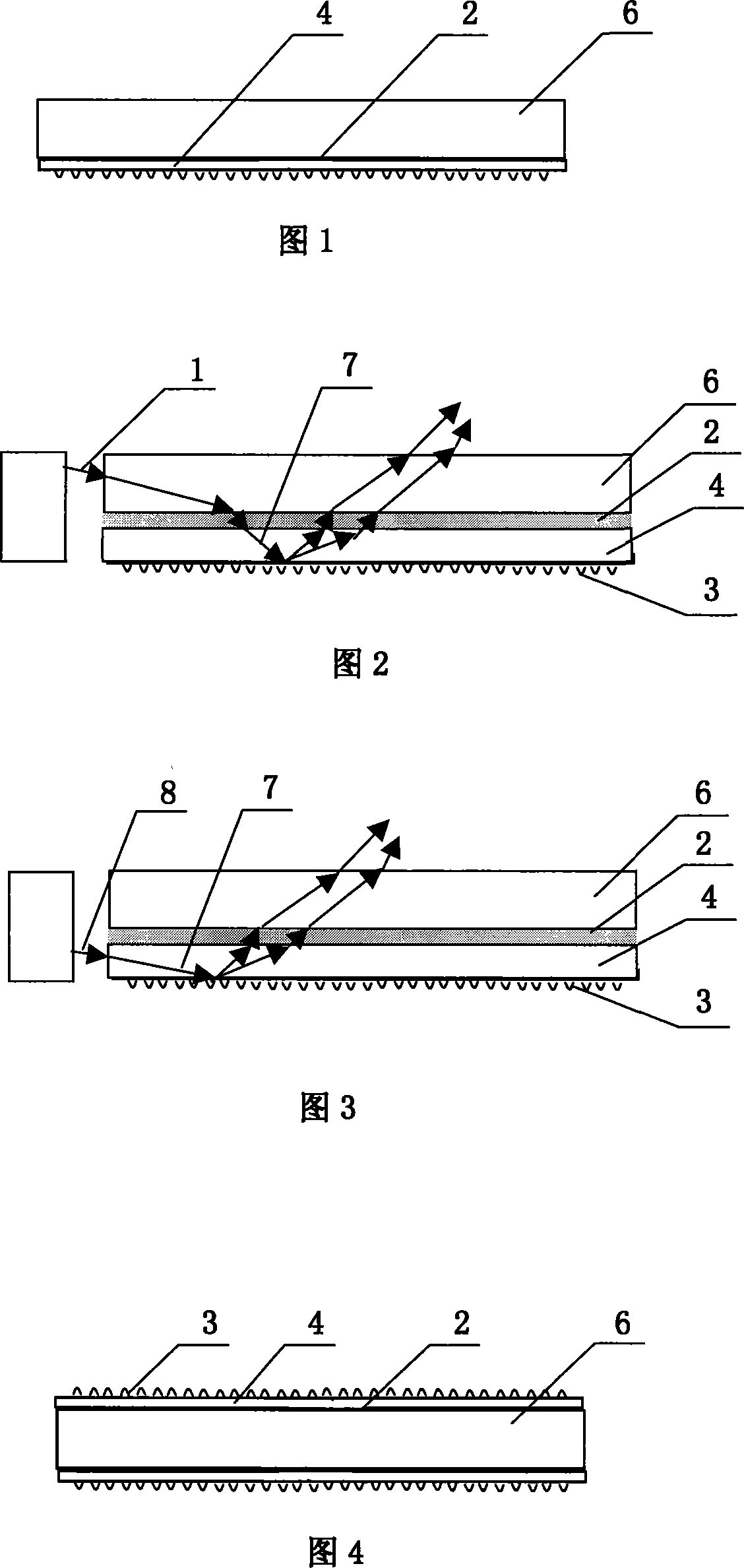

[0033] Embodiment 1: Referring to Fig. 1 to Fig. 3, Fig. 1 is a schematic diagram of a double-layer composite structure, wherein 6 is a PC board, 2 is a viscous composite material (light-curing resin), and 4 is a flexible light-guiding film after cutting. Its light guide principle is similar to the current general single-sided dot light guide plate.

[0034] The specific manufacturing process includes the following steps:

[0035] (1) making a metal mold for the production of the flexible light guide film 4;

[0036] (2) Fabricate flexible light-guiding film 4 by roll-to-roll micro-nano imprinting method;

[0037] (3) Coating the viscous substance cured resin on the non-dot surface of the flexible light guide film 4 by a roll-to-roll coating method;

[0038] (4) Precisely cut the light guide film 4 coated with photocurable resin according to the size of the light guide plate;

[0039] [5] Composite the slit light guide film 4 and the PC board 6 , and provide the process con...

Embodiment 2

[0042] Embodiment 2: Referring to Fig. 4, it is a schematic diagram of a three-layer composite structure, wherein 4 is a light guide film after cutting, 2 is a viscous composite material (high light-transmitting hot-melt adhesive), and 6 is a PMMA plate. The light guide principle of the three-layer structure is similar to the current light guide plate with double-sided dots on the upper and lower surfaces. The specific structure is as follows: two layers of flexible light guiding films 4 are provided, and the two layers of light guiding films 4 are respectively compounded on both sides of the PMMA sheet 6, and the outer surfaces of the two layers of light guiding films 4 are respectively provided with light guiding films. The inner surface of the dot 3 is coated with a high-transmittance hot-melt adhesive, and after heating, the light-guiding film is bonded to the PMMA plate.

Embodiment 3

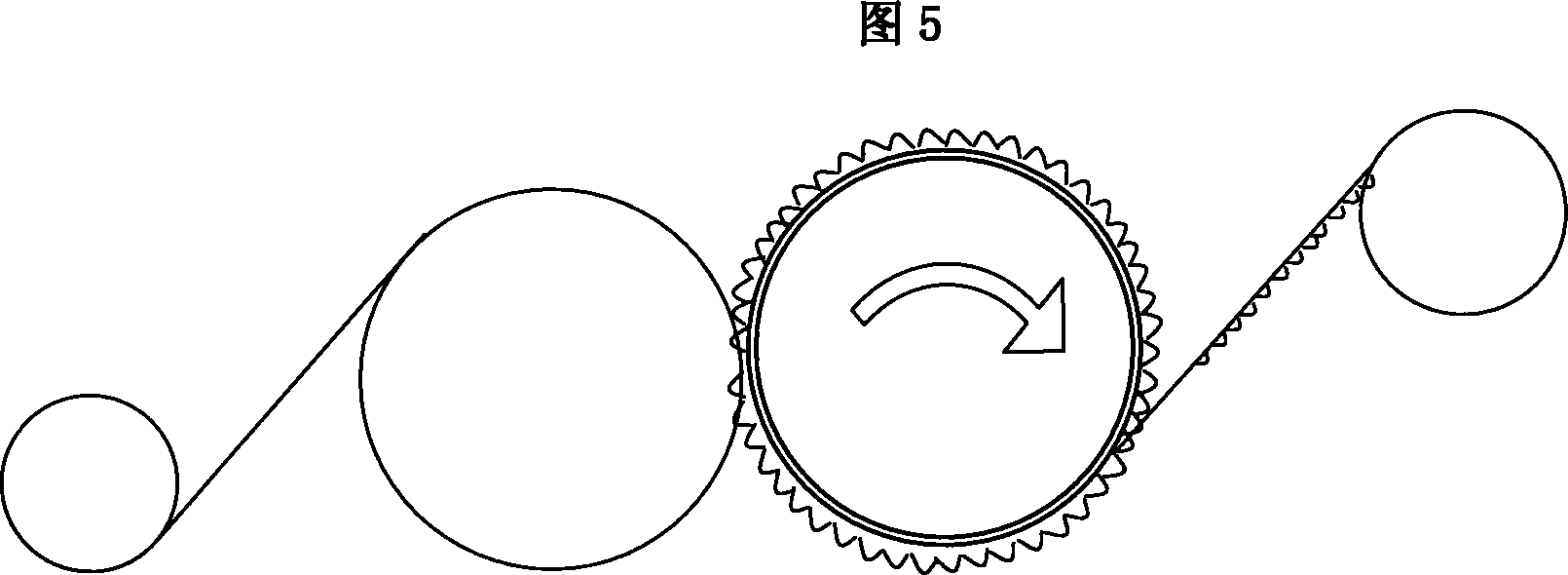

[0043] Embodiment 3: Refer to FIG. 5 , which is a schematic diagram of making a light guide film by roll-to-roll embossing. The embossing process uses the relative rotation of the driving roller and the driven roller to emboss the microstructured light guide dots on the surface of the mold core to the surface of the flexible PC film. The embossing process is line contact, and the plate roller rotates at a constant speed during the embossing process, so the pressure in the contact surface is very uniform. The roll of PC film is wound on the surface of the plate roll, and the embossing process is not limited by the area. At the same time, the speed of roll-to-roll embossing can reach tens of meters per second, which greatly improves production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com