Intelligent online uniformity adjusting system

A technology for adjusting the system and uniformity, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of different product quality, time-consuming and labor-intensive reaction speed, etc., to save labor investment, increase Throughput, the effect of achieving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is described in detail below, it should be pointed out that the technical solution of the present invention is not limited to the implementation manner described in the examples, those skilled in the art refer to and learn from the content of the technical solution of the present invention, on the basis of the present invention The improvement and design carried out above shall belong to the protection scope of the present invention.

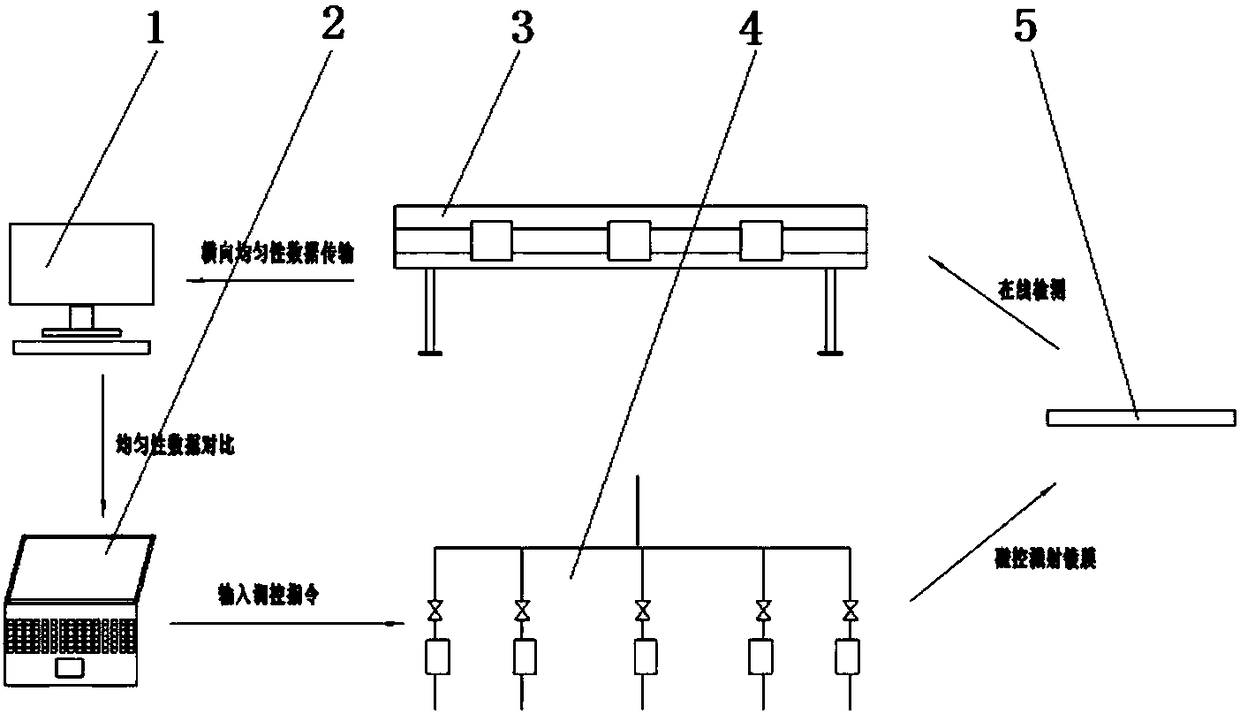

[0019] An intelligent online uniformity adjustment system, including: WinCC monitoring computer 1, uniformity comparison computer 3, online detection mechanism 2 and reaction gas control mechanism 4, WinCC monitoring computer 1, used for the monitoring system during the coating process of coated glass 5 The overall operation and signal transmission; the uniformity comparison computer 3, which transmits control instructions; the online detection mechanism 2, measures the lateral uniformity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com