Plasma processing device and processing method thereof

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems that the plasma density is easy to change, affect the uniformity and uniform distribution of substrate etching, and achieve increased plasma density, stable uniformity, Adjusting the Effects of Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

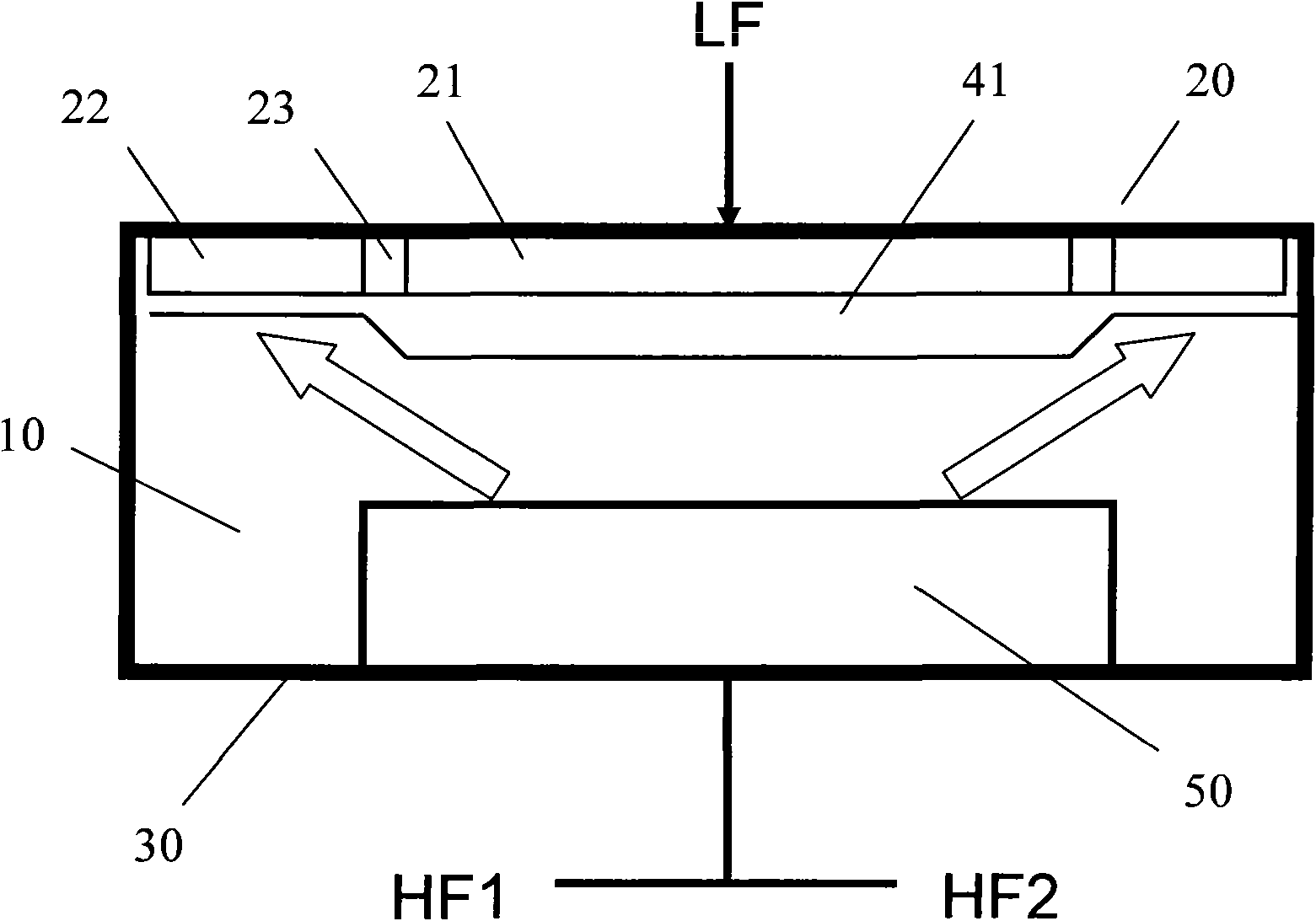

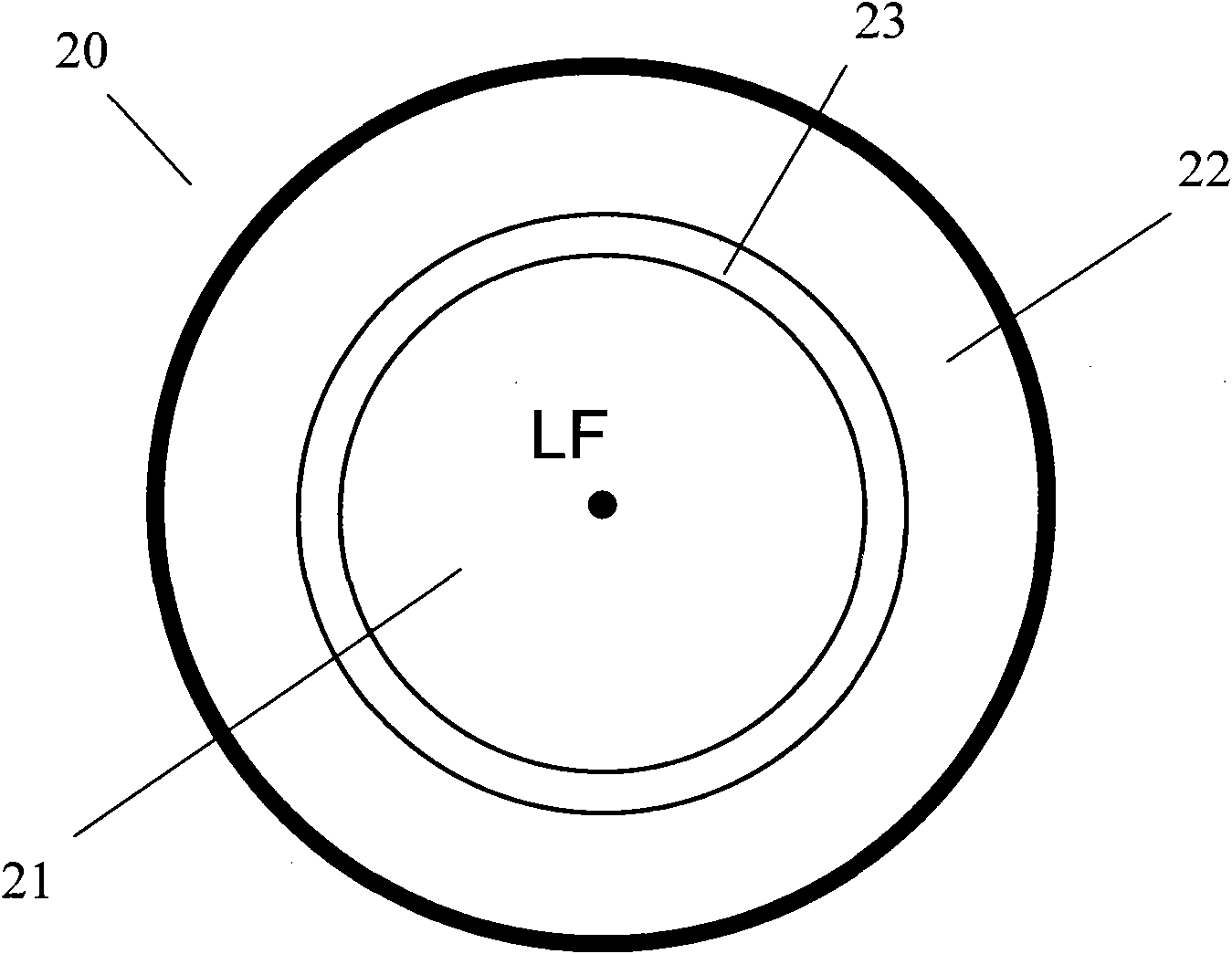

[0060] Please refer to figure 1 and figure 2 As shown, a plasma processing device provided by the present invention is used to generate gas plasma to react with the substrate 50 to realize etching and other processing of the substrate 50 . The capacitively coupled plasma processing device includes a processing chamber 10, an upper electrode 20 and a lower electrode 30 arranged in parallel in the processing chamber 10, an AC power supply LF connected to the upper electrode 20, and a first electrode connected to the lower electrode 30. RF power source HF1.

[0061] The processing chamber 10 is vacuumed, wherein a reactive gas for etching the substrate 50 is introduced, the reactive gas contains oxygen O 2 or nitrogen N 2 etching gas. The lower electrode 30 is horizontally arranged below the inside of the processing chamber 10 , and the substrate 50 to be processed is placed on the lower electrode 30 .

[0062] Corresponding to the lower electrode 30 , an upper electrode 20...

Embodiment 2

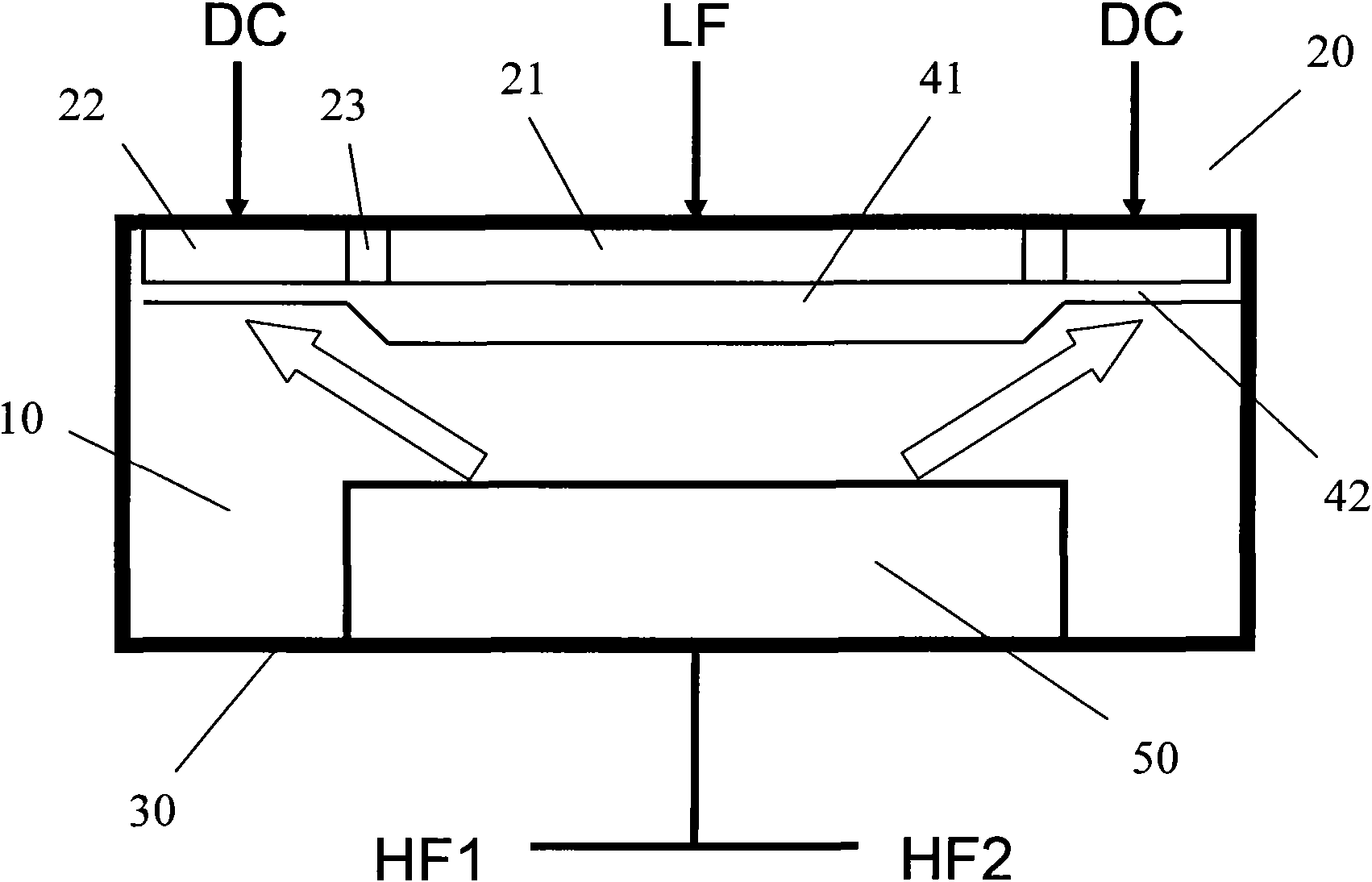

[0073] See image 3 As shown, this embodiment is similar to the overall structure of the plasma processing device provided in Embodiment 1, including a processing chamber 10 in which upper and lower electrodes are arranged in parallel; the lower electrode 30 is connected to the first radio frequency power source HF1, and can also be Simultaneously, a second radio frequency power source HF2 is applied. Among the several electrically insulating partitions provided on the upper electrode 20, an AC power source LF with adjustable voltage, current or power is applied to at least one partition respectively, and a first plasma sheath 41 is correspondingly formed in the processing chamber 10 below the partition, And the thickness of the generated first plasma sheath 41 can be controlled by adjusting the LF frequency of the AC power supply.

[0074] The only difference is that in this embodiment, a DC power supply DC with adjustable voltage, current or power is also applied to some of...

Embodiment 3

[0081] See Figure 4 As shown, this embodiment is similar to the overall structure of the plasma processing apparatus provided in Embodiment 1 and Embodiment 2, including a processing chamber 10 with upper and lower electrodes in parallel, and a first radio frequency power source is applied to the lower electrode 30 HF1 may also be applied with the second radio frequency power source HF2 at the same time, and the upper electrode 20 is divided into an inner upper electrode 21 and an outer upper electrode 22 which are electrically insulated from each other.

[0082] The difference of this embodiment is that the outer upper electrode 22 is connected to the AC power source LF with adjustable voltage, current or power as described in Embodiment 1, and the first plasma sheath 41 is formed under the outer upper electrode 22 .

[0083] In some embodiments, it is also possible to choose to apply a direct current power supply DC with adjustable voltage, current or power as described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com