Self-luminous road pavement structure and construction method thereof

A technology of road pavement and construction method, which is applied in the field of self-illuminating road pavement structure and its construction, can solve the problems of gravel embedding in unstable soil foundation, easy water accumulation and gaps, etc., to achieve the elimination of instability, strong process versatility, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

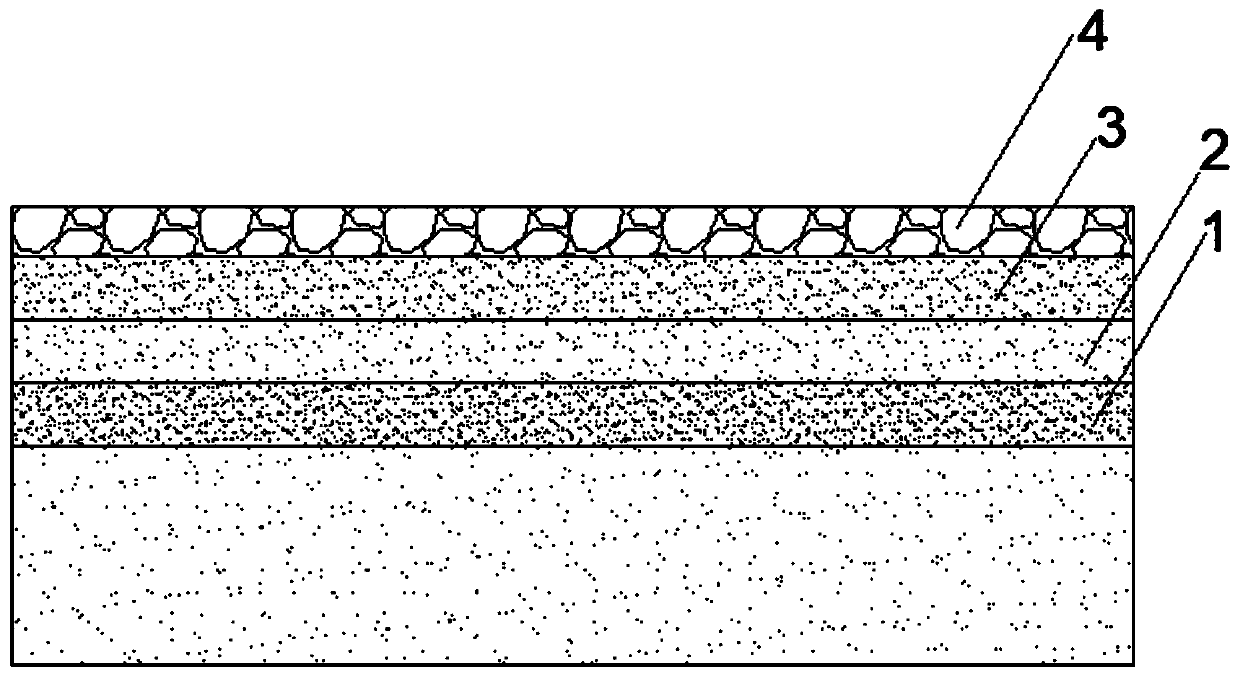

[0021] In this embodiment, a self-luminous road pavement structure is provided, including a water-sealed layer 1, a water-conducting layer 2, a water-permeable layer 3 and a self-luminous surface layer 4 arranged layer by layer from bottom to top, and the self-luminous surface layer 4 is filled with Artificial glow stone particles.

[0022] The thickness of the water sealing layer 1 is 10cm, and the compressive strength of the water sealing layer is 2.0Mpa; the raw materials of the water sealing layer include ordinary Portland cement and continuous graded crushed stone with a particle size of 1cm; The cement stabilized stone is poured, and the raw material of the low-grade cement stabilized stone is slag Portland cement or pozzolanic cement.

[0023] The thickness of the water-guiding layer 2 is 10 cm, and the raw material of the water-guiding layer includes continuously graded crushed stones with a particle size of 2-5 cm.

[0024] The permeable layer 3 is formed by pouring ...

Embodiment 2

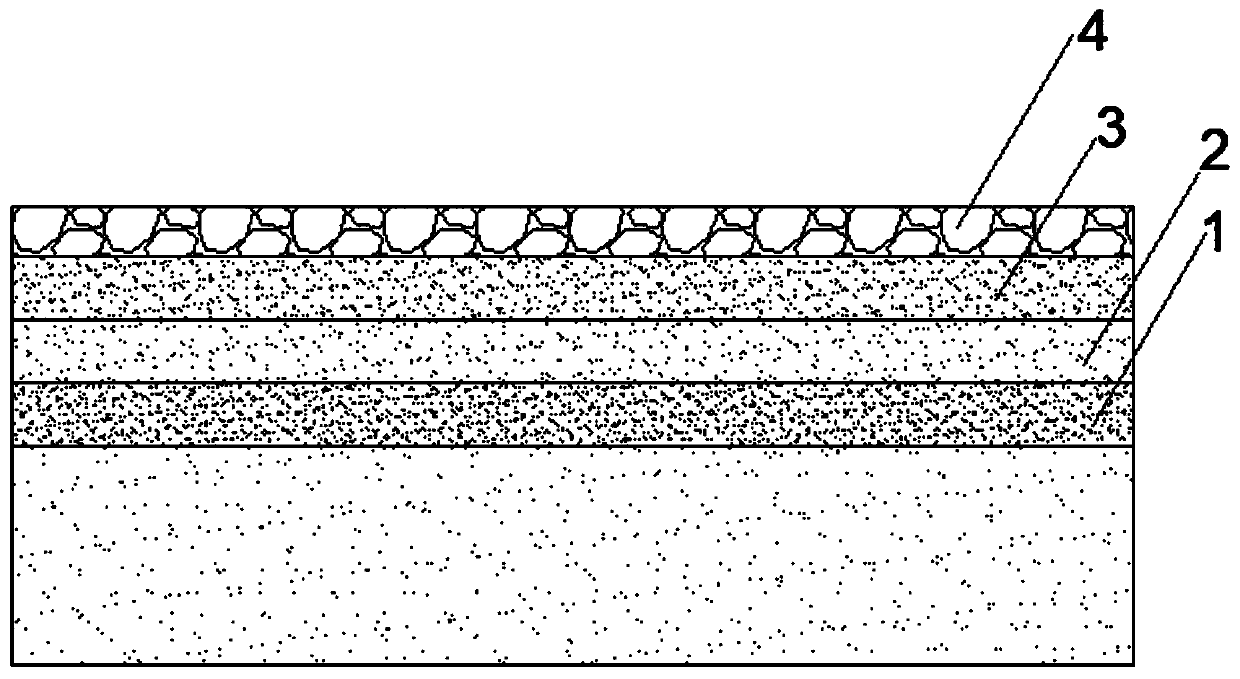

[0029] In this embodiment, a self-luminous road pavement structure is provided, including a water-sealed layer 1, a water-conducting layer 2, a water-permeable layer 3 and a self-luminous surface layer 4 arranged layer by layer from bottom to top, and the self-luminous surface layer 4 is filled with Artificial glow stone particles.

[0030] The thickness of the water sealing layer is 40cm, and the compressive strength of the water sealing layer is 6.0Mpa; the raw materials of the water sealing layer include ordinary Portland cement and continuous graded crushed stone with a particle size of 1-3cm. The water sealing layer is poured with low-grade cement stabilized stone, and the raw material of the low-grade cement stabilized stone is ordinary Portland cement.

[0031] The thickness of the water-conducting layer is 40 cm, and the raw material of the water-conducting layer includes continuously graded gravel with a particle size of 2-5 cm.

[0032] The permeable layer 3 is form...

Embodiment 3

[0037] On the basis of Example 1, the difference of Example 3 lies in the proportion of pervious concrete. In this example, the permeable concrete includes the following raw materials in parts by weight: 410Kg of cement, 130Kg of water, 1550Kg of aggregate, and 5Kg of water reducer , latex powder or nano-silica powder 16Kg.

[0038] Wherein, cement: water: aggregate: water reducer: latex powder or nano-silica powder = 1: 0.33: 3.97: 0.013: 0.041; the porosity of this mix ratio is 21%, and the water permeability coefficient is 13.6mm / s. The compressive strength is 33.8Mpa and the flexural strength is 3.5Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com