Porous medium liquid film small-channel cooling device

A technology of porous media and cooling device, which is applied in the direction of modification with liquid cooling, modification with cooling/ventilation/heating, modification with gaseous coolant, etc. It can solve the problem that the steam cannot be dissipated in time, affecting the cooling performance of equipment, and it is difficult to simultaneously Implementation and other issues to achieve the effect of shortening cooling time, decoupling connection and conflict, and efficient cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

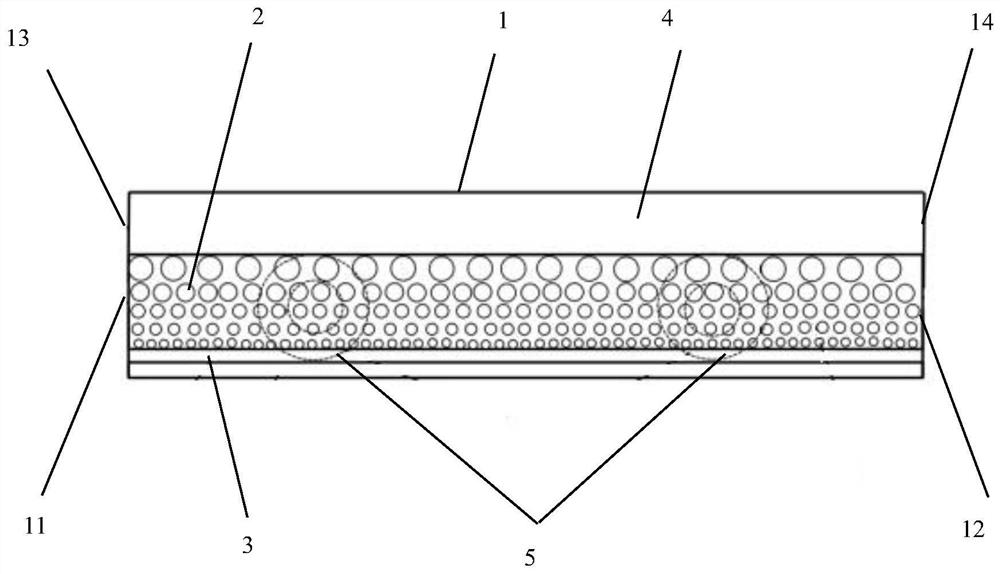

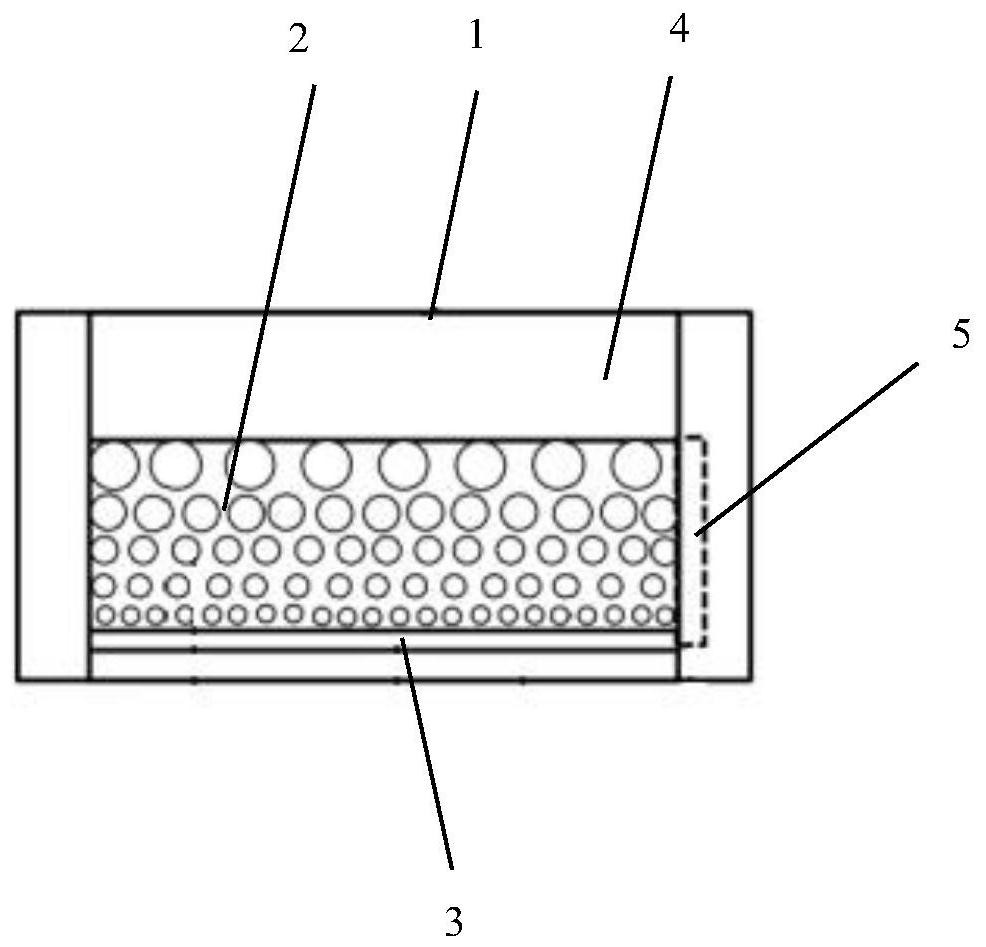

[0029] A porous medium liquid film small channel cooling device provided by an embodiment of the present invention, please refer to figure 1 , figure 2 and image 3 As shown, the channel cooling body 1 is included, and the channel cooling body 1 is a cuboid hollow structure. The channel cooling body 1 is provided with a porous structure 2 along the lateral direction. The porous structure 2 divides the channel cooling body 1 into upper and lower cavities. The porous structure Between the lower surface of the channel cooling body 1 and the inner bottom of the channel cooling body 1 is a flowing liquid film layer 3, between the upper surface of the porous structure 2 and the inner top of the channel cooling body 1 is an air evaporation channel 4, and the inner wall of the channel cooling body 1 is embedded An ultrasonic generator 5 is provided, and the ultrasonic generator 5 is located on one side of the porous structure 2. The ultrasonic waves emitted by the ultrasonic generat...

Embodiment 2

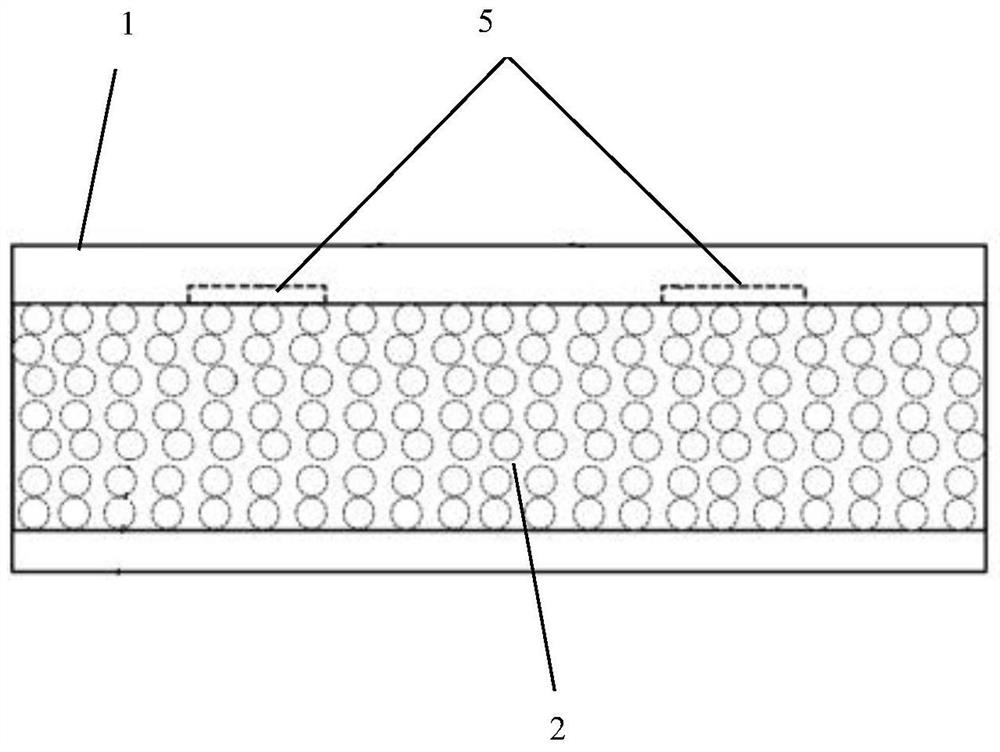

[0036] A porous medium liquid film small channel cooling device provided by an embodiment of the present invention, please refer to Figure 4 , Figure 5 and Figure 6As shown, the channel cooling body 1 is included, and the channel cooling body 1 is a cuboid hollow structure. The channel cooling body 1 is provided with a porous structure 2 along the lateral direction. The porous structure 2 divides the channel cooling body 1 into upper and lower cavities. The porous structure Between the lower surface of the channel cooling body 1 and the inner bottom of the channel cooling body 1 is a flowing liquid film layer 3, between the upper surface of the porous structure 2 and the inner top of the channel cooling body 1 is an air evaporation channel 4, and the inner wall of the channel cooling body 1 is embedded An ultrasonic generator 5 is provided, and the ultrasonic generator 5 is located on one side of the porous structure 2. One end of the channel cooling main body 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com