Catalyst carrier for olefin polymerization, preparation method and application thereof

A catalyst carrier and olefin polymerization technology, applied in the polymer field, can solve the problems affecting the continuous progress of the catalyst carrier preparation process for olefin polymerization, nozzle blockage, material blockage, etc., and achieve the effects of avoiding blockage, reducing production costs and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] According to a first aspect of the present invention, the present invention provides a method for preparing a catalyst carrier for olefin polymerization, the preparation method comprising:

[0024] 1) reacting the magnesium compound, the first alcohol compound and the oxirane compound optionally in the presence of an inert liquid medium to obtain a solid substance;

[0025] 2) Dissolving the solid substance in the second alcohol compound for emulsification to obtain a fluid mixed substance;

[0026] 3) solidifying the fluid mixed substance by spraying to obtain the catalyst carrier for olefin polymerization; wherein,

[0027] The general formula of the magnesium compound is MgXY, X is halogen, and Y is selected from halogen, or one of the following substituted or unsubstituted groups: C 1 ~C 14 Alkyl, C 1 ~C 14 Alkoxy, C 6 ~C 14 Aryl, C 6 ~C 14 Aryloxy;

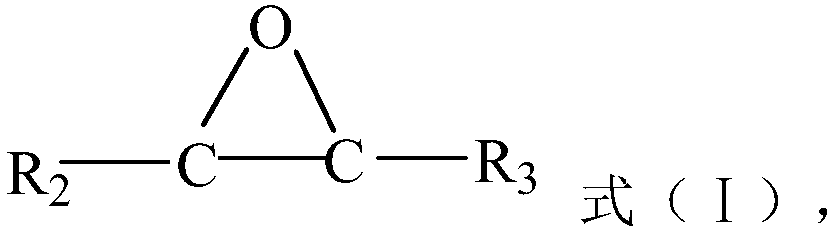

[0028] The general formula of the first alcohol compound is R 1 OH,R 1 for C 1 ~C 8 Alkyl or C 3 ~C 8...

Embodiment 1

[0085] This example is used to illustrate the preparation method of the catalyst carrier for olefin polymerization and the prepared catalyst carrier for olefin polymerization of the present invention.

[0086] In a 0.6L reaction kettle, add 0.08mol magnesium chloride and 1.6mol ethanol, heat up to 90°C under stirring, and after constant temperature reaction for 1 hour, add 0.42mol of epichlorohydrin, and press filter after 0.5 hour of reaction. Add 1.5mol ethanol, adopt high-speed agitation (2800rm) to carry out emulsification to form a fluid mixed substance, and use a sprayer containing a nozzle head and a material conduit to spray the fluid mixed substance into the 100°C circulating nitrogen in the sprayer tower body, The temperature of the fluid mixed substance in the material conduit is 15°C, and the temperature in the nozzle head is 120°C. The obtained solidified product was washed 4 times with hexane, and dried in vacuum for 1 h to obtain the catalyst carrier Z1.

[008...

Embodiment 2

[0090] This example is used to illustrate the preparation method of the catalyst carrier for olefin polymerization and the prepared catalyst carrier for olefin polymerization of the present invention.

[0091] In a 0.6L reactor, add 0.08mol magnesium chloride and 1.4mol ethanol, heat up to 90°C under stirring, and after 1.5 hours of constant temperature reaction, add 0.35mol of epichlorohydrin, press filter after 0.5 hours of reaction, and add 1.6mol of ethanol , using high-speed stirring (2800rm) to emulsify to form a fluid mixed substance, and use a sprayer containing a nozzle head and a material conduit to spray the fluid mixed substance into the white oil at 120 °C in the sprayer tower body, the fluidized The mixed mass had a temperature of 15°C in the material conduit and 120°C in the nozzle head. The obtained solidified product was washed 4 times with hexane, and dried in vacuum for 1 h to obtain the catalyst carrier Z2.

[0092] During the preparation of the catalyst c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com