Sand bag brick capable of realizing mutual adhesion and connection

A sandbag brick and woven bag technology, applied in the field of sandbag bricks, can solve the problems of poor strength and impact resistance, irregular geometry, unstable sandbag masonry, etc. The effect of the quick masonry feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The sandbag brick that can be mutually adhered of the present invention is realized in this way, and is described in detail below in conjunction with accompanying drawing.

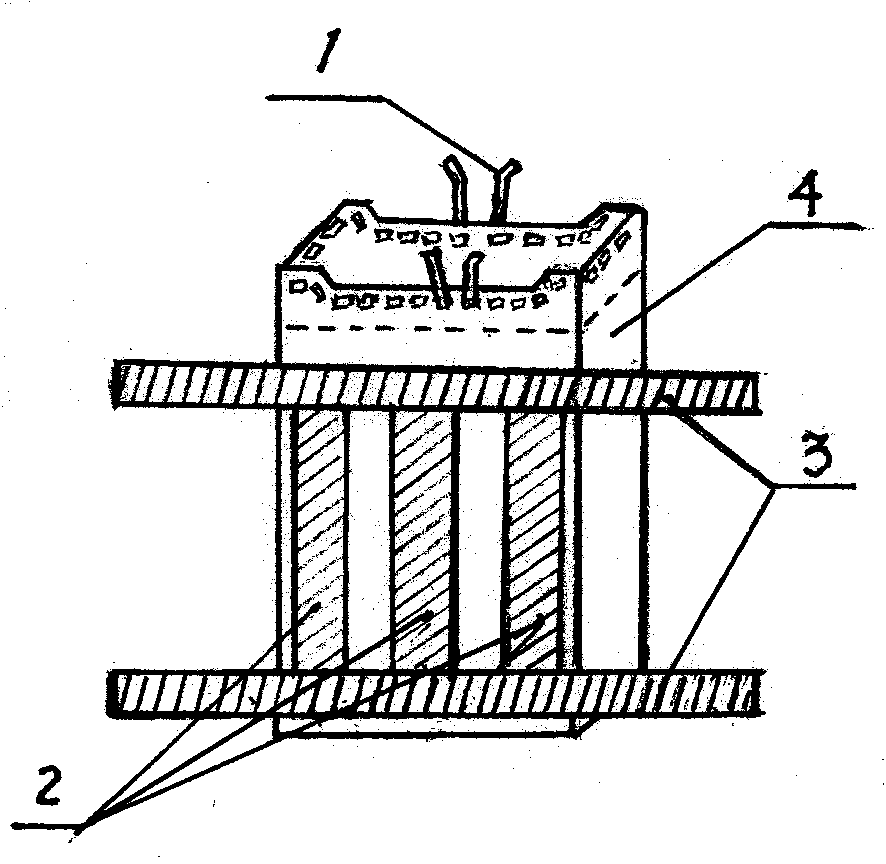

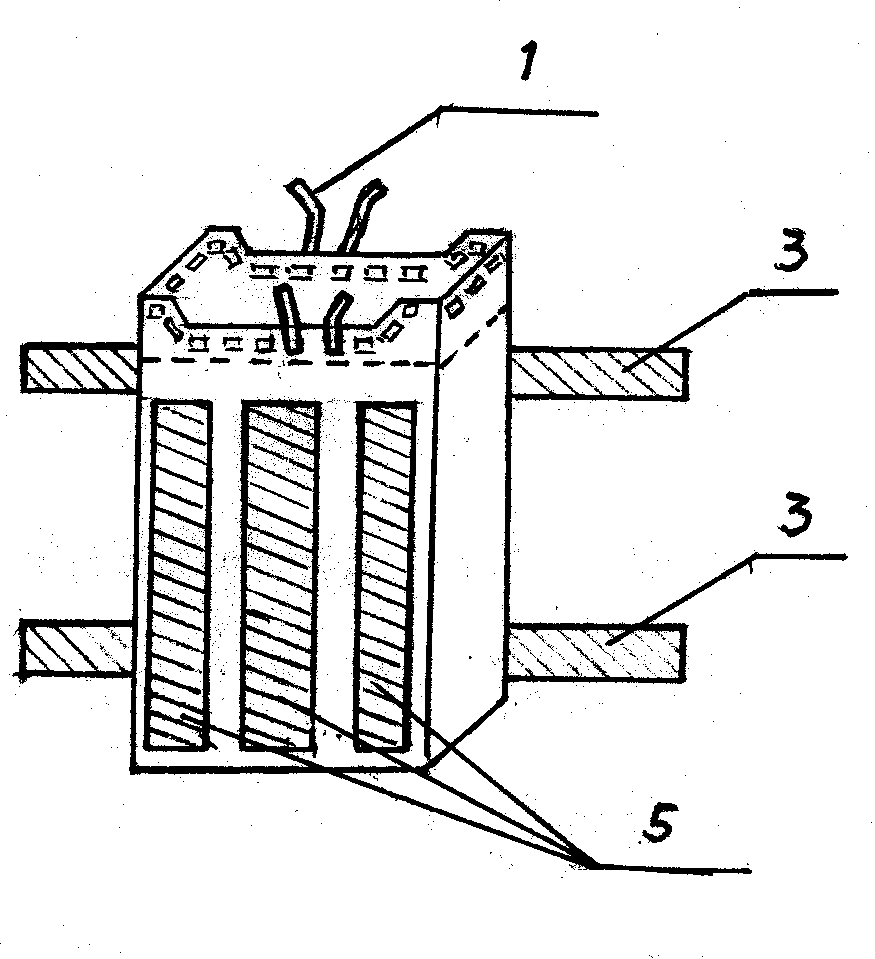

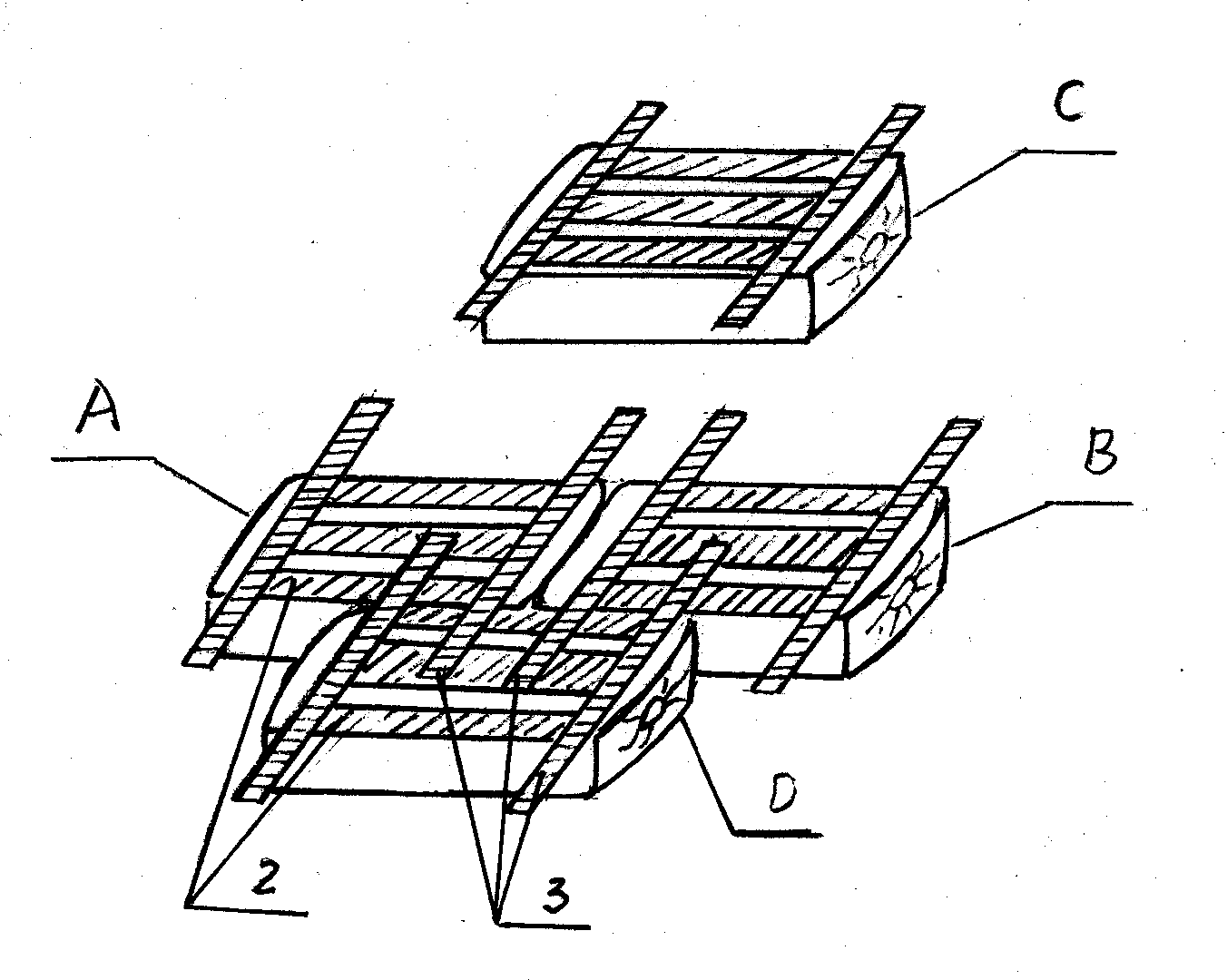

[0016] See figure 1 , figure 2 , the sandbag bricks that can adhere to each other in the present invention are composed of tightening rope 1, bristle Velcro 2, double-sided Velcro tape 3, woven bag 4 and round hair velcro 5, and woven bag 4 is made of polyethylene or polypropylene The woven material is made into a cuboid shape, the edge of the bag mouth is in the shape of a groove, and two tightening ropes 1 are arranged in a trapezoidal shape along the edge of the bag mouth; Tape 3 is arranged on the bristle Velcro 2; The back side of cuboid shape woven bag 4 is provided with round hair Velcro 5; After the woven bag 4 is filled with sand and soil, two tightening ropes 1 are tightened simultaneously, and the mouth of the bag is closed. Tighten and tie the two tightening ropes to form sandbag bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com