Jumping bin bricklaying method of light-weight brick furnace wall of annealing furnace

A technology for annealing furnaces and furnace walls, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as low compressive strength and flexural strength, cracking of bricks, and damage to the overall structure of the furnace wall. Long life, saving total cost, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A light-weight brick furnace wall jumping masonry method for an annealing furnace, which is implemented in sequence according to the following steps:

[0036] ① Preparation: including modeling, setting out and arrangement:

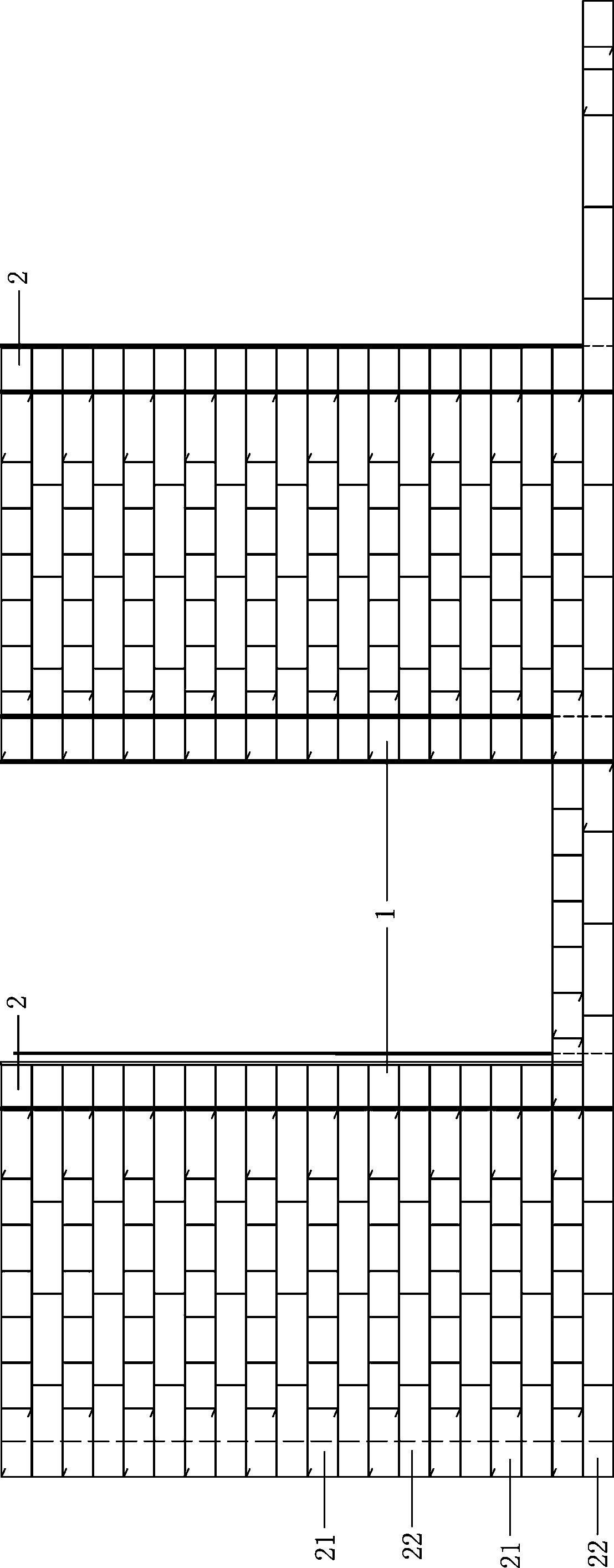

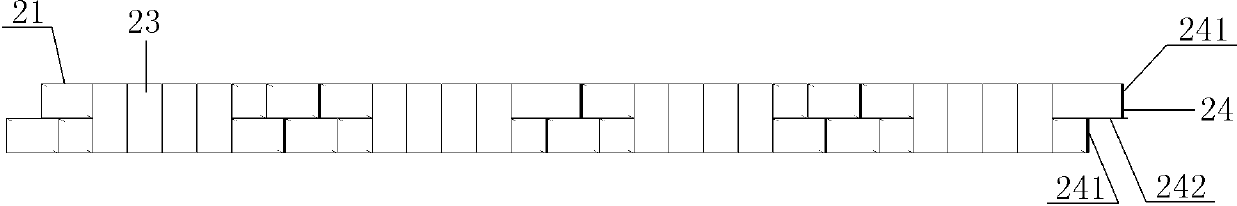

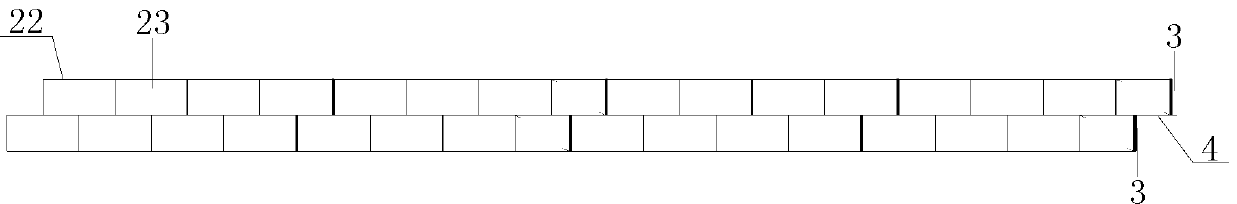

[0037] Modeling: Including referring to the size of the brick, the expansion coefficient of the brick and the total length of the furnace wall 1 according to the construction drawings and specifications, using a computer to simulate the width of each furnace wall plate 2 and expansion joint 3, and the combination of the furnace wall 1 build method;

[0038] Line setting: also known as line drawing, draw the width of each furnace wall plate 2 and the width of the expansion joint 3 between adjacent furnace wall plates 2 on the furnace shell in sequence according to the value determined by computer simulation;

[0039] Arrangement: According to the computer simulation, prearrange the assembly structure of each furnace wall plate 2, and pre-arrange the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com