Patents

Literature

50results about How to "Guarantee the quality of masonry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

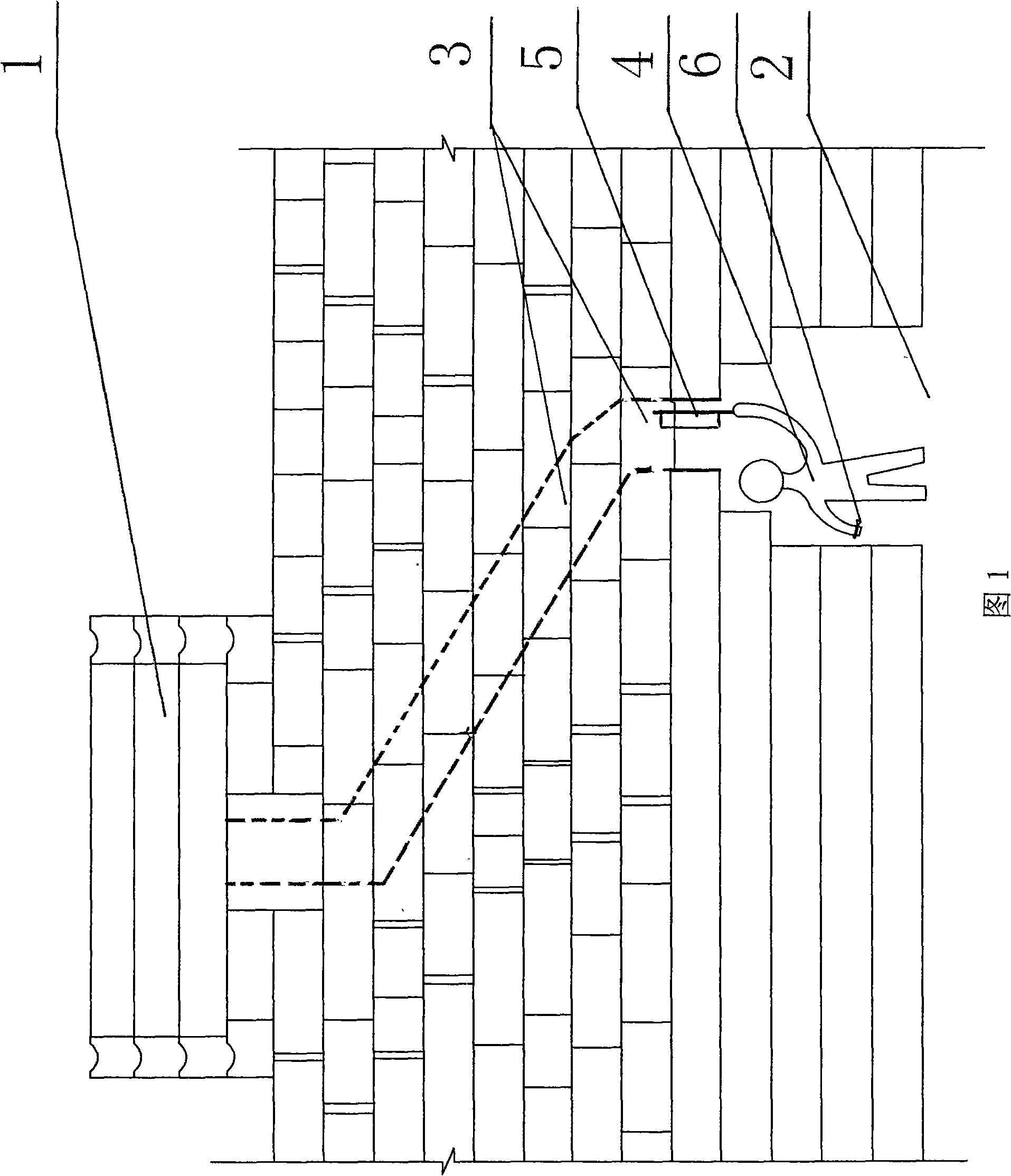

Building and supporting method for semiring brick on hoogoven's warm-air duct inside lining

InactiveCN101509051AEasy to control masonry qualityGuarantee the quality of masonryBrick-hot blast stovesBrickEngineering

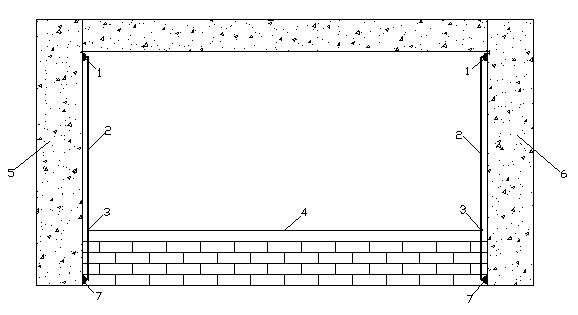

The invention relates to a method for supporting lining upper semiring masonry of hoogoven type warm-air duct, comprising the steps that bricking is carried out from external ring to internal ring, hidden construction is changed into open-type construction, and thin bamboo strips and assorted boards are utilized to temporarily support the masonry during bricking up light bricks and heavy bricks; wherein, two ends of the boards are put on the lining lower semiring of the duct, the upper ends of the thin bamboo strips are utilized to prop the upper semiring masonry being bricked up, the lower ends of the thin bamboo strips are exerted on the boards and prevented from sliding by the transverse parting strips on the boards, and the thin bamboo strips are taken down after the slurry is dried or the upper semiring is closed; and the thin bamboo strips and the boards are dismounted after the bricking is finished. The invention replaces the traditional support method by wooden arch stuffing to support the lining upper semiring masonry by the thin bamboo strips and the boards, thereby not only being convenient for construction but also good for improving masonry quality of lining upper semiring bricks of the duct.

Owner:CHINA FIRST METALLURGICAL GROUP

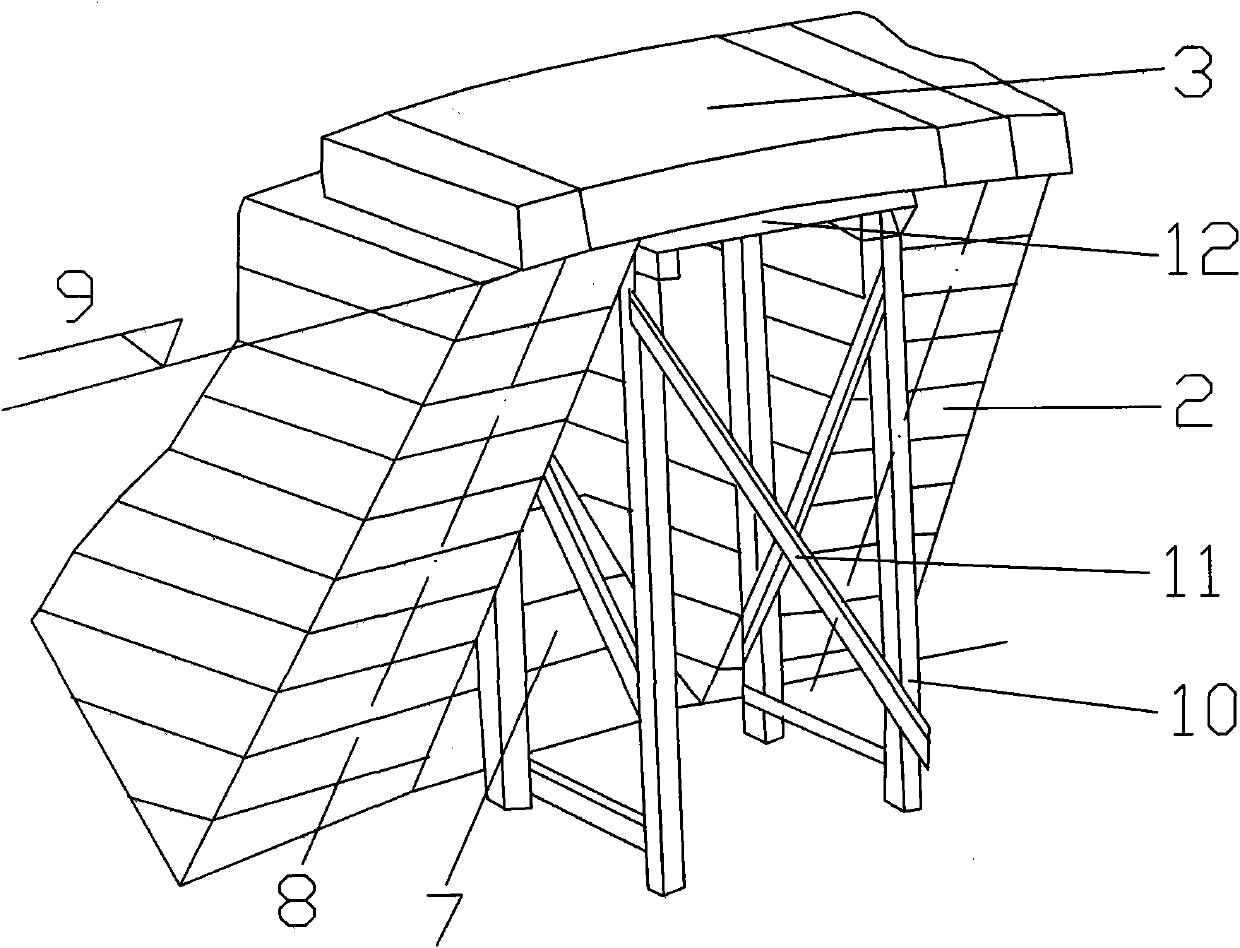

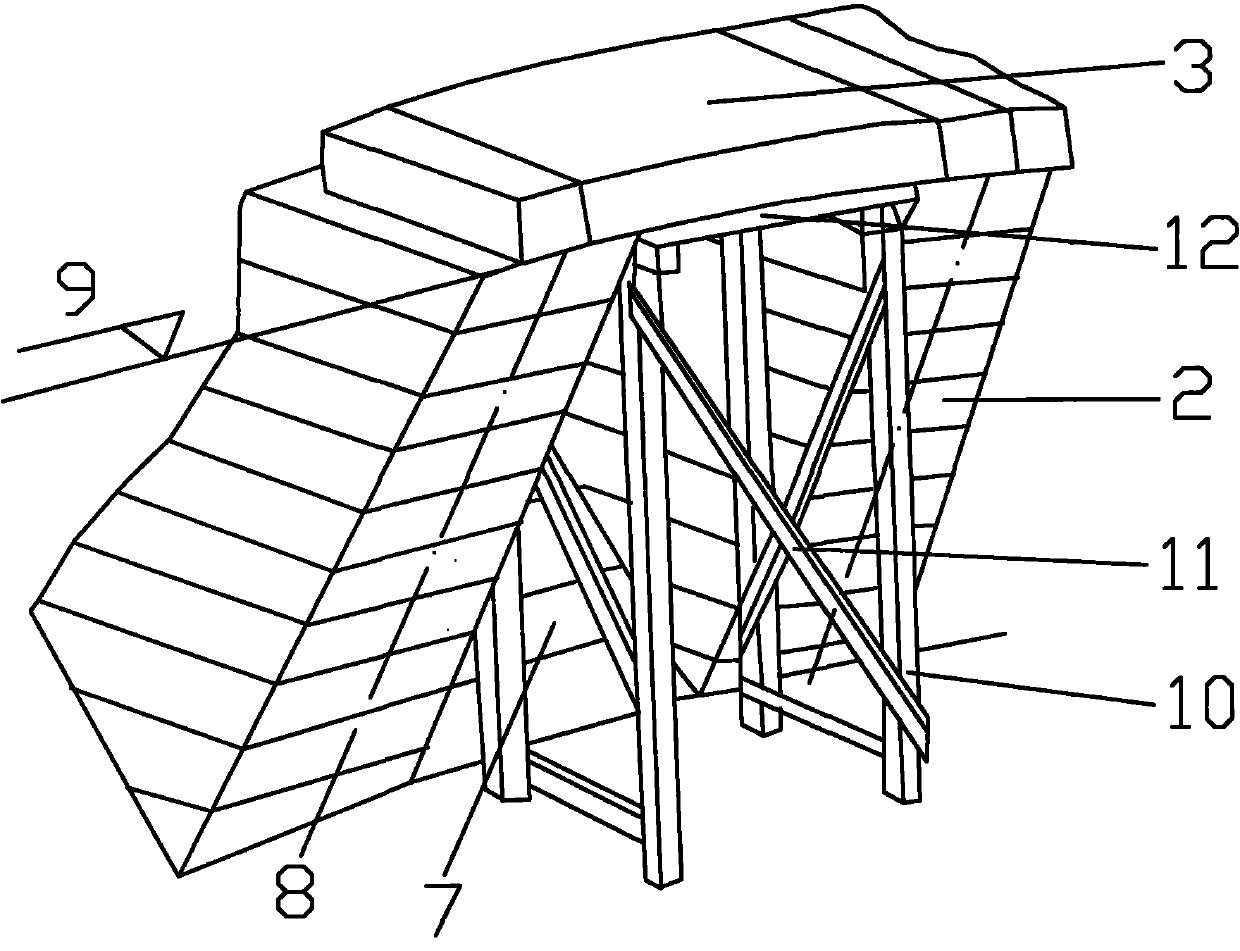

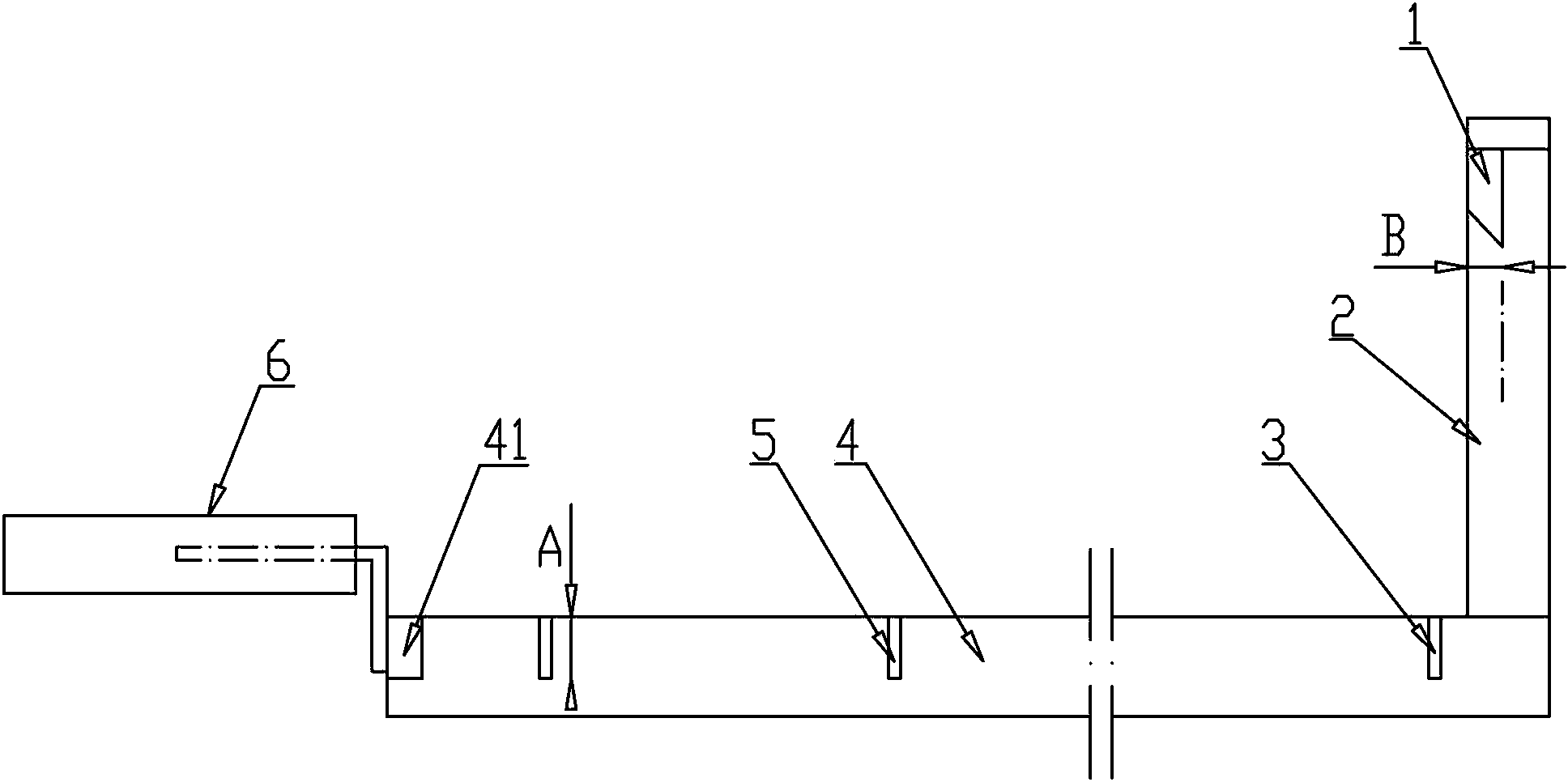

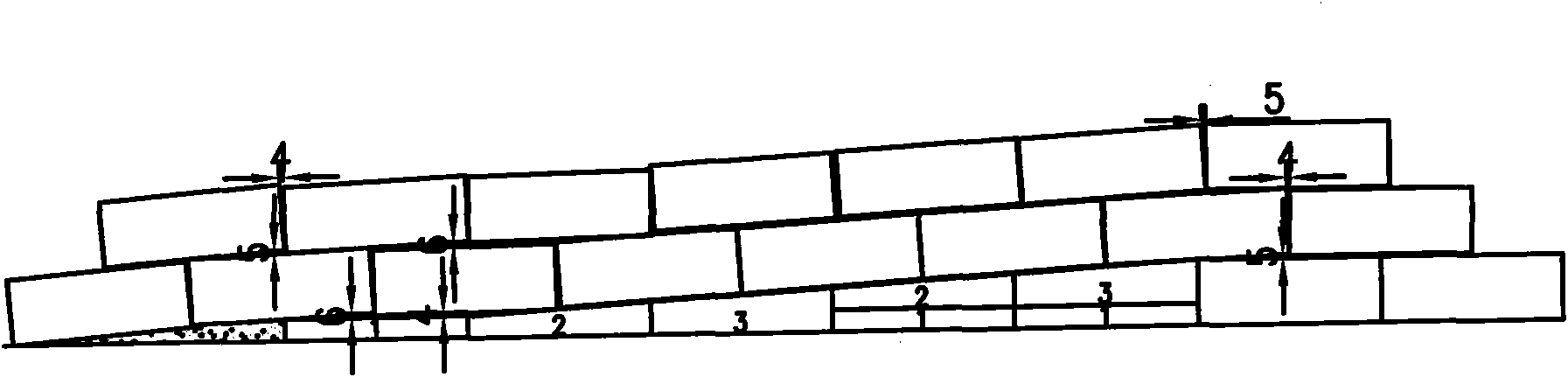

Novel method for building slope air course of coke dry quenching furnace

InactiveCN101948697AGuarantee the quality of masonryCoke quenchingFixed frameUltimate tensile strength

The invention relates to the technical field of coke dry quenching production processes, particularly provides a novel method for building a slope air course of a coke dry quenching furnace. The method comprises the following steps of: controlling the elevation of each layer of bricks for building the bracket of the slope air course by adopting a special control plate, filling mortar joints, and only building four layers each day at a building temperature of 5-35 DEG C to ensure that the top elevation of the bracket reaches design requirements and the mortar joints reach a certain strength; discharging a shaft line from each bracket, marking on the bracket, upward leading along a building height, ensuring that the shaft line of the bracket meets design, placing and stressing an overhead brick uniformly; and in the process of building the overhead brick, arranging a steel support fixing frame which can bear a large load for decomposing the stress of the bracket of the slope air course. According to the invention, the quality accidents of the coke dry quenching furnace that the brickworks in a lower slope air course area deform, collapse and the like in the building process of an annular air course, and the building qualities of the slope air course, an upper annular air course and a pre-storing section are ensured so that the quality of the brickworks in the slope air course area can reach code requirements.

Owner:中国十九冶集团有限公司湖北分公司

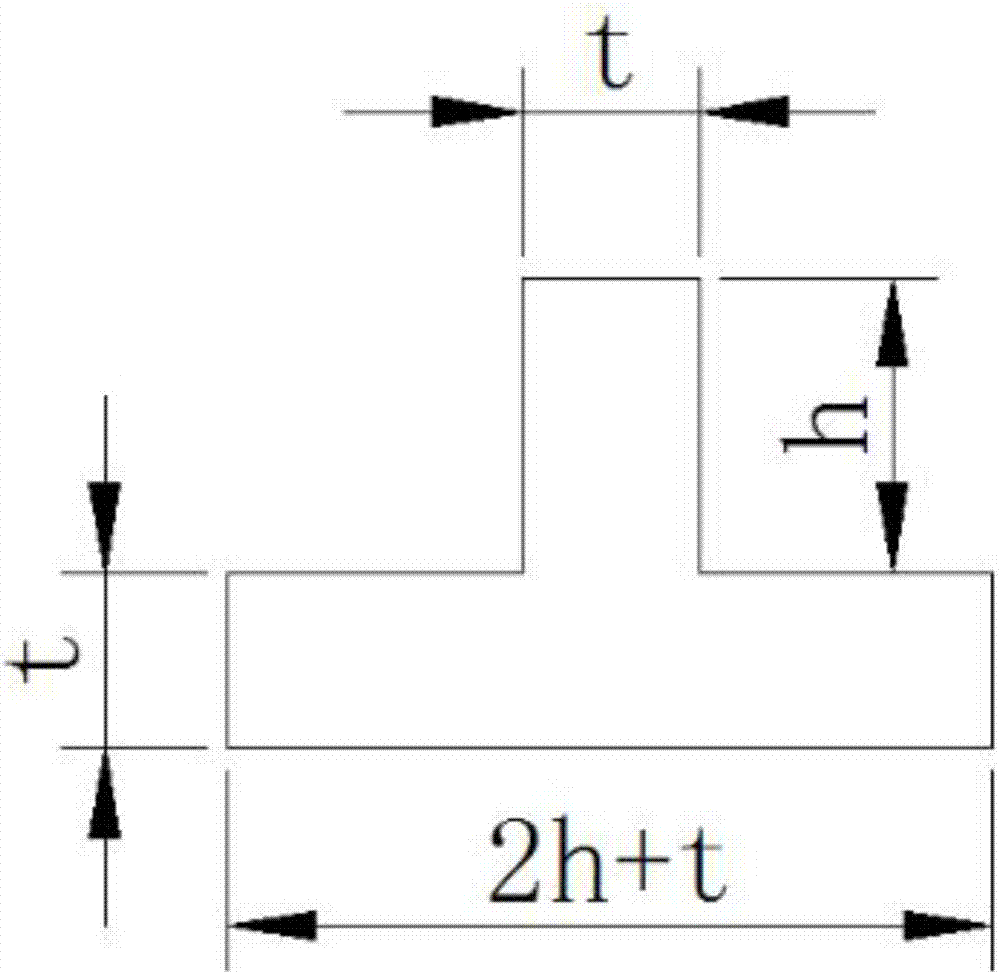

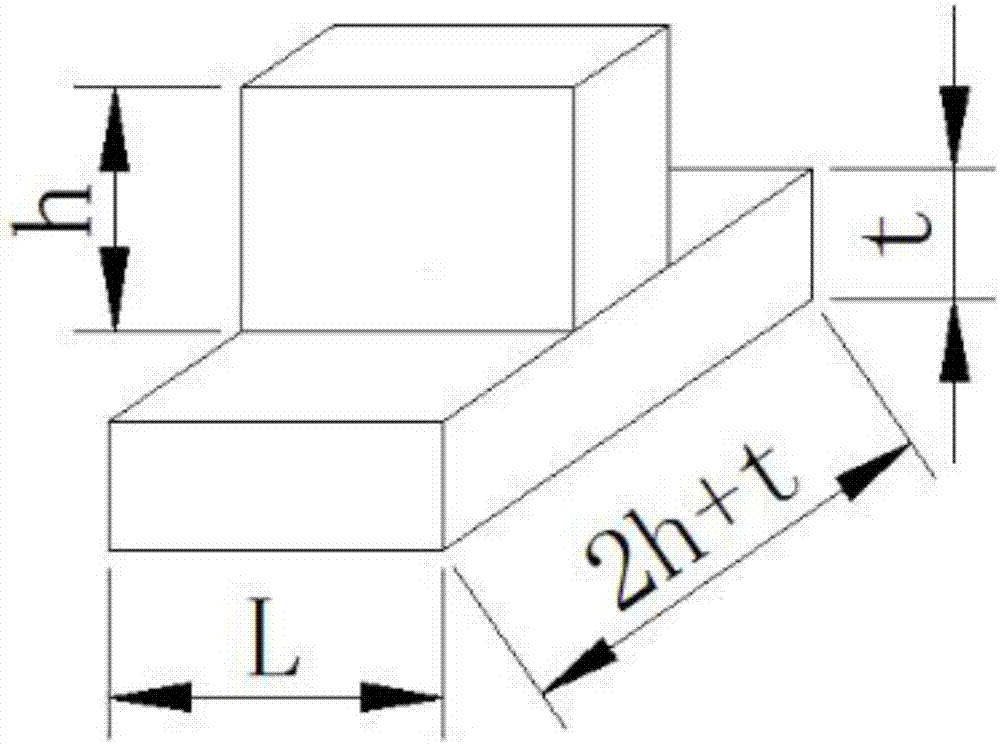

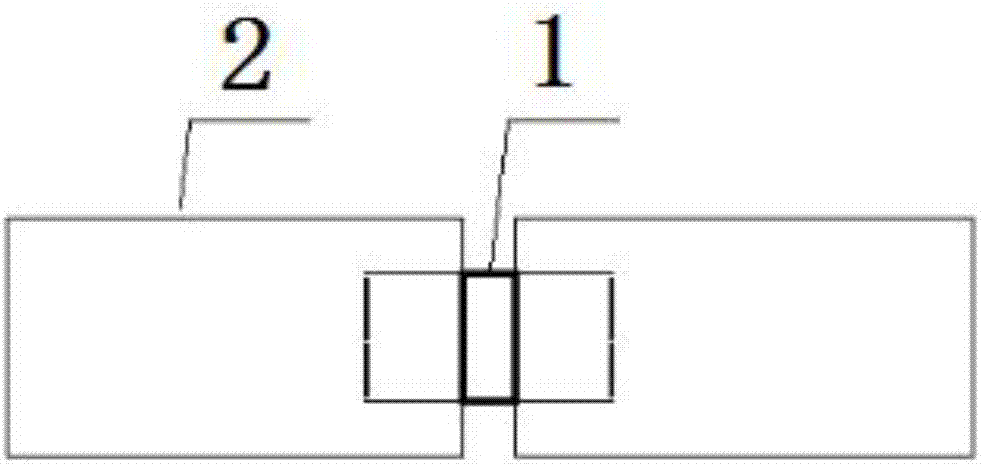

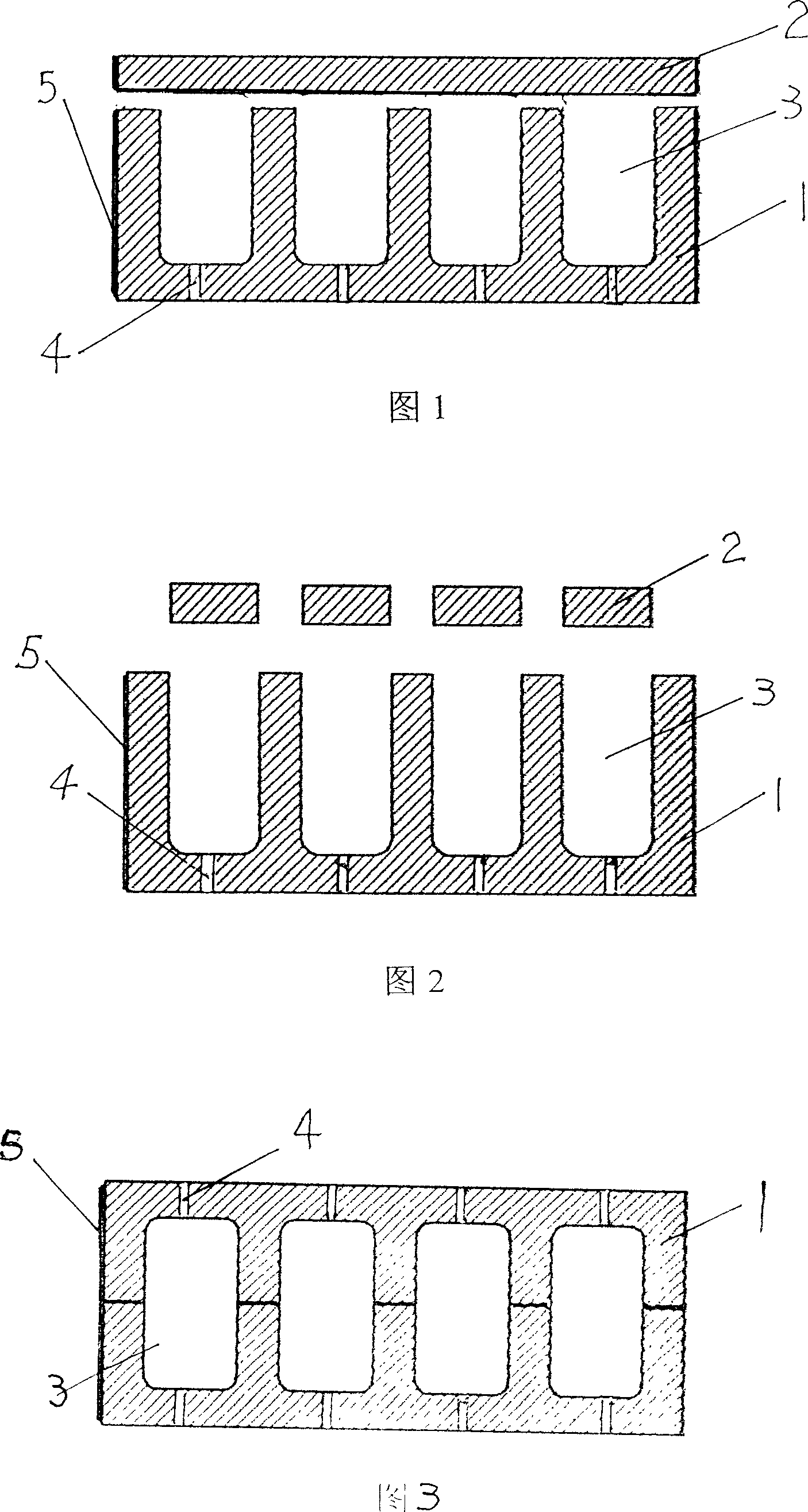

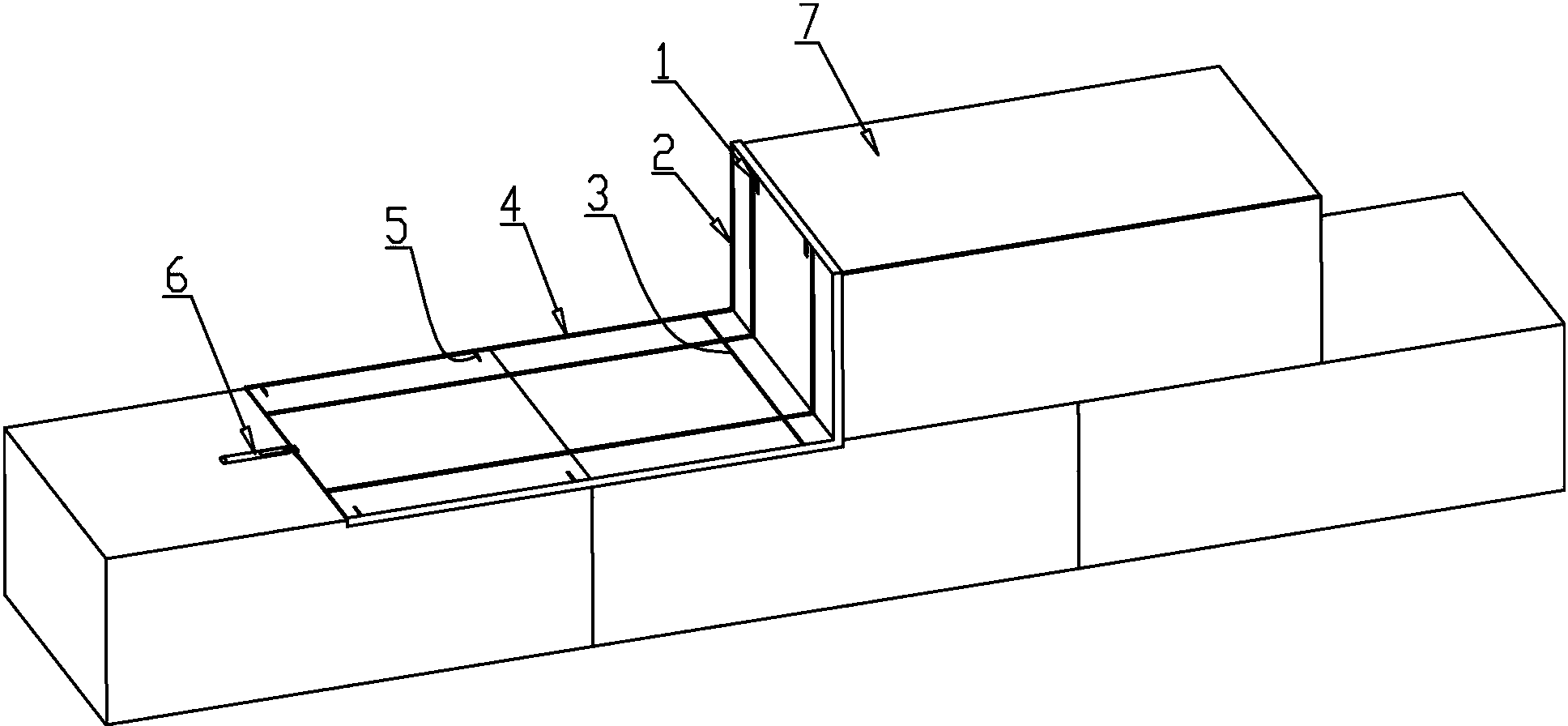

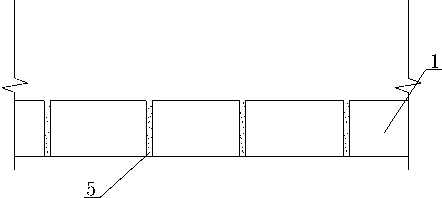

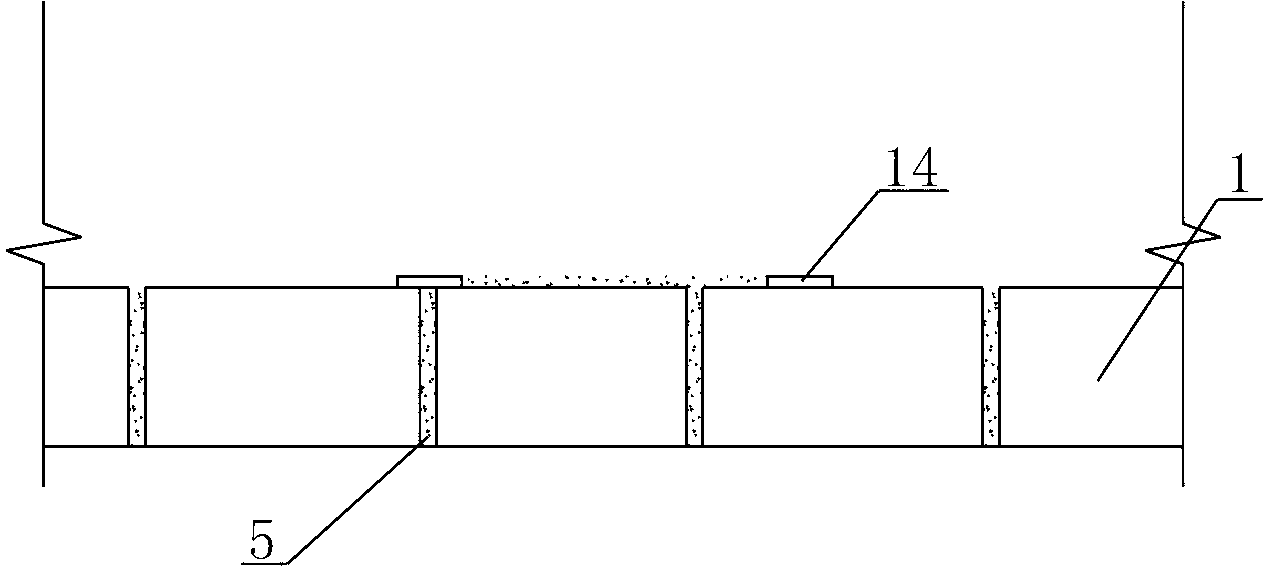

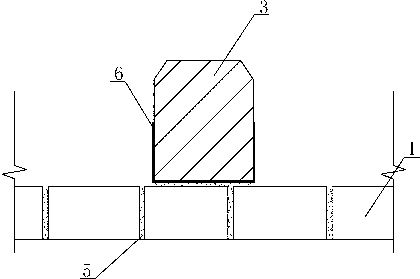

Construction method for controlling masonry horizontal mortar joint thickness and vertical masonry mortar joint width

InactiveCN107246149ANo need for limited construction techniquesNo need for restricted visionBuilding material handlingMortar jointBuilding construction

The invention discloses a construction method for controlling the masonry horizontal mortar joint thickness and the vertical masonry mortar joint width. The method comprises the steps of manufacturing a mortar joint control member, ejecting a masonry axial line and edge line, cleaning a base and marshaling a bottom layer masonry unit, arranging a mortar joint control member and completing masonry marshaling. The construction method for controlling the masonry horizontal mortar joint thickness and the vertical masonry mortar joint width has the advantages of being easy to operate, being not limited by construction technologies and visual deviation of marshaling personnel, being convenient to construct, being capable of controlling the thickness of a horizontal mortar joint and the width of a vertical mortar joint at any time in the marshaling process, and therefore providing powerful guarantee for improving the construction efficiency; the adopted mortar joint control member is prefabricated by adopting concrete remained in casting in a united way, waste can be turned into wealth, material waste is avoided, the uniformity of the thickness of the mortar joints is guaranteed at the same time, therefore the marshaling quality is reliably guaranteed, and the quality of appearance is also drastically improved.

Owner:TIANJIN 20 CONSTR

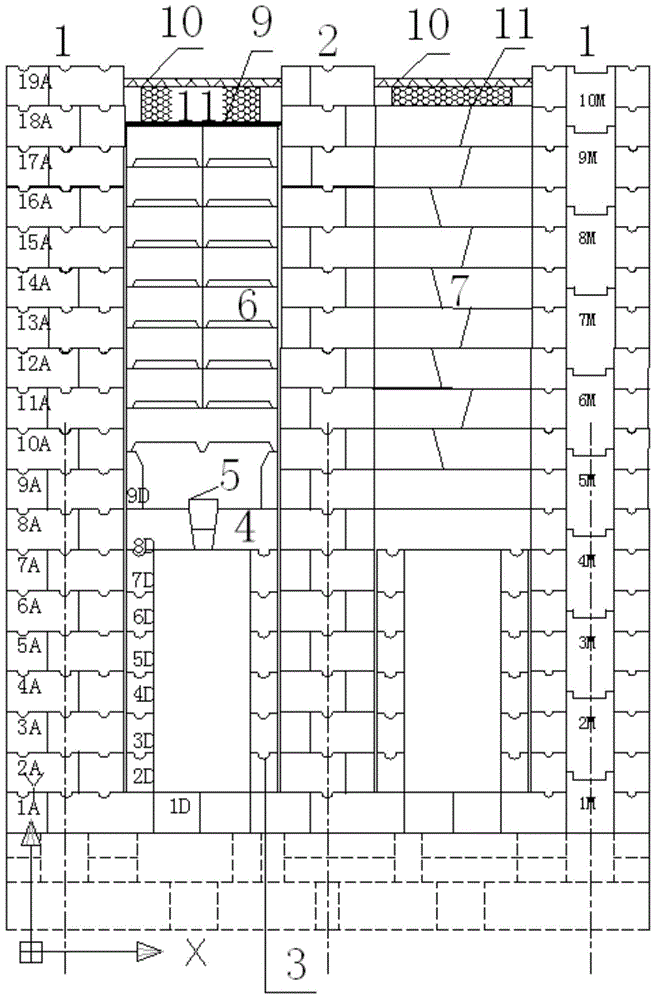

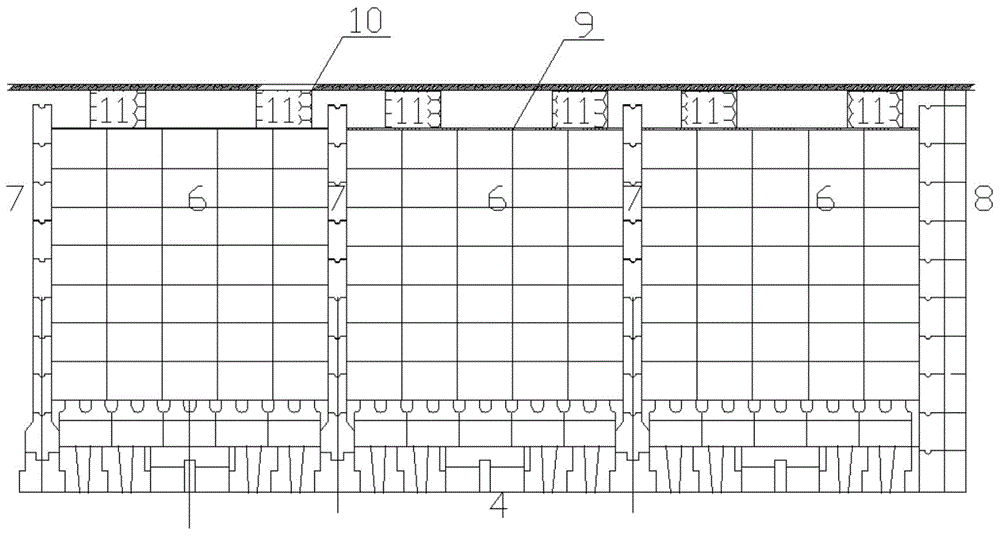

Down-adjusted 7m coke oven regenerative chamber constructing method

InactiveCN104927882AImprove working environmentCreate pollutionCoke oven brickworkBrickArchitectural engineering

The invention discloses a down-adjusted 7m coke oven regenerative chamber constructing method. The method comprises the following steps: firstly, alternately constructing main wall, single wall, small flue lining bricks and grating bricks of a small flue construction section according to construction section and construction order; and then, alternately constructing main wall, single wall, down-adjusted hole adjusting bricks, checker bricks, partition and enclosing wall of a regenerative chamber construction section according to construction section and construction order until reaching the top of a regenerative chamber. Therefore, the constructing method can expand a construction working surface, guarantee constructing quality, facilitate quality inspection, improve working efficiency, improve the working environment of workers and avoid dust pollution to the environment.

Owner:MCC TIANGONG GROUP

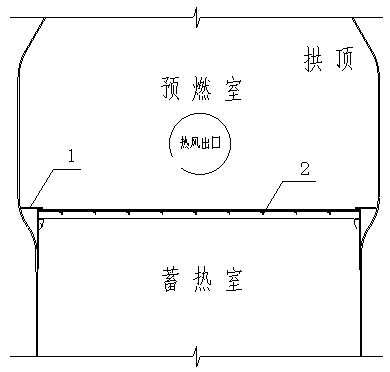

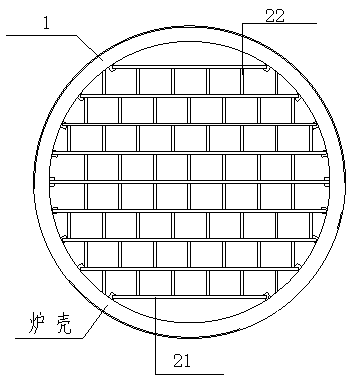

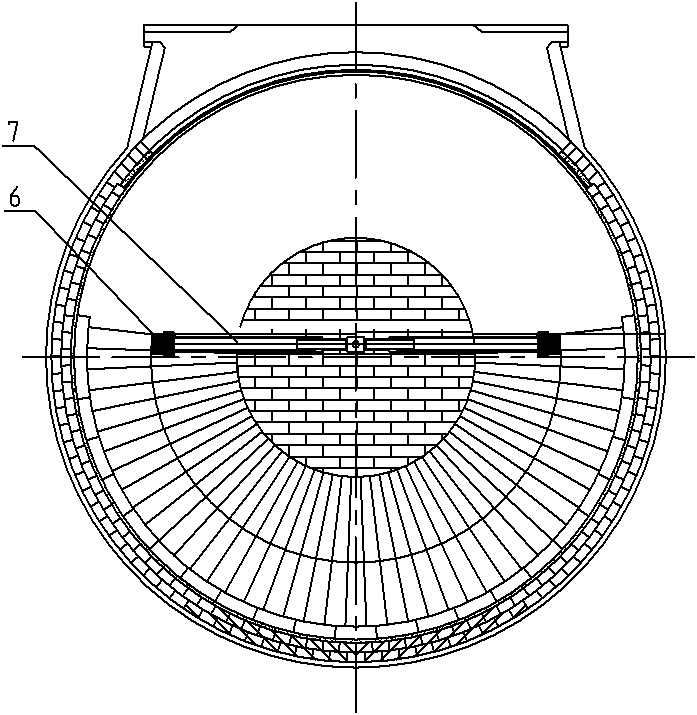

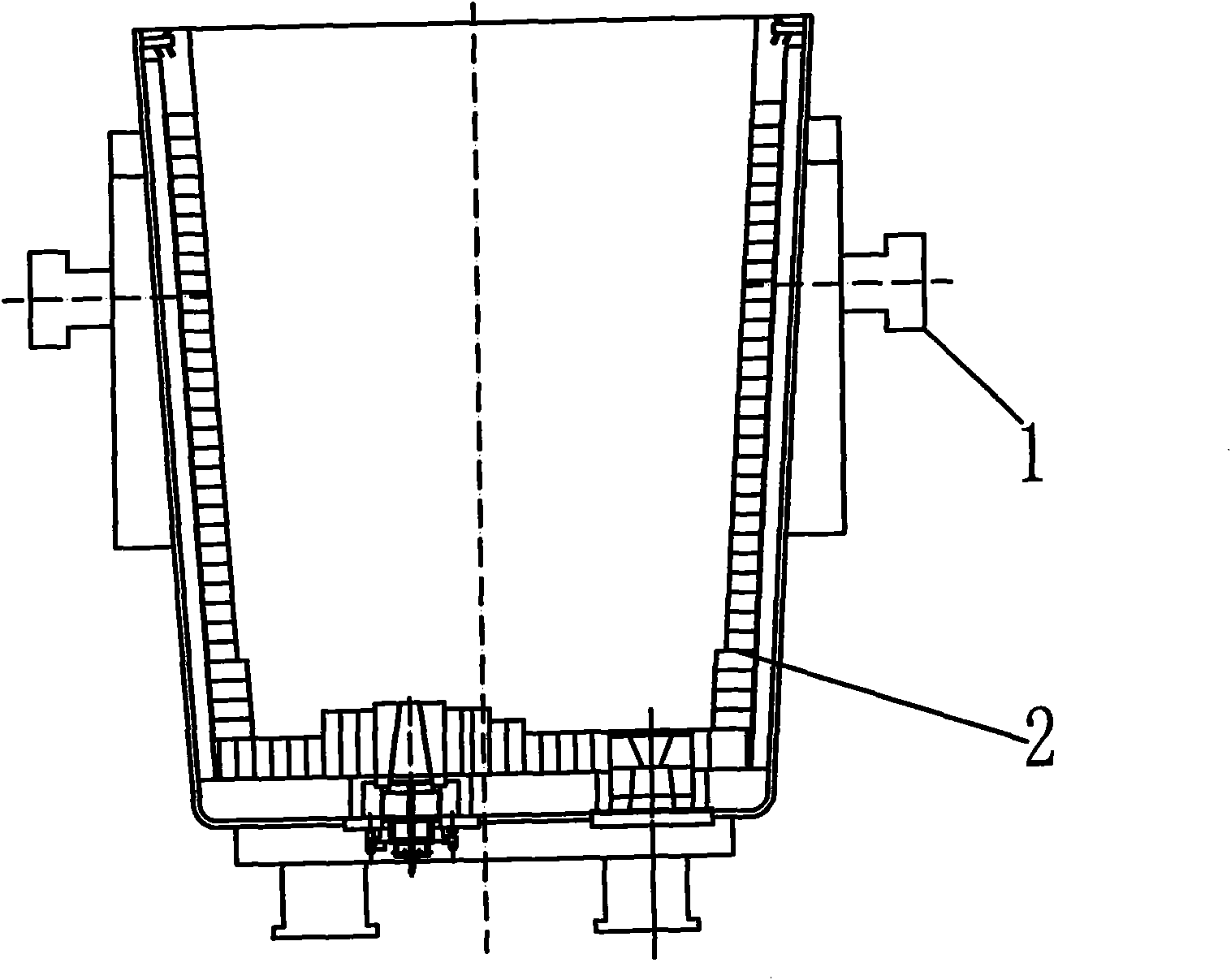

Top-combustion type hot-blast stove refractory material sectioned masonry construction method

InactiveCN107739766AGuarantee the quality of masonryImprove construction efficiencyBrick-hot blast stovesBrickHot blast

The invention relates to the field of metallurgical engineering construction, in particular to a top-combustion type hot-blast stove refractory material sectioned masonry construction method. The top-combustion type hot-blast stove refractory material sectioned masonry construction method is characterized by comprising the steps that 1, a platform is reasonably designed and erected according to the size of the construction platform needing to be erected on a brick holder and the mass of people, objects and machines on the platform, and it is guaranteed that the platform meets the safety requirements; 2, the construction platform in the step 1 is erected on the brick holder; and 3, refractory material masonry is simultaneously conducted on a regenerative chamber on the lower portion of a furnace body and a pre-combustion chamber above the construction platform. According to the top-combustion type hot-blast stove refractory material sectioned masonry construction method, the construction platform is erected on the brick holder at a hot air outlet, thus refractory material sectioned simultaneous construction on the lower regenerative chamber and the upper pre-combustion chamber is achieved, the construction efficiency is improved while the masonry quality is guaranteed, the construction period is shortened, the construction cost is reduced, and good application prospects are achieved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

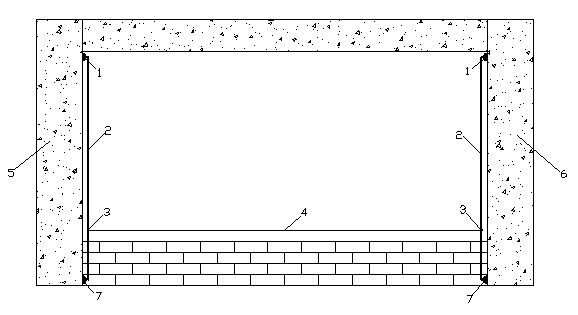

Method for controlling building quality of concrete frame structure walls

ActiveCN102561713AMasonry codeGuarantee the quality of masonryBuilding material handlingFloor slabControl line

The invention relates to a method for controlling building quality of concrete frame structure walls, which belongs to industrial and civil buildings. Horizontal control lines are marked at positions, distant from a floor by one meter, on the right side surface of a left column and a left side surface of a right column, and actual vertical control lines of a front side and a rear side of a wall to be built, a horizontal mortar joint position line between a first-layer brick and a second-layer brick at the bottom of the wall, and a horizontal position line on the upper surface of a top-layer brick are respectively marked on the side of the left column and the side of the right column; upper and lower suckers are respectively fixedly mounted on the left column and the right column, long staff gauges are respectively mounted on the upper and lower suckers fixed on the left column and the right column, and a cotton rope is tied between horizontal calibrating lines on scale clamps on the left long scale gauge and the right long scale gauge; and various layers of bricks are sequentially built according to the movable cotton rope until the bricks are built to the top of the wall, building of the wall is more standard, and building quality is guaranteed powerfully.

Owner:CHINA MCC17 GRP

Prefabricated filling wall system with hollow thermal insulation structure and construction method thereof

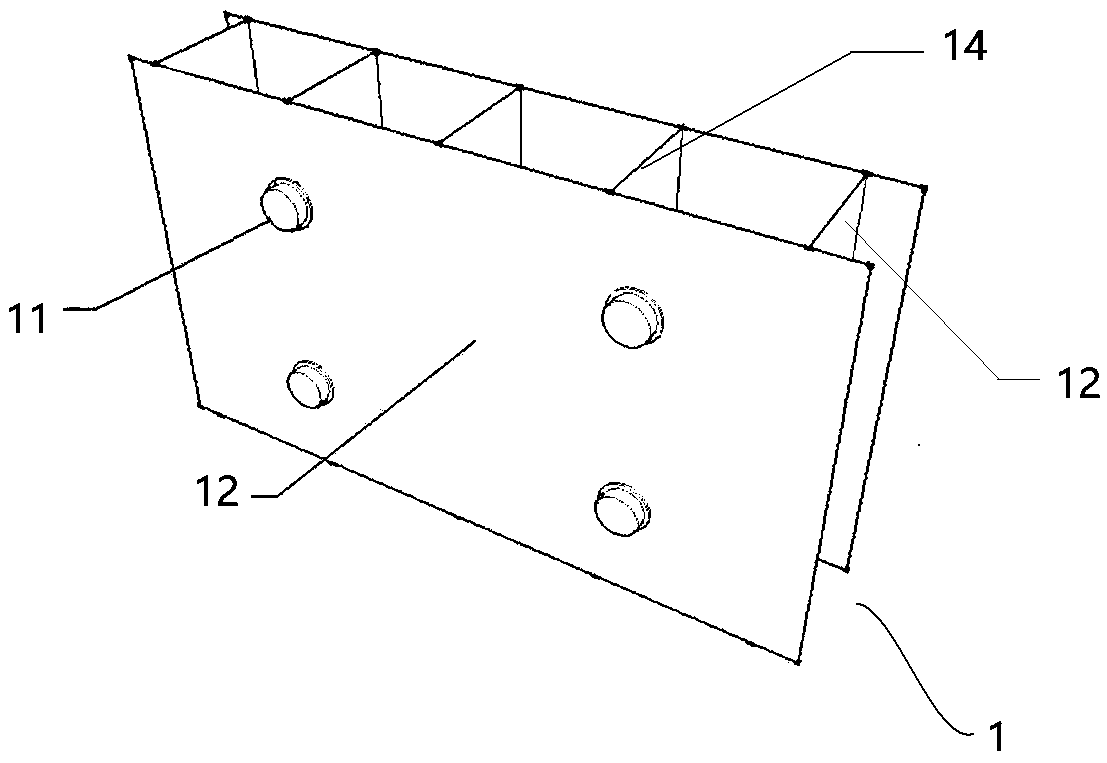

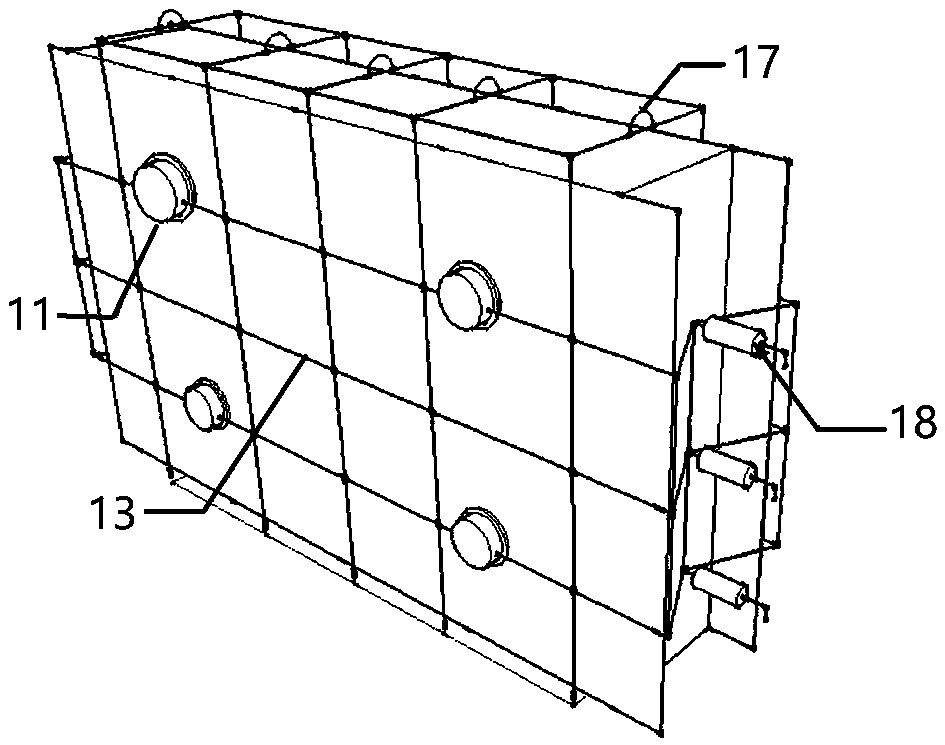

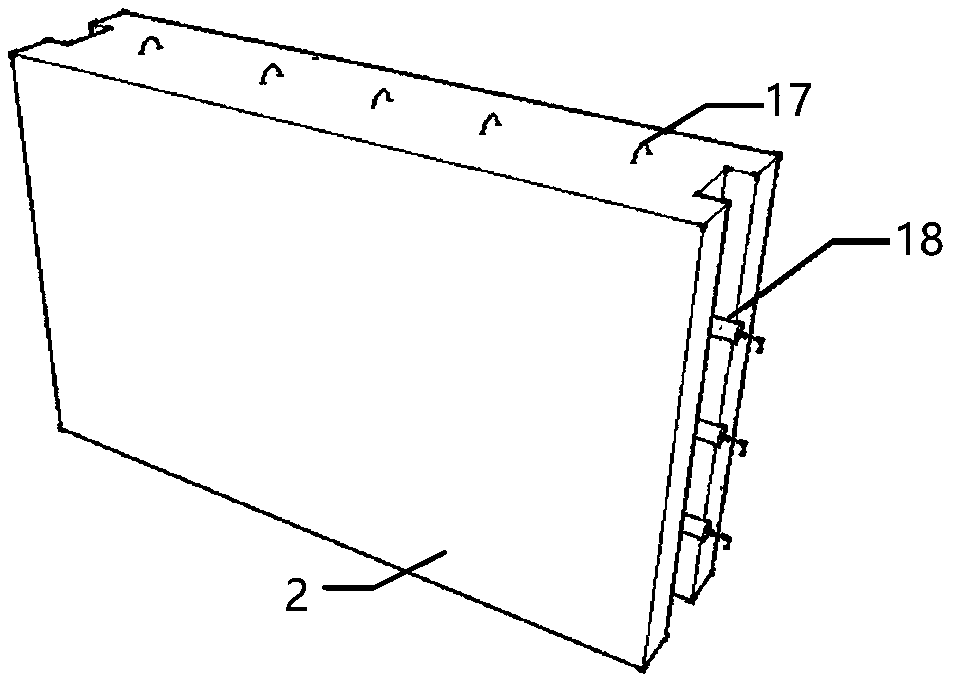

The invention discloses a prefabricated filling wall system with a hollow thermal insulation structure and a construction method thereof. The prefabricated filling wall comprises a hollow cavity box structure and a concrete shell layer, wherein the concrete shell layer is poured on the outer side surface of the hollow cavity box structure. The hollow cavity box structure comprises cushion blocks,a steel bar mesh frame, a hollow box body and partition boards, wherein the hollow box body is formed by surrounding of box wall plates; and the partition boards are arranged in a hollow box body in parallel and at intervals. At least four cushion blocks are arranged on the front and rear box wall plates of the hollow box body. The steel bar mesh frame is formed by tie tying of a transverse steelbar and a vertical steel bar, and is laid on the hollow box body. Holes are arranged on the cushion blocks, wherein the transverse steel bar can penetrate through the hoes. A groove is formed by the left and right side box wall plates of the hollow box body and the front and rear side box wall plates of the hollow box body. The prefabricated filling wall has simple structure, convenient construction, good thermal insulation and sound insulation performance, and little influence of human factors on the construction. Flexible connection is used for effectively suppressing cracks in the filling wall.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

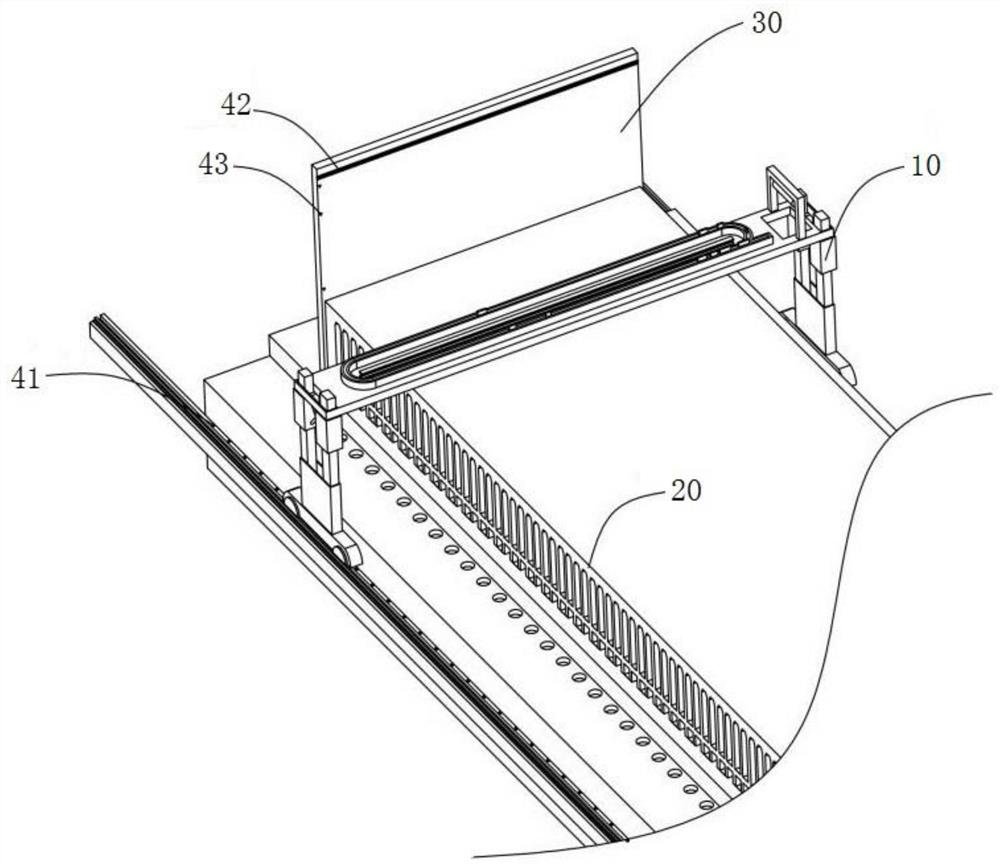

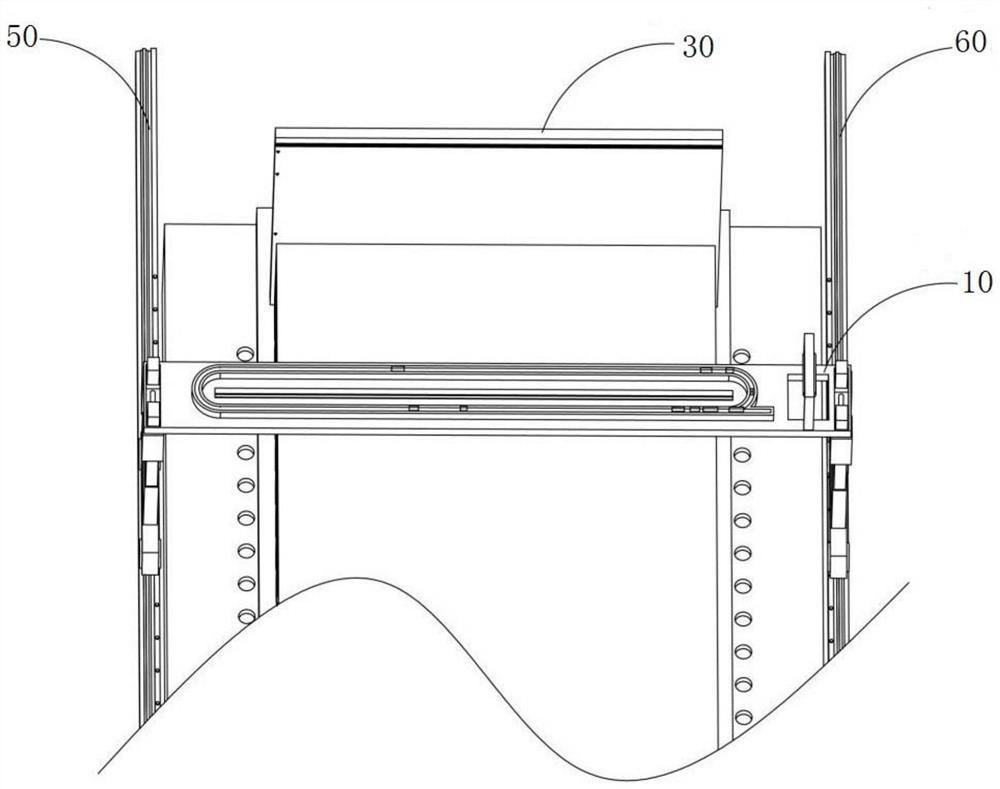

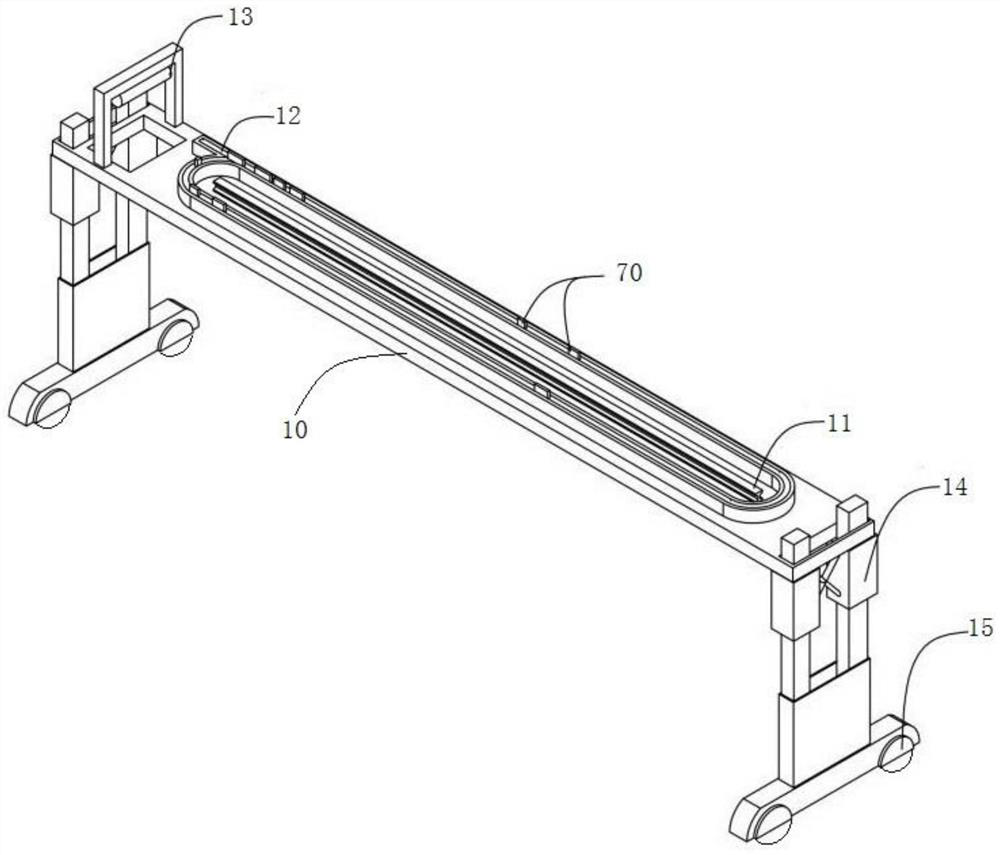

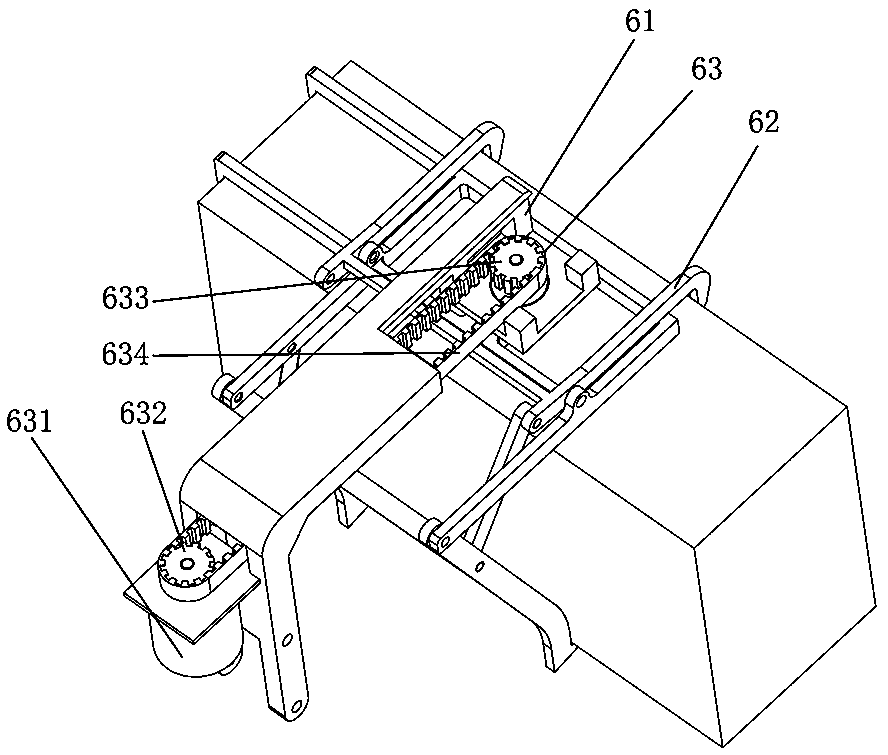

Process method and system for building coke oven by machine

PendingCN113150797ASave human effortImprove masonry qualityCoke oven brickworkMachine buildingProcess engineering

The invention relates to a process method and system for building a coke oven by a machine. The process method comprises the following steps of 1) early-stage preparation, 2) adjusting a beacon, 3) conveying the refractory material, and (4) building. The system comprises a building platform, an elevator, an annular conveying belt, a walking track, a building machine / building robot, a lifting mechanism and a walking mechanism. Starting from solving the problems of machine walking and raw material conveying, the machine building of the coke oven is realized, the building efficiency and the building quality can be greatly improved, and the human input and the coke oven construction cost are reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

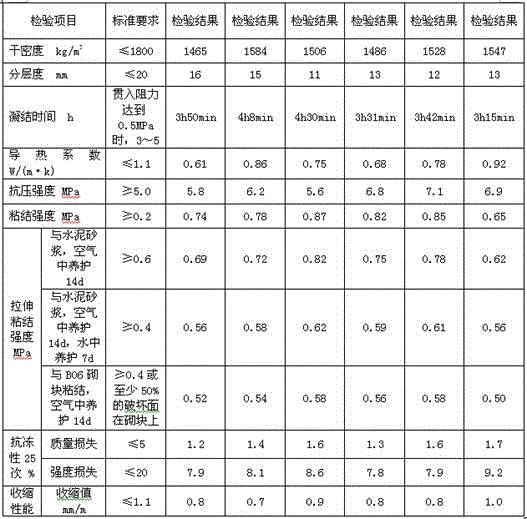

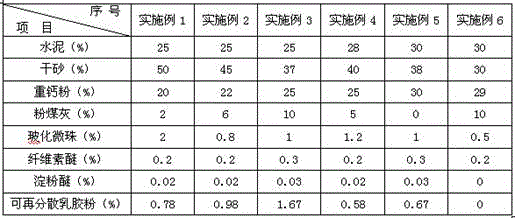

Masonry mortar for autoclaved aerated concrete

The invention relates to masonry mortar for autoclaved aerated concrete. The masonry mortar is prepared from the following components in percentage by mass: 25%-30% of cement, 30%-50% of dry sand, 10%-30% of heavy calcium carbonate, 0-10% of fly ash, 0-2% of thermal-insulating filler and 0.2%-2% of an additive. According to the masonry mortar, on the premise that identical performance of the masonry mortar for the autoclaved aerated concrete is guaranteed, the mechanical construction performance of the masonry mortar is improved, the problem of difficulty in construction mortar application to aerated concrete block masonry is solved, mortar on the masonry surface is applied uniformly, the masonry quality is guaranteed, and the construction efficiency is greatly improved.

Owner:SHAOXING YISHENG MORTAR

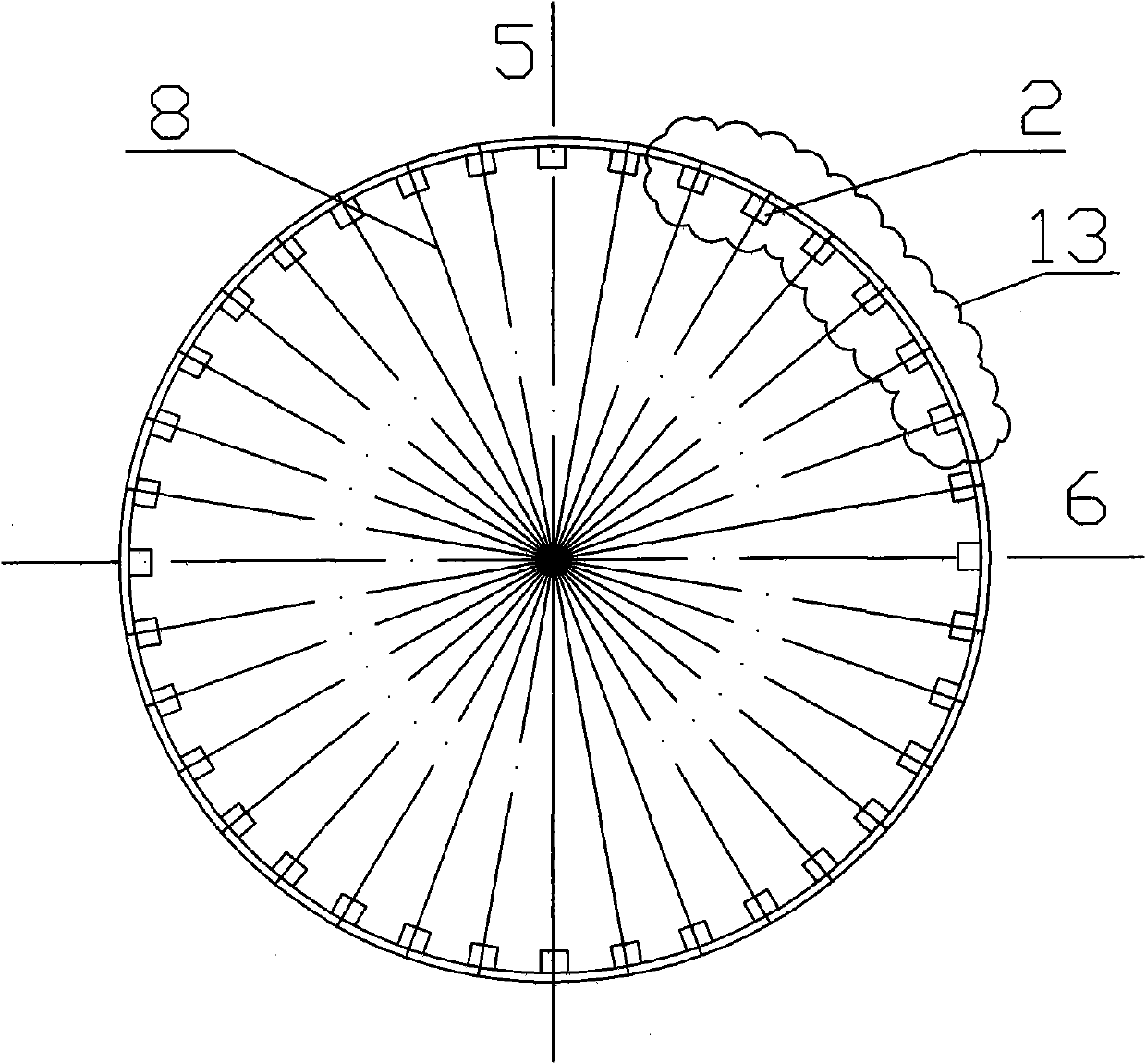

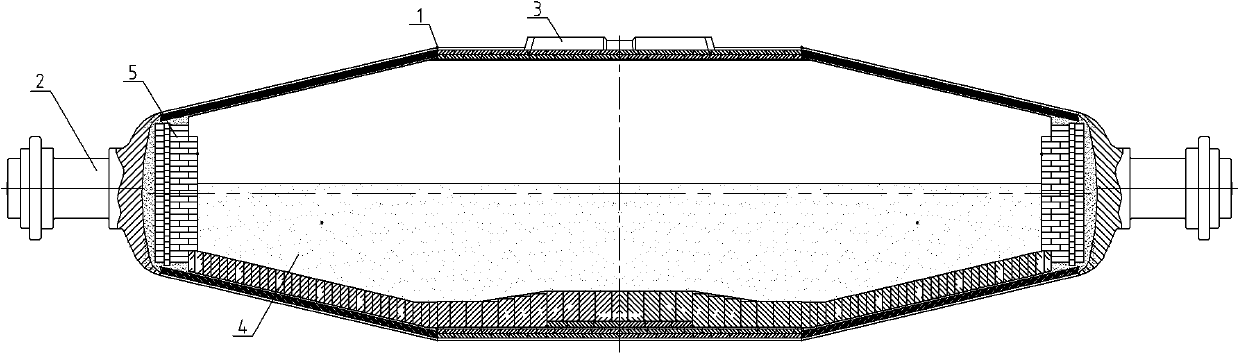

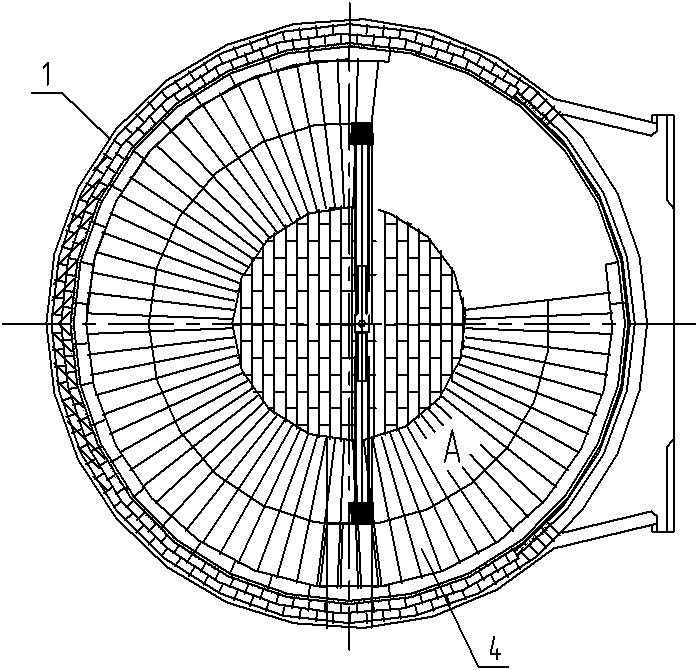

Construction method for using fireproof material in rotary cement kiln

ActiveCN104596291AEnsure construction safetyGuarantee the quality of masonryLinings repairCement kilnExternal image

The invention discloses a construction method for using a fireproof material in a rotary cement kiln. The construction method is characterized by comprising the following steps of new cylinder cleaning in a construction position; local wire arranging; laying of silicon-mullite series of bricks; laying pressure controlling; rotary kiln reexamining; checking and accepting. The construction method disclosed by the invention has the beneficial effects that the construction safety is ensured through the control on a key link, the laying quality is ensured, and a quality accident is prevented from happening; the construction specification of the fireproof material of the rotary cement kiln is supplemented; an effective laying standard is provided for allocating silicon-mullite series and high-aluminum series to various kiln types; the problems in a traditional laying method that since lot drawing and grape hanging phenomena are generated, the running period is seriously affected, a quality accident is caused, and the external image of an enterprise is seriously affected are solved.

Owner:ANHUI WUHU CONCH CONSTR & INSTALLATION ENG

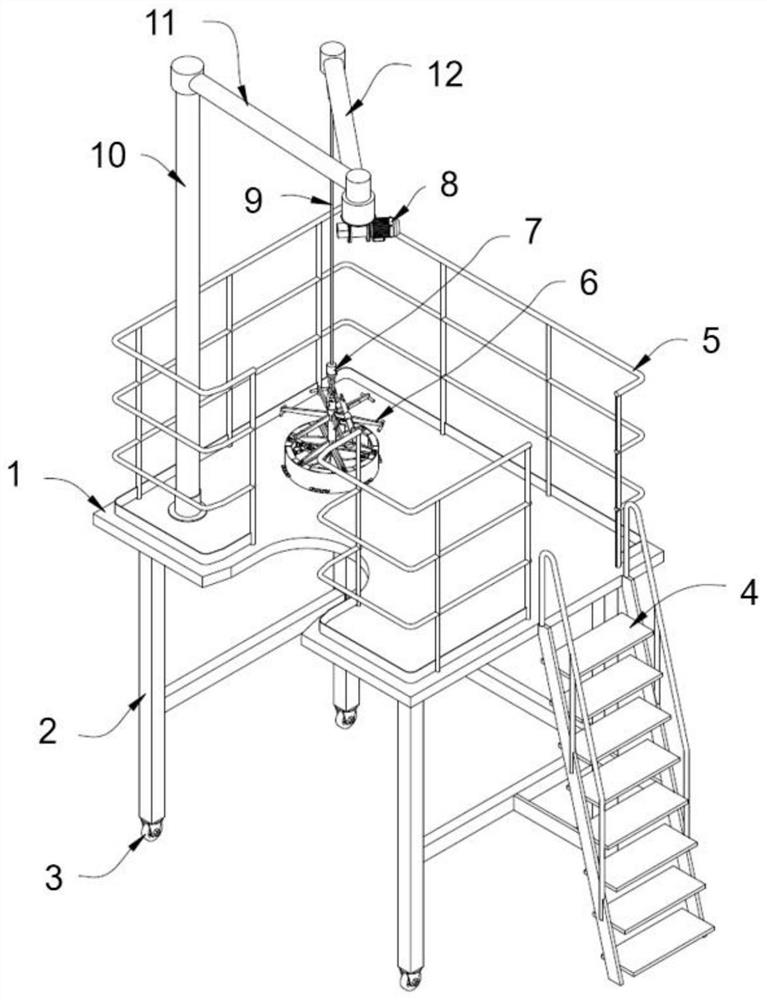

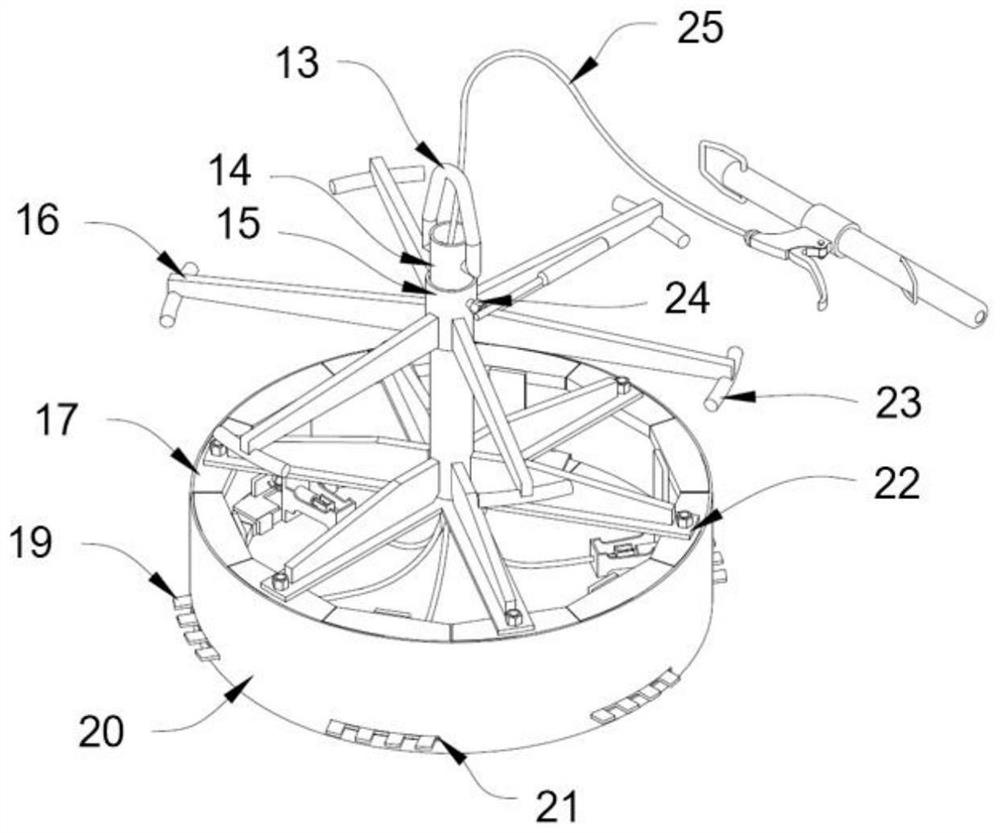

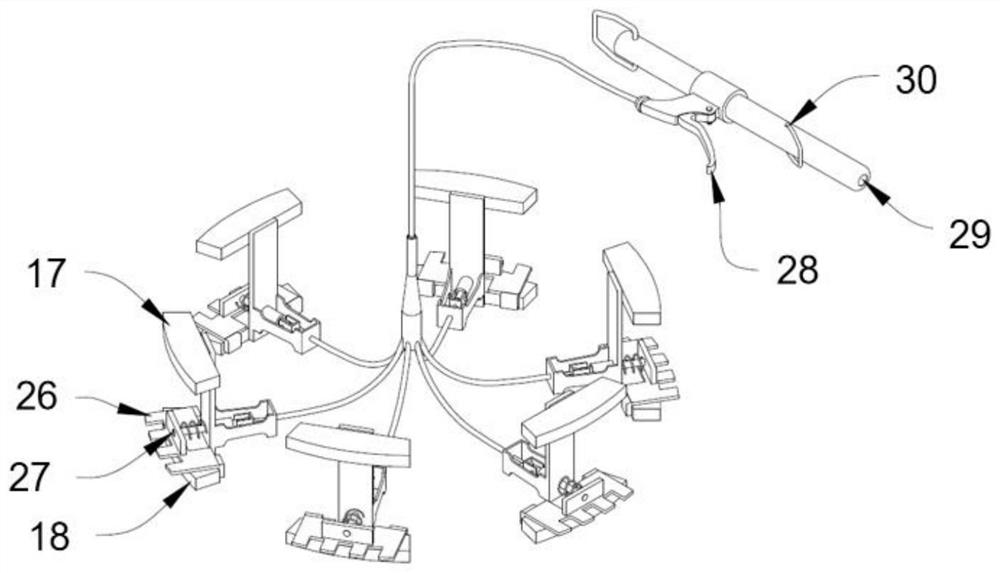

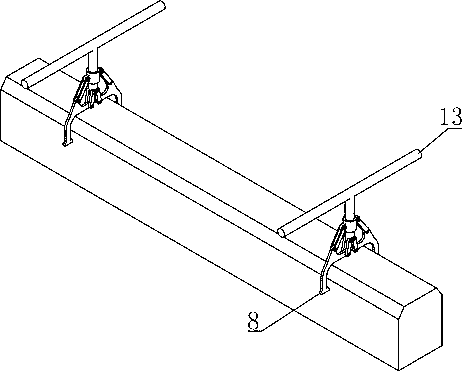

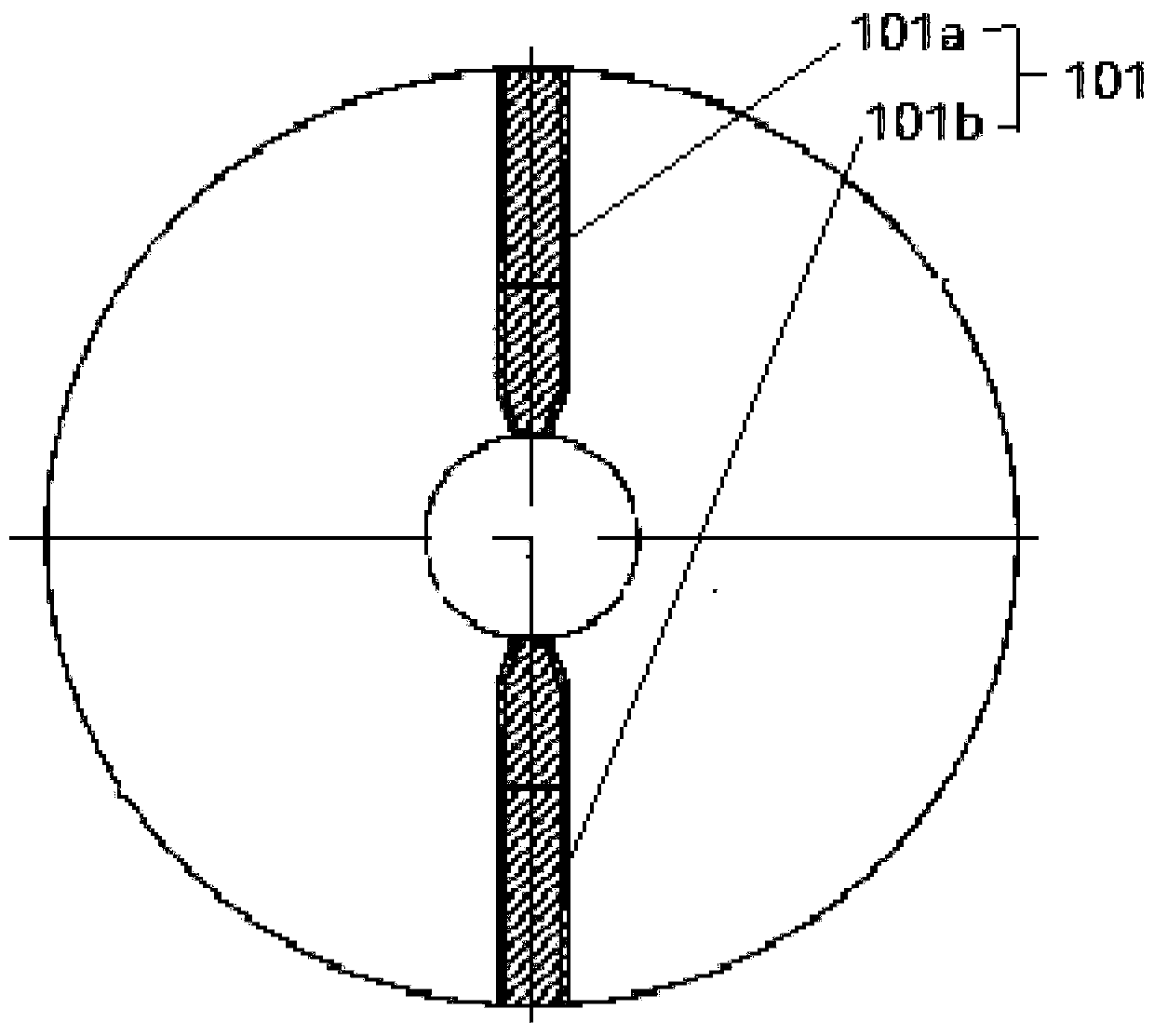

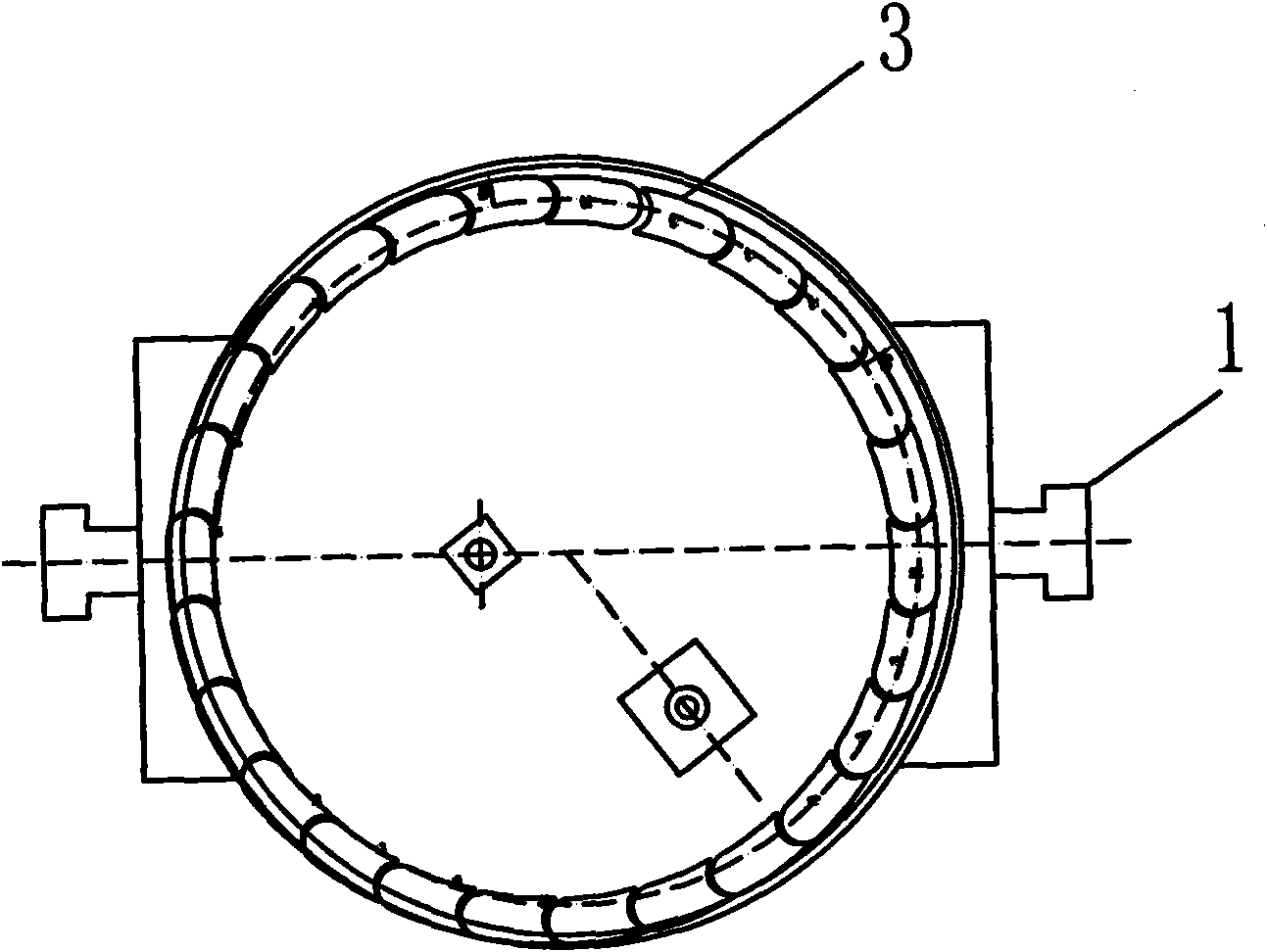

Modular mounting device and method for riser lining of coke oven

ActiveCN112499489AInhibit sheddingGuarantee the quality of masonryCoke oven brickworkCranesVehicle frameCoke burner

The invention provides a modular mounting device and method for a riser lining of a coke oven. The modular mounting device comprises an annular brickwork mounting vehicle, wherein the annular brickwork mounting vehicle mainly comprises a construction vehicle, a jib crane and an annular brickwork lifting appliance; the jib crane is connected to the construction vehicle; the annular brickwork lifting appliance is connected to the jib crane, and the annular brickwork lifting appliance clamps a built annular tube brick; the jib crane hoists the annular brickwork lifting appliance and tube bricks to a proper position together; the construction vehicle comprises a frame and a platform; the platform is horizontally mounted on the frame; and an opening matched with the radian of a pipeline of a riser is formed in one side of the platform. During use, the annular brickwork mounting vehicle is pushed to a riser placing place, and an upper-layer brick joint and a lower-layer brick joint are marked in a staggered manner; the tube bricks are built, and an expansion joint material is bound; the annular brickwork lifting appliance is combined with the annular tube brick; and the tube bricks are hoisted and mounted. According to the modular mounting device and method, vertical placement and building of the riser are achieved, meanwhile, constructors can complete building of the tube bricks outside the riser, the operation difficulty of building the riser lining is reduced, and the operation efficiency is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

Hollow glazed-face acid-resistant brick

InactiveCN1936233AOvercome the defect of small masonry surfaceImprove compactnessBuilding insulationsVertical ductsBrickHigh density

The invention relates to a chimney construction antiseptic material that includes the brick containing glaze. The feature is that at least one cavity is installed in the brick, and exhaust vent is set on it. It has the advantages of high density, low water absorption, and good acid resistance. It ensures the quality of brick placing.

Owner:张加江

Fire clay for silica brick building body of industrial kiln stove

The invention discloses a fire clay for a silica brick building body of an industrial kiln stove. The fire clay contains powder materials composed of a main raw material and an auxiliary raw material and an additive, wherein fused quartz aggregate SiO2 occupying equal to or larger than 99.5% is adopted as the main raw material, silicon fume SiO2 occupying equal to or larger than 94% is adopted as the auxiliary raw material, and the additive is phosphoric acid or aluminium dihydrogen phosphate solid. The fire clay has the advantages of being very small in thermal expansion coefficient and capable of reducing expansion and deformation of the silica building body in the temperature rising process of the stove and enabling the stove to be simple to operate and safe and reliable. The fire-resisting degree of the fire clay reaches above 1730 DEG C, is high in SiO2 content and free of CaO, accordingly is high in high-temperature alkali-resistant corrodibility, and the combustion condition at the reducing atmosphere is met. The fire clay is small in granularity, high in viscosity and simple in masonry construction, can meet the requirement that the masonry mortar joint is smaller than 1.5mm, ensures masonry quality and can prolong service life of the kiln stove.

Owner:CHINA LIGHT IND INT ENG CO LTD

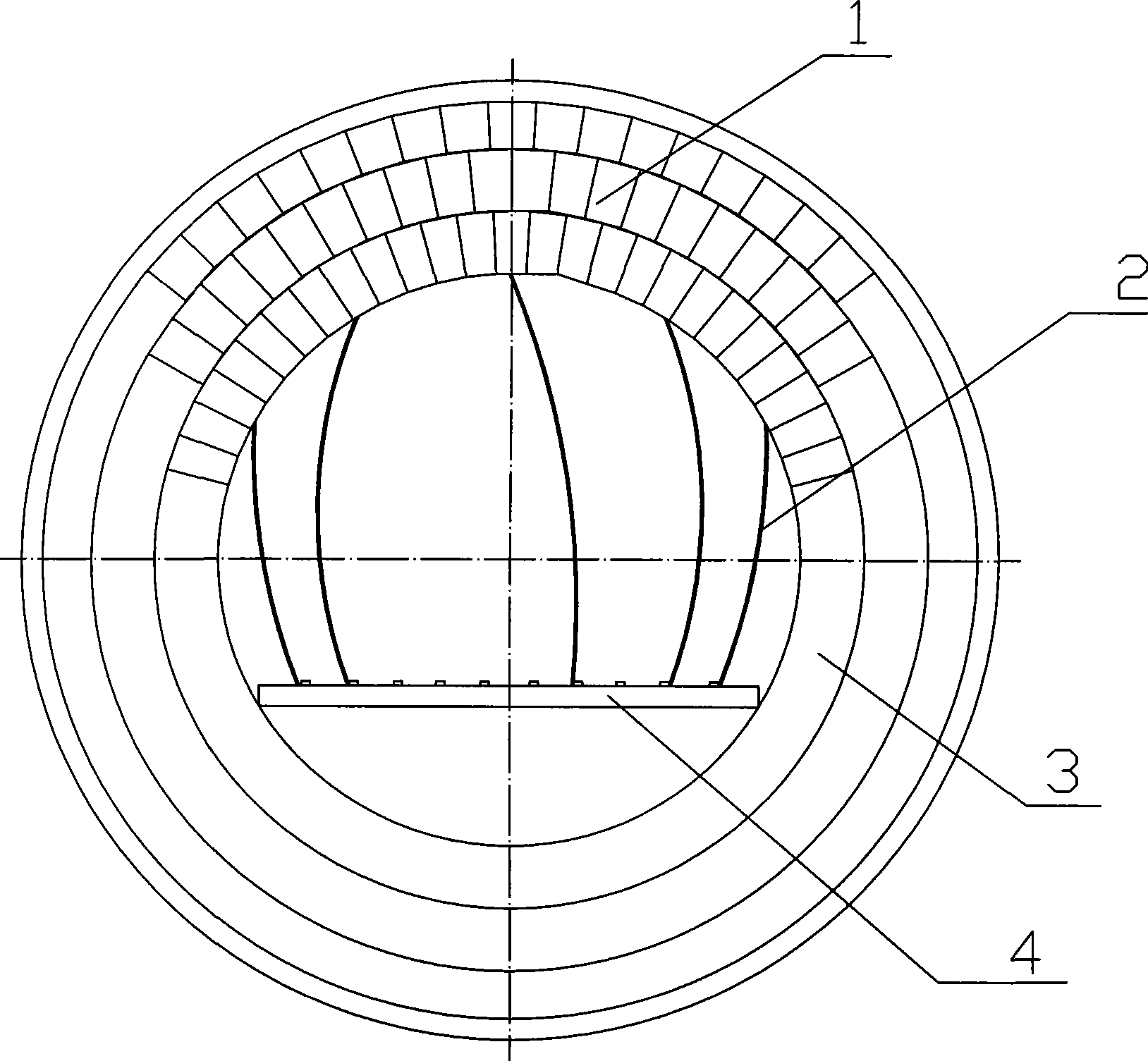

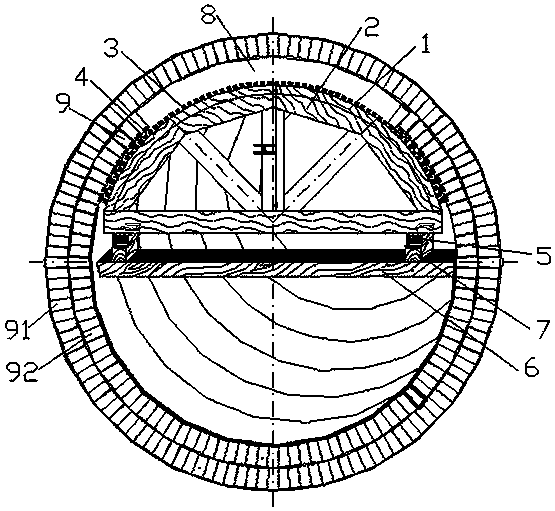

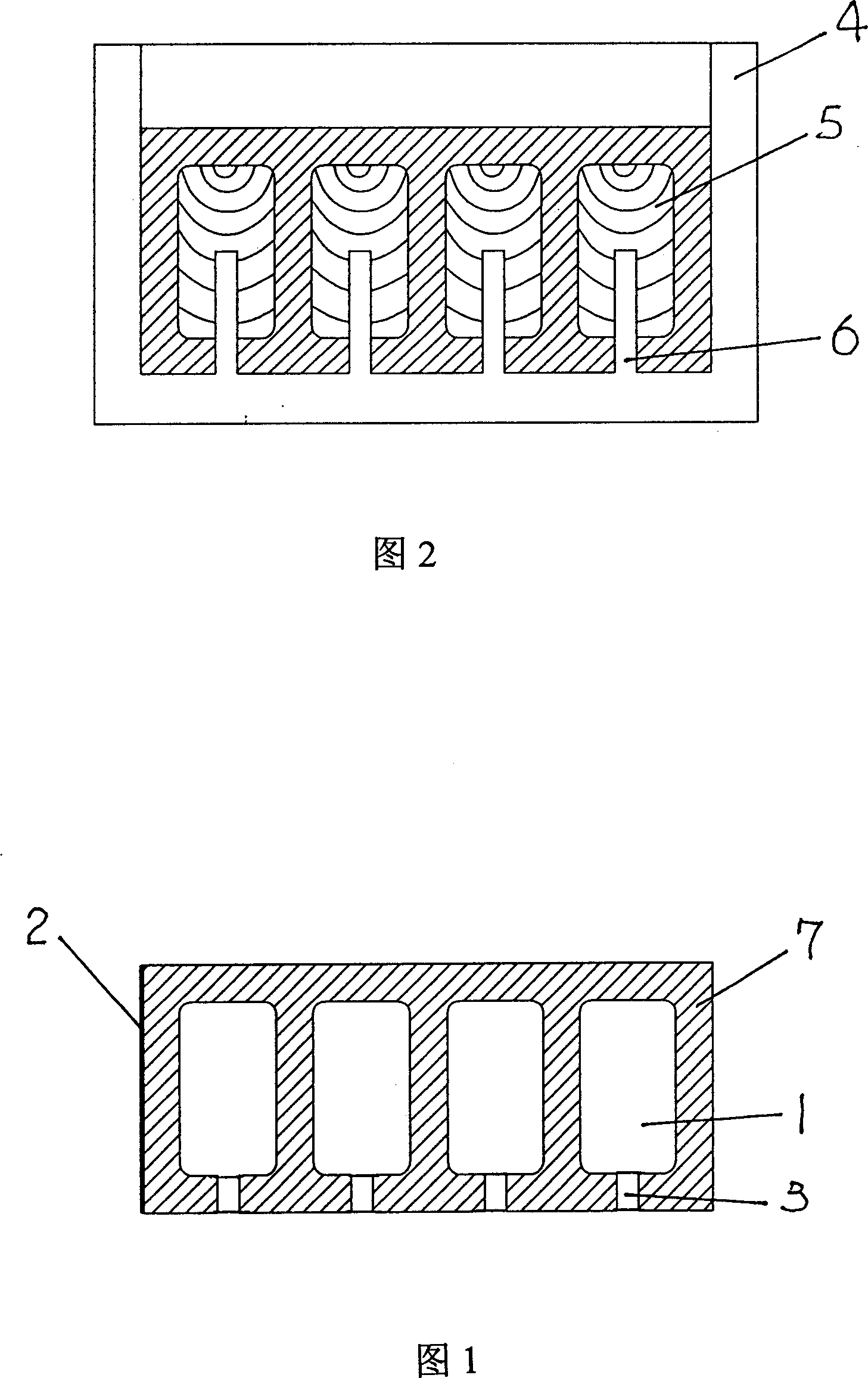

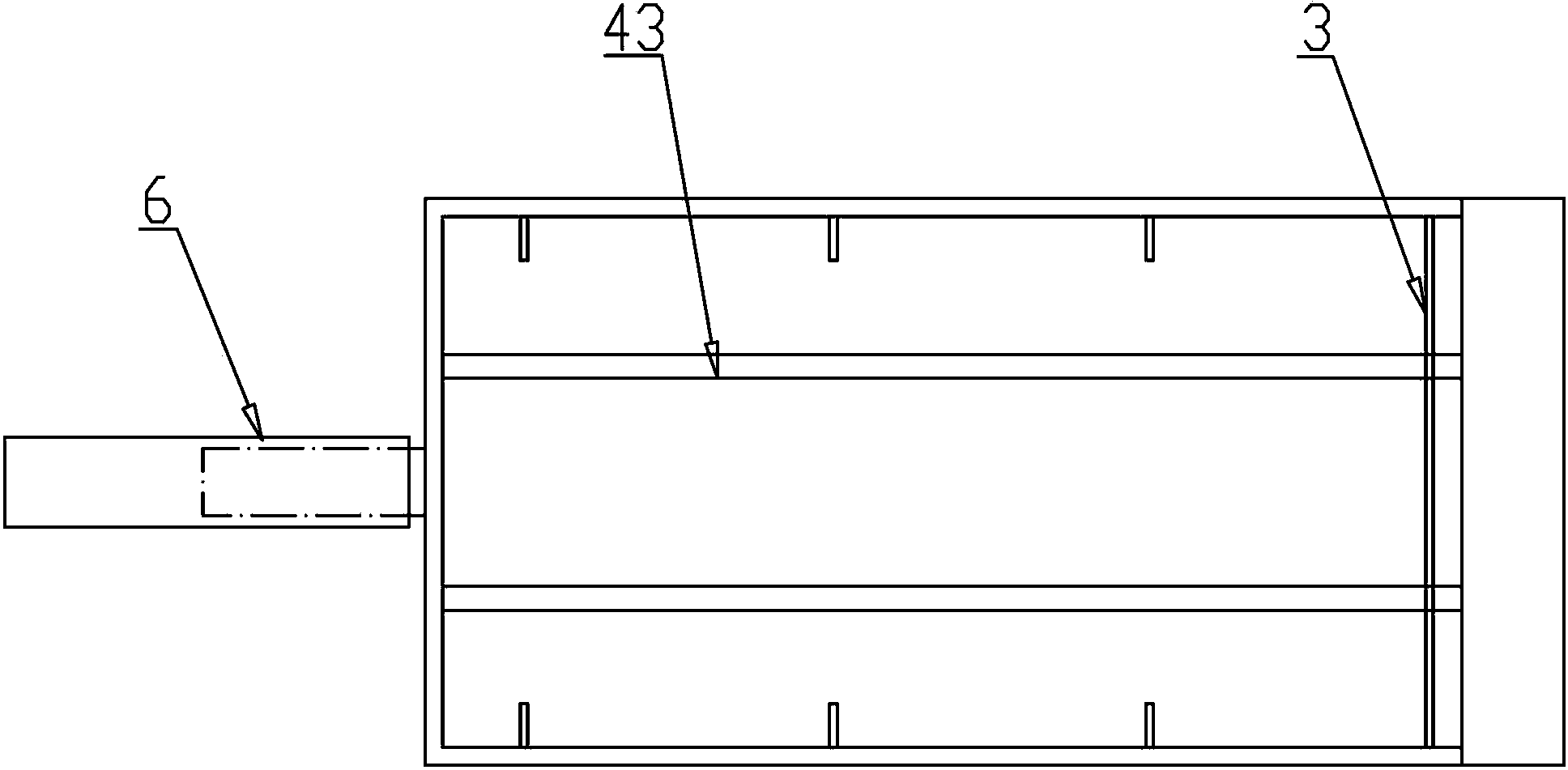

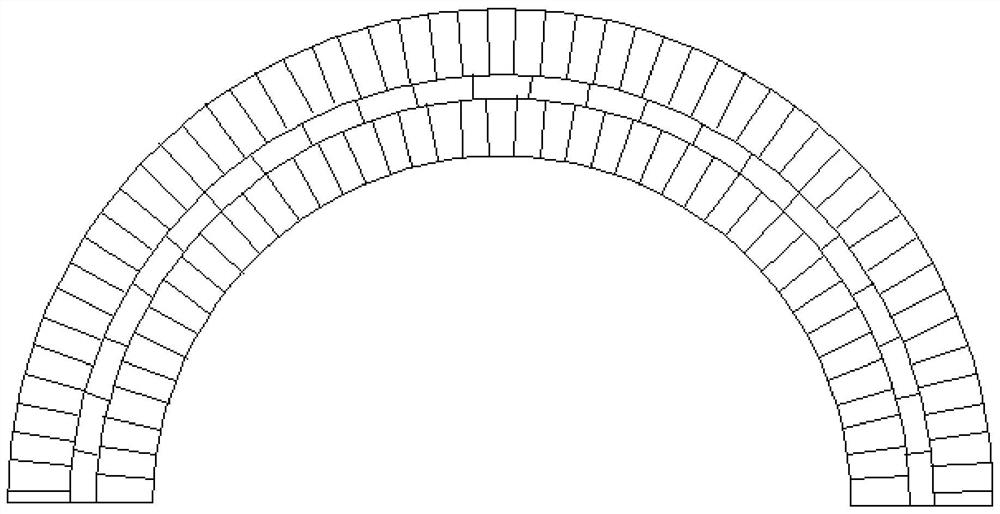

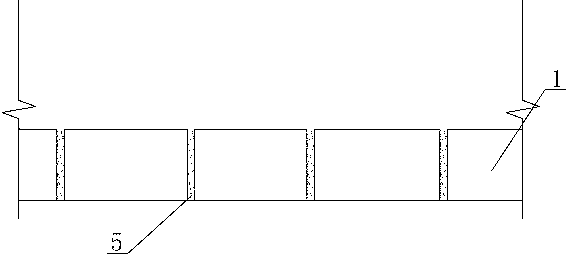

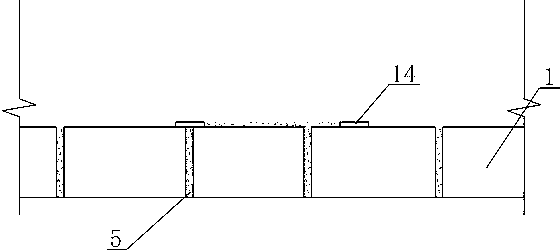

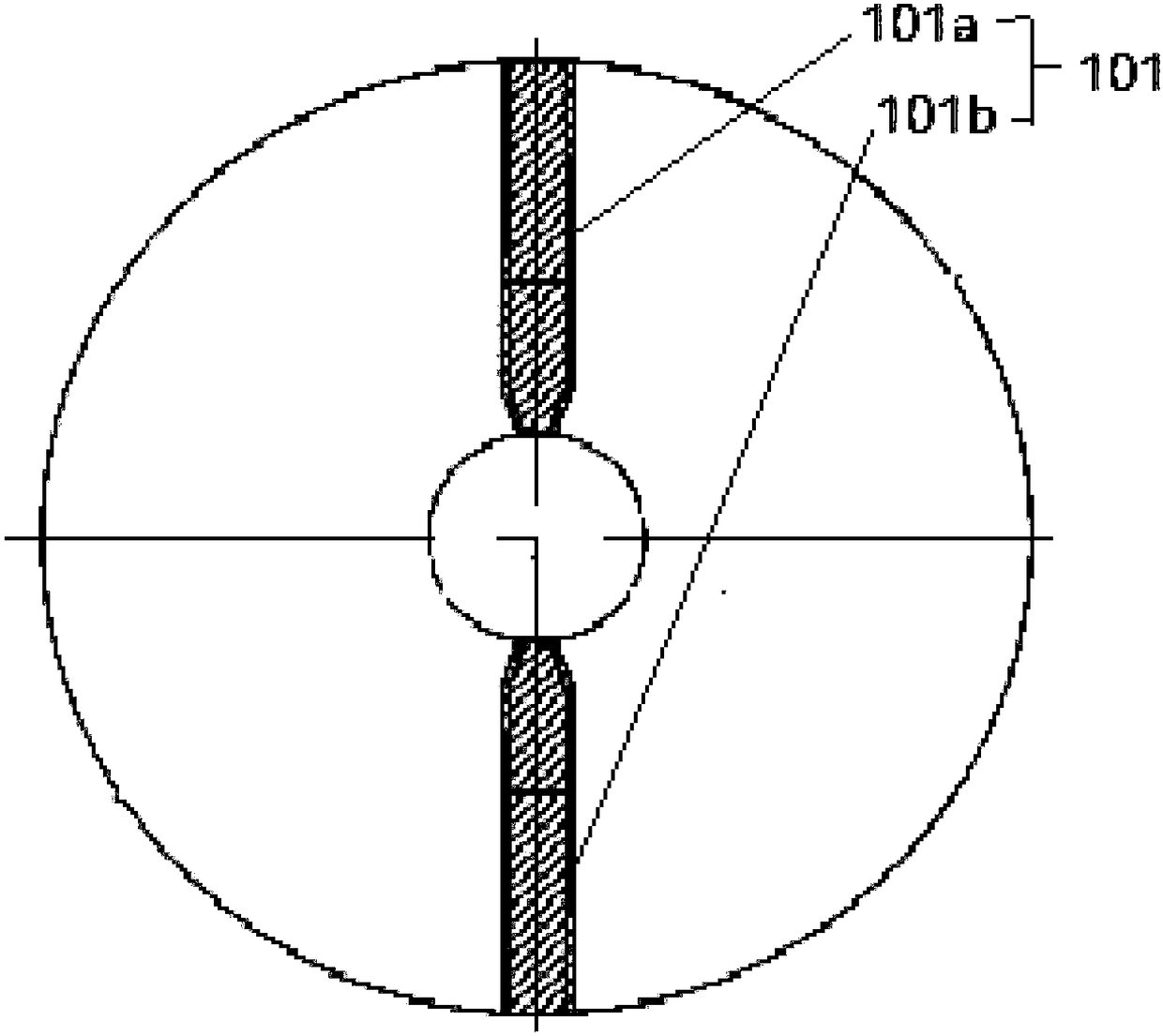

Method for building upper semi-circular arch roof lining of industrial furnace pipeline

InactiveCN109269303AGuarantee the quality of masonryEnsure mortar fullnessLinings repairBrickEngineering

The invention discloses a method for building an upper semi-circular arch roof lining of an industrial furnace pipeline, which comprises the following steps of: manufacturing a special last tire and asupport of the the special last tire to achieve masonry, wherein the last tire comprises a first last tire piece, a second last tire piece and a last tire strip, the diameter of the first last tire piece is larger than that of the second last tire piece, assembling nails and supporting the last tire, wherein the first last tire piece and the second last tire piece are positioned at the inner sideand outer side in the masonry direction, an end head of the inner side of the last tire strip is overlapped with a front ring brick, and the last tire is fixed after the built brick is inspected; building heat insulating layer bricks and working layer bricks on the supported last tire from inside to outside, building the bricks according to a ring until a closing brick is completely inserted, andfinishing the building of the whole ring; lowering down the last tire and moving out the last tire, checking the masonry effect, after the masonry is qualified, the last tire is erected at the position of a next ring according to the same method, and the next ring of bricks is built until the lining of the semi-circular arch roof of the whole pipeline is completely built. According to the method,the building blocks are visually controllable in the masonry process, the mortar fullness and the final masonry position of the building blocks are ensured, the masonry quality is ensured, and the service life is prolonged.

Owner:CHINA MCC20 GRP CORP

Construction method of torpedo hot metal mixer car fireproof bricks

InactiveCN102554203AReduce manufacturing costReduce maintenance costsMelt-holding vesselsFire brickEngineering

The invention relates to a construction method of torpedo hot metal mixer car fireproof bricks, which is characterized in that by using a characteristic that a barrel-shaped pot body of a torpedo hot metal mixer car can rotate around an ear shaft, the fireproof bricks are constructed in partition regions and operation can be kept on the ground. The construction sequentially comprises the following steps: 1) constructing the fireproof bricks till up to a position being in 200-300mm height above the central line of the pot body in the pot body along the inner wall of the pot body, and constructing the fireproof bricks on end walls at two sides; 2) arranging mixed hardwood along the stop end of the fireproof bricks, and fixing the stop end of the fireproof bricks along the length direction; 3) rotating the pot body by 90 degrees, and constructing an A area after the rotation; 4) arranged mixed hardwood along the stop end of the fireproof bricks of the A area, and fixing the stop end; and 5) continuously rotating the pot body by 180 degrees, and constructing a B area. Compared with the prior art, the construction method has the beneficial effects that 1) springboard and a mold erection for aloft work are avoided, so that the operation is convenient and is high in efficiency, and the labor intensity of workers can be greatly reduced; and 2) the construction quality of the fireproof bricks can be reliably ensured, and the utilization rate of a torpedo hot metal mixer car and the safe running of devices can be improved.

Owner:鞍钢集团(鞍山)铁路运输设备制造有限公司

Rapid changing method of pickling tank

The invention relates to an acid milling unit and particularly relates to a changing method of a pickling tank. The rapid changing method of the pickling tank comprises the following steps: step 1, simultaneously blanking a pipeline to assemble a pipe section, constructing and maintaining a liner main body of the pickling tank before machine halt; step 2, carrying out machine halt, and hoisting the pickling tank through four points in a balanced manner to a design workstation; step 3, constructing a joint of the liner main body and the outer walls of the pickling tank outside the pickling tank while paving the pipe section assembled in the pickling tank according to the design. The rapid changing method of the pickling tank effectively guarantees the construction quality, greatly shortens the influences of the construction on a production line, and makes profits for an owner.

Owner:CHINA MCC20 GRP CORP

Hollow glazed acid-proof brick and preparation method thereof

InactiveCN1952321AOvercoming the problem of small masonry surfacesOvercome small problemsConstruction materialCeramic shaping apparatusBrickFlue

The invention belongs to anticorrosive material for chimney buildings, especially relating to a cavum glaze anti-acid brick and the production method, comprising brick body with one cavum at least in it and glaze on the outside face. Said cavum is formed at one time and exhaust hole is set on the cavum. The production method is that making mud, making block at one forming, drying by wind, glaze, sintering in furnace. The invention is suitable for flue lining after gas desulfuration in thermal power plant and is provided with high compactness, low water absorbing (<=7%) and good anti-acid performance. It is not only light weight (volume weight: 1500-1800Kg / cm) but also can conquer small masonry face of hollow brick. The masonry face with brick is enlarged and grout plumpness in masonry is more than 90%. Building quality is guaranteed.

Owner:张加江

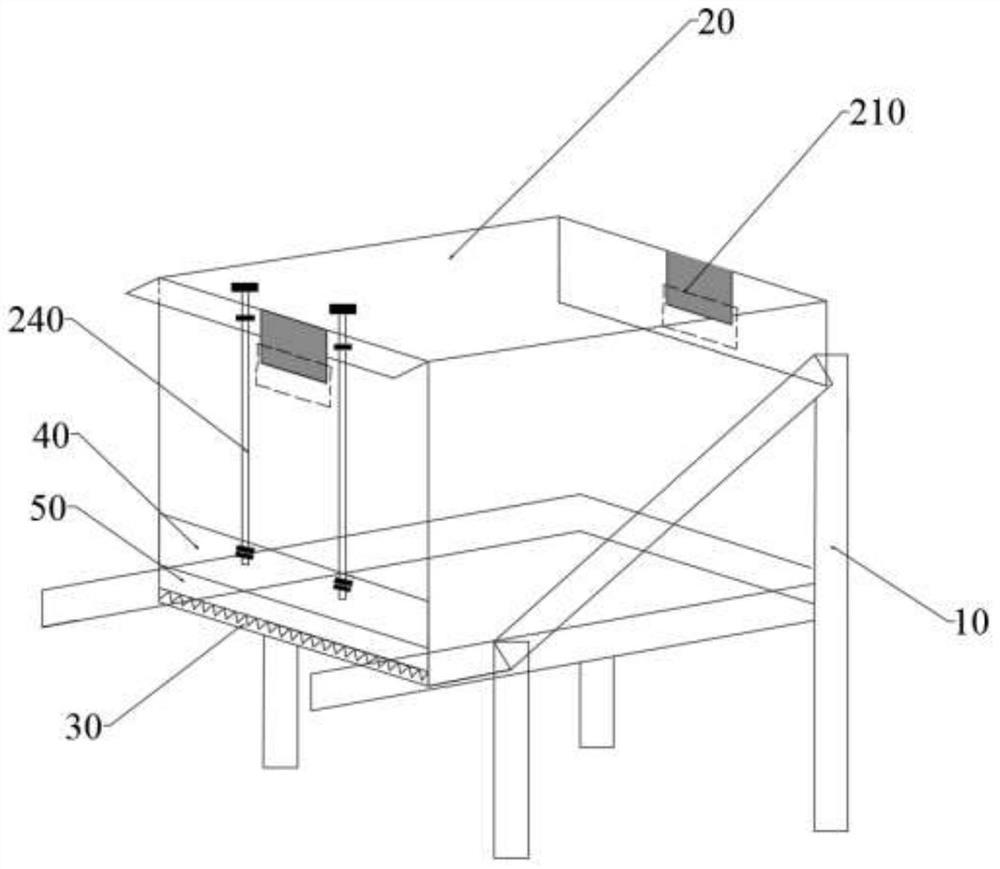

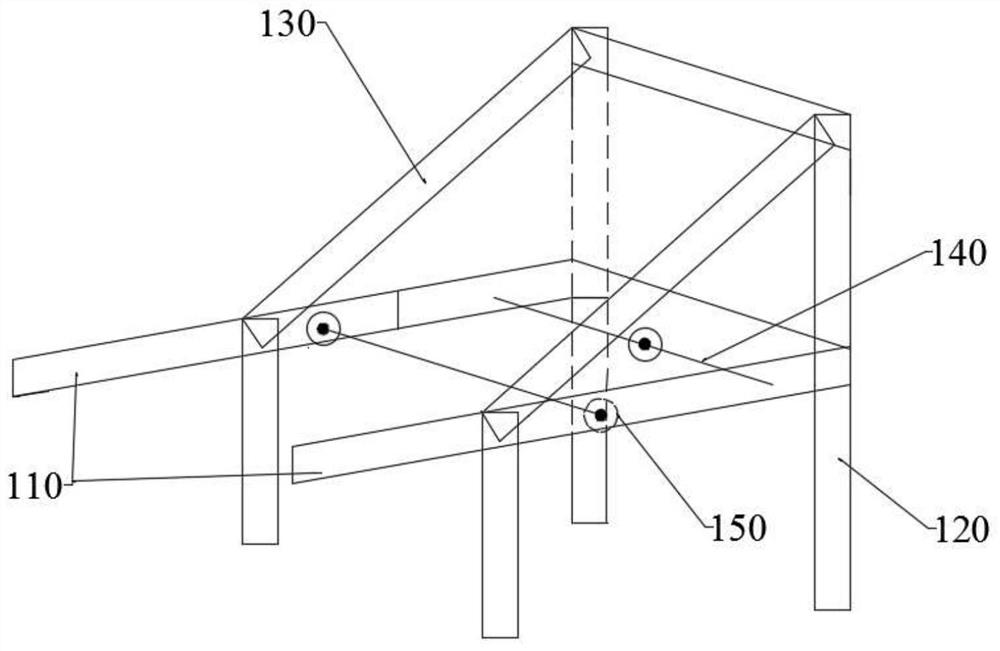

Mortar joint lining mould for aerated concrete block wall

ActiveCN103590614AGuarantee the quality of masonryImprove insulation performanceBuilding material handlingMaterials scienceSkill level

The invention discloses a mortar joint lining mould for an aerated concrete block wall. The mortar joint lining mould for the aerated concrete block wall comprises a bottom surface frame, wherein the bottom surface frame is a frame which is composed of opposite end plates and opposite side plates, , the upper end faces of the end plates are flush with the upper end faces of the side plates, the length of each end plate is larger than or equal to the width of the upper end face of a brick, and the side plates are higher than the end plates so that the inner wall of the lower end of each side plate can be clamped on the side wall of the brick; multiple vertical bottom surface limit pieces are arranged on the inner wall of the bottom surface frame, and the bottom end faces of the bottom surface limit pieces are flush with the bottom end faces of the end plates; a handle is further arranged on the outer side of the end plate at one end of the bottom surface frame. According to the mortar joint lining mould for the aerated concrete block wall, due to the fact that the end plates of the bottom surface frame are placed on the upper end face of the brick and the side plates of the bottom surface frame are clamped on the side wall of the brick, the laying height of mortar can be limited conveniently, evenness and smoothness of the thickness of the mortar are guaranteed, brick laying quality is guaranteed, requirements for the skill level of operators are lowered, the efficiency is improved by more than 20%, and waste of the mortar can be avoided.

Owner:GEZHOUBA XINJIANG ENG

Coke oven chute cleaning technology

InactiveCN101348723AGuarantee the quality of masonryCleaning saves time and effortCoke ovensCombustion chamberEngineering

The invention relates to a coke oven chute cleaning technology, which belongs to the coke oven assistant technology. The coke oven chute cleaning technology is characterized in that a glass mirror which is provided with a support and can adjust the mirror angle is vertically arranged on a chute inlet between a coke oven regenerator and a combustion chamber; the mirror surface of the glass mirror faces to the inside of the chute; when a furnace building worker enters into the coke oven chute for cleaning, the furnace building worker uses a cold-light source to irradiate the fa.ade of the glass mirror and simultaneously continuously adjusts the angle of the mirror surface until the reflected light of the glass mirror surface irradiates the inner wall of the chute and particularly irradiates the corner of the chute, and then fixes the glass mirror; and then the furnace building worker or a cleaner holds a tool to completely scrape residual slurry and other sundries on the inner wall of the chute, uses the reflected light of the glass mirror surface to reexamine until the chute is completely cleaned. Therefore, the cleaning work is quick and labor-saving and the chute is completely cleaned, consequently the masonry quality of a coke oven is guaranteed.

Owner:CHINA MCC17 GRP

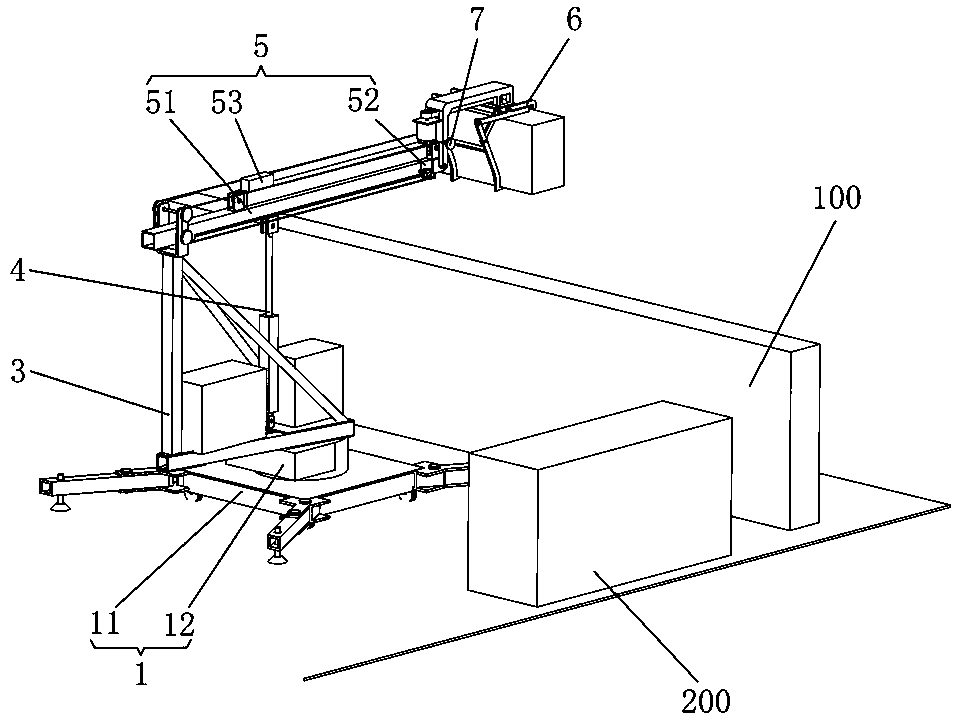

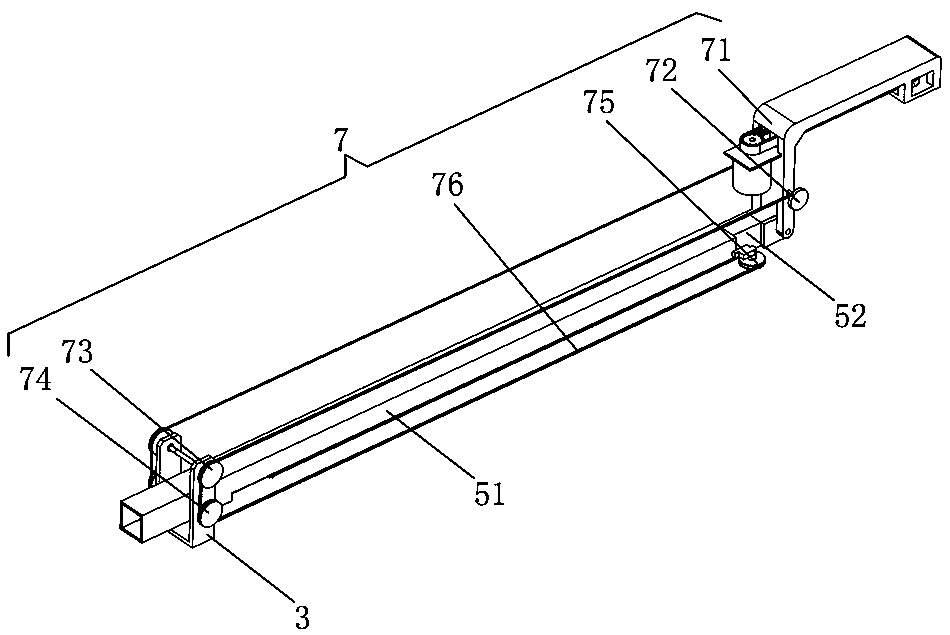

An automatic stacking machine and a wall-building control method

ActiveCN106881711BSimple structureThe overall structure is simple and reliableProgramme-controlled manipulatorGripping headsBrickStack machine

The invention discloses an automatic piling machine and a walling control method. The automatic piling machine comprises a base plate, a bracket, a variable amplitude telescopic mechanism, a linear telescopic mechanism, a clamping jaw mechanism and a clamping jaw horizontal holding mechanism; the bracket is installed on the base plate; one end of the linear telescopic mechanism is hinged to the upper end of the bracket, and the other end of the linear telescopic mechanism is connected with the clamping jaw mechanism through the clamping jaw horizontal holding mechanism; and one end of the variable amplitude telescopic mechanism is hinged to the bracket, and the other end of the variable amplitude telescopic mechanism is hinged to the middle of the linear telescopic mechanism. The walling control method comprises the steps that S1, main machine positioning is conducted; S2, brick pillar positioning is conducted; S3, wall body positioning is conducted; S4, the position and posture of the next brick are determined; S5, automatic reset is carried out for grabbing the next brick; S6, automatic bricklaying is conducted; S7, the laying position and posture of the brick are checked, if the requirement is met, the brick is put down, the process goes back to the step S4, and otherwise, the step S8 is carried out; and S8, wall position adjusting is conducted, specifically, the brick is adjusted manually, the adjusted brick laying position and posture are recorded, the spatial position of a new to-be-built wall body is solved according to all previous records, and the process goes back to the step S4.

Owner:刘耀宗

Construction method using hoisting clamp

The invention provides a construction method using a hoisting clamp. The construction method using a hoisting clamp comprises the following steps of: constructing a first-layer masonry; placing a mortar ash template on the first-layer masonry; flatly paving mortar ash joints in the limited area of mortar ash template, and then paving an acid-resistant rubber layer on the mortar ash joints; clamping the hoisting clamp on the sidewall of a filling block, and horizontally lifting the filling block and placing the filling block on the acid-resistant rubber layer; removing the mortar ash template and tightly bonding the acid-resistant rubber layers at the both sides of the filling block on the both sides of the filling block; and paving mortar ash joints at one side of a second-layer masonry material, closely combining the mortar ash joints with the acid-resistant rubber layers at the both sides of the filling block, and finishing construction for a second-layer masonry. With the adoption of the construction method provided by the invention, heavy-weight beams can be accurately and conveniently installed, the construction speed is fast, and the construction quality is guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

Putlog-hole-free construction method for building masonry wall

InactiveCN109083421AGuarantee the quality of masonryGuarantee perceptionBuilding material handlingScaffold accessoriesEngineeringRigid frame

The invention discloses a putlog-hole-free construction method for a building masonry wall. The method comprises the following steps of construction of a masonry body, construction of a ring-beam rigid frame formwork and putlog-hole-free construction of an external wall. According to the method, the putlog-hole-free construction of the wall is adopted, since the masonry body is built at a time, the phenomenon that masonry body mortar at putlog holes is not full is reduced, and the building quality and appearance of the masonry body are both guaranteed; through the putlog-hole-free constructionof the masonry body, the phenomenon is avoided that reserved putlog holes are not tightly filled, so that hollowing of a plastered wall surface and the leakage of an external wall are caused; throughthe putlog-hole-free construction of the masonry body, the engineering cost can be reduced, and the labor input is reduced.

Owner:庐江荣睿建设工程有限公司

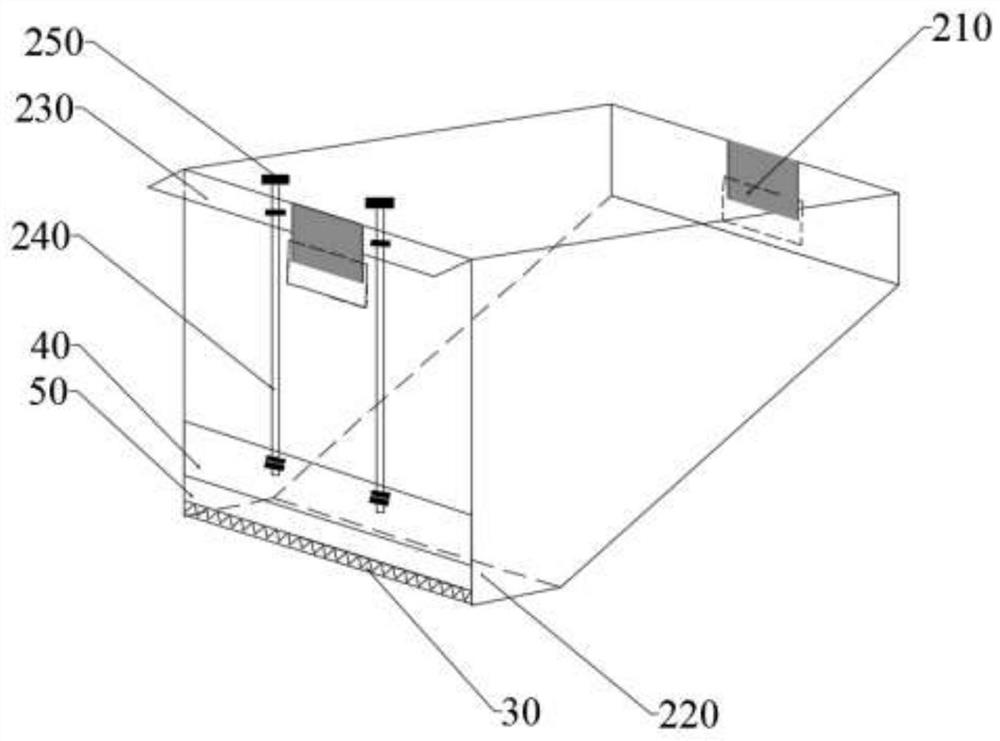

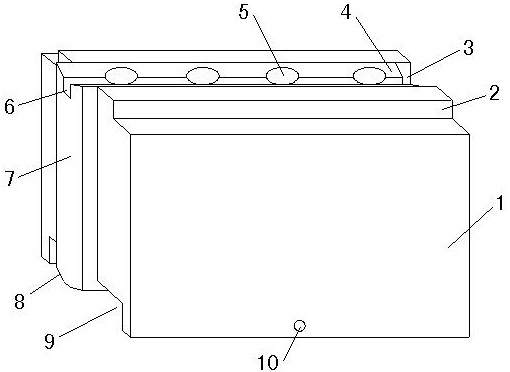

Mortar spreading device

PendingCN111894293AImprove masonry efficiencyEasy to moveBuilding material handlingSocial benefitsBrick

The invention provides a mortar spreading device. The mortar spreading device comprises a fixed support, a mortar storage bucket and a control steel plate, wherein the fixed support is arranged on a brick wall, the mortar storage bucket is arranged on the fixed support and contains mortar, the mortar storage bucket can move in the length direction of the brick wall and drives the fixed support tomove on the brick wall, a discharging port is formed in the side wall of the mortar storage bucket, then the mortar is released from the discharging port and spread on the brick wall, and the controlsteel plate is located on the side wall of the mortar storage bucket and can move in the vertical direction to stop at least part of the discharging port. By arranging the control steel plate on the side wall of the mortar storage bucket, the size of the discharging port can be controlled, thus the thickness at which the mortar is spread is controlled, and the requirement stipulated in the Code for Acceptance of Constructional Quality of Masonry Structures is met; and meanwhile, by adopting the mortar spreading device for construction, the efficiency of building walls can be significantly improved, the masonry structure is guaranteed, and the labor intensity of construction workers is lowered, creating certain economic benefits and social benefits to the society.

Owner:江苏苏南建筑安装工程有限公司

Gypsum block-based assembled wall building method and gypsum block

PendingCN113047470ARealize prefabricated masonrySimple and convenient constructionWallsAdhesive cementMining engineering

The invention provides a gypsum block-based assembled wall building method and a gypsum block. The method comprises the following steps of: after an upper layer gypsum block is built on a lower layer gypsum block, forming a cavity with a closed outer side surface in the length direction of a wall, placing steel bars in the cavity, directly assembling the gypsum blocks into the wall without other auxiliary materials, and injecting adhesive cement into the cavity after the flatness detection of the wall meets the requirement. The gypsum block comprises a gypsum block body, wherein a bottom groove is formed in the bottom surface of the gypsum block body in the length direction, a top table is arranged on the top surface of the gypsum block body, and grouting holes communicating with the bottom groove are formed in the two sides of the width direction of the gypsum block body. According to the invention, the steel bars are positioned in the closed cavity formed by the upper layer gypsum block and the lower layer gypsum block, and the adhesive cement is injected after the flatness of the vertical surface of the wall meets the technical requirement, so that the construction process is simple, convenient and fast, safe and reliable, the building quality is ensured, and the real assembled building of the non-bearing wall is realized.

Owner:孙明生

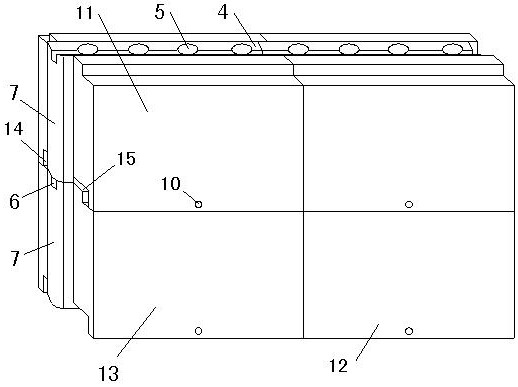

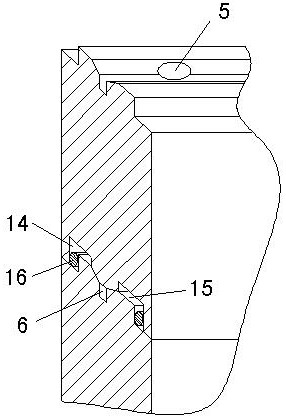

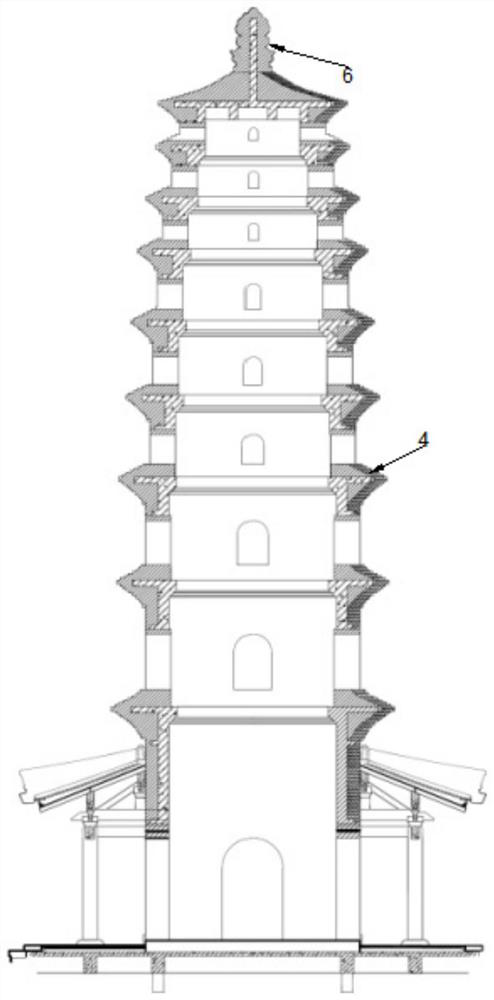

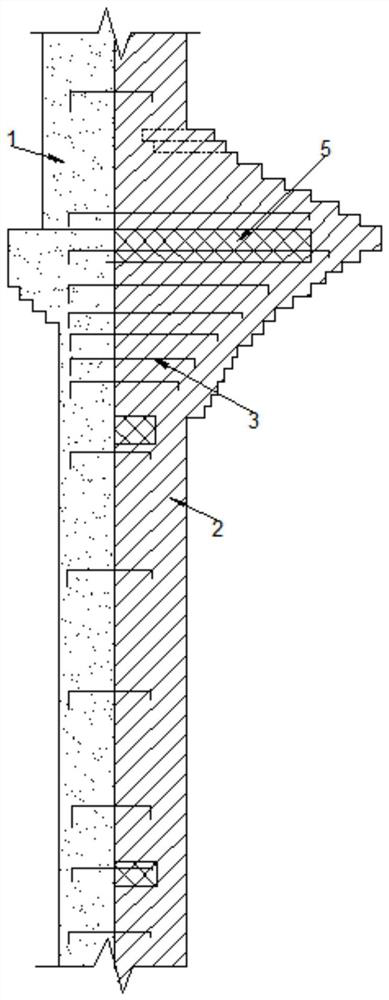

Dense eave type Tang tower ancient building structure and construction method

PendingCN112376982AGuarantee the quality of masonryImprove structural stabilityRoof coveringCovering/liningsReinforced concreteBrick

The invention provides a dense eave type Tang tower ancient building structure and a construction method, and relates to the technical field of buildings. A black brick tower structure form that an inner cylinder of a reinforced concrete shear wall is used as a framework and a black brick veneer is externally pasted and built is provided, and breaks through the design form of a traditional archaistic tower. The Tang tower ancient building structure comprises an internal supporting tower body and a black brick facing part; the black brick facing part is arranged on the outer surface of the internal supporting tower body; the internal supporting tower body is formed by pouring reinforced concrete; and the black brick veneer is formed by stacking black bricks. The dense eave type Tang tower ancient building structure is used for combining a modern structural design with traditional ancient building experience and process, and can be popularized and applied in similar ancient building andarchaistic building black brick tower construction in the future.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

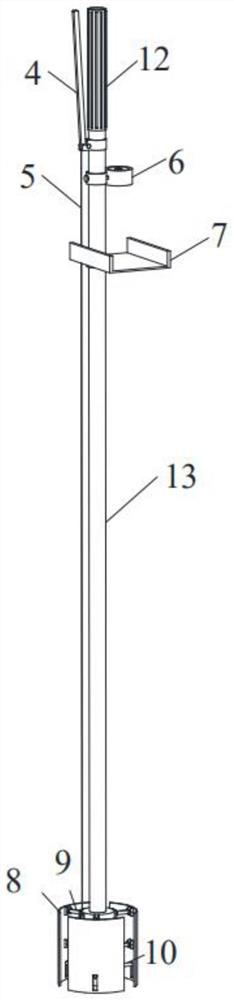

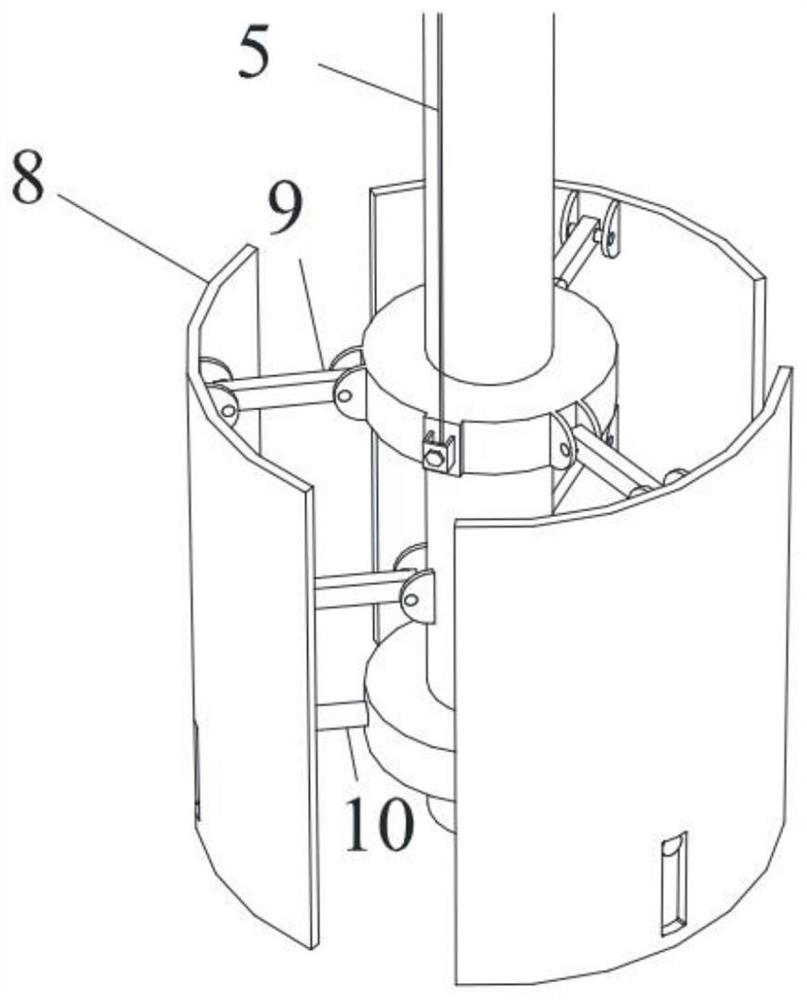

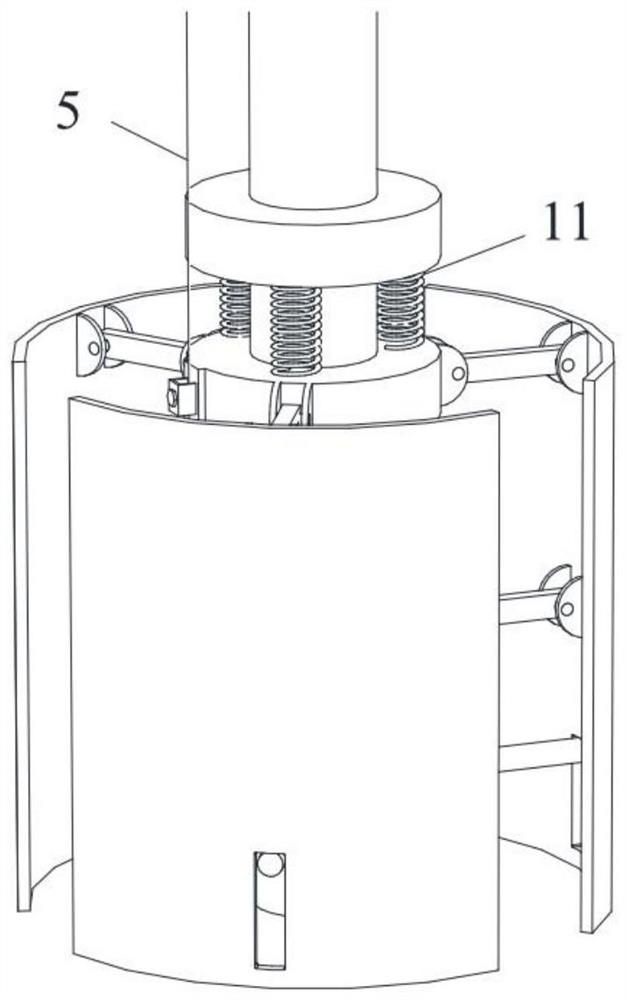

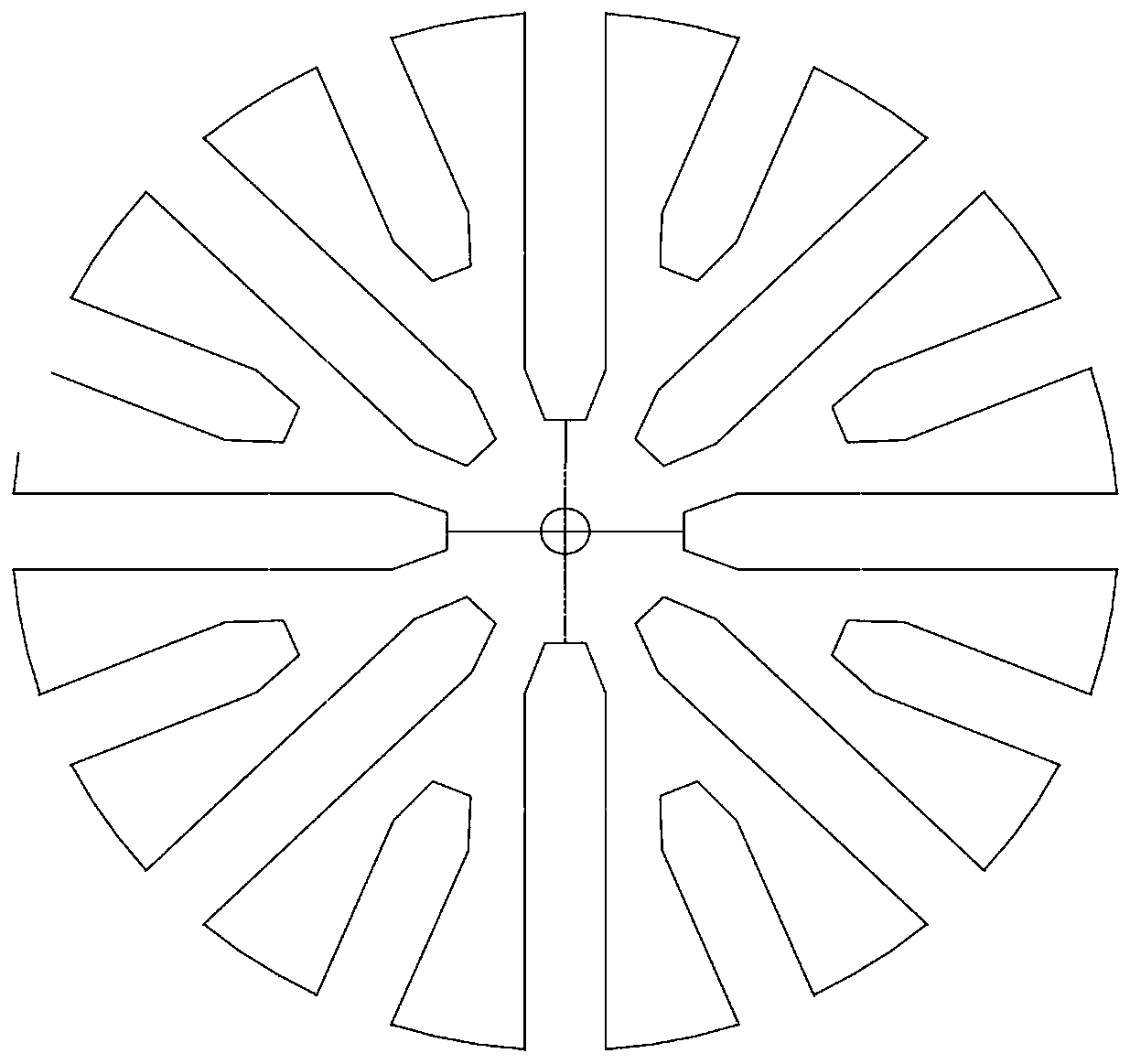

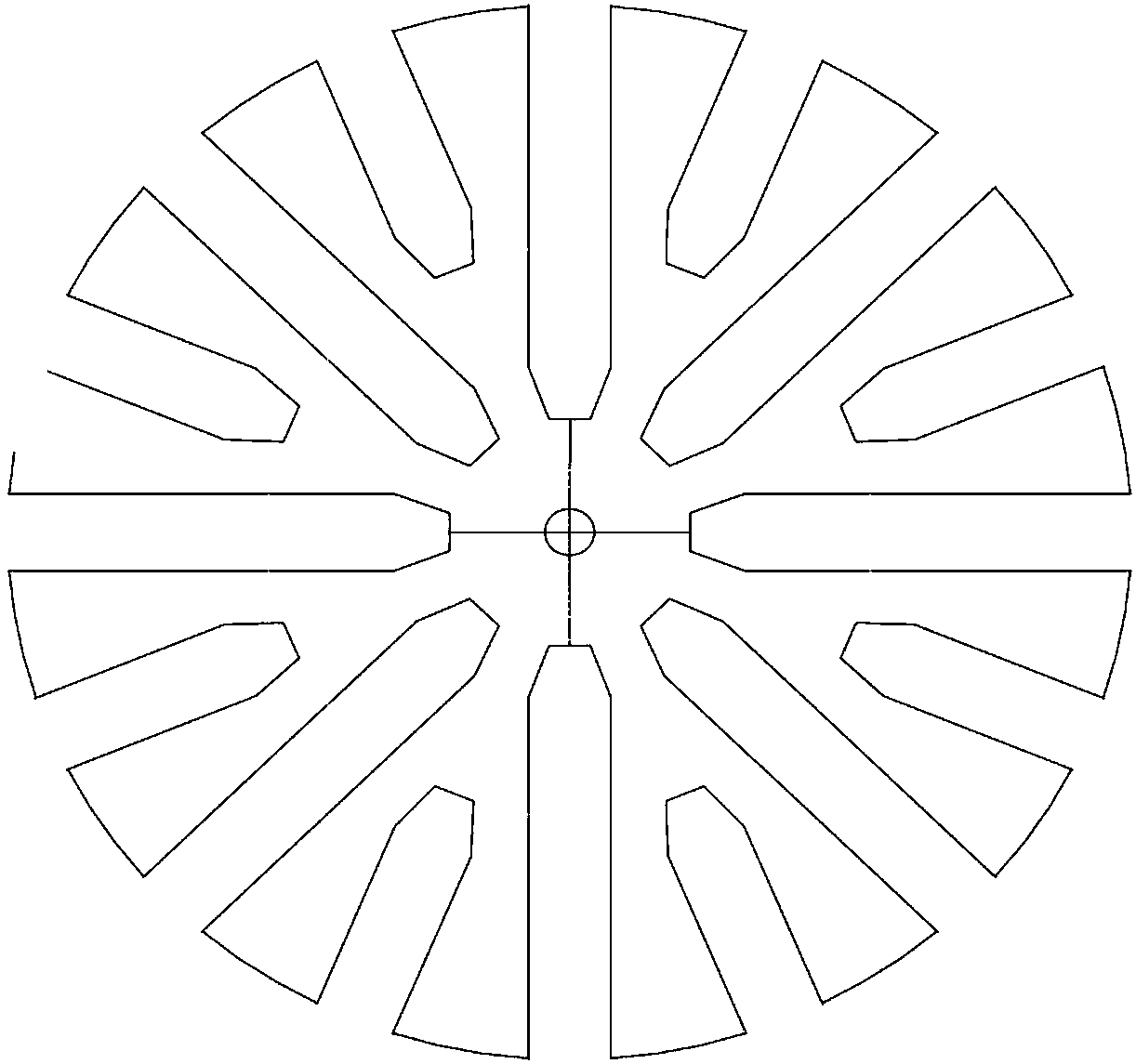

Device and method for controlling verticality and center distance of coke oven tube brick masonry

ActiveCN112574762BEasy to adjustPrevent fallingCoke oven safety devicesCoke oven brickworkInfraredClassical mechanics

The invention provides a device for controlling the verticality and center distance of coke oven pipe brick masonry, which includes a positioning device and a pipe brick hole cleaning device. An infrared rangefinder and a target for measuring the center distance, the positioning device includes a verticality correction device and a placement frame for placing the infrared rangefinder, the position of the positioning device can be adjusted, and the target is connected to the furnace by a screw The head is fixed. The positioning device is used to quickly measure and assist in adjusting the verticality and center distance of the pipe bricks. The infrared rangefinder and the target form a center distance measurement system. The verticality correction device is used to adjust the verticality of the pipe bricks. The invention can quickly and accurately adjust the verticality and center distance of pipe bricks, avoid the problems of upper and lower pipe bricks being misplaced and excessive center distance error resulting in re-laying, ensure the quality of masonry, and improve the efficiency of masonry.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method applying lifting clamp hook

The invention provides a construction method applying a lifting clamp hook. The method comprises the steps that: a first layer of masonry is constructed; a cement mortar template is arranged on the first layer of masonry; a cement mortar joint is flatly paved on an area restricted by the cement mortar template, and an acid-resistant rubber layer is paved on the mortar joint; mounting holes are processed on two sides of a filling block; the lifting clamp hook is hooked on the mounting holes of the filling block, and the filling block is horizontally lifted and placed on the acid-resistant rubber layer; the cement mortar template is removed; acid-resistant rubber layers on two sides of the filling block are closely adhered to the two sides of the filling block; a cement mortar joint is paved on one side of the second layer of the masonry material, and the cement mortar joint is closely combined with acid-resistant rubber layers on two sides of the filling block; and the construction of the second layer of masonry is completed. With the construction method, construction speed is high, and construction quality is ensured.

Owner:CHINA FIRST METALLURGICAL GROUP

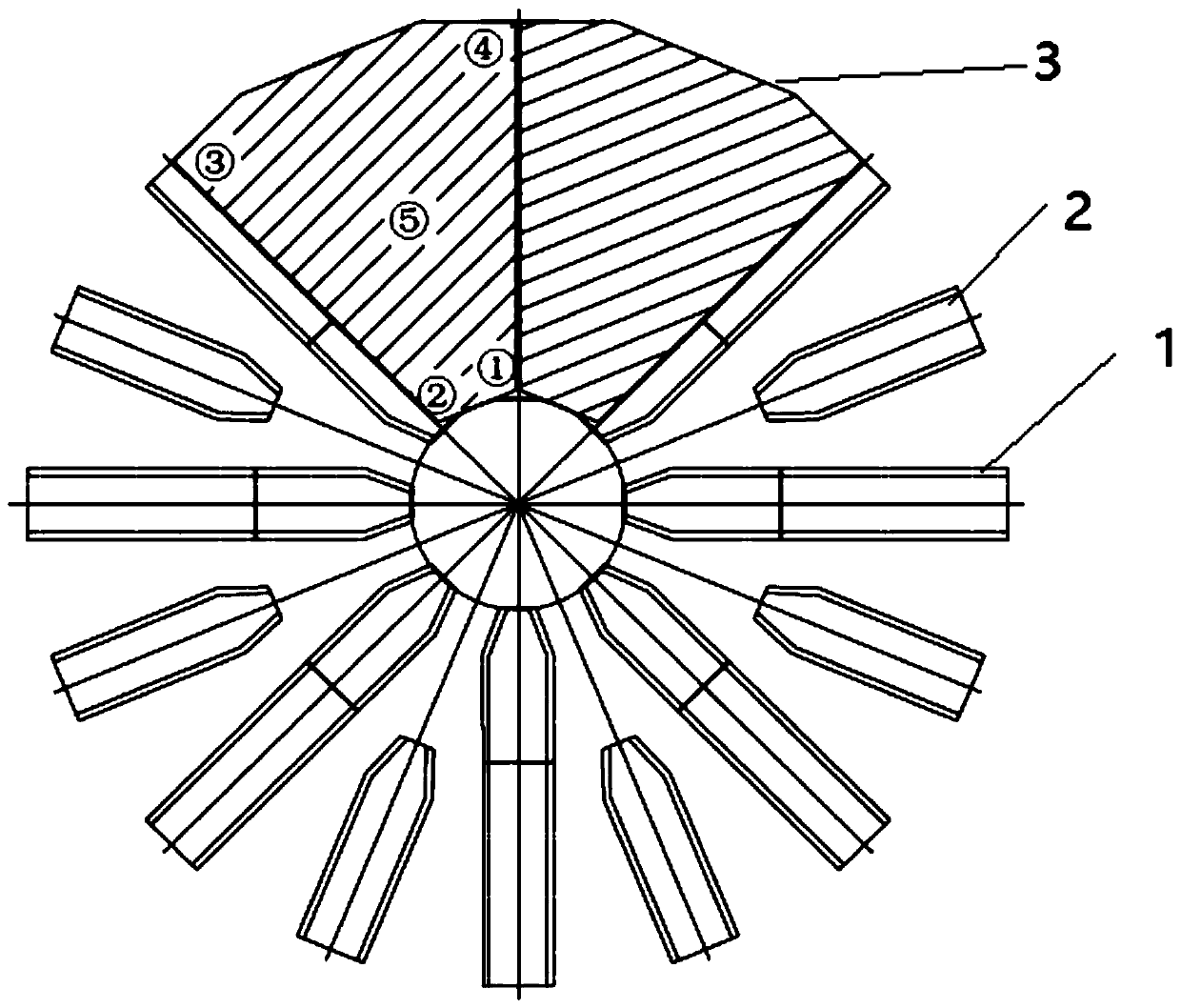

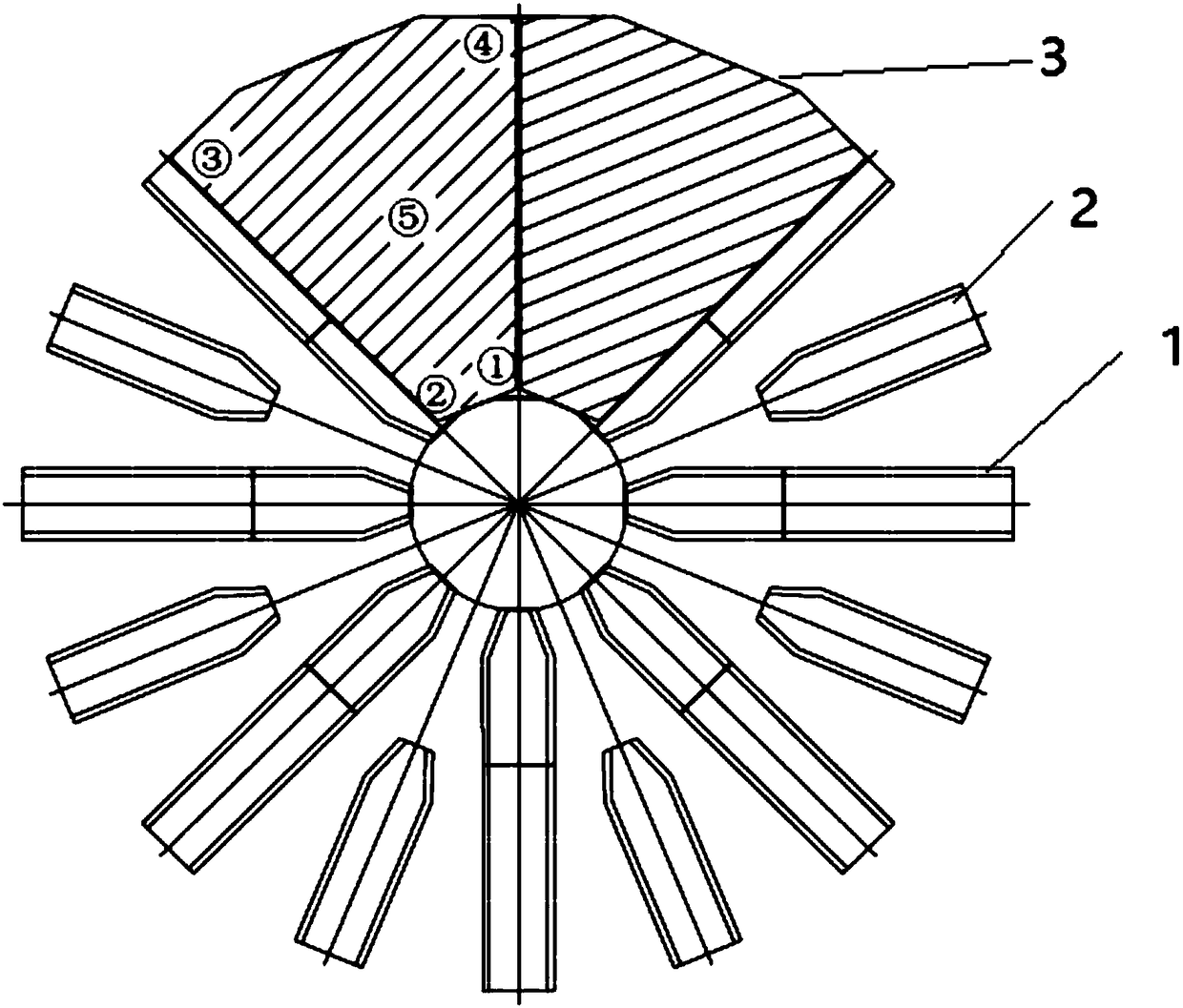

Steel coil support structure and construction method for silicon steel high temperature heat treatment furnace

ActiveCN108570551BImprove the flow fieldIncrease temperatureFurnace typesHeat treatment furnacesBogieBrick

The invention provides a steel coil supporting structure for a silicon steel high-temperature heat treatment furnace and a construction method. The supporting structure includes an even number of first support bodies, an equal number of second support bodies and an equal number of steel coil bricks. The first support bodies and the second support bodies are formed by laying a plurality of refractory bricks respectively, are arranged alternatively, and are arranged radially on the surface of a bogie. According to the supporting structure, gaps are left among the first and second support bodiesto facilitate air flow, thus achieving a good flow guiding effect, improving the flow field and the temperature field in a steel coil heat treatment process and further improving steel coil heat treatment quality. The supporting structure is stable, increases the yield of silicon steel and prolongs the service lifetime of the bogie.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

Steel coil supporting structure for silicon steel high-temperature heat treatment furnace and construction method

ActiveCN108570551AImprove the flow fieldIncrease temperatureFurnace typesHeat treatment furnacesBogieBrick

The invention provides a steel coil supporting structure for a silicon steel high-temperature heat treatment furnace and a construction method. The supporting structure includes an even number of first support bodies, an equal number of second support bodies and an equal number of steel coil bricks. The first support bodies and the second support bodies are formed by laying a plurality of refractory bricks respectively, are arranged alternatively, and are arranged radially on the surface of a bogie. According to the supporting structure, gaps are left among the first and second support bodiesto facilitate air flow, thus achieving a good flow guiding effect, improving the flow field and the temperature field in a steel coil heat treatment process and further improving steel coil heat treatment quality. The supporting structure is stable, increases the yield of silicon steel and prolongs the service lifetime of the bogie.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

Novel slope-forming brick for wall of ladle and slope forming process

ActiveCN102107276BExtended service lifeGuarantee the quality of masonryMelt-holding vesselsBrickStructural engineering

The invention relates to a novel slope-forming brick for a wall of a ladle, which is characterized in that an included angle between a thick-end side surface and a bottom surface of the slope-forming brick is less than 90 degrees, and an included angle between a thin-end side surface and a bottom surface of the slope-forming brick is more than 90 degrees. The invention further relates to a novel slope-forming process for the wall of the ladle by using the slope-forming brick mentioned above, which is characterized in that: a masonry structural unit comprises a first slope-forming brick Q1 (8), a first slope-forming brick Q2 (9), a first slope-forming bricks Q (10), a second slope-forming brick Q1 (8), a first sheet-like brick arranged on the second slope-forming brick Q1 (8), a second slope-forming brick Q2 (9), a second sheet-like brick arranged on the second slope-forming brick Q2 (9), a second slope-forming bricks Q (10) and a third sheet-like brick arranged on the second slope-forming bricks Q (10); the masonry structural unit is constructed circularly until reaching the masonry end, resulting in a slope structure with repeated initial end. The process ensures the uniformity of slope of the spiral upward masonry, so as to completely eliminate the over-standard horizontal brick joints and the over-standard triangular vertical brick joints and thus to ensure the masonry quality. The novel slope-forming brick for the ladle and the slope structure can completely eliminate the accident potential of steel seepage and steel leakage and effectively prolong the service life of the masonry structure.

Owner:武汉精鼎科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com